Henning Larsen - Copper Concept

Henning Larsen - Copper Concept

Henning Larsen - Copper Concept

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

p.4 <strong>Henning</strong><br />

10<br />

<strong>Larsen</strong><br />

- from the small to the large<br />

and the large in the small<br />

-vuotisjuhla<br />

p.12 European Architectural Awards<br />

p.16 IKHTYS – a symbol of church<br />

fellowship<br />

p.20 Polar architecture in copper<br />

stainless | copper | technology<br />

Architectural copper review<br />

Magazine for copper in the construction industry | 2005 / 2<br />

Kuparia Karibialla .... sivu 6<br />

Grönlannin korkein talo .... sivu 10<br />

Norjan kansalliskirjaston lisärakennus .... sivu 12<br />

Niels Torp: Miten arkkitehti ajattelee? .... sivu 14<br />

Toimistorakennus Helsingissä .... sivu 27

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

Architectural <strong>Copper</strong> Review December 2005<br />

Architectural <strong>Copper</strong> Review is published twice a<br />

year and has a circulation of 1,000 copies. Publisher is<br />

Outokumpu. The magazine is distributed to architects<br />

and professionals in the building construction industry<br />

in Europe.<br />

Editor:<br />

Lennart Engström tfn: +46-21-19 82 54 fax: +46-21-<br />

19 87 04 lennart.engstrom@outokumpu.com<br />

Address: Outokumpu <strong>Copper</strong> Products,<br />

Metallverksgatan 5, 721 09 Västerås, Sweden.<br />

2<br />

Creativity and copper<br />

Architectural creativity with copper, as a starting-point and seen in an<br />

international perspective is the focus of this issue of Architectural<br />

<strong>Copper</strong> Review. I am happy to see that copper is among the materials<br />

that inspire architects’ creativity. We are naturally also very pleased to<br />

be able to present the topic from different viewpoints in this magazine.<br />

One of the latest initiatives is <strong>Copper</strong> in Architecture Awards, where<br />

today not only Great Britain but also most of the European countries<br />

participate with inspiring entries. This has brought variation and<br />

breadth to the projects. I feel that the winning projects, as well as<br />

other prize-winning entries, show significant and promising creativity.<br />

Our interview with great Danish architect <strong>Henning</strong> <strong>Larsen</strong> shows that creativity has nothing to<br />

do with age. Impressively, he is bursting with ideas, even though he has passed 80. It is interesting<br />

in this context that <strong>Henning</strong> <strong>Larsen</strong>, like many other great names within architecture, has a<br />

special fondness for copper.<br />

We are very happy that a great name as Henrik <strong>Larsen</strong> agreed to an interview. Incidentally, I<br />

often find that architects are pleased with the exposure their projects get in our magazine.<br />

Do you have projects you would like us to know about? Please contact me or someone else on<br />

the editorial board. We are looking forward to hearing from you!<br />

I wish you pleasant reading.<br />

Lennart Engström, Editor<br />

Editorial staff:<br />

Mogens Præstegaard Denmark tel: +45 4323 7700 mogens.prastegaard@tibnor.se<br />

Dennis Wraamann Denmark tel: +45 3956 5056 dw@danske-ideselskab.dk<br />

Jan Erik Holler Norway tel: +47 6755 4620 jan.erik.holler@outokumpu.com<br />

Håkan Svedman Sweden tel: +46-21-19 82 50 hakan.svedman@outokumpu.com<br />

Mervi Tähtinen Finland tel: +358 2626 6612 mervi.tahtinen@outokumpu.com<br />

Publisher:<br />

Lennart Engström, Outokumpu.<br />

Layout and technical production:<br />

www.danske-ideselskab.dk, tel: +45 3956 5056

South Street 70 – parking garage with copper<br />

The parking garage on South Street (Södra Vägen) in Gothenburg is<br />

situated in a row of well-known buildings such as Universeum and World<br />

Cultural Museum, right by the southern entrance of the big amusement<br />

park Liseberg. The closest neighbour is a block of flats in functionalistic<br />

style.<br />

The site was earlier occupied by an<br />

older block of flats that burned and was<br />

subsequently demolished. The parking<br />

garage was built partly into the rock as a<br />

subterranean building. The joists are<br />

leaning and you drive up in a spiral<br />

movement. The garage has four and a<br />

half levels and room for approximately<br />

300 cars.<br />

The garage is built in concrete. Pillars,<br />

walls and banister components are pre-<br />

fabricated and the joists are cast in<br />

plastic.<br />

For the facade we were looking for a<br />

material that would give an open grid<br />

facade. Very soon, copper came to our<br />

mind. <strong>Copper</strong> is especially suitable in<br />

this context as it with time becomes<br />

greenish-brown and blends in with the<br />

Liseberg landscape. Furthermore, sev-<br />

eral buildings on Liseberg have by tradi-<br />

tion copper-green roofs, maybe a mem-<br />

ory from the World Exhibition of 1923<br />

in Gothenburg.<br />

The facade is built as a trellis that forms<br />

a transparent wall. The wall is meant to<br />

have a ”woven-textile” look where the<br />

character of the copper is important<br />

both from the outside and from the<br />

inside.<br />

The copper strips are made from one-<br />

millimetre-thick copper sheeting and are<br />

125mm wide. They are attached to a<br />

frame of thick stainless steel pipes. In<br />

each crossing point there is a bolt, and a<br />

washer in between to create more<br />

depth in the facade. The open area of<br />

the netting is 44 percent.<br />

The base is made in gabions, wire net-<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

