Nieco JF94E CE English Manual.qxd - Parts Town

Nieco JF94E CE English Manual.qxd - Parts Town

Nieco JF94E CE English Manual.qxd - Parts Town

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

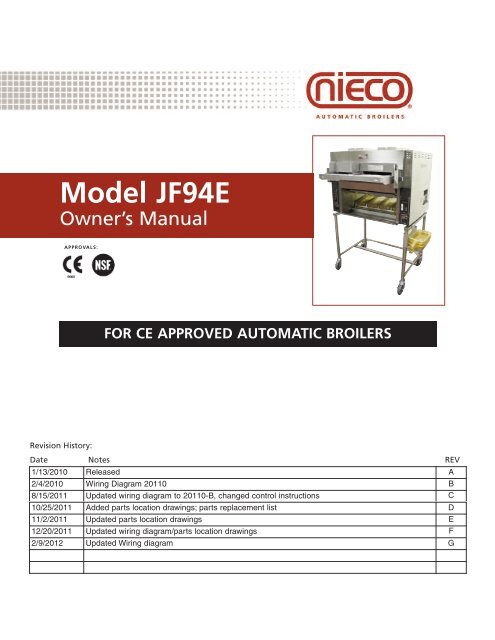

Model <strong>JF94E</strong><br />

Owner’s <strong>Manual</strong><br />

APPROVALS:<br />

FOR <strong>CE</strong> APPROVED AUTOMATIC BROILERS<br />

Revision History:<br />

Date Notes REV<br />

1/13/2010 Released A<br />

2/4/2010 Wiring Diagram 20110 B<br />

8/15/2011 Updated wiring diagram to 20110-B, changed control instructions C<br />

10/25/2011 Added parts location drawings; parts replacement list D<br />

11/2/2011 Updated parts location drawings E<br />

12/20/2011 Updated wiring diagram/parts location drawings F<br />

2/9/2012 Updated Wiring diagram G

!<br />

WARNING<br />

1. Do not store or use gasoline or other flammable vapors or liquids in the vicinity<br />

of this or any other appliance.<br />

2. Broiler area must be kept free of combustible materials, and the flow of combustion<br />

and ventilation air must not be obstructed. Operating personnel must<br />

not perform any maintenance or repair functions. Contact your <strong>Nieco</strong><br />

Authorized Dealer.<br />

3. Do not use this appliance in an area where a water jet could be used.<br />

4. Do not clean the appliance with a water jet.<br />

5. If the power supply cord is damaged, it must only be replaced by a repair shop<br />

appointed by the manufacturer.<br />

6. A switch with an all-pole disconnection and a contact separation of at least<br />

3mm shall be included in the fixed wiring.<br />

7. It is recommended that walls, etcetera, in the proximity of the appliance be<br />

made of non-combustible material, if not, they must be clad with a suitable<br />

non-combustible heat-insulating material and that the closest attention be<br />

paid to fire-prevention regulations.<br />

8. This appliance is not intended for use by persons (including children) with<br />

reduced physical, sensory or mental capabilities, or lack of experience and<br />

knowledge, unless they have been given supervision or instruction concerning<br />

use of the appliance by a person responsible for their safety. Children<br />

should be supervised to ensure that they do not play with the appliance.<br />

IMPORTANT:<br />

RETAIN THIS MANUAL IN A SAFE PLA<strong>CE</strong> FOR FUTURE REFEREN<strong>CE</strong><br />

2 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

INSTALLER NOTES<br />

1. This appliance is rated IP 20, Degree of Protection obtained from Enclosure.<br />

2. Nominal Power Rating: 380-415V 3Ø 25A<br />

Model kW Electrical Diagram<br />

<strong>JF94E</strong> 19 20110<br />

Calculated Average Consumption 16<br />

3. This appliance must be installed by a qualified installer, in compliance with all<br />

national, local regulations and institutions having jurisdiction.<br />

4. This machine should be connected to the supply with a plug with proper grounding.<br />

3 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

TABLE OF CONTENTS<br />

A. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5<br />

A.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5<br />

A.2 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5<br />

A.3 Service/Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

A.4 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6<br />

B. Machine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.1 Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.3 Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.4 Hood Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.5 Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.6 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

B.7 Pre-Operation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

C. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

C.1 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

C.2 Step-by-Step Lighting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

C.3 Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

C.4 Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13<br />

D. Assembly/Disassembly and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . .14<br />

E. Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25<br />

F. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26<br />

G. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29<br />

4<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

A.1 Description<br />

A. GENERAL INFORMATION<br />

The <strong>Nieco</strong> Model <strong>JF94E</strong> automatic broiler features patented Jet-Flow air<br />

technology which uses waste heat to help broil the product creating large energy<br />

savings. The JF94 also has easy cleaning and a simple and intuitive control<br />

package to help eliminate broiling problems and provide the operator with even<br />

greater control over the broiling environment.<br />

This manual provides the safety, installation and operating procedures for the<br />

<strong>Nieco</strong> Automatic Broiler Model <strong>JF94E</strong>. We recommend that all information<br />

contained in this manual be read prior to installing and operating the broiler.<br />

A.2 Warranty Information<br />

Please read the full text of the limited Warranty in this manual.<br />

If the unit arrives damaged, contact the carrier immediately and file a damage<br />

claim with them. Save all packing materials when filing a claim. Freight damage<br />

claims are the responsibility of the purchaser and ARE NOT covered under<br />

warranty.<br />

The warranty does not extend to:<br />

• Damages caused in shipment or damage as a result of improper use.<br />

• Installation of electrical service.<br />

• Normal maintenance as outlined in this manual.<br />

• Malfunction resulting from improper maintenance not in accordance with the steps contained in<br />

this manual and any applicable training.<br />

• Damage caused by abuse or careless handling outside of the normal operating procedures<br />

contained in this manual.<br />

• Damage from moisture into electrical components.<br />

• Damage from tampering with or removal of any safety device.<br />

IMPORTANT!<br />

Keep these instructions for future reference. If the unit changes ownership,<br />

be sure this manual accompanies the equipment.<br />

IMPORTANT<br />

The <strong>Nieco</strong> Corporation reserves the right to change specifications and product design in<br />

accordance with the general terms and conditions outlined in the BURGER KING ® /Vendor<br />

agreement. Such revisions do not entitle the buyer to corresponding changes, improvements,<br />

additions or replacements for previously purchased equipment.<br />

5<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

A.3 Service/Technical Assistance<br />

If you experience any problems with the installation or operation of your broiler, contact your local<br />

