chapter 1 - Bentham Science

chapter 1 - Bentham Science

chapter 1 - Bentham Science

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

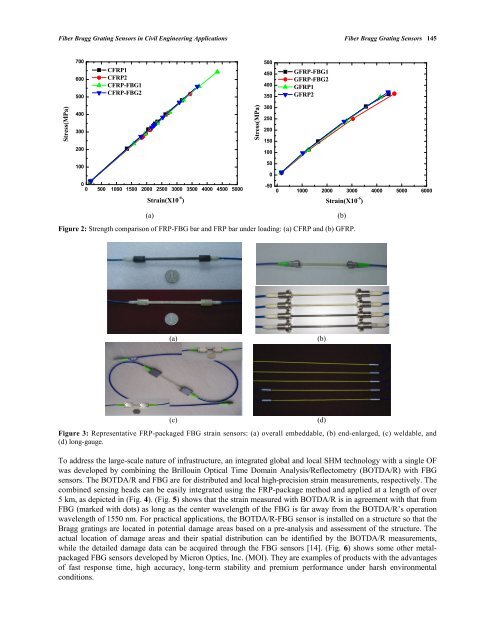

Fiber Bragg Grating Sensors in Civil Engineering Applications Fiber Bragg Grating Sensors 145<br />

Stress(MPa)<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

CFRP1<br />

CFRP2<br />

CFRP-FBG1<br />

CFRP-FBG2<br />

0<br />

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000<br />

Strain(X10 -6 )<br />

(a) (b)<br />

Figure 2: Strength comparison of FRP-FBG bar and FRP bar under loading: (a) CFRP and (b) GFRP.<br />

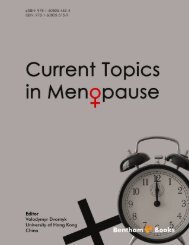

(a)<br />

(c)<br />

Figure 3: Representative FRP-packaged FBG strain sensors: (a) overall embeddable, (b) end-enlarged, (c) weldable, and<br />

(d) long-gauge.<br />

To address the large-scale nature of infrastructure, an integrated global and local SHM technology with a single OF<br />

was developed by combining the Brillouin Optical Time Domain Analysis/Reflectometry (BOTDA/R) with FBG<br />

sensors. The BOTDA/R and FBG are for distributed and local high-precision strain measurements, respectively. The<br />

combined sensing heads can be easily integrated using the FRP-package method and applied at a length of over<br />

5 km, as depicted in (Fig. 4). (Fig. 5) shows that the strain measured with BOTDA/R is in agreement with that from<br />

FBG (marked with dots) as long as the center wavelength of the FBG is far away from the BOTDA/R’s operation<br />

wavelength of 1550 nm. For practical applications, the BOTDA/R-FBG sensor is installed on a structure so that the<br />

Bragg gratings are located in potential damage areas based on a pre-analysis and assessment of the structure. The<br />

actual location of damage areas and their spatial distribution can be identified by the BOTDA/R measurements,<br />

while the detailed damage data can be acquired through the FBG sensors [14]. (Fig. 6) shows some other metalpackaged<br />

FBG sensors developed by Micron Optics, Inc. (MOI). They are examples of products with the advantages<br />

of fast response time, high accuracy, long-term stability and premium performance under harsh environmental<br />

conditions.<br />

Stress(MPa)<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

GFRP-FBG1<br />

GFRP-FBG2<br />

GFRP1<br />

GFRP2<br />

-50<br />

0 1000 2000 3000 4000 5000 6000<br />

(b)<br />

(d)<br />

Strain(X10 -6 )