By Fritz Olausson, Lund & Valentin Architects<br />

ting filled with the same type of granite<br />

as the existing bedrock. Around the<br />

building there is light limestone, to<br />

visually anchor the building to the<br />

ground and to bind copper ions from<br />

rainwater to the limestone.<br />

The staff members at Lund & Valentin<br />

who have worked on the project are<br />

architects Fritz Olausson, Bo Karlberg<br />

and Görel Abrahamsson and building<br />

engineers Rolf Johannesson and Hans<br />

Solborg,<br />

Building proprietor:<br />

Gothenburg City Parking AB<br />

Architect: Lund & Valentin Architects<br />

Construction: Spännbalkskonsult<br />

Electrical work: Probeko AB<br />

Site work: Viproj AB<br />

Water/ventilation/sanitation:<br />

Bengt Dahlgren AB<br />

Contractor: Skanska Sverige AB<br />

Contractor copper facades:<br />

Hisingstads Bleck och Plåtslageri AB<br />

3

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

Henrik <strong>Larsen</strong>’s famous door handle – Sewer lid in cast iron adorned with water drops – <strong>Copper</strong> lamp designed for the opera house<br />

<strong>Henning</strong> <strong>Larsen</strong> – from the small to<br />

<strong>Henning</strong> <strong>Larsen</strong>, 80 years old – world renowned Danish architect whose<br />

mind wanders from the small to the large, and the large in the small,<br />

from detail to entirety. He is master of creating, from a sketch, everything<br />

from door handles, chairs, furnishings and buildings to master<br />

plans, the latest one an overall plan for the town Dalian in northern<br />

China.<br />

The independent artist, such as the<br />

painter or the sculptor, has nothing else<br />

to consider than the material he or she<br />

is working with. The architect is a<br />

craftsman, with the difficult task to take<br />

into consideration all human functions,<br />

materials, techniques and social condi-<br />

tions.<br />

<strong>Henning</strong> <strong>Larsen</strong> is a dreamer, a creative<br />

visionary who thinks in practical terms<br />

and knows how to materialize an idea.<br />

He is an architect who has had the<br />

possibility to realize the most prestig-<br />

ious projects, sometimes with setbacks.<br />

But how does he think when he creates?<br />

I am on my way to visit <strong>Larsen</strong> in<br />

Copenhagen. I find the address,<br />

Vesterbrogade 76 and <strong>Henning</strong> <strong>Larsen</strong>s<br />

Tegnestue. The office is on the two top<br />

stories of an eight-story building. The<br />

receptionist announces my visit. <strong>Larsen</strong><br />

has his work station, “<strong>Henning</strong>’s<br />

4<br />

Corner”, at one end of the large open-<br />

plan office. He greets me with a big<br />

smile; it has been 45 years since we last<br />

saw each other in Stockholm.<br />

It’s been a long time, we say simultane-<br />

ously. We are both marked by the<br />

passing years.<br />

A lot has happened since that time in<br />

1961, when <strong>Larsen</strong> won first prize in a<br />

Nordic architect contest for the new<br />

university building in Stockholm. We sit<br />

down and I show him a photo I took at<br />

the competition. He studies it for a long<br />

time and laughs.<br />

Do you remember that time? – Yes, I<br />

remember it like it was yesterday – from<br />

the joy over the first prize and the<br />

celebration, to the disappointment. I will<br />

never forget it.<br />

Cheated on the commission<br />

<strong>Henning</strong> <strong>Larsen</strong> was granted first prize<br />

for the very special architecture with an<br />

Text og photo: Alf Folmer<br />

Architect: SAR/MAA, Sweden<br />

mail: alf@mbox316.swipnet.se<br />

entirely new and fresh approach to the<br />

university environment in human scale, a<br />

university for 10,000 students. All<br />

buildings were placed on a large, floating<br />

concrete deck that was shaped for the<br />

landscape. Below the deck there was<br />

parking space for 3,000 cars. Young<br />

<strong>Larsen</strong> was at the time unknown as an<br />

architect.<br />

What were you thinking, when you were<br />

awarded such an honourable prize?<br />

– I was in Denmark at the time and<br />

couldn’t believe it at first! I was sum-<br />

moned to Stockholm to receive the<br />

prize. Then the cold shower and the<br />

disappointment.<br />

The politicians’ viewpoint was that a<br />

Swedish university should be designed<br />

by a Swedish architect. So I was in fact<br />

cheated on the commission, which<br />

instead was given to the second-prize<br />

winner, the well-known Swedish archi-<br />

tect David Heldén, who had designed

Cafeteria chair in steel – The opera house in Copenhagen – General plan for Dalian in China.<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