Authorized <strong>Nieco</strong> Distributor.<br />

Fill in the information bellow and have it handy when calling your authorized service agency for assistance.<br />

The serial number is on the broiler rating plate on the side of the unit.<br />

Purchased from:<br />

Date of Purchase:<br />

Model No.:<br />

Serial No.:<br />

For the name of your local Authorized <strong>Nieco</strong> Distributor, please call (800) 821-2141 (U.S. Only).<br />

Use only genuine <strong>Nieco</strong> replacement parts in your broiler. Use of replacement parts other than those supplied<br />

by Authorized <strong>Nieco</strong> Distributors and Service Agencies will void the warranty and may significantly<br />

alter the performance of your broiler. <strong>Nieco</strong> and the Burger King Corporation have worked together to create<br />

a set of standards for broiler performance, food quality and food safety. The use of non-<strong>Nieco</strong> parts is<br />

capable of affecting these criteria, and may affect broiler performance, parts longevity and food safety. Your<br />

local Authorized <strong>Nieco</strong> Distributor and Service Agent has been factory trained and has a complete supply<br />

of parts for your <strong>Nieco</strong> Automatic Broiler.<br />

You may contact the factory direct at +1-707-284-7100 if you have trouble locating your local <strong>Nieco</strong><br />

Distributor.<br />

A.4 Important Safety Information<br />

Throughout this manual, you will find the following safety words and symbols that signify important safety<br />

issues with regards to operating or maintaining the equipment:<br />

WARNING<br />

GENERAL WARNING. Indicates<br />

information important to the proper<br />

operation of the equipment. Failure<br />

to observe may result in damage to<br />

the equipment and/or severe bodily<br />

injury or death.<br />

CAUTION<br />

GENERAL CAUTION. Indicates<br />

information important to the proper<br />

operation of the equipment. Failure<br />

to observe may result in damage to<br />

the equipment.<br />

6<br />

WARNING<br />

ELECTRICAL WARNING. Indicates<br />

information relating to possible<br />

shock hazard. Failure to observe<br />

may result in damage to the equipment<br />

and/or severe bodily injury or<br />

death.<br />

WARNING<br />

HOT SURFA<strong>CE</strong> WARNING. Indicates<br />

information important to the handling<br />

of equipment and parts.<br />

Failure to observe caution could<br />

result in personal injury.<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

A.4 Important Safety Information (Continued.)<br />

In addition to the warnings and cautions in this manual, use the following guidelines for safe operation of<br />

your <strong>Nieco</strong> Automatic Broiler:<br />

• Read and follow all instructions before using this equipment.<br />

• Install or locate broiler only for its intended use as described in this manual.<br />

• Do not operate this equipment if it has a damaged cord or plug, if it is not working properly or if it<br />

has been otherwise damaged.<br />

• This equipment should only be serviced by authorized personnel. Contact your local <strong>Nieco</strong><br />

Distributor for adjustment or repair.<br />

• Use only genuine <strong>Nieco</strong> replacement parts for your broiler. Failure to do so will void the warranty<br />

and may significantly alter the performance of your broiler. <strong>Nieco</strong> and the Burger King<br />

Corporation have worked together to create a set of standards for broiler performance, food quality<br />

and food safety. The use of non-<strong>Nieco</strong> parts is capable of affecting these criteria, and may affect<br />

broiler performance, parts longevity and food safety.<br />

The following warnings and cautions appear throughout the manual and should be carefully<br />

observed:<br />

• Turn the broiler off and disconnect the plug before performing any service, maintenance or<br />

cleaning on the broiler.<br />

• Always allow the broiler to fully cool before performing any service, maintenance or<br />

cleaning. Failure to wait for the broiler to cool fully may result in personal injury.<br />

• The procedures in this manual may include reference to the use of chemical products. The<br />

<strong>Nieco</strong> Corporation does not endorse the use of any particular cleaning/degreasing agent.<br />

Use only those chemicals that are approved for use in the BURGER KING ® SYSTEM.<br />

• The broiler should be grounded according to local electrical codes to prevent the<br />

possibility of electrical shock. It requires a grounded receptacle with separate electrical<br />

lines, protected by fuses or circuit breakers of the proper rating.<br />

• All electrical connections must be in accordance with local electrical codes and any other<br />

applicable codes.<br />

• The use of adequate ventilation (as rated in this manual) with this broiler is mandatory.<br />

Failure to adequately ventilate this unit and provide safe operating distances (as specified<br />

in this manual) is a fire safety hazard. Follow the instructions for emergency broiler<br />

shutdown in the event of an emergency.<br />

• No attempt should be made to operate this appliance in the event of a power failure.<br />

WARNING ELECTRICAL SHOCK HAZARD. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD<br />

RESULT IN SERIOUS INJURY OR DEATH:<br />

_ Electrical ground is required on this appliance.<br />

_ Check with a qualified electrician if you are in doubt as to whether the appliance is properly<br />

grounded.<br />

_ Do not use water on or near the control box for risk of serious injury or death due to<br />

electrical shock.<br />

WARNING, HIGH TEMPERATURES WITH HOT SURFA<strong>CE</strong>S. FAILURE TO FOLLOW THESE PRO<strong>CE</strong>-<br />

