HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

This standard has two categories, or types, A and B. Only type A <strong>rope</strong>s are recommended for<br />

work purposes. Both types <strong>of</strong> <strong>rope</strong> have low extension during normal working procedures, but<br />

they have sufficient stretch to dissipate the type <strong>of</strong> forces likely to be generated by the<br />

progression <strong>of</strong> operatives along them, up to those generated by a fall from the anchor point.<br />

(This severity <strong>of</strong> fall, where the distance travelled before arrest equals the length <strong>of</strong> <strong>rope</strong><br />

arresting the fall, is known as fall factor 1).<br />

The sheath on low-stretch <strong>rope</strong>s is generally thicker than that <strong>of</strong> dynamic <strong>rope</strong>s, specifically to<br />

withstand the wear and tear <strong>of</strong> <strong>rope</strong> adjustment devices.<br />

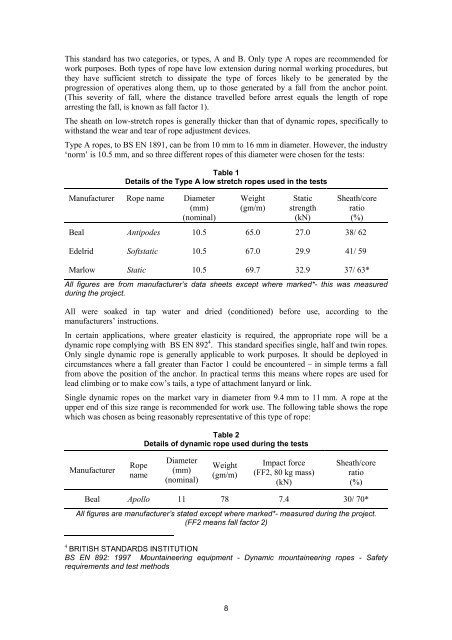

Type A <strong>rope</strong>s, to BS EN 1891, can be from 10 mm to 16 mm in diameter. However, the industry<br />

‘norm’ is 10.5 mm, and so three different <strong>rope</strong>s <strong>of</strong> this diameter were chosen for the tests:<br />

Table 1<br />

Details <strong>of</strong> the Type A low stretch <strong>rope</strong>s used in the tests<br />

Manufacturer Rope name Diameter<br />

(mm)<br />

(nominal)<br />

8<br />

Weight<br />

(gm/m)<br />

Static<br />

strength<br />

(kN)<br />

Sheath/core<br />

ratio<br />

(%)<br />

Beal Antipodes 10.5 65.0 27.0 38/ 62<br />

Edelrid S<strong>of</strong>tstatic 10.5 67.0 29.9 41/ 59<br />

Marlow Static 10.5 69.7 32.9 37/ 63*<br />

All figures are from manufacturer’s data sheets except where marked*- this was measured<br />

during the project.<br />

All were soaked in tap water and dried (conditioned) before use, according to the<br />

manufacturers’ instructions.<br />

In certain applications, where greater elasticity is required, the appropriate <strong>rope</strong> will be a<br />

dynamic <strong>rope</strong> complying with BS EN 892 4 . This standard specifies single, half and twin <strong>rope</strong>s.<br />

Only single dynamic <strong>rope</strong> is generally applicable to work purposes. It should be deployed in<br />

circumstances where a fall greater than Factor 1 could be encountered – in simple terms a fall<br />

from above the position <strong>of</strong> the anchor. In practical terms this means where <strong>rope</strong>s are used for<br />

lead climbing or to make cow’s tails, a type <strong>of</strong> attachment lanyard or link.<br />

Single dynamic <strong>rope</strong>s on the market vary in diameter from 9.4 mm to 11 mm. A <strong>rope</strong> at the<br />

upper end <strong>of</strong> this size range is recommended for work use. The following table shows the <strong>rope</strong><br />

which was chosen as being reasonably representative <strong>of</strong> this type <strong>of</strong> <strong>rope</strong>:<br />

Manufacturer<br />

Rope<br />

name<br />

Table 2<br />

Details <strong>of</strong> dynamic <strong>rope</strong> used during the tests<br />

Diameter<br />

(mm)<br />

(nominal)<br />

Weight<br />

(gm/m)<br />

Impact force<br />

(FF2, 80 kg mass)<br />

(kN)<br />

Sheath/core<br />

ratio<br />

(%)<br />

Beal Apollo 11 78 7.4 30/ 70*<br />

All figures are manufacturer’s stated except where marked*- measured during the project.<br />

(FF2 means fall factor 2)<br />

4 BRITISH STANDARDS INSTITUTION<br />

BS EN 892: 1997 Mountaineering equipment - Dynamic mountaineering <strong>rope</strong>s - Safety<br />

requirements and test methods