You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

inside >>><br />

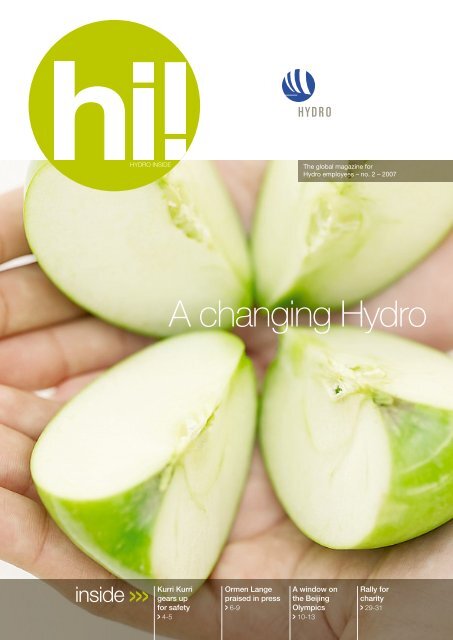

HYDRO INSIDE The global magazine for<br />

<strong>Hydro</strong> employees – no. 2 – 2007<br />

A <strong>changing</strong> <strong>Hydro</strong><br />

Kurri Kurri<br />

gears up<br />

for safety<br />

> 4-5<br />

Ormen Lange<br />

praised in press<br />

> 6-9<br />

A window on<br />

the Beijing<br />

Olympics<br />

> 10-13<br />

Rally for<br />

charity<br />

> 29-31

there!<br />

<strong>Hydro</strong> has undergone major changes<br />

over the past five years. But the company’s<br />

viable industrial traditions stretching back<br />

101 years, its strong market positions, as<br />

well as its talented and loyal workforce, will<br />

live on from the autumn of 2007 in three<br />

leading global companies: the fertilizer<br />

company Yara, the aluminium and power<br />

company <strong>Hydro</strong>, and in the global oil<br />

industry’s biggest offshore operator.<br />

The spin-off and merger of <strong>Hydro</strong>’s<br />

oil and gas business with Statoil is an<br />

extensive project, and many in both <strong>Hydro</strong><br />

and Statoil are facing new opportunities<br />

and challenges.<br />

Other parts of <strong>Hydro</strong>’s operations are<br />

also about to undergo big changes. It is<br />

in such situations that the quality of the<br />

employees and the organization is put to<br />

the test and is seen to prevail.<br />

I have been asked questions and<br />

listened to comments indicating that the<br />

vast majority are enthusiastic and filled with<br />

expectation regarding the changes facing<br />

them. My impression is that this applies<br />

both to those introwho textare body joining copy theintro newtext oil<br />

company T body and those copywho introare text continuing body copy in<br />

<strong>Hydro</strong> as an<br />

intro<br />

aluminium<br />

text body<br />

company.<br />

copy intro text<br />

And yet many are uncertain. What about<br />

body copy intro text body copy.<br />

me, what about my job? These are natural<br />

Body copy Body copy Body copy Body<br />

and sound reactions. I share this uncer-<br />

copy Body copy Body copy Body copy Body<br />

tainty. And every day I am with colleagues<br />

who<br />

copy<br />

are<br />

Body<br />

feeling<br />

copy<br />

the<br />

Body<br />

same<br />

copy<br />

emotions.<br />

Body copy Body<br />

copy Meanwhile Body copy myBody gut reaction, copy Body andcopy the Body<br />

reactions copy Bodyofcopy commentators, Body copy Body analysts copy andBody<br />

investors copy Body worldwide copy Body indicate copy Body that we copy have Body<br />

made copy Body the right copydecision. Body copy ThisBody is because copy Body<br />

we copy are Body making copythese Bodychanges copy Body fromcopy a Body<br />

position copy Body of strength. copy Body copy Body copy<br />

By means of bold moves and hard work<br />

we have added great value ensuring that<br />

more than 40,000 well qualified employees<br />

have jobs that are even more secure<br />

hi! > writer<br />

and exciting.<br />

photos > photographer<br />

contents<br />

4-5<br />

Safety in center. Keeping track of safety gear<br />

systematically saves money and improves safety<br />

performance.<br />

6-9<br />

Ormen Lange a star. We know the Ormen Lange gas<br />

project is a big deal. The rest of the world is taking notice,<br />

too.<br />

10-13<br />

Foot in the door in China. Isn’t exporting fabricated<br />

aluminium products to China like selling sand in the Sahara?<br />

14-15<br />

Seeing is believing. Virtual reality isn’t just for exploring<br />

undersea reservoirs – it can also improve safety offshore.<br />

16-25<br />

A <strong>changing</strong> <strong>Hydro</strong>. The proposed merger of <strong>Hydro</strong>’s<br />

oil and gas activities with the Norwegian company Statoil<br />

is certainly a big deal. But there are some other notso-small<br />

deals happening, too, that are <strong>changing</strong> <strong>Hydro</strong>.<br />

26-27<br />

When small is beautiful. Little things can mean a lot,<br />

both for the environment and the bottom line.<br />

29-31<br />

Ride of a lifetime. It takes determination. Paul Farrugia<br />

spent 16 days riding a motorbike across South Africa to<br />

help that country’s fight against poverty and disease.<br />

32-33<br />

Art and engineering – two sides of the same coin.<br />

For Joe Brown, his computer-driven engineering work and<br />

his whimsical paintings complement each other – both<br />

require foresight and determination to see them through.<br />

34-35<br />

Postcard from Newton Aycliffe<br />

hi&lo 28 hi5 36

hi!> team<br />

Editor-in-chief > Cecile Ditlev-Simonsen<br />

Managing Editor > Craig Johnson (craig.johnson@hydro.com)<br />

Editorial board > Halvor Molland (Aluminium Metal),<br />

6 10 14<br />

26<br />

29<br />

next issue<br />

May 2007<br />

Ideas? Contact:<br />

Craig Johnson<br />

<strong>Hydro</strong> (F472B)<br />

NO-0240 Oslo,<br />

Norway<br />

craig.johnson@<br />

hydro.com<br />

contents hi! 3<br />

Ole Johan Sagafos (Aluminium Products), Bjørn Otto Sverdrup<br />

(Oil & Energy), Ragnvald Bertheussen (Other Businesses).<br />

Design and production > item ltd and Media Center (3700017)<br />

Photo: Scanpix<br />

The businesses<br />

leaving <strong>Hydro</strong> will<br />

go on to create<br />

value in their new<br />

homes.