DURES COULD RESULT IN SERIOUS INJURY:<br />

_ Do not attempt to clean, disassemble or perform maintenance on this broiler until it is fully<br />

cooled as per the instructions contained in this manual.<br />

7<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

B. INSTALLATION<br />

B.1 Pre-Installation<br />

Uncrate the broiler and inspect for shipping damage. Remove the tape securing the machine parts, and<br />

install the parts in their proper location. If there are obvious or concealed damages to any part of the<br />

broiler, please contact your freight carrier. The factory warranty does not cover freight damage.<br />

B.2 Mounting<br />

Follow the mounting instructions if this function is not performed by the installer.<br />

B.3 Leveling<br />

The grease drain system is based on a gravity-flow design. Therefore, it is extremely important that the<br />

broiler be placed on a level surface.<br />

B.4 Hood Requirements<br />

This appliance must be installed under a ventilation hood of adequate size.<br />

Do not obstruct the flow of combustion and ventilation air. An adequate air supply must be available for<br />

safe and proper operation.<br />

B.5 Clearance<br />

Keep appliance area free from combustibles.<br />

To facilitate disassembly and service of the unit a minimum of 24” (610 mm) should be allowed on the<br />

control panel (feed end) of the broiler.<br />

REQUIRED AND RECOMMENDED CLEARAN<strong>CE</strong>S<br />

Back of broiler<br />

Sides of broiler<br />

Front of broiler<br />

(Feed end)<br />

REQUIRED for<br />

installation near<br />

combustible walls<br />

and construction<br />

B.6 Electrical Connection<br />

Power requirements are stated on the unit nameplate and must be connected accordingly. Before starting<br />

broiler, tighten all electrical connections in control box. An electrical wiring diagram can be found<br />

inside the control box.<br />

Note: Disconnect power before servicing.<br />

B.7 Pre-Operation Check<br />

Be sure that all parts are installed in the proper location.<br />

REQUIRED for installation<br />

near non-combustible<br />

walls and<br />

construction<br />

RECOMMENDED by<br />

<strong>Nieco</strong> for proper disassembly<br />

and service<br />

12” (305 mm) 0” (0 mm)<br />

0” (0 mm)<br />

12” (305 mm)<br />

12” (305 mm)<br />

0” (0 mm)<br />

0” (0 mm)<br />

0” (0 mm)<br />

24” (610 mm)<br />

8 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

C.1 Controls and Indicators<br />

ON THE MAIN SIDE<br />

1. Belt Speed Control (P/N 13727-B) - Used to set the<br />

broil time on the meat belt.<br />

2. On/Off Indicator Light (P/N 4402) - Glows when the<br />

broiler is on.<br />

3. Main On/Off Switch (P/N 15480) - Used to turn the<br />

main power supply to the broiler on or off.<br />

4. Belt Reverse Button (P/N 13579) - In the event of a<br />

belt jam, push and hold the belt reverse button in to<br />

help free anything that may be caught in the belt to<br />

help clear a jam.<br />

5. Temperature Control (P/N 19235) - Helps keep the<br />

broiler temperature stable when the broiler is under<br />

heavy load.<br />

ON THE FLEX SIDE<br />

1. Multi Product Control (P/N 15161-B) - Used to broil a<br />

variety of products that may require different settings<br />

(WHOPPERS ® , Chicken, XT)<br />

2. Belt Reverse Button (P/N 13579) - In the event of a<br />

belt jam, push and hold the belt reverse button in to<br />

help free anything that may be caught in the belt to<br />

help clear a jam.<br />

3. Temperature Control (P/N 19235) - Helps keep the<br />

broiler temperature stable when the broiler is under<br />

heavy load.<br />

C. OPERATION<br />

9<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

1<br />

1<br />

4<br />

5<br />

3<br />

2<br />

3<br />

2

C.1 Controls and Indicators (Continued.)<br />

(2)<br />

(1) LED DISPLAY - Shows current product selection and cook time.<br />

(1)<br />

Multi-speed control P/N 15161-B<br />

(2) PRODUCT SELECTION BUTTONS - Press to select different presets for different products.<br />

(3) ADJUSTMENT BUTTONS - Use to adjust product cook times, element settings and product names.<br />

(4) SELECTION INDICATOR LIGHT - Lights up to show which button is selected.<br />

10<br />

(4)<br />

(3)<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

C.2 Lighting Procedures<br />

PRE-LIGHTING PREPARATION<br />

1. Broiler is<br />

centered under<br />

hood and<br />

plugged in<br />

NORMAL IGNITION<br />

2. Turn ventilation<br />

system on<br />

1. Turn the MAIN POWER SWITCH on.<br />

2. Allow broiler to heat for 45 minutes before<br />

cooking. Do not cook during the warm up<br />

period.<br />

C.3 Shutdown Procedures<br />

PLANNED SHUTDOWN<br />

1. Allow the broiler<br />

to run free of<br />

any product for<br />

10 minutes.<br />

This will burn<br />

the chain clean.<br />

2. Turn off the<br />

Main Power<br />

Switch.<br />

EMERGENCY SHUTDOWN<br />

1. Turn off the<br />

MAIN POWER<br />

SWITCH.<br />

CAUTION<br />

FOR YOUR SAFETY: Do not store<br />

or use gasoline or other flammable<br />

vapors or liquids in the vicinity of<br />

this or any other appliance.<br />

WARNING<br />

THE VENTILATION SYSTEM MUST<br />

BE ON AT ALL TIMES DURING<br />

BROILER OPERATION. OPERATING<br />

BROILER WITHOUT PROPER<br />

VENTILATION IS A SEVERE FIRE<br />

HAZARD.<br />

11 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

1.<br />

3. Wait for 30<br />

minutes<br />

for the<br />

broiler to<br />

cool.<br />

CAUTION<br />

FOR YOUR SAFETY: In the event of<br />

a prolonged power failure, no<br />

attempt should be made to operate<br />

this appliance.

