Adhesives and Tapes

Adhesives and Tapes

Adhesives and Tapes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12<br />

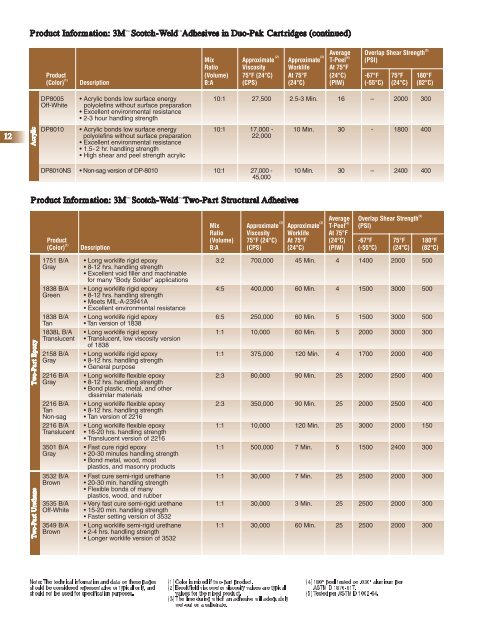

Product Information: 3M Scotch-Weld <strong>Adhesives</strong> in Duo-Pak Cart ridges (continued)<br />

Acrylic<br />

Average Overlap Shear Strength (5)<br />

Mix Approximate (2)<br />

Approximate (3)<br />

T-Peel (4)<br />

(PSI)<br />

Ratio Viscosity Worklife At 75°F<br />

Product (Volume) 75°F (24°C) At 75°F (24°C) -67°F 75°F 180°F<br />

(Color) (1)<br />

Description B:A (CPS) (24°C) (PIW) (-55°C) (24°C) (82°C)<br />

DP8005 • Acrylic bonds low surface energy 10:1 27,500 2.5-3 Min. 16 – 2000 300<br />

Off-White polyolefins without surface preparation<br />

• Excellent environmental resistance<br />

• 2-3 hour h<strong>and</strong>ling strength<br />

DP8010 • Acrylic bonds low surface energy 10:1 17,000 - 10 Min. 30 - 1800 400<br />

polyolefins without surface preparation 22,000<br />

• Excellent environmental resistance<br />

• 1.5- 2 hr. h<strong>and</strong>ling strength<br />

• High shear <strong>and</strong> peel strength acrylic<br />

DP8010NS • Non-sag version of DP-8010 10:1 27,000 - 10 Min. 30 – 2400 400<br />

45,000<br />

P roduct Information: 3M Scotch-Weld Two-Pa rt Structural <strong>Adhesives</strong><br />

Two-Pa rt Epoxy<br />

Two-Part Urethane<br />

Average Overlap Shear Strength (5)<br />

Mix Approximate (2)<br />

Approximate (3)<br />

T-Peel (4)<br />

(PSI)<br />

Ratio Viscosity Worklife At 75°F<br />

Product (Volume) 75°F (24°C) At 75°F (24°C) -67°F 75°F 180°F<br />

(Color) (1)<br />

Description B:A (CPS) (24°C) (PIW) (-55°C) (24°C) (82°C)<br />

1751 B/A • Long worklife rigid epoxy 3:2 700,000 45 Min. 4 1400 2000 500<br />

Gray • 8-12 hrs. h<strong>and</strong>ling strength<br />

• Excellent void filler <strong>and</strong> machinable<br />

for many "Body Solder" applications<br />

1838 B/A • Long worklife rigid epoxy 4:5 400,000 60 Min. 4 1500 3000 500<br />

Green • 8-12 hrs. h<strong>and</strong>ling strength<br />

• Meets MIL-A-23941A<br />

• Excellent environmental resistance<br />

1838 B/A • Long worklife rigid epoxy 6:5 250,000 60 Min. 5 1500 3000 500<br />

Tan • Tan version of 1838<br />

1838L B/A • Long worklife rigid epoxy 1:1 10,000 60 Min. 5 2000 3000 300<br />

Translucent • Translucent, low viscosity version<br />

of 1838<br />

2158 B/A • Long worklife rigid epoxy 1:1 375,000 120 Min. 4 1700 2000 400<br />

Gray • 8-12 hrs. h<strong>and</strong>ling strength<br />

• General purpose<br />

2216 B/A • Long worklife flexible epoxy 2:3 80,000 90 Min. 25 2000 2500 400<br />

Gray • 8-12 hrs. h<strong>and</strong>ling strength<br />

• Bond plastic, metal, <strong>and</strong> other<br />

dissimilar materials<br />

2216 B/A • Long worklife flexible epoxy 2:3 350,000 90 Min. 25 2000 2500 400<br />

Tan • 8-12 hrs. h<strong>and</strong>ling strength<br />

Non-sag • Tan version of 2216<br />

2216 B/A • Long worklife flexible epoxy 1:1 10,000 120 Min. 25 3000 2000 150<br />

Translucent • 16-20 hrs. h<strong>and</strong>ling strength<br />

• Translucent version of 2216<br />

3501 B/A • Fast cure rigid epoxy 1:1 500,000 7 Min. 5 1500 2400 300<br />

Gray • 20-30 minutes h<strong>and</strong>ling strength<br />

• Bond metal, wood, most<br />

plastics, <strong>and</strong> masonry products<br />

3532 B/A • Fast cure semi-rigid urethane 1:1 30,000 7 Min. 25 2500 2000 300<br />

Brown • 20-30 min. h<strong>and</strong>ling strength<br />

• Flexible bonds of many<br />

plastics, wood, <strong>and</strong> rubber<br />

3535 B/A • Very fast cure semi-rigid urethane 1:1 30,000 3 Min. 25 2500 2000 300<br />

Off-White • 15-20 min. h<strong>and</strong>ling strength<br />

• Faster setting version of 3532<br />

3549 B/A • Long worklife semi-rigid urethane 1:1 30,000 60 Min. 25 2500 2000 300<br />

Brown • 2-4 hrs. h<strong>and</strong>ling strength<br />

• Longer worklife version of 3532<br />

Note: The technical information <strong>and</strong> data on these pages<br />

should be considered representative or typical only, <strong>and</strong><br />

should not be used for specification purposes.<br />

(2)Brookfield (1)Color is mixed viscometer if two-part viscosity product.<br />

values for the mixed product. values are typical<br />

(3)The wet-out time on during a substrate. which an adhesive will adequately<br />

(4)180°peel tested on .030" aluminum per<br />

ASTM D 1876-61T.<br />

(5)Tested per ASTMD 1002-64.