the large and the large in the small<br />

the high-rise buildings in the new<br />

Stockholm City.<br />

This caused a big disappointment and a<br />

great stir in Swedish and Danish newspa-<br />

pers and the entire architectural profes-<br />

sion. What was your opinion of the<br />

Swedes after this? – It was not fair play,<br />

<strong>Larsen</strong> says gloomily. I was angry. The<br />

politicians were totally blind for good<br />

architecture. Giving the assignment to a<br />

Swedish architect became more impor-<br />

tant than getting good architecture. But<br />

this is not how it works today.<br />

David Heldén’s second prize entry was<br />

an ordinary proposal with six eight-floor<br />

buildings, all with the same pre-fabri-<br />

cated building technique as the high-rise<br />

buildings in Stockholm City, the facades<br />

pale green, cool and sterile. Today they<br />

stand there as a disgrace.<br />

However, <strong>Larsen</strong>’s proposition received<br />

international attention. It became his<br />

great break-through and the beginning of<br />

an international career. Ten years later<br />

<strong>Larsen</strong>’s university proposal was carried<br />

out in Trondheim, Norway. He was at<br />

that time an established and well-known<br />

architect with a large office in<br />

Copenhagen.<br />

Amputated tower<br />

In 1989, <strong>Larsen</strong> won the competition of<br />

Söders Tower in Stockholm. The pro-<br />

posal was a 40-story office building.<br />

Then the politicians started to meddle in<br />

the architecture.<br />

They thought that Söder’s ”campanile”<br />

competed with the famous city hall<br />

building across the city, designed by<br />

Swedish national architect Ragnar<br />

Östberg.<br />

This started a fight over the height and<br />

architecture of the building. The plans<br />

were revised and trimmed several times.<br />

New contractors were hired and this<br />

started discussions about building meth-<br />

ods. <strong>Larsen</strong>’s strong tower architecture<br />

was trimmed down to 23 floors and<br />

changed to a block of flats. It was like<br />

letting the air out of good architecture.<br />

Another setback in Sweden, how do you<br />

deal with it? – Everybody wants to get<br />

involved in the architecture. I am embit-<br />

tered by the market in Sweden being<br />

totally run by entrepreneurs and politi-<br />

cians. We had conflicts from the very<br />

beginning. The biggest problem was JM<br />

BYGG, who started to change details<br />

and materials without permission. I had<br />

strived for using thoroughly worked-out<br />

materials and details, and I got very<br />

upset. Today, Söders Tower stands as an<br />

unfinished piece of architecture. I don’t<br />

wish to have my name on it. I am very<br />

disappointed but not unforgiving, says<br />

<strong>Larsen</strong>.<br />

<strong>Copper</strong> architecture<br />

The Swedish bureaucracy is so tough<br />

that for instance when an architect<br />

selects copper as roof material there is<br />

great resistance from the authorities.<br />

They believe that copper is harmful to<br />

the environment, although there is proof<br />

that copper ions from rainwater are<br />

bound in the ground and never enter the<br />

groundwater. <strong>Copper</strong> is nature’s own<br />

building block and even necessary for<br />

human life.<br />

Have you met problems with using<br />

copper in other countries? – I have<br />

never had any problems. Nobody ob-<br />

jects if we want to use copper in<br />

Denmark, everyone likes it, says <strong>Larsen</strong>.<br />

He shows some pictures of his copper<br />

architecture. – This is Mekoprint, two<br />

factories in Stövring, Denmark. It is an<br />

international project that I decided to<br />

cover entirely with copper and a large<br />

glass facade. Mekoprint’s copper archi-<br />

5

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

The copper-clad Unibank headquarters blends in nicely with Copenhagen’s historical milieu.<br />

<strong>Henning</strong> <strong>Larsen</strong> in 1961. He had recently won first prize<br />

in a Scandinavian architect contest for Stockholm<br />

University. He was very happy – for a short while.<br />

tecture is now a prominent landmark in<br />

the Northern Jutland town of Stövring.<br />

The attractive building in a warm cop-<br />

per-brown has won architectural con-<br />

tests.<br />

– But the best of my copper architec-<br />

ture is probably Unibank’s new head-<br />

quarters in the centre of Copenhagen. I<br />

have achieved a nice interplay between<br />

the copper and the old environment.<br />

Also this project has won awards for its<br />

convincing architecture that respectfully<br />

blends in with the historical neighbour-<br />

hood. The building is known for enrich-<br />

ing the urban landscape along<br />

Copenhagen’s harbour.<br />

– <strong>Copper</strong> is a classical and timeless<br />

material. We have new projects in the<br />

making and nobody will stop us from<br />

using copper, says <strong>Larsen</strong> firmly.<br />

6<br />

The Music Building in Uppsala<br />

We take a tour of the large office. In<br />

the model department four people are<br />

working on large-scale models of on-<br />

going projects. There are models high<br />

and low.<br />

What use do you have of the models? –<br />

A drawing is two-dimensional. To study<br />

the models allows us to experience a<br />

three-dimensional project. We also use<br />

computers to create visual perspective.<br />

We move on to the conference room.<br />

One wall is covered by a blackboard<br />

filled with rough sketches, visualized<br />

ideas from a meeting. <strong>Larsen</strong> wipes<br />

away some of the sketches from the<br />

board and quickly draws a new one. I<br />

can see that it depicts an Uppsala<br />

silhouette.<br />

Model of proposal to Unibank’s headquarters in Copenhagen. Half of the block has<br />

copper cladding.<br />

You are making a sketch of Uppsala,<br />

what is happening there? -Yes, you are<br />

right, it is Uppsala. We are finally on<br />

the way there, but again with some<br />

setbacks. We won first prize with a<br />

proposition for a concert- and congress<br />

building, an enormous project. I wanted<br />

to create a crystal in the middle of old<br />

Uppsala. The proposal is a building with<br />

reflecting facades that make it light and<br />

airy in the urban landscape. From the<br />

inside you get a magnificent panoramic<br />

view of the castle, cathedral and library.<br />

This is what I sketched on the board.<br />

But when the proposal became public<br />

the objections started, from the politi-<br />

cians and from the general public.<br />

Uppsala New Post wrote, ”At first I<br />

thought it was a picture of the ice hotel<br />

in Norrland. God help us! A 30-meter<br />

tall glass colossus – have the judges no

feeling for Uppsala?” People were<br />

upset and protested. Many thought<br />

that the proposal was an insult to<br />

Uppsala’s beautiful old milieu.<br />

Advocates of the project fought to<br />

carry it through. With a few small<br />

changes it will be built. The ground-<br />

breaking was solemnly done. The<br />

building is underway and is estimated<br />

to be completed in 2007.<br />

Opera house as a memorial<br />

of a family<br />

During our conversation <strong>Larsen</strong> be-<br />

comes enthusiastic. He starts telling me<br />

about his latest project, the one that<br />

almost ended in disaster: The<br />

<strong>Henning</strong> <strong>Larsen</strong> 2005 in his office in Copenhagen, now a world-renowned architect. He would like to tie<br />

up in bundles those who meddles in his architecture and put them back where they belong.<br />