C.4 Control Operation<br />

IMPORTANT: THIS BROILER IS SHIPPED WITH FACTORY PRESETS THAT MUST BE CHANGED.<br />

If this is the initial start-up for your broiler, ALL control settings must be made according to BURGER KING® specifications. Follow the<br />

steps outlined for calibration and changing preset times.<br />

MAIN SIDE CONTROLS<br />

1. SETTING BELT SPEEDS<br />

Press up arrow to increase broil time; press the down<br />

arrow to decrease broil time. After you have set the<br />

control the display will be flashing. Press the center<br />

square to save your changes. NOTE: After making<br />

changes to the broil time, if you do not press the center<br />

square button, your changes will not be saved.<br />

2. TEMPERATURE CONTROLS<br />

Electric broilers are equipped with a Broil Temperature Stabilizer Control that senses when the<br />

broiler is being used, and adjusts the temperature to keep the broiler hot during heavy use.<br />

The control consists of two parts - a temperature probe to sense the internal temperature of<br />

the broiler, and the control itself.<br />

3. SETTING THE TEMPERATURE CONTROL<br />

Use the up and down<br />

arrows to set the time.<br />

Press the center<br />

square button to save<br />

your changes.<br />

In order to assure proper operation, the Temperature Control must be set for operation in the restaurant. Follow these<br />

step by step instructions when the broiler is new, and once per month after.<br />

Step 1: Be sure all pieces of the broiler are in place. Make sure the broiler is plugged in and the exhaust hood is turned<br />

on. Turn the broiler on.<br />

Step 2: MAIN SIDE OF THE BROILER: Set the temperature (bottom number) to 380º C (716° F). Use the up or down<br />

arrows on the control to set the temperature. The bottom number is the set temperature and the top number is<br />

the actual temperature.<br />

FLEX SIDE OF THE BROILER: Set the temperature (bottom number) to 275º C (527° F). Use the up or down<br />

arrows on the control to set the temperature. The bottom number is the set temperature and the top number is<br />

the actual temperature.<br />

12 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

C.4.5 FLEX SIDE CONTROLS<br />

1. Multi-Product Control<br />

How it works: The multi-product control is<br />

designed to let you broil different products on the<br />

flex side of the broiler. The control allows you to<br />

have different broiler settings for each product<br />

selection button. Use a grease pen to mark the<br />

white area with the product name.<br />

2. Normal Operation<br />

Press the product selection button (number) for<br />

the product you wish to cook. The display will<br />

show the product name and cook time and the<br />

light next to the product selection button will be lit.<br />

NOTE: Be sure the belt is clear of any products<br />

before pressing a new product selection button.<br />

3. Changing Belt Speeds<br />

Push the product selection button you want to<br />

adjust then push the up and down arrows to<br />

make changes, then press the center square button<br />

to save them.<br />

4. Changing Upper Heat Element Settings<br />

To adjust element settings press the product<br />

selection button you wish to change, then press<br />

the product selection button one more time. The<br />

screen will read Duty Cycle and show a percentage.<br />

Press the up and down buttons to adjust the<br />

element power up or down (0 = off; 100% = Full<br />

on). Press the center square button after you are<br />

done adjusting the duty cycle to save your<br />

changes.<br />

5. Changing Product Names<br />

Push the product selection button which you want<br />

to assign a name to. Press and hold the center<br />

square button for 15 seconds. The control will<br />

enter the edit name screen for that button. Use<br />

the up and down buttons to change the characters.<br />

Press the center square button once to move<br />

to the next character until you are finished editing<br />

the product name for that button (10 character<br />

limit). Press and hold the PRODUCT SELECTION<br />

BUTTON for 5 seconds to save the changes and<br />

return to normal operation.<br />

2<br />

3<br />

4<br />

5<br />

13 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

D. CLEANING AND DISASSEMBLY<br />

Turn broiler off. Disconnect the power supply to the broiler before cleaning or servicing. Allow to cool for 30<br />

minutes prior to cleaning/disassembly. Leave the ventilation system on during cooling. Use only approved<br />