Keeping track<br />

of safety gear<br />

systematically<br />

saves money and<br />

improves safety<br />

performance<br />

Safety<br />

in the<br />

center

Team co-ordinator Michael Wilson and his colleagues at<br />

Kurri Kurri are benefiting from improved safety performance<br />

and the Safety Maintenance Center.<br />

T<br />

he aluminium smelter in Kurri<br />

Kurri, Australia, distributed close<br />

to 13,000 pieces of safety equip-<br />

ment to employees last year – a lot to<br />

keep track of. That’s the job of the Safety<br />

Maintenance Center.<br />

“When we issue a piece of safety equip-<br />

ment, we know it is according to Australian<br />

and site safety standards. It has not been<br />

lying around in the back of a car the last six<br />

months, with paint all over it,” says site safety<br />

officer Jim York.<br />

Together with assistant safety officers<br />

Gregory Cook and Simon Lane he inspected<br />

and issued close to 13,000 pieces of safety<br />

gear in 2006. This includes 3,764 Racal hel-<br />

mets, 1,791 harnesses and 1,789 lanyards.<br />

The process and results of the system are<br />

impressive, making the Safety Maintenance<br />

Center a significant contributor to a record low<br />

total recordable injury statistic of 2.1 in 2006.<br />

In addition, <strong>Hydro</strong> saves big money through<br />

loss prevention.<br />

It wasn’t always that way. Ten years ago,<br />

each worker had individual safety gear, and<br />

50 Racal helmets, each priced at around<br />

$800, were lost every year. Other equipment<br />

was misplaced and lost, and – very import-<br />

ant – safety equipment was not inspected<br />

regularly.<br />

Last year, though, only one of the Racal<br />

helmets was not returned. The Safety Main-<br />

tenance Center then could identify who had<br />

been issued the helmet, and the department<br />

in question had to replace it.<br />

Since all equipment is tagged and all activi-<br />

ties logged on a computer, the use of safety<br />

equipment can be optimized in cooperation<br />

with the manufacturer. One example is Racal<br />

helmet filters. The center now knows exactly<br />

how many times each of the 110 helmets has<br />

been used. York estimates the annual savings<br />

on filters alone to be around $30,000.<br />

“The people working at the Safety Maint-<br />

enance Center are all certified to inspect the<br />

safety equipment we issue. All equipment is<br />

clearly tagged and identified, has its designat-<br />

ed storage area, and we know exactly when<br />

it expires or requires servicing. We dismantle,<br />

clean, and inspect everything before it is re-<br />

issued,” says York.<br />

Based on this success, all contractors<br />

working at the smelter are also offered the<br />

use of safety equipment from the center.<br />

hi! > Halvor Molland<br />

photos > Halvor Molland<br />

Safety officer Jim York (right) and assistant Gregory Cook inspect a Racal helmet at the Safety Maintenance Center in Kurri Kurri, Australia.<br />

safety first hi! 5<br />

– 25%<br />

Goal!<br />

<strong>Hydro</strong> made its goal of a<br />

20 percent drop in the total<br />

number of injuries in 2006<br />

– by a good margin.<br />

The number of total recordable<br />

injuries (TRI) has been<br />

falling steadily over time,<br />

although the ambitious target<br />

of a 20 percent reduction in<br />

injuries set by President and<br />

CEO Eivind Reiten has not<br />

been reached every year.<br />

Last year, though, the trend<br />

was very positive – a reduction<br />

of around 25 percent, for<br />

a TRI rate of 4.0. The reduction<br />

in the TRI rate for 2005<br />

was 10 percent.<br />

“Certain business areas<br />

have achieved great improvements,”<br />

says Jack Simensen,<br />

head of safety in the corporate<br />

Health, Safety and Environment<br />

department. “Several<br />

units have achieved an improvement<br />

of more than 50<br />

percent, but we still have a<br />

list of units that are lagging<br />

behind, and unfortunately<br />

certain units also have reported<br />

a setback. This of course<br />

gives grounds for follow-up.”<br />

Despite the overall improvement,<br />

<strong>Hydro</strong> experienced one<br />

workplace fatality in 2006.<br />

Jens Hinrichs, a project engineer<br />

at the aluminium extrusion<br />

plant in Birtley, England,<br />

died in an accident in early<br />

November.<br />

“Every fatal accident is one<br />

too many,” Simensen says,<br />

adding that the number of<br />

fatal accidents has also fallen<br />

over time.<br />

The fatal accident at Birtley<br />

has been investigated, and a<br />

report has been distributed<br />

on the <strong>Hydro</strong> intranet so that<br />

others can learn from the<br />

experience.

We know the Ormen Lange gas project is a big deal. T

The rest of the world is taking notice, too<br />

hi! 7<br />

>>>

Ormen Lange<br />

a star<br />

H<br />

ydro’s Ormen Lange project<br />

is attracting a good deal of<br />

attention far beyond the small<br />

community of Aukra on the northwest<br />

coast of Norway, where the gas will be<br />

brought ashore for processing.<br />

So far, Ormen has been seen by millions<br />

of television viewers worldwide on Discovery<br />

Channel, as well as Russian and German<br />

programs. The Langeled pipeline part of the<br />

project, which connects the landfall site and<br />

a terminal in England, has been covered by<br />

the BBC and several UK newspapers.<br />

Here are some of the most prestigious:<br />

• The Ormen Lange project reappeared on<br />

TV when National Geographic Channel<br />

featured it in the “Megastructures” series.<br />

• Ormen Lange went to Hollywood when<br />

<strong>Hydro</strong>’s film “The Traveller,” featuring Lonely<br />

Planet host Ian Wright, won top honors at<br />

the US International Film and Video Festival.<br />

• Popular Science magazine featured the<br />

Ormen Lange/Langeled project in a “Best<br />

of What’s New in 2006” feature.<br />

• The jewel in the crown as far as the energy<br />

industry is concerned was when the project<br />

captured the esteemed Platt’s Global<br />

Energy Project of the Year prize in New<br />

York City in late 2006.<br />

“Ormen was unanimously voted into first place<br />

by all 10 of the Platt’s Global Energy Award’s<br />

judges – the first time ever in the history of the<br />

awards,” says Lars H. Bjelvin, head of Ormen<br />

Lange communication.<br />

“The project is a fantastic vehicle for getting<br />

across strategic messages supporting <strong>Hydro</strong>’s<br />

business goals. Its features and strengths are<br />

very much the same as those <strong>Hydro</strong> has devel-

oped as an industrial frontrunner during the<br />

past 100 years.”<br />

One of the most important facets <strong>Hydro</strong><br />

wants to show about Ormen Lange is close<br />

and constructive cooperation with project<br />

partners, suppliers and the public, including<br />

academia and science institutions.<br />

“Managing a project like this cultivates two<br />

other strengths that both Ormen Lange and<br />

<strong>Hydro</strong> are increasingly known for – being a<br />

technological visionary that progressively<br />

develops new, groundbreaking technologies,<br />

and being a performance champion that<br />

consistently delivers large-scale projects with-<br />

in agreed time and cost frames,” Bjelvin says.<br />

“<strong>Hydro</strong> trademarks like technology, project<br />

performance and cooperation are the ones<br />

we need to tailor and communicate to stake-<br />

holders and decision makers, bilaterally and<br />

publicly, wherever we have growth ambitions.”<br />

<strong>Hydro</strong> recently completed just such a com-<br />

munications campaign in Russia. “Today <strong>Hydro</strong><br />

is widely recognized by both Russian business<br />

and political leaders as a leading company<br />

within subsea technology and especially as a<br />

company that’s always on time and budget,”<br />

says Bjelvin.<br />

This is the fi rst time in my life that we’re getting so<br />

much focus on a project. It makes you proud when<br />

National Geographic and Discovery Channel want<br />

to cover Ormen Lange, even before we’re done.<br />

This really brings Ormen Lange to the people, and<br />

it’s very stimulating for the whole project team.<br />

Tom Røtjer, senior vice president, Projects<br />

Conveying this image is strategically imperat-<br />

ive in a country like Russia, with its abundant<br />

petroleum resources yet difficult framework<br />

conditions, which are coupled with intensify-<br />

ing competition between international com-<br />

panies that have upstream petroleum growth<br />

ambitions.<br />

“Going into <strong>Hydro</strong>’s last year as an opera-<br />

tor on Ormen Lange, the project’s trademark<br />

strengths will be steadily marketed towards<br />

other key decision makers in different parts<br />

of the world – the Americas, Europe, the<br />

Middle East and Africa, to mention some,”<br />

says Bjelvin.<br />

“We always tailor our message to the local<br />

business realities in the places where we have<br />

growth ambitions. We do it both bilaterally and<br />

publicly through a complete mix of channels<br />

in order to get the message across – Ormen<br />

Lange and <strong>Hydro</strong> is all about three features:<br />

technology, performance and cooperation.”<br />

hi! > David Burke<br />

photos > Øivind Leren, Tor Hammerstad,<br />

Helge Hansen, Dag Thorstensen<br />

hi! 9

Foot<br />

in the door<br />

in China<br />

Isn’t exporting fabricated<br />

aluminium products to<br />

China like selling sand<br />

in the Sahara?