Copenhagen Opera House, the largest<br />

opera house in Scandinavia. An enor-<br />

mous building that cost almost three<br />

billion crowns to build. Officially, the<br />

opera house is a gift to the city from<br />

ship-owner, grand old man Mærsk<br />

McKinnney Møller, Denmark’s most<br />

powerful capitalist, but Møller’s real<br />

motive is for the opera to primarily be a<br />

memorial of the giver and his family,<br />

especially his parents. Møller bought a<br />

closed military area on the island<br />

Holmen for several million crowns. This<br />

is where he wanted the opera house, in<br />

line with the royal castle Amalienborg<br />

that is situated on the other side of the<br />

bay; the castle on one side and the<br />

memorial on the other. The ship-owner<br />

decided that the architect had to be the<br />

most prominent in Denmark, <strong>Henning</strong><br />

<strong>Larsen</strong>.<br />

This is a fantastic project. It must be one<br />

of the best you ever created?<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

– Certainly not! Already in the beginning<br />

the ship-owner meddled in the architec-<br />

ture, from the material selection to the<br />

facade design. For example, I wanted the<br />

most important facade of the opera<br />

house to be entirely in glass with an<br />

open view of the harbour and the city.<br />

My vision was for the large roof to look<br />

like it was floating on a large glass bub-<br />

ble, a fantastic contribution to architec-<br />

ture. Then Møller decided he didn’t like<br />

the glass facade. He feared that the<br />

visitors to the opera would feel like they<br />

were in a fishbowl. Instead he insisted<br />

on a solid facade. As a compromise,<br />

heavy strips of steel would be used to<br />

cover the glass and screen the pano-<br />

ramic view.<br />

To <strong>Larsen</strong> this was to give up on what<br />

he felt was the most important architec-<br />

7

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

tural feature of the opera house.<br />

But you didn’t resign from the opera<br />

project? – The contract with Møller<br />

bound me hand to foot, I could not get<br />

out. The contract states specifically that<br />

the commissioner makes the decisions.<br />

Møller threatened to sue, which would<br />

have ruined me and put my staff of more<br />

than one hundred people out of work.<br />

Møller is a ship-owner and knows a lot<br />

about ships and finances, but nothing<br />

about architecture, <strong>Larsen</strong> says bitterly.<br />

The much fought-over building is now<br />

completed and inaugurated. The news-<br />

paper Berlinske Tidene raves about the<br />

opera house, however mostly over the<br />

inside, while Politiken calls it ”a hunch-<br />

backed creation. The overall design is a<br />

patchwork without originality”. In the<br />

urban landscape the building is intrusive,<br />

an over dimensioned block. The pre-<br />

dominate glass facade with its steel<br />

8<br />

strips is nicknamed ”the Grille” and ”the<br />

Toaster”. In spite of this, the opera has<br />

been awarded several prizes for its<br />

architecture. – I’m hoping to some time<br />

in the future be able to remove the<br />

disgraceful steel strips on the glass<br />

facade. I will not be satisfied until that<br />

happens, says <strong>Larsen</strong>.<br />

Hired a lawyer<br />

Wise from bad experiences with med-<br />

dling commissioners, entrepreneurs and<br />

politicians, <strong>Henning</strong> <strong>Larsen</strong>s Tegnestue<br />

has now hired a lawyer in order to<br />

create contracts and agreements based<br />

on the architect’s terms. Entrepreneur,<br />

commissioner and architect always<br />

work closely together and there is<br />

always a risk for conflicts. It is impor-<br />

tant to solve problems right away,<br />

before they get out of hand.<br />

Mekoprint, Støvring, Denmark<br />

Söders Tower viewed from the park. The winning proposal for Söders Tower in Stockholm, 40<br />

floors, 140 meters tall. (Turning Torso in Malmö is 190 meters tall and has 54 floors.) The Tower<br />

was reduced to 23 floors.<br />

Have you seen results of this? – We<br />

Plan for the Stockholm University proposal<br />

have more international projects today,<br />

and the contract is then extremely<br />

important. We have already noticed the<br />

benefits with having our own lawyer. As<br />

an architect you are a creative visionary,<br />

often with your head up in the blue. The<br />

lawyer stands firmly with both feet on<br />

the ground and makes sure that we<br />

avoid serious conflict of interest.<br />

When <strong>Larsen</strong> creates<br />

To sketch is typical for <strong>Larsen</strong>. The<br />

blackboard is full of sketches. They are<br />

his tools in the creation process.<br />

How does your mind work and where<br />

do you get your ideas? – My upbringing<br />

has shaped my life and the way I think. I<br />

learned practical thinking while being<br />

apprentice to a carpenter and getting my<br />

diploma, and theoretical thinking in my<br />

architectural studies. Also my religious<br />

upbringing has shaped me. My father

The concert- and congress building in Uppsala will shine like a<br />

crystal in the urban landscape.<br />

Model of the university proposal,<br />

see also the plan above.<br />

sang in the church choir and I loved to<br />

sit in the church and listen to the music.<br />

I discovered that church music and the<br />

church building belong together. The<br />

music by Bach is architectural music.<br />

When listening to Bach I hear and see<br />

architecture.<br />

You are known to sketch a lot. – When I<br />

sketch I experience music, rhythm and<br />

shape. It is like playing a musical score of<br />

sense impressions that in turn become<br />

visions, which become sketches and<br />

later materialize into architecture.<br />

<strong>Larsen</strong> has become a Danish national<br />

symbol of sorts, a maestro of architec-<br />

ture. As a professor he is a sought-after<br />

educator who knows the art of inspiring<br />

and sharing his ideas. I am certain that a<br />

new generation architect students will<br />

use <strong>Larsen</strong>’s thoughts and ideas in new<br />

and exciting architecture.<br />

From inside the concert house you have<br />

a panoramic view of Uppsala.<br />

Mekoprint, Støvring, Denmark<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