cleaning, degreasing and sanitizing solutions.<br />

WARNING<br />

LEAVE THE VENTILATION HOOD<br />

ON DURING COOLING. FAILURE TO<br />

DO SO COULD POSE A FIRE<br />

SAFETY HAZARD.<br />

CAUTION<br />

Follow the Disassembly and<br />

Reassembly steps to ensure proper<br />

operation of the broiler. Failure to<br />

do so may result in operational<br />

problems.<br />

ALL PARTS ARE CLEANED ON A DAILY BASIS UNLESS OTHERWISE NOTED<br />

Follow the steps for proper disassembly. Reverse the order for reassembly.<br />

How to read the cleaning section<br />

The tools needed to<br />

clean the part<br />

How to remove and<br />

clean the parts.<br />

The name of the part to be cleaned.<br />

Meat Guides<br />

Tools<br />

3-Compartment Sink<br />

Instructions<br />

Scrub Pad<br />

1. Pull each meat guide out slightly from the bottom,<br />

then lift off.<br />

2. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

The location of the part.<br />

14<br />

Feed End<br />

WARNING<br />

BROILER PARTS ARE HOT. DO<br />

NOT ATTEMPT TO DISASSEMBLE<br />

THE BROILER UNTIL IT IS FULLY<br />

COOL. FAILURE TO FOLLOW THIS<br />

INSTRUCTION MAY RESULT IN<br />

SEVERE INJURY.<br />

Clean: Every 4 hours<br />

When to clean the part.<br />

Picture of the part to be<br />

removed and cleaned.<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

Cleaning the Broiler<br />

!<br />

STOP<br />

Tools Needed<br />

3-Compartment Sink<br />

Degreaser<br />

Heat<br />

Resistant<br />

Gloves<br />

Utility<br />

Knife<br />

No-Scratch Pad Scrub Pad<br />

Soft Bristle<br />

Brush<br />

Towel<br />

Small Orifice<br />

Brush<br />

Large Orifice<br />

Brush<br />

Important Symbols<br />

Shaft Cleaning<br />

Tool<br />

This “Stop” sign shows a step in the procedure that<br />

must be followed exactly or personal safety could<br />

be affected.<br />

This warning symbol shows a step in the procedure<br />

that must be followed exactly or broiler<br />

performance could be affected.<br />

This “puzzle” symbol shows a step in the<br />

reassembly procedure that must be followed.<br />

Meat Guide - P/N 19762<br />

Tools<br />

3-Compartment Sink<br />

Instructions<br />

Scrub Pad<br />

1. Pull the meat guide out slightly from the bottom,<br />

then lift off.<br />

2. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

Feed End<br />

Instructions<br />

1. Allow the broiler to run free of product for 10<br />

minutes before turning it off. This allows any<br />

residue to burn off the chains.<br />

2. Shut the broiler off and let it cool for 30 minutes<br />

before disassembly and cleaning.<br />

3. Close the main gas valve and unplug the broiler<br />

before cleaning.<br />

4. Always leave the ventilation hood on during the<br />

30 minute cool down period.<br />

5. Use only approved cleaning solutions.<br />

6. Allow parts to air dry after cleaning.<br />

Clean: Every 4 hours<br />

15 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

!<br />

Feeder Cover - P/N 17066<br />

Tools<br />

3-Compartment Sink<br />

Instructions<br />

1. Slide the feeder cover towards you until it comes<br />

off.<br />

2. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

1. Pull the release pin.<br />

2. Lift push bar and wire belt feeder bases up and off.<br />

3. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

DO NOT lift the feeder base by the feeder bar or the<br />

chains. This will damage the feeder base.<br />

REASSEMBLY: Pull the release pin and place feeder<br />

base in position.<br />

Feed End<br />

Push Bar P/N 22348/Wire Belt Feeder Base - P/N 22353<br />

Tools<br />

3-Compartment Sink<br />

Instructions<br />

Scrub Pad<br />

Scrub Pad<br />

Feed End<br />

Clean: Every 4 hours<br />

Clean: Every 4 hours<br />

16 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

Feeder Housing - P/N 22295<br />

Tools<br />

3-Compartment Sink<br />

Instructions<br />

Scrub Pad<br />

1. Lift and remove.<br />

2. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

REASSEMBLY: Hang feeder housing on brackets.<br />

Front Heat Shield - P/N 20468<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Scrub Pad<br />

3-Compartment Sink<br />

Instructions<br />

1. Lift shield up and off.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Feed End<br />

Feed End<br />

17 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Daily

!<br />

Grease Pan - P/N 18546<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

1. Slide grease pan out.<br />

Scrub Pad<br />

3-Compartment Sink<br />

Make sure grease pan is cool before putting in water<br />

or it may warp the pans.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Warming Pan Shield - P/N 16840<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Scrub Pad<br />

3-Compartment Sink<br />

Instructions<br />

1. Slide warming pan shield out.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Feed End<br />

Feed End<br />

18 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Daily

Lower Heat Reflectors - P/N 20472<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Scrub Pad<br />

3-Compartment Sink<br />

Instructions<br />

1. Slide reflectors out.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Holding Pan Bracket - P/N 16946<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

Scrub Pad<br />

3-Compartment Sink<br />

1. Lift and slide bracket out.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Feed End<br />

Feed End<br />

19 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Monthly<br />

Clean: Daily

Product Holding Area<br />

Tools<br />

Soapy Towel<br />

Sanitized Towel<br />

Instructions<br />

1. Clean product holding area while still warm.<br />

2. Wring out a soapy towel and wash product holding<br />

area.<br />

3. Wring out a sanitized towel and wipe product<br />

holding area.<br />

Feed End Grease Trough - P/N 17052<br />

Tools<br />

Scrub Pad<br />

3-Compartment Sink<br />

Instructions<br />

1. Slide grease trough towards you.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Feed End<br />

Feed End<br />

20 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Daily

Discharge Heat Shield - P/N 20469<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

Scrub Pad<br />

3-Compartment Sink<br />

1. Lift up and off broiler.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

REASSEMBLY: Make sure brackets go over the frame<br />

of the broiler.<br />

Product Slide - P/N 20474<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

Scrub Pad<br />

3-Compartment Sink<br />

1. Tilt and lift pins off hooks; lift off.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash, rinse, and sanitize in the 3-compartment<br />

sink.<br />

REASSEMBLY: Make sure return pan hangs on<br />

brackets.<br />

Discharge End<br />

Discharge End<br />

21 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Daily

!<br />

Stripper Blade - P/N 18919<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Scrub Pad<br />