hi! 11

If you fi nd it difficult to change your long-held perceptions you<br />

should stay away from China. Things are developing here so<br />

quickly that even the most dynamic among us are struggling to<br />

keep up.<br />

Gérard Lugrin<br />

Windows from <strong>Hydro</strong> are destined to adorn the Morgan Center in Beijing.<br />

C<br />

hina represents a vast growing<br />

market – 1.3 billion people in<br />

the fastest growing economy<br />

in the world. Demand for aluminium is<br />

increasing, but so are the abilities of<br />

Chinese producers, who are working<br />

hard to catch up to Western standards.<br />

Still, <strong>Hydro</strong> is selling its advanced alumin-<br />

ium building systems products – including<br />

for high-profile constructions connected to<br />

the 2008 Olympic Games in Beijing – for<br />

this booming construction market.<br />

Says Gérard Lugrin, who is developing <strong>Hydro</strong><br />

Building Systems in China: “Why shouldn’t<br />

we sell our advanced building systems in<br />

the world’s fastest growing market?”<br />

Lugrin operates out of a big new ware-<br />

house and office building outside Beijing,<br />

from which <strong>Hydro</strong> is currently making its<br />

first major delivery here.<br />

Wicona brand window systems from<br />

<strong>Hydro</strong> will form a highly visible part of the<br />

setting for the Beijing Olympic Games, the<br />

Morgan Center.<br />

In the last year, he has built up a staff of tal-<br />

ented Chinese employees, including several<br />

who have solid construction industry experi-<br />

ence. In the autumn of 2006 they moved into<br />

their new warehouse, signed their first major<br />

contracts and established important links with<br />

the Chinese building industry, property devel-<br />

opers, metal building specialists and architects.<br />

They have also drawn up their plans for the<br />

coming years when the Wicona and Technal<br />

brands will be developed to take their natural<br />

position in this enormous market.

The size of the Chinese market for alumin-<br />

ium building products is not that easy to<br />

gauge. Lugrin estimates a volume of roughly<br />

1 million tonnes per year for the type of pro-<br />

ducts that <strong>Hydro</strong> supplies. <strong>Hydro</strong> Building<br />

Systems’ niche in this market is probably<br />

around 100,000 tonnes.<br />

But they are not alone. Both European<br />

and Chinese suppliers are chasing shares<br />

in the market for top-quality products. More-<br />

over, the Chinese authorities are about to<br />

introduce stringent new requirements con-<br />

cerning the energy efficiency of buildings.<br />

“The new specifications outlined are<br />

intended to improve the energy efficiency of<br />

new buildings by 65 per cent,” he explains.<br />

“They will be more stringent than the most<br />

rigorous specifications in Europe.<br />

“This represents a great opportunity for us,<br />

but it also means that Chinese producers will<br />

soon catch up in this field. Several of them<br />

already deliver very advanced building systems.<br />

If we intend to keep ahead in terms of quality<br />

and technically advanced solutions, we need<br />

to intensify our product development efforts.<br />

Our most demanding clients in China do not<br />

set lower standards than our European ones.”<br />

Lugrin and his team are off to a flying start,<br />

but they know that a large and growing market<br />

Personal profile<br />

Gérard Lugrin – ‘pioneer’<br />

Gérard Lugrin has been <strong>Hydro</strong> Building Systems’ representative in Beijing for one year,<br />

but he is no industry newcomer. The 59-year-old French architect has spent his entire<br />

career in the aluminium industry, most of it with Technal, which became part of <strong>Hydro</strong><br />

in 2002. He has lived all over the world – in Morocco, Thailand, Europe and the Middle<br />

East. and traveled for 15 years in Africa, Middle East and South America. Lugrin came<br />

to Beijing from Bahrain. He describes himself as a typical pioneer. That’s what he likes<br />

doing best – setting up, building, getting the wheels to turn. Afterwards he prefers to<br />

withdraw and hand over to the locals. This is clearly the right thing to do in China.<br />