The opera house in Copenhagen. Notice the steel strips that<br />

cover the large glass façade.<br />

<strong>Henning</strong> <strong>Larsen</strong>’s copper architecture is<br />

described in Architectural <strong>Copper</strong> Review,<br />

issues 12 and 14.<br />

9

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

New Art Museum in Tallinn Text: Hannele Numminen<br />

The new art museum Kumu was inaugurated in September 2005. The<br />

construction work started in October 2002 and now, three years later,<br />

the big project is finalized. The building is one of the most important<br />

projects since Estonia got its independence. Tallinn’s art museum was<br />

designed by Finnish architect Pekka Vapaavuori, who won the high-class<br />

architectural contest in competition from as many as 230 entries. The<br />

new museum’s façade is almost entirely clad by patinated copper.<br />

<strong>Copper</strong> facade<br />

Contractor for the copper installation<br />

was Estonian company Esco AS, led by<br />

Siimon Peep. The company took on the<br />

great challenge at the same time as it<br />

won the bidding for the museum’s metal<br />

assembly. A close cooperation with the<br />

Finnish copper manufacturer was a<br />

10<br />

condition for a successful project. Peep<br />

told us that one of the pre-manufac-<br />

tured models for the cassettes was<br />

approved. The cassette, fabricated with<br />

a welt machine, met the requirements<br />

from the planners and was installed on<br />

the museum’s façade. The use of these<br />

cassettes prevented inner tension of the<br />

sheets, and it was also possible to give<br />

the material sharp and straight edges.<br />

For the façade elements, 0.80mm-thick<br />

copper was used, which is well suited<br />

for cassette manufacturing.<br />

The ground level base elements are<br />

often exposed to more stress and were<br />

therefore made of a stronger 1.5mm-<br />

thick sheet. The S-profiles in the façade’s<br />

seams are of the dimension 0.6mm,<br />

while other special parts, for example<br />

the grating, are made of 3mm and 4mm-<br />

thick material. The cassette type used<br />

was Outokumpu Nordic Panel 302.<br />

The walls are made of regular concrete<br />

with heat insulation and ventilation<br />

Photos: Siimon Peep

opening. Waterproof veneer membrane<br />

of 9-15mm-dimension was placed on the<br />

surface and green-patinated copper was<br />

fastened on the veneer membrane with<br />

stainless steel mountings. The type of<br />

joint used was angled seam. An attrac-<br />

tive and tight seam was achieved by<br />

closing the seams when the cassettes<br />

were installed. The vast, green-patinated<br />

and rounded copper surface gives the<br />

building and impressive and distinguished<br />

exterior that will be seen by many<br />

visitors to the museum.<br />

Challenges and practice<br />

The copper parts for the Art Museum<br />

were delivered from Finland to Tallinn,<br />

where sheet metal works Esco arranged<br />

with a special area for the project. In<br />

this way the pre-manufacturing could be<br />

done as a separate project, before the<br />

actual installation. Head of the installa-<br />

tion work was Imre Tael and the plan-<br />

ning was done by Raul Aprimann. On<br />

the site, 10-15 people worked with the<br />

installation in different shifts.<br />

The installation work had some unex-<br />

pected complications. To join straight<br />

and bent parts was especially tricky, says<br />

Siimon Peep from Esco AS. One of the<br />

most demanding phases was the assem-<br />

bly of copper sheeting to the main<br />

façade, between the pillars. The work<br />

was complicated by the narrow space,<br />

the very high requirements on the<br />

underlying construction, the measure-<br />

ments and the long installation time.<br />

With no previous experience with this<br />

kind of project, everything had to be<br />

learned from scratch and the workers<br />

had to try different ways of doing things.<br />

The tight timetable was also a challenge<br />

for such a difficult project. The under-<br />

taking generated a lot of new experi-<br />

ence, and today the group is consider-<br />

ably better prepared for possible new<br />

challenges.<br />

A large amount of green-patinated<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

Nordic Green copper was used in the<br />

project; for the outer facade 2,200m 2<br />

(of which approximately1,200m 2 are<br />

curved parts), the inner façade approxi-<br />

mately 1,300m 2 (of which 650m 2 perfo-<br />

rated material). Cassettes and sheets for<br />

the outer facade 500m 2 , and Nordic<br />

Green and Nordic Brown grating 120m 2 .<br />

Architect: Pekka Vapaavuori<br />

<strong>Copper</strong> work: Esco AS, Tallinn<br />

Main contractor: Merko/Estonia<br />

11

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

European Architectural Awards<br />

12<br />

As an offshoot of the European <strong>Copper</strong> in Architecture<br />

campaign, the <strong>Copper</strong> in Architecture Awards have<br />

been given out in Great Britain. This year the com-<br />

petition was extended to include 18 countries, and<br />

attracted a total of 60 candidates. The jury of archi-<br />

tects had Paul Finch from The Architectural Review<br />

as foreman, and could in September declare the<br />

winners at a ceremony in London.