3-Compartment Sink<br />

Instructions<br />

1. Tilt stripper blade away from chain; lift off<br />

brackets.<br />

Make sure stripper blade is cool before putting in<br />

water or it may warp.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

REASSEMBLY: Hang stripper blade on brackets.<br />

Chain Shafts<br />

Tools<br />

Shaft Cleaning<br />

Tool P/N 9128<br />

Instructions<br />

1. Scrape each shaft of both belts on the discharge<br />

end with the wide end of the shaft cleaning tool.<br />

The tool is located on the clip on main side control<br />

box.<br />

2. Wipe shaft cleaning tool with a towel.<br />

Discharge End<br />

Discharge End<br />

22 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Daily

Grease Trough - P/N 16307<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

Scrub Pad<br />

3-Compartment Sink<br />

1. Lift and slide the grease trough out of the broiler.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

REASSEMBLY: Be sure grease trough is pushed all the<br />

way into the broiler.<br />

Grease Box - P/N 16382<br />

Tools<br />

Degreaser<br />

Scrub Pad<br />

Instructions<br />

3-Compartment Sink<br />

1. Lift grease box off.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

REASSEMBLY: Put grease box on before the grease<br />

trough.<br />

Side<br />

Side<br />

23 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Daily

Incendalyst P/N 20860<br />

Tools<br />

Heat Resistant Gloves<br />

Instructions<br />

EXTREMELY HOT! Be careful not to burn yourself.<br />

1. Grasp lifting pin and lift catalyst off to remove<br />

from chimney.<br />

2. SOAK IN WARM WATER FOR 1 HOUR. RINSE WITH<br />

WATER ONLY. NEVER USE ANY CHEMICALS ON THE<br />

CATALYST.<br />

3. Lay flat to drain water and let air dry overnight.<br />

4. Make sure catalyst is dry before putting back on<br />

broiler.<br />

Incendalyst Chimney P/N 22293<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

Scrub Pad<br />

3-Compartment Sink<br />

EXTREMELY HOT! Be careful not to burn yourself.<br />

1. Lift chimney from top of broiler.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Top<br />

CAUTION:<br />

Extremely Hot<br />

Top<br />

CAUTION:<br />

Extremely Hot<br />

24 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Daily<br />

Clean: Weekly

Upper Air Box Reflector P/N 19099<br />

Tools<br />

Heat Resistant Gloves<br />

Degreaser<br />

Instructions<br />

Scrub Pad<br />

3-Compartment Sink<br />

EXTREMELY HOT! Be careful not to burn yourself.<br />

1. Lift reflector from the top of the air boxes.<br />

2. Take to sink area and spray with degreaser.<br />

3. Wash with a scrub pad, rinse, and sanitize in the<br />

3-compartment sink.<br />

Top<br />

CAUTION:<br />

Extremely Hot<br />

25 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Weekly

Air Boxes P/N 19040 (Front); 19022 (Back)<br />

Tools<br />

Heat Resistant Gloves<br />

Instructions<br />

EXTREMELY HOT! Be careful not to burn yourself.<br />

1. Loosen and remove hoses as marked by the<br />

arrows.<br />

2. Lift the air boxes from the broiler. Note that the<br />

front air box has two (2) inlet valves and the back<br />

air box only has one (1).<br />

3. Clean the air holes (example shown with an arrow)<br />

on both boxes with a brush or an orifice brush if<br />

they are badly clogged.<br />

4. Reassemble making sure the front air box with two<br />

inlet valves is in the front side of the broiler.<br />

CAUTION:<br />

Extremely Hot<br />

Soft Bristle<br />

Brush<br />

Large Orifice<br />

Brush<br />

1.<br />

2.<br />

3.<br />

Top<br />

AIR HOLES<br />

26 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

Clean: Weekly<br />

BACK OF BROILER<br />

FRONT OF BROILER

E. TROUBLESHOOTING<br />

Always verify that the broiler is properly assembled, the hood is on and broiler is plugged in.<br />

No power to broiler when the switch is turned on.<br />

Power is on, broiler is lit, but the conveyor belts are not<br />

turning.<br />

Feeder belt not moving.<br />

Feeder jams.<br />

Burgers sticking to slide or stripper blade.<br />

COOKING PROBLEMS<br />

Burgers under or over cooked.<br />

Excessive flaming in broiler.<br />

27<br />

Check: Broiler is plugged in.<br />

Ventilation hood is on.<br />

Circuit Breaker on wall panel is on.<br />

Check for a jam in the conveyor belt. Check the stripper<br />

blade to make sure it is installed properly.<br />

Make sure the feeder is assembled properly.<br />

Check for jam.<br />

Make sure the drive pin is engaged.<br />

Make sure the burgers are not frozen together.<br />

Clean the slide and stripper blade very thoroughly.<br />

Check cookout temperature (undercooking).<br />

Main side: adjust conveyor belt speed.<br />

Flex side: adjust conveyor speed and duty cycle.<br />

Clean the catalyst if equipped.<br />

Check the hood for proper operation.<br />

Check product for overcooking.<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

