HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

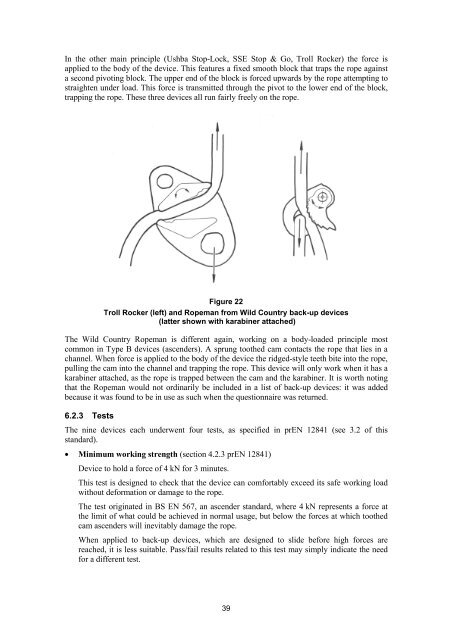

In the other main principle (Ushba Stop-Lock, SSE Stop & Go, Troll Rocker) the force is<br />

applied to the body <strong>of</strong> the device. This features a fixed smooth block that traps the <strong>rope</strong> against<br />

a second pivoting block. The upper end <strong>of</strong> the block is forced upwards by the <strong>rope</strong> attempting to<br />

straighten under load. This force is transmitted through the pivot to the lower end <strong>of</strong> the block,<br />

trapping the <strong>rope</strong>. These three devices all run fairly freely on the <strong>rope</strong>.<br />

Figure 22<br />

Troll Rocker (left) and Ropeman from Wild Country back-up devices<br />

(latter shown with karabiner attached)<br />

The Wild Country Ropeman is different again, working on a body-loaded principle most<br />

common in Type B devices (ascenders). A sprung toothed cam contacts the <strong>rope</strong> that lies in a<br />

channel. When force is applied to the body <strong>of</strong> the device the ridged-style teeth bite <strong>into</strong> the <strong>rope</strong>,<br />

pulling the cam <strong>into</strong> the channel and trapping the <strong>rope</strong>. This device will only work when it has a<br />

karabiner attached, as the <strong>rope</strong> is trapped between the cam and the karabiner. It is worth noting<br />

that the Ropeman would not ordinarily be included in a list <strong>of</strong> back-up devices: it was added<br />

because it was found to be in use as such when the questionnaire was returned.<br />

6.2.3 Tests<br />

The nine devices each underwent four tests, as specified in prEN 12841 (see 3.2 <strong>of</strong> this<br />

standard).<br />

• Minimum working strength (section 4.2.3 prEN 12841)<br />

Device to hold a force <strong>of</strong> 4 kN for 3 minutes.<br />

This test is designed to check that the device can comfortably exceed its safe working load<br />

without deformation or damage to the <strong>rope</strong>.<br />

The test originated in BS EN 567, an ascender standard, where 4 kN represents a force at<br />

the limit <strong>of</strong> what could be achieved in normal usage, but below the forces at which toothed<br />

cam ascenders will inevitably damage the <strong>rope</strong>.<br />

When applied to back-up devices, which are designed to slide before high forces are<br />

reached, it is less suitable. Pass/fail results related to this test may simply indicate the need<br />

for a different test.<br />

39