Information about the next <strong>Copper</strong><br />

in Architecture Awards will soon be<br />

made public. If you have an entry,<br />

please contact :<br />

helpline@copperdev.co.uk.<br />

Information about <strong>Copper</strong> in Archi-<br />

tecture Awards can be found on:<br />

www.cda.org.uk/arch and<br />

www.copperconcept.org.<br />

The winner of European <strong>Copper</strong><br />

Award 2005 is the beautiful<br />

Laajasalo Church in Helsinki,<br />

designed by Kari Jarvinen Ja Merja<br />

Nieminen. Specialist contractor:<br />

Outokumpu/Levykaksikko.<br />

The church’s main areas are facing the<br />

street corner and are very prominent.<br />

The copper-clad campanile is separated<br />

from the church to complete the ap-<br />

proach to the building. The large facades<br />

are clad in green-patinated copper<br />

sheets in strips of 150, 200 and 250mm.<br />

The brown-patinated light towers facing<br />

the yard shine like lighthouses at night<br />

and let sunlight in during the day. The<br />

interior surfaces are made mostly in<br />

different kinds of wood, while the<br />

carpentry of the altar is partly framed<br />

with copper.<br />

The judges said about this project: ”A<br />

beautiful church where copper has been<br />

used in layers, almost like a cliff face,<br />

with soft colours and controlled tones<br />

that will develop over time, adding to<br />

the harmonious relationship with its<br />

natural landscape setting. The build-up<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

of copper panels is concealed with flat,<br />

striated surfaces creating an extreme<br />

horizontality and unmistakable quality.”<br />

13

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

Also awarded a commendation in<br />

the 2005 European category is the<br />

impressive Service Centre Munich<br />

designed by Staab Architekten.<br />

Specialist contractor: Regensburger<br />

Metallbau.<br />

14<br />

Like a bar of copper, the building<br />

crouches on a centrally located lot. Its<br />

precise, simple shape and its copper<br />

facade made it blend into the colours of<br />

the Theresienwiese. The facade will over<br />

time accumulate patina to match the<br />

colour of the slope behind the building.<br />

Areas used for movement are glazed,<br />

and then protected from sunlight and<br />

vandalism by a perforated metal facade.<br />

The judges commented: ”This is a bold,<br />

monolithic building, forged from a<br />

perforated copper screen, which could<br />

be considered as a bar of gold in the<br />

landscape, intriguing to visitors. An<br />

extreme solution that works well, the<br />

service centre possesses a distinctive<br />

calmness.”

One of the joint winners is Queen<br />

Mary College Student Village,<br />

London, designed by Feilden Clegg<br />

Bradley. Specialist contractor: T &<br />

P Roofing.<br />

For 2005, there was a separate category<br />

covering UK projects, and the judges<br />

decided on two very different projects<br />

as Joint Winners.<br />

The new Westfield Student Village is<br />

one of the largest new student residence<br />

schemes in Britain, with 995 bed spaces.<br />

The Student Village comprises six build-<br />

ings, including two copper-clad buildings<br />

on the ”exposed” public edges of the<br />

site. It has a surface of approximately<br />

9,000m 2 of both pre-oxidised and pre-<br />

patinated copper.<br />

The judges said about this project: ”The<br />

result is a serene but urban environ-<br />

ment. The copper is intrinsic to the<br />

’honest’, thin-skin approach to facade<br />

design that enables a break-up of build-<br />

ing mass and window systems.”<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