MEAT GUIDE<br />

P/N 19762<br />

FEED END HEAT SHIELD<br />

P/N 20468<br />

PATTY SHIELD<br />

P/N 16691<br />

F. PARTS LOCATION DRAWINGS<br />

Feed End View<br />

FEEDER COVER<br />

P/N 17066<br />

PUSH BAR FEEDER<br />

P/N 22348<br />

WIRE BELT FEEDER<br />

P/N 22353<br />

FEEDER HOUSING<br />

P/N 22295<br />

LOWER HEAT REFLECTOR<br />

P/N 20472<br />

WARMING PAN<br />

SHIELD<br />

P/N 16840<br />

GREASE PAN<br />

P/N 18546<br />

28 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

IN<strong>CE</strong>NDALYST<br />

P/N 20860<br />

HOOD, CHIMNEY<br />

P/N 22293<br />

F. PARTS LOCATION DRAWINGS<br />

Discharge, Side & Top View<br />

UPPER HEAT REFLECTOR<br />

P/N 19099<br />

ROD BELT, 5’ PER SIDE<br />

P/N 6035<br />

GREASE BOX<br />

P/N 16382<br />

GREASE THROUGH<br />

P/N 16307<br />

HEAT SHIELD,<br />

DISCHARGE<br />

P/N 20469<br />

PRODUCT RETURN SLIDE<br />

P/N 20474<br />

STRIPPER BLADE<br />

P/N 18919<br />

29 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

THERMOCOUPLE<br />

P/N 18861<br />

F. PARTS LOCATION DRAWINGS<br />

Right Side Control Box<br />

ELEMENT, 1000W, 380V<br />

P/N 20295<br />

CONTROL SPEED<br />

P/N 15161-B<br />

RELAY, 8A<br />

P/N 18093<br />

RELAY, 20A<br />

P/N 20724<br />

30 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

TOOL,<br />

CLEANING<br />

P/N 9128<br />

BLOWER<br />

P/N 18447<br />

ELEMENT,<br />

1000W, 230V<br />

P/N 20418<br />

CIRCUIT BREAKER,<br />

20A<br />

P/N 11965<br />

CIRCUIT BREAKER,<br />

25A<br />

P/N 19161<br />

CONTROL, TEMP<br />

P/N 19235

ELEMENT, 1000W, 380V<br />

P/N 20295<br />

F. PARTS LOCATION DRAWINGS<br />

Left Side Control Box<br />

THERMOCOUPLE<br />

P/N 18861<br />

SCR BASE<br />

P/N 4136<br />

CONTROL, BELT SPEED<br />

P/N 13727-B<br />

INDICATOR LIGHT<br />

P/N 4402<br />

SWITCH, 50A<br />

P/N 15480<br />

31 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

CONTROL, TEMP<br />

P/N 19235<br />

RELAY<br />

P/N 15329<br />

CIRCUIT BREAKER, 25A<br />

P/N 19161<br />

SPROCKET, 35B32<br />

P/N 13699<br />

SPROCKET, 35C19<br />

P/N 11081<br />

BLOWER<br />

P/N 18447<br />

SPROCKET, 35B10<br />

P/N 17899

F. PARTS LOCATION DRAWINGS<br />

Motor Control Box (On discharge of broiler)<br />

GEAR MOTOR, DC,<br />

BRUSHLESS<br />

P/N 17932<br />

POWER<br />

CONNECTION,<br />

TERMINAL<br />

BLOCK<br />

P/N 17382<br />

CONTACTOR,<br />

4 POLE, 24V<br />

P/N 18889<br />

TRANSFORMER,<br />

230/115-24V<br />

P/N 19001<br />

RECTIFIER<br />

P/N 12725<br />

FUSE HOLDER<br />

P/N 4405-31<br />

FUSE, 2AMP<br />

P/N 4621-02<br />

32 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

CLUTCH ASSEMBLY<br />

P/N 15882<br />

F. PARTS LOCATION DRAWINGS<br />

Clutch Assembly<br />

SPROCKET, CLUTCHED,<br />

BELLEVILLE SPRING<br />

P/N 14900<br />

BEARING, SHOULDER<br />

WASHER, LARGE,<br />

FEEDER DRIVE<br />

P/N 14896<br />

33 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

WIREBELT, 12” WIDE<br />

P/N 17409<br />

BUSHING FLANGED<br />

P/N 19913<br />

ROLL PIN<br />

P/N 11114<br />

F. PARTS LOCATION DRAWINGS<br />

Feeder Assembly<br />

COLLAR, SHAFT<br />

P/N 6099<br />

BUSHING<br />

FLANGED<br />

P/N 19913<br />

SHAFT, DRIVE<br />

P/N 22298<br />

SHAFT, DRIVE,<br />

P/N 22298<br />

SPROCKET,<br />

ROLLER CHAIN, 12T<br />

P/N 20883<br />

SPROCKET, ROLLER<br />

CHAIN, 12T<br />

P/N 20883<br />

COLLAR, SHAFT<br />

P/N 6099<br />

COUPLE, DRIVE<br />

P/N 11194<br />

BUSHING<br />

FLANGED<br />

P/N 19913<br />

BUSHING FLANGED<br />

P/N 19913<br />

SPROCKET,<br />

WIREBELT, 24T<br />

P/N 20882<br />

PUSHBAR FEEDER<br />

P/N 15617<br />

ROLL PIN<br />

P/N 11114<br />

CHAIN, LADDER, 6 SETS<br />

OF 17 LINKS<br />

P/N 11381<br />

COUPLE, DRIVE<br />

P/N 11194<br />

TENSIONER, PUSHBAR,<br />

PTFE, LEFT<br />

P/N 22296<br />

34 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

TENSIONER, PUSHBAR,<br />

PTFE, RIGHT<br />

P/N 22297

OCTOBER 11, 2011<br />

PART NO. DESCRIPTION<br />

G. PARTS REPLA<strong>CE</strong>MENT LIST<br />

AIR SYSTEM<br />

