HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

HSE: Industrial rope access - investigation into items of personal ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.4 CONTAMINATED ROPE TESTS<br />

A limited number <strong>of</strong> tests were carried out on sections <strong>of</strong> <strong>rope</strong> that had been exposed to<br />

contaminants. The choice <strong>of</strong> contaminants was based on those which are likely to be routinely<br />

encountered on a work site. Direct contamination such as chemical spills, battery acid and<br />

engine oil were not considered as they are, firstly, easily avoidable and recognisable, and<br />

secondly, already subject to published data. Two contaminants likely to be found on an<br />

industrial work site, and on which little data was available, were studied: rust and bird<br />

droppings.<br />

3.4.1 Rust<br />

Sections <strong>of</strong> <strong>rope</strong> were left in a bucket filled with water along with around 1 kg <strong>of</strong> steel swarf<br />

(metal shavings). After about six months the sections were removed and left to dry. Rust<br />

staining was seen on all the sections. The worst affected parts were then tied up <strong>into</strong> lanyards<br />

using double overhand knots. These were then tested in the same way as the other knots<br />

described previously. When compared to the double overhand knot tests, tied in new <strong>rope</strong>, no<br />

additional reduction in strength was found. This does not necessarily mean rust has no effect on<br />

polyamide <strong>rope</strong>s. The amount <strong>of</strong> rusting that occurred was limited by the amount <strong>of</strong> oxygen<br />

dissolved in the water. After some time this was used up and rusting slowed considerably.<br />

Periodically removing the <strong>rope</strong>, allowing it to dry and then re-immersing it would have resulted<br />

in far worse degrees <strong>of</strong> rusting. This would also be a more accurate simulation <strong>of</strong> the conditions<br />

likely to be encountered in <strong>rope</strong> <strong>access</strong>. Also, whilst the rust itself may not cause damage, the<br />

iron would form chelates 6 with the organic acids that are likely to be formed in such wetting and<br />

drying scenario. Both the chelates and the organic acids would be very likely to cause<br />

weakening <strong>of</strong> the nylon fibres. More research in this complex area would be necessary before<br />

any definite conclusions could be drawn.<br />

Rope<br />

brand<br />

Type<br />

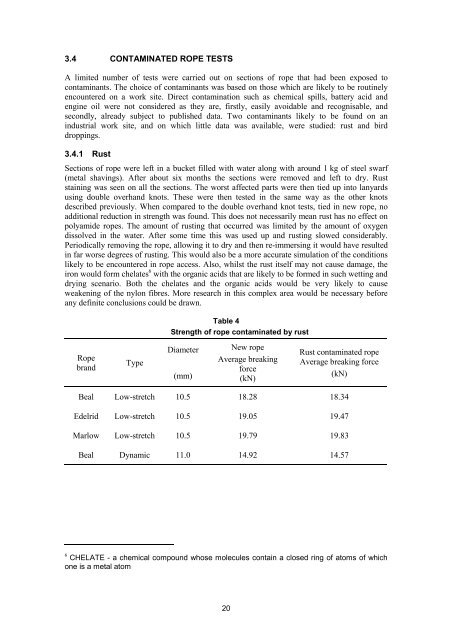

Table 4<br />

Strength <strong>of</strong> <strong>rope</strong> contaminated by rust<br />

Diameter<br />

(mm)<br />

New <strong>rope</strong><br />

Average breaking<br />

force<br />

(kN)<br />

20<br />

Rust contaminated <strong>rope</strong><br />

Average breaking force<br />

(kN)<br />

Beal Low-stretch 10.5 18.28 18.34<br />

Edelrid Low-stretch 10.5 19.05 19.47<br />

Marlow Low-stretch 10.5 19.79 19.83<br />

Beal Dynamic 11.0 14.92 14.57<br />

6<br />

CHELATE - a chemical compound whose molecules contain a closed ring <strong>of</strong> atoms <strong>of</strong> which<br />

one is a metal atom