Annual Report 2010 - About Heraeus

Annual Report 2010 - About Heraeus

Annual Report 2010 - About Heraeus

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Materials and Technologies Business Group –<br />

<strong>Heraeus</strong> Materials Technology<br />

The materials and technologies business group (<strong>Heraeus</strong> Materials Technology) develops and manufactures high-tech industrial<br />

products using precious metals, such as gold, silver, and platinum-group metals, as well as high-melting-point, nonprecious<br />

refractory metals. Based on a broad portfolio of technologies and deep added value, <strong>Heraeus</strong> Materials Technology<br />

is a skilled partner for processing these precious metals and other innovative materials. As a technology leader with decades<br />

of experience and facilities around the world, this business group is a leading provider in many key markets.<br />

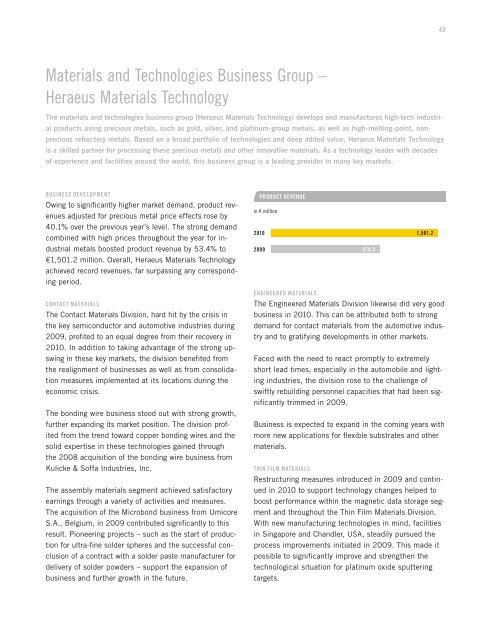

BUSINESS DEVElOPMENT<br />

Owing to significantly higher market demand, product revenues<br />

adjusted for precious metal price effects rose by<br />

40.1% over the previous year’s level. The strong demand<br />

combined with high prices throughout the year for industrial<br />

metals boosted product revenue by 53.4% to<br />

€1,501.2 million. Overall, <strong>Heraeus</strong> Materials Technology<br />

achieved record revenues, far surpassing any corresponding<br />

period.<br />

CONTaCT MaTERIalS<br />

The Contact Materials Division, hard hit by the crisis in<br />

the key semiconductor and automotive industries during<br />

2009, profited to an equal degree from their recovery in<br />

<strong>2010</strong>. In addition to taking advantage of the strong upswing<br />

in these key markets, the division benefited from<br />

the realignment of businesses as well as from consolidation<br />

measures implemented at its locations during the<br />

economic crisis.<br />

The bonding wire business stood out with strong growth,<br />

further expanding its market position. The division profited<br />

from the trend toward copper bonding wires and the<br />

solid expertise in these technologies gained through<br />

the 2008 acquisition of the bonding wire business from<br />

Kulicke & Soffa Industries, Inc.<br />

The assembly materials segment achieved satisfactory<br />

earnings through a variety of activities and measures.<br />

The acquisition of the Microbond business from Umicore<br />

S.A., Belgium, in 2009 contributed significantly to this<br />

result. Pioneering projects – such as the start of production<br />

for ultra-fine solder spheres and the successful conclusion<br />

of a contract with a solder paste manufacturer for<br />

delivery of solder powders – support the expansion of<br />

business and further growth in the future.<br />

<strong>2010</strong><br />

2009<br />

PRODUCT REVENUE<br />

in € million<br />

ENGINEERED MaTERIalS<br />

978.3<br />

1,501.2<br />

The Engineered Materials Division likewise did very good<br />

business in <strong>2010</strong>. This can be attributed both to strong<br />

demand for contact materials from the automotive industry<br />

and to gratifying developments in other markets.<br />

Faced with the need to react promptly to extremely<br />

short lead times, especially in the automobile and lighting<br />

industries, the division rose to the challenge of<br />

swiftly rebuilding personnel capacities that had been significantly<br />

trimmed in 2009.<br />

Business is expected to expand in the coming years with<br />

more new applications for flexible substrates and other<br />

materials.<br />

ThIN FIlM MaTERIalS<br />

Restructuring measures introduced in 2009 and continued<br />

in <strong>2010</strong> to support technology changes helped to<br />

boost performance within the magnetic data storage segment<br />

and throughout the Thin Film Materials Division.<br />

With new manufacturing technologies in mind, facilities<br />

in Singapore and Chandler, USA, steadily pursued the<br />

process improvements initiated in 2009. This made it<br />

possible to significantly improve and strengthen the<br />

technological situation for platinum oxide sputtering<br />

targets.<br />

43