is not in itself a guarantee of success. You also<br />

need a real ability and willingness to under-<br />

stand where you naturally fit in Chinese culture.<br />

Gérard Lugrin is enthusiastic – and there can<br />

be no doubt that his people are too. He says<br />

that he faces the tasks confronting him with<br />

due humility. Moreover, he is greatly impressed<br />

by the tempo and determination in today’s<br />

developing China.<br />

“Just look around! There’s hardly a block in<br />

this huge city that isn’t dominated by several<br />

big cranes. New skyscrapers are going up all<br />

over the place. There are market opportunities<br />

as far as the eye can see,” he says. “This is<br />

tremendous. I’ve never experienced anything<br />

like it.”<br />

hi! > Ole Johan Sagafos<br />

photos > Ole Walter Jacobsen<br />

Preparations are under way<br />

for the 2008 Olympics in Beijing.<br />

hi! 13

Virtual reality isn’t just for exploring undersea<br />

reservoirs – it can also improve safety offshore<br />

Seeing

is believing<br />

F<br />

or the fi rst time, computer<br />

codes designed to analyze gas<br />

hazards are being combined<br />

with virtual reality (VR) to deliver safety<br />

training.<br />

The program has been created by the<br />

Oil & Energy Research Center in Porsgrunn,<br />

Norway, to help offshore and onshore per-<br />

sonnel to understand and reduce offshore<br />

risk, and to improve safety.<br />

<strong>Hydro</strong> platform managers gathered in the<br />

Oseberg VR room at the Sandsli offices near<br />

Bergen to take part in an interactive demon-<br />

stration of the new training tool. The program<br />

combines realistic three-dimensional com-<br />

puter-assisted design models with in-house<br />

design and gas hazard analysis tools. It is<br />

fully interactive, so you can simulate new<br />

incidents online, simply by defining a new<br />

leak and placing it wherever you like.<br />

“The main goal is to increase awareness<br />

of barrier philosophy, risk levels and to com-<br />

municate emergency preparedness mea-<br />

sures,” says project leader Olav Sæter.<br />

There’s nothing virtual about the need to im-<br />

prove awareness. Last year, <strong>Hydro</strong> accounted<br />

for nearly half of all reported gas leak incidents<br />

in the Norwegian offshore sector.<br />

“It’s not so easy to communicate risk levels,<br />

but using this tool we can see and experience<br />

virtual situations,” says Gry Offernes, head of<br />

safety, security & emergency preparedness in<br />

Operations.<br />

For example, she cites offshore workers<br />

who build makeshift wind shelters on plat-<br />

forms without consulting technical safety<br />

representatives: “This program visually dem-<br />

onstrates the consequences!”<br />

Here’s how it works.<br />

“Now we’re in a very dangerous situation,”<br />

explains Sæter, simulating a potentially cata-<br />

strophic gas leak in the compressor module<br />

on Grane, the model platform used in the<br />

<strong>Hydro</strong>-designed VR program. Sound effects<br />

of gas leaks and explosions have been in-<br />

corporated to make the situation as realistic<br />

as possible. All simulated data is generated<br />

by advanced codes for gas hazard analysis,<br />

including sites where leaks are likely to occur<br />

and wind conditions.<br />

Training scenarios are designed around five<br />

steps of development in a gas leak situation<br />

– source, gas dispersion, ignition, explosion<br />

fire and major accident. Wind also appears<br />

in the form of color-coded lines and arrows<br />

depicting directions and speeds.<br />

The VR risk and safety program can be<br />

used anywhere – from the CAVE virtual reality<br />

viewing room to laptop computer – thanks<br />

to a software application that can run on<br />

different hardware platforms. All you need is<br />

3D goggles. Even a laptop conveys the same<br />

sense of 3D depth as CAVE.<br />

hi! > David Burke<br />

photo > Vidar Hardeland<br />

It’s not so easy to communicate risk levels, but using this tool<br />

we can see and experience virtual situations.<br />

Gry Offernes<br />

Olav Sæter demonstrates the VR safety<br />

program for platform managers and other<br />

future users.<br />

hi! 15

A <strong>changing</strong><br />

inside >>><br />

<strong>Hydro</strong><br />

Eivind Reiten<br />

Photo: Helge Hansen

The proposed merger of <strong>Hydro</strong>’s oil and gas activities<br />

with the Norwegian company Statoil is certainly a big deal.<br />

But there are some other not-so-small deals happening<br />

that are <strong>changing</strong> <strong>Hydro</strong>.<br />

<strong>Hydro</strong> Polymers, which has about 1,200 employees, is<br />

to be sold or launched on a stock exchange, much as<br />

the former Agri business – now Yara – experienced three<br />

years ago. <strong>Hydro</strong> Production Partner and Production<br />

Services (more than 1,000 employees in total) are also<br />

being prepared for sale.<br />

See what your colleagues – and some former colleagues<br />

– have to say.<br />

>>><br />

<strong>Hydro</strong> Polymers’<br />

‘can-do’ attitude<br />

> 18-21<br />

Yara blazes its<br />

own trail<br />

> 22-24<br />

A <strong>changing</strong> Innovation <strong>Hydro</strong> hi! 17<br />

Bittersweet exit,<br />

but jobs remain<br />

> 24-25

‘<strong>Hydro</strong> is <strong>changing</strong>, and<br />

we’re <strong>changing</strong>’<br />

The employees at <strong>Hydro</strong> Polymers in Aycliffe,<br />

England, know how to tackle change<br />

T<br />

he chairman of Bakelite Ltd.,<br />

the fi rst company to run the<br />

industrial site at Newton Aycliffe<br />

after World War II, commented in 1951:<br />

“Workers in the North East are the finest type<br />

they could possibly be, adaptable, hard work-<br />

ing and capable of picking up new processes<br />

very quickly.”<br />

That’s certainly still true today. In the inter-<br />

vening years, other companies have done<br />

business here, with <strong>Hydro</strong> Polymers the latest,<br />

starting when <strong>Hydro</strong> acquired the site in 1982.<br />

Much of the workforce is drawn from the<br />

local area, and more than a few employees<br />

can point to family members also employed<br />

here. More than a few have worked for more<br />

than one owner.<br />

So what do they think about plans to<br />

divest <strong>Hydro</strong> Polymers, either through a sale<br />

to another company or by creating a new,<br />

independent company through a stock listing?<br />

hi! > Craig Johnson<br />

photos > Terje S. Knudsen

We have nothing to be afraid of<br />

from a new owner. We have a strong<br />

operation and good, capable people.<br />

Bill Wood<br />

Bill Wood<br />

Site director<br />

30 years<br />

A <strong>changing</strong> Innovation <strong>Hydro</strong> hi! 19<br />

‘A strong operation’<br />

Communication is important, otherwise<br />

you’re left in a black hole. Now that it’s<br />

out in the open it’s so much easier. We<br />

can explain the positives of standing on<br />

our own two feet.<br />

We believe <strong>Hydro</strong> will treat us in a fair<br />

manner. This site has a lot to be grateful<br />

for when you look at what has been<br />

developed here.<br />

I’ve worked for two owners: British<br />

Industrial Plastics, and then <strong>Hydro</strong>. We<br />

recognize <strong>Hydro</strong> is <strong>changing</strong>, and we’re<br />

<strong>changing</strong>. We have nothing to be afraid<br />

of from a new owner. We have a strong<br />

operation and good, capable people.<br />

>>>

Carl Fawcett<br />

Process operator<br />

– Compounds<br />

10 years<br />

‘Lot of uncertainty’<br />

My father has been here nearly<br />

30 years. I started in October<br />

1996 on the mixing floor in<br />

Compounds, when I was start-<br />

ing a family of my own.<br />

It’s one of the best-paying<br />

places around. I believe it’s<br />

a firm that wants to help you<br />

along.<br />

There’s a lot of uncertainty,<br />

especially among the younger<br />

lads. There are lots of plants<br />

around England that are closing<br />

down.<br />

I don’t see the divestment as<br />

a bad thing. Whatever direction<br />

we take, we can focus a bit<br />

more. The profitability is there.<br />

I’ve got three kids – 2½, 6<br />

and 11 – and live just down the<br />

road. And while I might wish<br />

something else for them, I’d like<br />

to think that something will still<br />

be here when they get older.<br />

Brent Morfoot<br />

Process operator – Compounds<br />

2 years<br />

‘New era coming’<br />

I worked for 19 years at Great Lakes Chemicals here in<br />

Aycliffe, then due to closure I applied here at <strong>Hydro</strong>, and<br />

I’ve never looked back. I always looked at <strong>Hydro</strong> as the one<br />

that did things right. When I was at Great Lakes, we’d ask<br />

ourselves, What would <strong>Hydro</strong> do? Why don’t we do that?<br />

I’m born and bred here. Wife Jill, and two kids, Stacey,<br />

16, and Carl, 13.<br />

If this divestment had happened two years ago – when<br />

times were tough and we were low on orders – I might have<br />

been worried. But we’ve had a big upturn, we’re working<br />

chockablock. I’d be more worried if I was working anywhere<br />

else than <strong>Hydro</strong>.<br />

There’s a willingness to change by the employees. We<br />

never stand still here.<br />

We’ve come through a hard time, but we’ve got a bright<br />

future. This is the pinnacle, it’s where everyone wants to<br />

work.<br />

There’s a new era coming, and if we carry on pulling in<br />

the right direction, I can see any transition causing minimal<br />

disruption. With our willingness for change and the strong<br />

teamwork ethic we have, there’s no reason why we cannot<br />

look forward with belief of exciting times ahead. Keeping<br />

our high standards and positive thinking are the keys to<br />

success.<br />

Lee Edgar<br />

Craftsman and<br />

Amicus union shop steward<br />

15 years<br />

‘Positive about the future’<br />

I started 15 years ago, as an apprentice<br />

mechanical engineer. I’m now shift engi-<br />

neer in Compounds, doing preventive<br />

maintenance and breakdown mainte-<br />

nance.<br />

I’ve been a shop steward since last<br />

July. If anyone has a problem, they can<br />

come to me.<br />

People are a bit disappointed. They<br />

understand <strong>Hydro</strong>, and <strong>Hydro</strong> has been<br />

good for Aycliffe.<br />

They’re not scared of change – We’ve<br />

been through a lot. It’s something we’re<br />

good at. Change is going to come. You<br />

can’t fight it, you have to live with it.<br />

I’m married, with two kids – boys 3<br />

years and 8 months. You’ve got to feel<br />

a little bit worried, but I’m quite positive<br />

about the future.<br />

People try their hardest here.<br />

more on Aycliffe > page 34-35

Geoff Richardson<br />

Training technologist<br />

35 years<br />

‘Loyalty both ways’<br />

My father started at this site in 1952 and left in 1985 as BXL’s<br />

personnel manager. I started in 1972 when my father got me a<br />

position on the Resin Plant after I had served time in the Royal<br />

Artillery and other local employment. My son Michael works<br />

here, too, in the warehouse.<br />

It was really manual, very hard work. I started on the bottom<br />

rung of the ladder, cleaning. I worked through the department<br />

to become shift manager, followed by Maintenance Shutdown<br />

Coordinator, now my current position is Training Technologist.<br />

You get some experience with people after 35 years. I’ve<br />

mellowed – there was no one more pigheaded than I was. You<br />

could say I’ve got a degree in life.<br />

It’s a shame that it’s the route <strong>Hydro</strong> thinks we have to go.<br />