The other Joint Winner is the<br />

Spiral Café, Birmingham, designed<br />

by Marks Barfield Architects.<br />

Specialist contractor: Thomas Vale.<br />

Located in St. Martin’s Square, the Spiral<br />

Café is a distinctive shell-like enclosure<br />

inspired by the Fibonacci principles of<br />

growth in nature. The building is formed<br />

by eight curved structural ribs that<br />

enclose the seating and serving area.<br />

After the external copper work had<br />

been completed, artist Andy Elton was<br />

commissioned to apply a coloured finish<br />

to the external cladding.<br />

The judges commented: ”It fully exploits<br />

a geometric idea to generate an intrigu-<br />

ing form that is nonetheless functional.<br />

The spiral form maximises the architec-<br />

tural characteristics of copper and the<br />

surface patination treatment is beauti-<br />

fully handled.”<br />

15

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

IKHTYS<br />

– a symbol of church fellowship<br />

The Art Chapel, designed by architect Matti Sanaksenaho in 1996, is<br />

also called St. Henry’s Ecumenical Art Chapel and was inaugurated in<br />

May 2005. The building is situated high on a mountain and surrounded<br />

by pine trees.<br />

Architects Pirjo Sanaksenaho and Enrico<br />

Garbin also participated in the planning<br />

work. Kain Tapper designed the altar<br />

and the glass paintings are signed by<br />

Hannu Konola. To finalize the project<br />

has been a long and demanding process,<br />

as the financing, material and labour for<br />

the biggest part were provided through<br />

collected funds. Today, the chapel is<br />

ready to be taken into use by eight<br />

16<br />

different religious communions. The<br />

chapel is already known around the<br />

world, for instance in Japan, Sofia and<br />

Moscow.<br />

A landmark for the Christian<br />

common hope<br />

The idea for the chapel came from<br />

Hannu Konola, an artist. The tall glass<br />

paintings on both sides of the altar are<br />

his creation. The variation of the glass<br />

surface reflects the versatility of life – it<br />

is sometimes smooth and sometimes<br />

rough. The windows are “the eyes of the<br />

fish” through which the light trickles and<br />

lights up the inner chapel. The project<br />

was a great challenge and has demanded<br />

much work. The building itself is a piece<br />

of art, whose exceptional shape creates<br />

different images in the human mind.<br />

For the façade, a shiny copper was used<br />

that has already darkened. Later on the<br />

surface will turn green, as the copper<br />

grows its patina. The architect was

aware of the characteristics of the<br />

copper and used it in his planning. The<br />

fish theme is seen again in the seam<br />

work, where the copper strips are<br />

mounted in a scale-like fashion.<br />

The interior is executed entirely in pine<br />

and is in its simplicity an attractive and<br />

impressive sight. The centre isle extends<br />

in a slight elevation up to the altar. The<br />

altar and pews are designed in an una-<br />

dorned fashion by Kain Tapper. Tapper<br />

passed away while the construction<br />

work was still going on and never saw<br />

the finished chapel. Both natural materi-<br />

als, copper and pine, have their own<br />

form language and make the chapel<br />

unique. The chapel is also a miracle of<br />

sorts when it comes to its dimensions.<br />

When looking at the outside gable there<br />

is no indication that this is a colossal<br />

building.<br />

One man’s work of art<br />

The project was challenging for the<br />

professionals also in terms of building<br />

technique. Details, such as window<br />

assembly, required specific expertise.<br />

Because of the shape and height of the<br />

chapel, most of the work had to be done<br />

from a crane. Unusually, all installations<br />

were performed by one man, sheet<br />

metal worker Jari Lehtinen, who dis-<br />

played excellent workmanship. The<br />

facades were clad with copper sheeting<br />

that was cut into different sizes. Under<br />

the copper surface is a regular board<br />

lining covered by moulded veneer.<br />

Horizontal locks were used for the seam<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

work and at the assembly sliding clips<br />

were used, which allow movement when<br />

the material moves due to the changes<br />

in temperature. Lethinen finished the<br />

extensive assembly work in only two<br />

and a half months.<br />

Architect: Matti Sanaksenaho<br />

Altar and interior: Kain Tapper<br />

Glass paintings: Hannu Konola<br />

Sheet metal work: Jari Lehtinen<br />

17

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

18<br />

T H E K A L E I D O S CO P E<br />

Use of copper for renovation<br />

and construction in Russia<br />

The company Master Profil has delivered 3,000m 2<br />

Nordic Brown copper for the renovation of the<br />

roof of St. Simeon Church and St. Anna Church in<br />

St. Petersburg. The entrepreneurs were renova-<br />

tion- and building contractor Lapin Enterprise,<br />

which is specialized in roof- and façade work in St.<br />

Petersburg’s historical centre.<br />

During the renovation only part of the roof was<br />

replaced. The rest was in good condition and<br />

could be preserved. Because of this it was impor-<br />

tant that the new copper looked “old” and not<br />

too different from the original roof. The experts<br />

found that the best solution was to use Nordic<br />

Brown – factory-oxidized copper.<br />

For the renovation of the railway station in<br />

Cheljabinski Master Profile delivered 2,200m 2<br />

Nordic Brown. The contractor was a company<br />

called Simplex. The main domes of the railway<br />

station were made in bright copper with scale-like<br />

texture. With time the copper turned darker. In<br />

order for the other buildings to be in harmony<br />

with the domes it was decided to use Nordic<br />

Brown. The 23-metre-long strips for the roof<br />

were manufactured on-site and installed without<br />

problems, even though the temperature was<br />

minus 23o. Neither the copper nor its oxidized<br />

surface was damaged when the material was<br />

shaped.<br />

For a hotel construction on the Kivi Island,<br />

3,200m 2 of Nordic Brown copper was delivered.<br />

The hotel is designed by architects Solodovnikov<br />

and roof assembly is performed by Altes Plus.

”Light” – design Roberto Cutoli<br />

Young designers compete in copper<br />

Last spring, a tradeshow was held in<br />

Milan called ”Abitarecon il Rame”<br />

(living with copper). The focus was on<br />

interior design and the use of copper<br />

in homes.<br />

Among other items, prize-winning<br />

products from an earlier design<br />

contest were shown, where young<br />

designers created new and beautiful<br />

decorative items in copper. These<br />

products have all passed the proto-<br />

type stage and can be purchased at<br />

the Italian market by interested<br />

interior decorators.<br />

One of the items was a decorative<br />

copper drapery designed by Marc<br />

Krusin, who made it by connecting<br />

laser-cut copper plates. This drapery<br />

was also exposed in a larger scale<br />

(22,000 laser-cut plates) at the inter-<br />

national fashion show in Florence,<br />

where it received favourable atten-<br />

tion.<br />

<strong>Copper</strong> drapery by Marc Krusin<br />

”Sky” – new thinking in radiator design ”Circle” – design Francesco Giannatasio<br />

Other items were mainly different<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

