HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

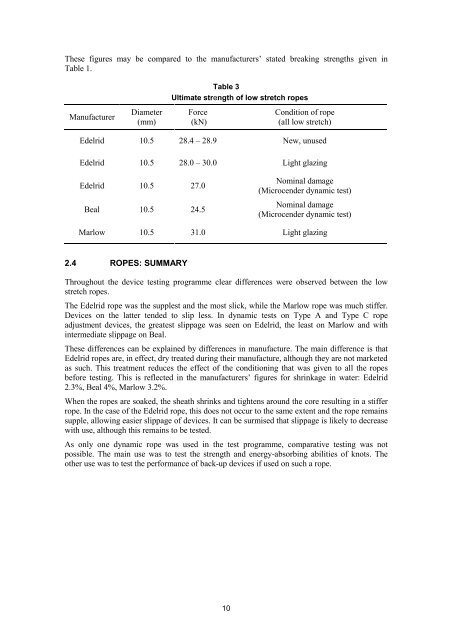

These figures may be compared to the manufacturers’ stated breaking strengths given in<br />

Table 1.<br />

Manufacturer<br />

Diameter<br />

(mm)<br />

Table 3<br />

Ultimate strength <strong>of</strong> low stretch <strong>rope</strong>s<br />

Force<br />

(kN)<br />

10<br />

Condition <strong>of</strong> <strong>rope</strong><br />

(all low stretch)<br />

Edelrid 10.5 28.4 – 28.9 New, unused<br />

Edelrid 10.5 28.0 – 30.0 Light glazing<br />

Edelrid 10.5 27.0<br />

Beal 10.5 24.5<br />

Nominal damage<br />

(Microcender dynamic test)<br />

Nominal damage<br />

(Microcender dynamic test)<br />

Marlow 10.5 31.0 Light glazing<br />

2.4 ROPES: SUMMARY<br />

Throughout the device testing programme clear differences were observed between the low<br />

stretch <strong>rope</strong>s.<br />

The Edelrid <strong>rope</strong> was the supplest and the most slick, while the Marlow <strong>rope</strong> was much stiffer.<br />

Devices on the latter tended to slip less. In dynamic tests on Type A and Type C <strong>rope</strong><br />

adjustment devices, the greatest slippage was seen on Edelrid, the least on Marlow and with<br />

intermediate slippage on Beal.<br />

These differences can be explained by differences in manufacture. The main difference is that<br />

Edelrid <strong>rope</strong>s are, in effect, dry treated during their manufacture, although they are not marketed<br />

as such. This treatment reduces the effect <strong>of</strong> the conditioning that was given to all the <strong>rope</strong>s<br />

before testing. This is reflected in the manufacturers’ figures for shrinkage in water: Edelrid<br />

2.3%, Beal 4%, Marlow 3.2%.<br />

When the <strong>rope</strong>s are soaked, the sheath shrinks and tightens around the core resulting in a stiffer<br />

<strong>rope</strong>. In the case <strong>of</strong> the Edelrid <strong>rope</strong>, this does not occur to the same extent and the <strong>rope</strong> remains<br />

supple, allowing easier slippage <strong>of</strong> devices. It can be surmised that slippage is likely to decrease<br />

with use, although this remains to be tested.<br />

As only one dynamic <strong>rope</strong> was used in the test programme, comparative testing was not<br />

possible. The main use was to test the strength and energy-absorbing abilities <strong>of</strong> knots. The<br />

other use was to test the performance <strong>of</strong> back-up devices if used on such a <strong>rope</strong>.