I like <strong>Hydro</strong>. But this is just another challenge. Yara has done<br />

well – we’ll do well.<br />

This is a fantastic site. A lot has happened over the last<br />

25 years. When the site was owned by BXL there were 1,500<br />

people here, now we have just under 400. I’d like to say it’ll<br />

be here 50 years from now.<br />

Loyalty has worked both ways. A lot of people here enjoy<br />

coming to work, and <strong>Hydro</strong> has been good for the site.<br />

I could take my pension, but I don’t have any desire to retire.<br />

I moved up from the bottom, and I still have energy and moti-<br />

vation.<br />

Carolle Land<br />

Personnel officer<br />

11 years<br />

‘Rise to the challenge’<br />

A <strong>changing</strong> Innovation <strong>Hydro</strong> hi! 21<br />

I’ll have been here 12 years in May. I started in a secretarial role, and after<br />

a couple of years moved into HR; my current position is Personnel Officer.<br />

I love interacting with people, we have an open-door policy where<br />

people can come in and talk confidentially. HR is there to help support<br />

and advise the workforce. These are exciting times.<br />

I was here during a possible takeover a number of years ago. They<br />

were our main competitor and a lot of people didn’t want to go with them.<br />

We all breathed a sigh of relief when it didn’t go through.<br />

From a workforce point of view, we’ve had some tough years, not<br />

defined as a core business and being for sale. But we continue to do<br />

our best irrespective of what is going on. The workforce always adjusts.<br />

Every month is a challenge, and we rise to that challenge. Whatever<br />

we’re asked to do, we do more. It’s in the fabric of what we do here,<br />

continually looking to improve.<br />

With this divestment, we all know it’s definitely going to happen, people<br />

will carry on regardless. We’re really quite proud of our workforce and<br />

their achievements. Whatever happens, our workforce has a lot to give.<br />

People want to come and work for us. There is a lot of opportunity for<br />

people here to move within the organization.<br />

There are mixed emotions. Of the just under 400 employees, about<br />

120 have more than 25 years’ service. These employees have seen a lot<br />

of changes.<br />

It’s to be expected that these are worrying times for some people.<br />

People will have worries for themselves and for the site, it’s their bread<br />

and butter. We are not frightened of hard work and I know we will rise to<br />

the challenge.