types of electric fittings and radiators<br />

that had stimulated to new thinking.<br />

Laura Sonzogni showed her futuristic<br />

radiator ”Sky” while Roberto Cutoli<br />

and Francesco Giannatasio exhibited<br />

electric fittings in new shape.<br />

19

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

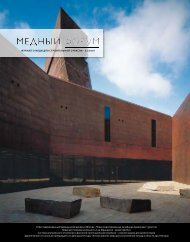

Polar architecture in copper<br />

One year ago we had an article in<br />

Architectural <strong>Copper</strong> Review about the<br />

preparations for the construction of the<br />

new research village in Longyearbyen on<br />

Svalbard. Today the project is almost<br />

completed. Four sheet metal workers<br />

have during more than one year assem-<br />

bled 10,000m 2 copper to the roof and<br />

facades, and the initially shiny copper has<br />

now turned a more distinguished<br />

bronze-coloured nuance. Some interior<br />

work is still going on, but everything will<br />

be ready for the inauguration later this<br />

fall, when the University Centre on<br />

Svalbard A/S, UNIS, takes over the daily<br />

operation.<br />

On Svalbard all buildings stand on poles a<br />

distance from the ground, due to the<br />

constant ground frost. This gives the<br />

observer an unusual sight experience; all<br />

20<br />

buildings seem to be floating above the<br />

ground. This is also true for the new<br />

research village, which is built on poles.<br />

Here, the mystique becomes a compo-<br />

nent of the architectural experience; the<br />

massive, copper-clad building looks like<br />

it is floating freely and the geometry of<br />

the ground disappears in mystical forma-<br />

tions among the poles under the building.<br />

Jarmund/Vigsnaes are the architects<br />

behind the project. They have gathered<br />

inspiration from the surrounding harsh<br />

landscape and created an organic star-<br />

shaped building, where the details were<br />

created with great care and regard to<br />

winds, ice and snow. The research village<br />

with its 8,500m 2 houses both lecture<br />

halls, research laboratories, offices and<br />

exhibition areas for Svalbard Museum.<br />

The sheet metal works were undertaken<br />

by Norwegian company Erling Freitag A/S.<br />

The climate on Svalbard is in itself a<br />

challenge for a sheet metal worker who<br />

in biting cold winter storms must per-<br />

form advanced and detailed work re-<br />

quiring high dexterity. In addition, this<br />

project had some very complicated<br />

metal-construction details that had to

e resolved. The roof is made with strip<br />

covering in semi-hard 0.7mm copper<br />

sheets. The single-lock welts are elevat-<br />

ed (50mm-high) primarily for aesthetical<br />

reasons to intensify the shadows. The<br />

longest roof slope is totally 60 metres<br />

(with a 5o roof fall). The copper strips<br />

on the roof slope are divided into ap-<br />

proximately ten-metre-long pieces with<br />

a fixed zone in the middle and move-<br />

ment joints along the roof fall, which<br />

also must work sideways across the<br />

slope. A stiff mounting plate in the welt<br />

was soldered on and equipped with a<br />

capillary break. The finishing against the<br />

single-lock welt was performed with<br />

extra care in order not to hinder the<br />

movement across the strips. The metal<br />

details were pre-fabricated in a shop at<br />

the work site and placed already bent on<br />

the roof.<br />

Svalbard and Longyearbyn have always<br />

guaranteed their visitors strong nature<br />

experiences, as studies of both white<br />

whales and polar bears are a common<br />

activity. Today they can also offer a visit<br />

to the research village and a study of<br />

world-class polar architecture.<br />

Architects:<br />

Jarmund/Vigsnaes, Tønsberg<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

Sheet metal works: Erling Freitag A/S<br />

Area: 8.500 m 2<br />

Roof and facades: 1,000 m 2 , semi-hard<br />

0,7-mm-thick copper sheet<br />

21

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

<strong>Copper</strong> in Sandefjord’s archipelago in Norway<br />

On one of the islands outside<br />

Sandefjord, construction of a weekend<br />

house by the sea has just been finished.<br />

The house is embedded between the flat<br />

rocks and blends in nicely with the harsh<br />

archipelago landscape on the island. The<br />

roof is strip-covered with green-pati-<br />

nated copper.<br />

When passing the island by boat at a<br />

distance, it is hard to make out the<br />

details on the roof; the green-patinated<br />

22<br />

copper blends in with the low-growing<br />

green vegetation on the island.<br />

Architect firm Kvartal 19 in Sandefjord<br />

has designed the house and Vestfold<br />

Kobber & Blikkenslagerverksted AS, also<br />

from Sandefjord, performed the copper<br />

assembly.<br />

www.copperconcept.org<br />

International website for copper in architecture<br />

Photo: Perv Olav Berg

New copper training centre<br />

offers hands-on experience<br />

A new training centre, “the <strong>Copper</strong> Studio”,<br />

opened at Outokumpu Pori mill in Finland last<br />

April. The centre focuses on the use of copper<br />

in building and construction and targets archi-<br />

tects, designers, building contractors, local<br />

authorities, roofing contractors and students.<br />

Visitors come both from Finland and other<br />

important markets, such as Scandinavia, Russia,<br />

Germany and the United Kingdom.<br />

Each target group receives a tailor-made train-<br />

ing package consisting of basic information on<br />

copper, Nordic products, Nordic Systems and<br />

Designer’s Tool. Designer’s Tool is made espe-<br />

cially for designers and provides detailed an-<br />

swers to various questions.<br />

Participants get hands-on experience in bending<br />

and installing copper. They also have the oppor-<br />

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

Nordic Systems includes a wide selection of<br />

facade elements: cassettes, panels, fastening<br />

systems and formed detail components. We<br />

can also fabricate project-specific components<br />

Available surface treatments are Nordic Brown and Nordic Green Plus.<br />

23

Architectural <strong>Copper</strong> Review | 2005 / 2<br />

You can choose between our standardized Nordic Modular Roofs or ready to install, built -to- spec Prefabricated Roofs.<br />

tunity to view Outokumpu’s Nordic<br />

Systems in full scale and professionally<br />

installed.<br />

More than 160 people in groups of 8-10<br />

have visited the <strong>Copper</strong> Studio during<br />

24<br />

the last six months. The innovation and<br />

new thinking presented by the centre<br />

have met with great interest, and we<br />

often hear comments like, “Why has<br />

this not been done before?” This is the<br />

best response we could ask for.<br />

The <strong>Copper</strong> Studio is an important tool<br />

for spreading information about copper<br />

as an excellent building material and at<br />

the same time present new products<br />

manufactured in copper.<br />

Visit our website outokumpu.com<br />

For more information<br />

on copper products visit:<br />

www.nordicgreen.com<br />

www.nordicbrown.com<br />

www.nordicdecor.com<br />

www.outokumpu.com/nordic systems<br />

www.copperconcept.org<br />

www.outokumpu.com