Three years ago,<br />

<strong>Hydro</strong>’s Agri business<br />

was launched as<br />

an independent<br />

company called Yara.<br />

How is it doing today?<br />

Yara:<br />

independent,<br />

focused<br />

and growing<br />

Some strengths – like our size and<br />

reach – are inherited. Others – like<br />

our business model, productivity<br />

focus and organizational structure –<br />

are developing as we move forward.<br />

Thorleif Enger

U<br />

ntil 2003, <strong>Hydro</strong>’s Agri operations<br />

formed the historical backbone<br />

of the company. It was where<br />

the company got its start just over a<br />

century ago, making fertilizer. Then it was<br />

“demerged” from <strong>Hydro</strong> and listed on the Oslo<br />

Stock Exchange. Today, Yara is the world’s un-<br />

disputed leader in the field of plant nutrition.<br />

The company’s ambitions grew after its<br />

launch: Yara aims to be the “industry shaper”<br />

with a 10 percent market share by 2010.<br />

Fast facts<br />

• Yara is the global leader in plant<br />

nutrients, with sales to more than<br />

120 countries<br />

• Core business is production and<br />

marketing of nitrogen-based<br />

fertilizers and ammonia, the key<br />

raw material for nitrogen fertilizers<br />

• Employees: 6,800<br />

• Share price at launch, NOK 41;<br />

early 2007, around NOK 165<br />

“Being spun off opened up a lot of new<br />

opportunities for us. We have been care-<br />

ful to take advantage of them and actively<br />

communicate what we stand for and where<br />

we are going,” says Yara’s chief personnel<br />

officer, Anne Grethe Dalane.<br />

“As an independent company, our area<br />

of operation became more clear-cut. It was<br />

easier to develop a coherent strategy and<br />

set specific goals. We were able to create<br />

our own identity; our corporate culture is<br />

probably even more results-oriented today<br />

than it was previously.”<br />

Culture and brand building are two of the<br />

six planks in Yara’s program to realize its am-<br />

bition to be the “industry shaper.” The others<br />

are profitable growth, efficient operations, a<br />

better cost structure and innovation.<br />

Despite all the changes the company has<br />

gone through, Dalane believes that most<br />

employees have not experienced any major<br />

upheaval.<br />

“Identity and a sense of belonging have a<br />

very strong local dimension: 98 percent of<br />

our employees work outside the company’s<br />

head offices in Oslo, and 85 percent work<br />

outside Norway. We still have a decentralized<br />

organization, and the further away from Oslo<br />

you get, the less people will have noticed the<br />

change.<br />

“It is important that we all see the real po-<br />

tential of Yara and the business we operate.<br />

A <strong>changing</strong> Innovation <strong>Hydro</strong> hi! 23<br />

“Being spun off from <strong>Hydro</strong> opened up a lot of<br />

new opportunities for Yara,” says chief personnel<br />

officer Anne Grethe Dalane.<br />

That is something that CEO Thorleif Enger has<br />

always been crystal clear about – that we have<br />

a strong desire for growth.<br />

“Although a lot of necessary restructuring<br />

was carried out before we were spun off, we<br />

have continued to increase the efficiency of<br />

our operations. This has also led to a cut in the<br />

workforce – from around 8,000 then to fewer<br />

than 7,000 now.<br />

“If we go back four years, Agri (today’s Yara)<br />

was part of a 40,000-strong <strong>Hydro</strong> workforce.<br />

The fact that we are now a separate, smaller<br />

– and leaner – organization has probably<br />

played a part in how we feel about our jobs<br />

and our role. It may actually be easier for each<br />

individual employee to see the value of what<br />

we do, and lines of decision have definitely<br />

got shorter.”<br />

Dalane adds a little wryly: “I don’t think any-<br />

one in today’s Yara wants to be part of all the<br />

changes that are currently going on at <strong>Hydro</strong>.<br />

It is easier to be yourself.”<br />

hi! > Trond Aasland<br />

photos > PhotoDisc, Trond Aasland<br />

>>>

Trust and a culture of cooperation<br />

were things we were good at in the<br />

<strong>Hydro</strong> days, and which we are trying<br />

to keep at Yara.<br />

Arthur Frank Bakke<br />

<strong>Hydro</strong>’s culture lives on<br />

“I would say that most Yara em-<br />

ployees are happy about the spin-<br />

off from <strong>Hydro</strong>. Our employment<br />

conditions have been well taken<br />

care of, and developments in the<br />

market have definitely been on<br />

our side in the past few years,”<br />

says senior union representative<br />

Arthur Frank Bakke.<br />

Bakke is chairman of Herøya Arbei-<br />

derforening (the local union) and leader<br />

of the company’s European Works<br />

Council. He says that it was extremely<br />

important to the employees that their<br />

salary, insurance and pension rights,<br />

as well as other benefits, did not suffer<br />

as a result of the change. “These con-<br />

ditions have been – to put it simply –<br />

well taken care of, and have not been<br />

the cause of any friction,” he points out.<br />

Bakke explains that <strong>Hydro</strong> Agri under-<br />

went an extensive turnaround before it<br />

was spun off from <strong>Hydro</strong> in 2003. “This<br />

was important for what we subsequent-<br />

ly managed to achieve in the market.”<br />

What kind of culture does Yara have<br />

today? Are elements from the <strong>Hydro</strong><br />

days still embedded there?<br />

“We have probably brought with<br />

us some of <strong>Hydro</strong>’s corporate culture.<br />

The company still has its head offices<br />

in Norway and the Norwegian state<br />

remains a major shareholder. Never-<br />

theless, the composition of the work-<br />

force means that Yara is gradually be-<br />

coming a more international company.”<br />

Bakke also points out that trust and<br />

a culture of cooperation are advantages<br />

that all sides are trying to keep alive.<br />

“We were good at that in the <strong>Hydro</strong><br />

days, and we are trying to keep it going<br />

in Yara. Neither trust nor cooperation<br />

happen by themselves. They have to<br />

be created and to some degree depend<br />

on the individuals concerned. It is when<br />

union representatives feel that they are<br />

treated as equals that it is possible to<br />

make cooperation work.”<br />

T<br />

he Grenland area of southern<br />

Norway centered around Pors-<br />

grunn is still a center of heavy<br />

industry, but the <strong>Hydro</strong> logo no longer<br />

dominates the landscape as it once did.<br />

Yara has been spun off from <strong>Hydro</strong>, mag-<br />

nesium production has ceased, <strong>Hydro</strong> Poly-<br />

mers will become an independent company<br />

or will be sold off. Units like <strong>Hydro</strong> Production<br />

Partner are on their way out of the <strong>Hydro</strong> fold.<br />

With the changes that have occurred in<br />

the last few years, and those soon to come,<br />

<strong>Hydro</strong> will have a very small presence in this<br />

historic area. That doesn’t mean everyone<br />

is turning out the lights. <strong>Hydro</strong> has helped<br />

ensure that life goes on here, say two men –<br />

a senior manager and a union leader – who<br />

also have a long history here.<br />

“<strong>Hydro</strong> has taken the initiative to safeguard<br />

the future of its own production facilities and<br />

contribute to the establishment of new busi-<br />

nesses,” says Søren Sem, former head of<br />

<strong>Hydro</strong>’s operations in Porsgrunn.<br />

At the same time, solar cell producer REC<br />

ScanWafer has opened a major production<br />

facility in the area, and almost 90 companies<br />

of various shapes and sizes have established<br />

operations in the Industrial Park. This has<br />

accelerated since the exit from magnesium<br />

production.<br />

In fact, more than 3,000 people now work<br />

at the Herøya industrial site, more than before<br />

<strong>Hydro</strong>’s withdrawal.<br />

“<strong>Hydro</strong> as an industrial locomotive is on its<br />

way out of the Grenland area. We have arrived<br />

at a historic watershed,” says Bakke, leader<br />

of the local union Herøya Arbeiderforening.<br />

“This is not something we are happy about,<br />

but we believe that good, alternative solutions<br />

can be found. We expect that <strong>Hydro</strong> will con-<br />

tinue to shoulder its responsibilities and follow<br />

up as it has done during previous restructuring<br />

at Herøya.”<br />

Says Sem: “I can’t help but feel sad, what<br />

I call ‘nostalgic grief,’ about what is happen-<br />

ing now, after 85 years. It is incredible that it<br />

lasted so long.” Sem worked for <strong>Hydro</strong> for<br />

40 years, starting as an apprentice in the<br />

limestone quarries in 1956, and ending as<br />

general manager at Herøya.<br />

Are these developments right or wrong?

<strong>Hydro</strong>’s dominant position is coming to an end<br />

in a historic ‘home,’ but industry lives on<br />

“I don’t want to say anything about whether<br />

it is right or wrong. It is an international trend.<br />

We may find change difficult, but restructuring<br />

has always been part of our existence,” says<br />

Sem.<br />

“If we had not made the changes that we<br />

have done here at Herøya over the past 25<br />

years, there would not have been much left<br />

of us. The creation of <strong>Hydro</strong> Industrial and<br />

Business Parks has been extremely impor-<br />

tant, with the focus on innovation and shared<br />

services. I hope <strong>Hydro</strong> will remain the parks’<br />

landlord and operator,” says Bakke.<br />

“We have probably placed too much reliance<br />

on heavy industry and the security provided by<br />

<strong>Hydro</strong> here. But now growth must take place<br />

in other forms. The closure of the magnesium<br />

Arthur Frank Bakke, leader of the local union,<br />

Herøya Arbeiderforening, and former general<br />

manager of <strong>Hydro</strong>’s Herøya facility, Søren Sem,<br />

feel sad that <strong>Hydro</strong> is on its way out of the<br />

Grenland area, but believe that the restructuring<br />

process will create secure new jobs.<br />

plant showed that people are concerned about<br />

the fate of the industry – 10,000 people turned<br />

out to protest.”<br />

Sem adds: “That union representatives<br />

and management have worked together has<br />

been crucial to our success in attracting new<br />

businesses here. The unions deserve credit for<br />

thinking strategically, not just concentrating on<br />

pay and benefit issues.”<br />

“Our members understand that you have<br />

to be competitive if you are going to attract<br />

investment,” says Bakke.<br />

Both men agree that focus would have<br />

been difficult to achieve if <strong>Hydro</strong> were to con-<br />

tinue operating all the activities at Herøya.<br />

“These and all the other industrial compa-<br />

nies in the Grenland area now need to fight<br />

for adequate framework conditions. If the gas<br />

pipeline comes to Grenland, which I strongly<br />

believe it will do, the area will flourish still fur-<br />

ther,” adds Bakke.<br />

“And I would like to point out that Grenland<br />

is the jewel in Norway’s crown, both with re-<br />

gard to industrial development and as a place<br />

to live – with easy access to the coast, forests<br />

and mountains,” says Sem.<br />

hi! > Tom Karl Andersen<br />

photo > Gisle Nomme<br />

A <strong>changing</strong> Innovation <strong>Hydro</strong> hi! 25<br />

<strong>Hydro</strong> may leave, but jobs remain

Little things can mean a lot, both for<br />

the environment and the bottom line<br />

When small<br />

is beautiful<br />

Research and development can be considered<br />

complicated and difficult to access, but it is often<br />

the simple things that provide the best results.<br />

Henning Reier Nilsen

Henning Reier Nilsen.<br />

“N<br />

othing could be better than boos-<br />

ting productivity and at the same<br />

time achieving environmental<br />

benefits,” says Director of Technology<br />

Henning Reier Nilsen of <strong>Hydro</strong> Polymers.<br />

“Excellent collaboration between Polymers’<br />

R&D department and operations environment<br />

is the key to the improvement projects that<br />

generate better returns and make our busi-<br />

ness more sustainable,” he says.<br />

Reier Nilsen is one of the most experienced<br />

petrochemical technologists in Scandinavia.<br />

Though he has contributed to many develop-<br />

ments, he is keen to stress that it is the inter-<br />

play between all those involved that counts.<br />

“Such projects are largely about developing<br />

a process from an idea, via the laboratory and<br />

pilot project, through to a fully-fledged plant<br />

process. Many different kinds of challenges will<br />

arise along the way. We technologists need to<br />

be involved, following up operations and help-<br />

ing to identify solutions to the problems that<br />

occur,” he explains.<br />

Last year was the best ever for Polymers<br />

operations, and particularly for the VCM plant<br />

at Rafnes in Norway. An important reason for<br />

this success is a project that has resulted in<br />

lower energy consumption per produced unit<br />

and the possibility of increasing production.<br />

“Research and development is often<br />

considered complicated and difficult to make<br />

accessible, but it is often the little things that<br />

produce the best results – as for example<br />

when we decided to install an empty pipe on<br />

the cracker furnace at the VCM plant. This<br />

enables the reaction to continue after the<br />

process gas has left the furnace, without the<br />

need to supply more heat”.<br />

The result is 15 percent lower energy con-<br />

sumption and 15 percent greater production.<br />

“Others have tried this out before us, but<br />

failed. This technology is now being installed<br />

at QVC in Qatar, where Polymers have a 30<br />

percent share. We hope to achieve the same<br />

effect there,” says Reier Nilsen.<br />

The improvements completed in 2006 en-<br />

able even more ambitious targets to be set in<br />

2007. Reier Nilsen is targeting daily produc-<br />

tion of 1,550 tonnes at the Rafnes VCM plant,<br />

which was originally designed for 900 tonnes<br />

per day.<br />

“The future will be all about the introduction<br />

of biological raw materials; bringing renew-<br />

able resources into the vinyl chain. Ethylene<br />

gas and chlorine are the most important raw<br />

materials in today’s PVC production. There are<br />

several ways of extracting the ethylene of the<br />

future from natural materials; one of them is<br />

to gasify wood and obtain it via methanol, but<br />

we are working on other ways also,” explains<br />

Reier Nilsen.<br />

<strong>Hydro</strong> has patented a technology that is<br />

based on hydrogen-conductive membranes.<br />

This may prove to be extremely useful for<br />

Polymers.<br />

“We can imagine using this technology in a<br />

process where CO 2 emissions are dramatic-<br />

ally reduced. The advantages are that CO 2<br />

emissions will be very low and the ethylene<br />

processing plant compact and efficient,” says<br />

Reier Nilsen.<br />

“Leading the field in the technology area,<br />

with a complete understanding of our pro-<br />

cesses, provides us with the opportunity of<br />

being the operator in the industry that makes<br />

the best possible use of resources, while pro-<br />

ducing even better financial results.”<br />

hi! > Trond Aasland<br />

photos > Terje S. Knudsen, iStock.com<br />

hi! 27

&<br />

i<br />

lo<br />

Leak on results<br />

investigated<br />

A Norwegian newspaper somehow got<br />

a hold of <strong>Hydro</strong>’s recent financial results<br />

before the official release date, and an<br />

investigation has been launched to dis-<br />

cover what happened. “We’ll do what we<br />

can to prevent it from happening again,”<br />

CEO and President Eivind Reiten says.<br />

Milestone for<br />

Norwegian plant<br />

January 28 marked the 60th anniversary<br />

of the founding of the aluminium plant Årdal<br />

Verk A/S, which <strong>Hydro</strong> acquired in 1986,<br />

but a big celebration is planned for this fall.<br />

Despite the phasing out of the Søderberg<br />

facility this year, the plant will supply output<br />

of more than 180,000 tonnes – much greater<br />

than the original capacity of 24,000 tonnes.<br />

Discovery in the<br />

Barents Sea<br />

<strong>Hydro</strong> has proved the presence of<br />

oil and gas in the exploration well on<br />

the Nucula prospect in the Barents Sea<br />

off northern Norway. Further evaluation<br />

is needed to determine the importance<br />

of the discovery. The process was an<br />

environmental winner, too, attracting<br />

praise from Norwegian authorities.<br />

Castings sale approved<br />

<strong>Hydro</strong> has completed the sale of its<br />

Automotive Castings business to<br />

the Mexican automotive supplier<br />

Nemak, following approval by the<br />

European Commission. The European<br />

operations included in the deal have a<br />

total of 2,200 employees, while joint-<br />

venture Castech in Mexico employs<br />

1,000 people.<br />

hi&lo

Ride<br />

of a lifetime<br />

It takes determination.<br />

Paul Farrugia spent<br />

16 days riding a motorbike<br />

across South Africa<br />

to help that country’s<br />

fight against poverty<br />

and disease<br />

W<br />

hen Paul Farrugia found out<br />

about a gruelling motorbike ride<br />

1,550 miles (2,500 km) round<br />

South Africa, it took him about 30 seconds<br />

to decide to take part.<br />

Persuading his wife took a little longer, but<br />

now he has raised £4,500 for charity, provided<br />

vital transportation for African health workers<br />

– and had the ride of a lifetime. <strong>Hydro</strong> helped<br />

him on his way.<br />

Paul, who works at <strong>Hydro</strong>’s Automotive<br />

Structures plant in Worcester, UK, is no<br />

stranger to charity events. “I’ll have a go at<br />

anything, really,” he says modestly. He really<br />

does mean anything: he had already com-<br />

pleted a sponsored run from Land’s End to<br />

John O’Groats for the Meningitis Trust. That’s<br />

874 miles (1,400 km) from the southern tip of<br />

the Cornwall, England, to the northern tip of<br />

Scotland.<br />

Thumbing the pages of Motorcycle News<br />

magazine, something caught Paul’s eye.<br />

Enduro Africa, a sponsored motorbike ride<br />

around South Africa, was preparing for its<br />

inaugural run and the organizers were looking<br />

for participants.<br />

“I’ve just got to do this,” was his first re-<br />

action. He visited the organizers’ website,<br />

which only strengthened his resolve. “It was<br />

the reason that it was being done, the charity<br />

aspect, that spurred me on,” he says. “It was<br />

such a good cause.”<br />

good neighbor<br />

Enduro Africa is a unique and challenging<br />

motorbike adventure in aid of Riders for<br />

Health, which supplies motorbikes to help<br />

health workers reach people to deliver pre-<br />

hi! 29<br />

>>>

ventative healthcare. The trip is organized by<br />

Global Enduro and involves 100 bikers from<br />

all over the world tackling 16 days of dusty<br />

and demanding riding through some of South<br />

Africa’s most rugged and isolated terrain.<br />

Paul was already a keen motorcyclist,<br />

and Enduro Africa appealed to his sense of<br />

adventure. Although his four children were<br />

enthusiastic from the outset, his wife took<br />

some convincing – but once persuaded,<br />

she gave him her full support.<br />

Once his application had been accepted,<br />

he spent 12 months raising the £4,500<br />

necessary to take part. Paul organised<br />

events ranging from virtual horse racing<br />

to a 12-hour line dance marathon. “It was<br />

an enjoyable 12 months, I got a lot of help<br />

from a lot of people,” he says.<br />

His colleagues in <strong>Hydro</strong> showed enthusi-<br />

astic support. Paul wonders if it was because<br />

they relished the prospect of seeing photos<br />

of him getting chased and eaten by the local<br />

wildlife. Africa is, after all, big game country.<br />

“I had to disappoint them,” he chuckles.<br />

<strong>Hydro</strong> supported Paul in his fundraising<br />

quest, giving him time off work, lending equip-<br />

ment for events and by rounding up the pro-<br />

ceeds of one fundraising event from £320 to<br />

£500. Paul praises the culture in <strong>Hydro</strong> that<br />

allowed him to pursue the cause, and his<br />

colleagues’ willingness to give money. “It’s<br />

the way people are here,” he says, “People<br />

are happy to help anyone in charity work.”<br />

The ride took place in November 2006.<br />

“It was absolutely stunning,” says Paul. “The<br />

scenery, the people, the camaraderie, the<br />

riding experience, the weather, the smiling<br />

faces of children who just wanted to touch<br />

you, the hospitality. The whole thing was<br />

just overwhelming.”<br />

“I feel extremely privileged and very lucky<br />

to have been given the opportunity to have<br />

After Riders for Health provided motorbikes to a district in Zimbabwe, malaria deaths dropped by 20 percent.<br />

They now aim to provide reliable transport for health workers throughout Africa by 2015.<br />

taken part in such an event. It was the many<br />

generous donations that made it possible,”<br />

says a grateful Paul, whose Yamaha bike has<br />

now been handed over to Riders for Health<br />

to be prepared for use by a health worker.<br />

hi! > Colin Dobinson<br />

photos > Global Enduro participants

Africa’s colossal distances<br />

prevent health and development<br />

agencies from<br />

making an impact in the<br />

fight against poverty<br />

and disease. People are<br />

dying of easily preventable<br />

diseases, simply because<br />

they cannot be reached.<br />

Enduro Africa involves 100 bikers riding for 16 days through some of South Africa’s most rugged and isolated terrain. <strong>Hydro</strong> employee<br />

Paul Farrugia is second from left. Afterwards, participants donated their new Yamaha AG200s worth £4,500 each to the charity.<br />

Fast facts<br />

Riders for Health<br />

Millions of children in<br />

Africa die of diarrhoea<br />

and measles, simply because<br />

no one can reach<br />

them with healthcare.<br />

Riders for Health trains<br />

health workers to ride<br />

and maintain motorcycles,<br />

so they can<br />

reach remote communities<br />

with the kind of<br />

regular healthcare that<br />

we take for granted.<br />

Enduro Africa is a<br />

16-day sponsored ride<br />

around South Africa,<br />

where each participant<br />

donates his or her new<br />

Yamaha AG200 worth<br />

£4,500 to the charity<br />

after the event.<br />

Despite Africa being<br />

one of the toughest<br />

environments there is<br />

for any vehicle, each<br />

bike will last at least<br />

six years, cover<br />

100,000 km and help<br />

up to 20,000 people.<br />

For more<br />

www.riders.org<br />

good neighbor<br />

hi! 31

Art and<br />

engineering<br />

– two sides of the same coin<br />

I’<br />

in the US.<br />

m a manufacturing engineer<br />

at <strong>Hydro</strong>’s aluminium extrusion<br />

plant in Kalamazoo, Michigan,<br />

I’ve been here for about 15 years, and now<br />

I program CNC (computer numerical control)<br />

machines and a robotic welder to execute<br />

precise semi-fabrication tasks. Some of the<br />

products are truck bumpers, for example.<br />

In my free time, I paint pictures of landscapes<br />

and figures.<br />

Who?<br />

Joe Brown<br />

What?<br />

Manufacturing engineer<br />

Where?<br />

Aluminium Products, Kalamazoo, Michigan, US<br />

For Joe Brown, his computer-driven engineering work and<br />

his whimsical paintings complement each other – both<br />

require foresight and determination to see them through<br />

Engineering is very nuts-and-bolts, nothing<br />

in common with art, you’d think. But my<br />

work and art both draw on the same well of<br />

creativity, and both require the same level<br />

of determination to see a project through.<br />

When creating art you must be fearless<br />

and confident in your imagination and<br />

creativity in your approach or you will never<br />

complete anything or improve. Works the<br />

same at <strong>Hydro</strong>!<br />

Art forces me to try new techniques,<br />

which helps me to not be intimidated<br />

when something new comes along or<br />

must be attempted, like different materials<br />

and techniques.<br />

With both engineering and art, you have<br />

to think outside of the box. And you can ask<br />

anyone, they’ll tell you I’m not just outside<br />

of the box, I can’t even find the box!<br />

I create a disciplined environment for<br />

myself. I set specific goals I want to attain<br />

and then I’m very systematic and creative

in how to reach them. In other words, it’s<br />

“project management.”<br />

Art helps me to see an end product – the<br />

completed painting – and to envision the<br />

steps required to meet my desired result.<br />

Art helps me see a finished product before<br />

there is anything tangible or physically there.<br />

Art forces me to keep trying. I never start<br />

a painting without finishing it, and sometimes<br />

you are surprised by the end result. The<br />

creative process in art forces you to work<br />

Ask anyone, they’ll tell you.<br />

I’m not just outside of the box,<br />

I can’t even fi nd the box!<br />

Joe Brown<br />

through issues and perceived mistakes.<br />

You are usually surprised at how well some<br />

“mistakes” work out and actually become<br />

part of your style, after the first unexpected<br />

mistake they become planned steps.<br />

Art helps me to listen to other people<br />

and possibly use their ideas and visions<br />

to create something they would like. When<br />

completing a commissioned painting it is<br />

just like working with a customer at <strong>Hydro</strong>.<br />

You take their need, vision, desire and<br />

attempt to create something that meets all<br />

their requirements.<br />

Much as I enjoy painting, I’m staying put...<br />

I’m not quitting my day job.<br />

hi! > as told to Craig Johnson<br />

web link > see more of Joe Brown’s art at<br />

www.joebrownart.com<br />

my job hi! 33

A ‘new’ town with<br />

a lot of history<br />

<strong>Hydro</strong> Polymers<br />

– Aycliffe plant<br />

Employees: 400<br />

Acquired by <strong>Hydro</strong>: 1982<br />

Products: PVC resins and<br />

compounds

T<br />

he “Newton” part of the name<br />

means “new town,” a British<br />

program that created towns from<br />

scratch, starting just after World War II.<br />

Every square inch of England has a story<br />

behind it, though, and this patch was<br />

earlier called “Acley,” after the site of a<br />

Saxon settlement.<br />

The industrial site now occupied by <strong>Hydro</strong><br />

Polymers was used for munitions manufac-<br />

ture – Royal Ordinance Factory No. 27, it was<br />

called during the early 1940s. The Aycliffe<br />

Angels, women who staffed the munitions<br />

operations during the war, kept the factory<br />

humming as well as the home fires burning.<br />

Life in the early post-war years in Aycliffe<br />

can only be looked at by our modern eyes<br />

with awe. Returning soldiers didn’t know if<br />

there would be work for them, the women<br />

who ran the factories found themselves<br />

largely unemployed.<br />

There was little in the way of housing near-<br />

by, meaning sometimes arduous “commutes.”<br />

One worker counted himself lucky to be able<br />

to cycle from home, 10 miles away as the<br />

crow flies but many more in actuality.<br />

First came Bakelite Ltd., an early plastics<br />

company, as the first post-war owner. In fact,<br />

for many years afterward, the faint outline of<br />

the company name was still visible on one of<br />

the original buildings.<br />

Next came Bakelite Xylonite Ltd. the pro-<br />

duct of a merger with British Xylonite. In 1974,<br />

British Industrial Plastics entered the picture.<br />

<strong>Hydro</strong> bought the company in 1982. The<br />

operation nearly changed hands again, in the<br />

late 1990s, when <strong>Hydro</strong> considered selling its<br />

entire petrochemicals business to a European<br />

competitor, but the deal fell through.<br />

In the near future, a new logo – and name<br />

– will mark the site.<br />

hi! > Craig Johnson<br />

photos > used with the kind permission of<br />

www.aycliffeangels.org.uk<br />

more on Aycliffe > page 18-21<br />

postcard from Newton Innovation Aycliffe hi! 35<br />

The Aycliffe<br />

Angels at work.

Rolled<br />

Products<br />

has been<br />

defined<br />

a “core<br />

business”<br />

in <strong>Hydro</strong>.<br />

What does<br />

that mean<br />

to you?<br />

Markus Baier,<br />

Controller,<br />

Germany<br />

Hans-Erik Vatne,<br />

Plant Manager,<br />

Norway<br />

Miguel Lizarraga,<br />

Production<br />

Manager,<br />

Spain<br />

Monika Schucht,<br />

Procurement<br />

& Logistics,<br />

Germany<br />

Rolf Schencking,<br />

Plant manager,<br />

Malaysia<br />

The uncertainty of<br />

the past years has<br />

changed. Since quite<br />

some people left, we<br />

must keep competent<br />

colleagues. For this,<br />

the message was<br />

important. I do not<br />

see us going hunting<br />

for additional capacities,<br />

but within our<br />

frame we will work to<br />

improve our market<br />

position.<br />

There is no doubt that<br />

the prolonged strategy<br />

process in <strong>Hydro</strong> has<br />

created much uncertainty<br />

in the Holmestrand<br />

rolling mill. We<br />

have lost a couple of<br />

key persons in this<br />

period. It is therefore<br />

very well received. This<br />

enables our complete<br />

organization to focus<br />

100 percent on the improvements<br />

in quality<br />

and productivity that<br />

are required in order to<br />

increase our profitability<br />

to a satisfactory level.<br />

For us, the situation<br />

remains unclear. Since<br />

2000, we have had no<br />

major investment. We<br />

need to revamp the<br />

cold mill. It would cost<br />

twice our annual profit.<br />

But by doing this and<br />

by focusing – narrowing,<br />

concentrating –<br />

our product portfolio,<br />

we could add much<br />

more to the benefit we<br />

genuinely create with<br />

the short lead-time of<br />

our continuous-casting<br />

process.<br />

When I attended a<br />

leadership course four<br />

years back, we forecast<br />

this way forward for<br />

<strong>Hydro</strong>. Now that the<br />

split will come, we need<br />

to solidify our position<br />

in the market for the<br />

coming years. I hope a<br />

new drive will come to<br />

inspire our organization.<br />

This calms down worries<br />

in Rolled Products,<br />

as we now can expect<br />

more stability for our<br />

employees. But as a<br />

core business, we must<br />

answer the question,<br />

How we will grow? Still,<br />

we are well positioned<br />

as a supplier into Asian<br />

markets. But within five<br />

years, this will be seriously<br />

threatened unless<br />

we take measures.<br />

hi 55<br />

Print: Kampen Grafisk, Oslo