20909 CONNECTOR, FLEX, 3⁄4 X 16” - ASSY<br />

20821 AIR TUBE, MANIFOLD, BLOWER - WLDMT<br />

19764 HEATER HOSE, 3/4” ID X 2”<br />

19040 AIR BOX, FRONT, 13.38“, JF-G/E - WLDMT<br />

19022 AIR BOX, REAR, FLAT, 13.38”“, JF-E - WLDMT<br />

18447 BLOWER, HIGH PRESSURE, 24VDC, 2 WIRE<br />

BELT DRIVE SYSTEM & BEARINGS<br />

17932 GEAR MOTOR, DC, BRUSHLESS, OFFSET SHAFT<br />

17907 BEARING, SLEEVE, 3/8”, SNAP-IN<br />

17906 BRACKET, SUPPORT, 3/8“ MOTOR SHAFT<br />

17899 SPROCKET, 35B10, 3/8” BORE<br />

20430 COVER, CHAIN/FINGER GUARD, DRIVE SHAFT, JF<br />

17907 BEARING, SLEEVE, 3/8”, SNAP-IN<br />

18998 DRIVE SHAFT, DUAL 13“ BELT, JF - ASSY<br />

13699 SPROCKET, 35B32, 3/4” ID<br />

18997 DRIVE SHAFT, OUTER TUBE, 13“ BELT - WLDMT<br />

18996 DRIVE SHAFT, 33.33“, 13” BELT, JF - WLDMT<br />

18919 STRIPPER BLADE, FIXED, DUAL 13” BELT, JF<br />

15655 ROD, KEYED 5/8“ X 16-3/4“ LONG, 13” BELT - WLDMT<br />

6049 BEARING, PTFE,1“W X 1-7/8“H, Ø5/8“ SHAFT<br />

6047 BEARING, PTFE,1“W X 1-7/8”H, Ø3/4“ SHAFT<br />

6046 BEARING, PTFE,1”W X 1-7/8“H, Ø1-1/4“ SHAFT<br />

6035 ROD BELT,7GA,5/8“PITCH,13“ WIDE<br />

6027 CHAIN, ROLLER, #35<br />

20430 COVER, CHAIN/FINGER GUARD, DRIVE SHAFT, JF<br />

22293 HOOD, CHIMNEY, IN<strong>CE</strong>NDALYST, JF - WLDMT<br />

22291 HEAT REFLECTOR, ELEMENTS, UPPER, JF94/84<br />

20474 SLIDE, 4 LANE, 28.5” FRAME, JF - WLDMT<br />

20472 REFLECTOR, ELEMENT, LOWER, 12.5” W - WLDMT<br />

20469 HEAT SHIELD, REAR, 28.5’’ FRAME, JF<br />

20468 HEAT SHIELD, FEEDER/FRAME, 28.5“ FRAME, JF<br />

19099 HEAT REFLECTOR, UPPER, <strong>JF94E</strong><br />

18546 GREASE PAN, NON VENTED - 28.5“ FRAME<br />

17052 TRAY, GREASE DRIP - 28.5“ FRAME<br />

16946 FRAME, SUPPORT, HOLDING PAN, 4 LANE, MPB<br />

16840 SHIELD, HEAT, SHUTTLE<br />

16794 RACK, STACKING, PATTY PAN<br />

16382 PAN, HOTEL, 1/9 X 4” DEEP<br />

16307 TRAY, SLUDGE - 28.5” FRAME - WLDMT<br />

9128 TOOL, SHAFT CLEANING<br />

35 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

G. PARTS REPLA<strong>CE</strong>MENT LIST<br />

ELECTRICAL ELEMENTS & CONTROLS<br />

22288 COVER, ENCLOSURE, ELEC/MOTORS, REAR, JF<br />

22287 COVER, ENCLOSURE, ELEC/AIR, JF-E, R<br />

22286 COVER, ENCLOSURE, ELEC/AIR, JF-E, L<br />

22285 ENCLOSURE, ELEC/MOTOR, REAR, JF-E - ASSY<br />

22278 ENCLOSURE, ELEC/AIR, JF94/84E, RIGHT - ASSY<br />

20876 CONTROL GUARD, 7”“ LONG, ELECTRICAL BOX<br />

20724 RELAY, SOLID STATE, 20A, 600V, DC COIL<br />

19161 CIRCUIT BREAKER, 277/480V, 25A. 3 POLE<br />

19235 CONTROL, DIGITAL TEMP, 24VAC, SSR OUT<br />

15161-B CONTROL, SPEED MULTI-CHANNEL, VERTICAL<br />

19161 CIRCUIT BREAKER, 277/480V, 25A. 3 POLE<br />

11965 CIRCUIT BREAKER, 20A<br />

18092 RELAY BASE, DIN MOUNT, 8 PIN<br />

18093 RELAY, 250VAC, 24V COIL, 8A, 8 PIN<br />

18686 TERMINAL BLOCK, 4 X 4MM, SC, GRAY<br />

4621-02 FUSE, 2 AMP<br />

4405-31 TERMINAL BLOCK, FUSE HOLDER, TYPE M<br />

19001 TRANSFORMER, 230/115-24V, 7.3A<br />

18889 CONTACTOR, 4 POLE, 24V, COIL<br />

12725 RECTIFIER, SINGLE PHASE BRIDGE, 25A 200V<br />

4621-02 FUSE, 2 AMP<br />

15480 SWITCH, ROCKER, 50A CIRCUIT BREAKER<br />

13727-B CONTROL, BRUSHLESS MOTOR<br />

IDLER SPROCKET, 35C19, 3/8”“ BORE<br />

4402 INDICATOR LIGHT, GREEN, 28V<br />

4136 SCR BASE<br />

20418 ELEMENT - 31’’, 1000W, 230V, Ø.55<br />

20295 ELEMENT - 17.5”“, 1000W, 380V, Ø.49 - WLDMT (<strong>CE</strong>)<br />

20291 ELEMENT - 17.5”“, 1000W, 208V, Ø.49 - WLDMT (DOMESTIC)<br />

18168 CABLE, MOTOR, 4 WIRE W/CONNECTOR<br />

18861 THERMOCOUPLE PROBE, 1.88”, TYPE J, 48“ LEADS<br />

13579 SWTCH, MOTOR REVERSING<br />

18687 END COVER, 2 X 4MM, SC, GRAY<br />

4405-01 END STOP, GRAY (103 002.26)<br />

22269 ENCLOSURE, ELEC/AIR, JF94/84E, LEFT - ASSY<br />

SHEET METAL PARTS<br />

16403 BRACKET, MOUNTING, STRIPPER BLADE - RIGHT<br />

16402 BRACKET, MOUNTING, STRIPPER BLADE - LEFT<br />

15689 ROD, CROSS SUPPORT - .63” X 28.5”<br />

6300 ROD, CROSS SUPPORT - 5/8“ X 26,875”<br />

6028 COLLAR, SET, 5/8” BORE<br />

16838 BRACKET, TENSIONING, ROD BELT<br />

36 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

G. PARTS REPLA<strong>CE</strong>MENT LIST<br />

18910 SUPPORT, ELEMENT/AIR, UPPER, REAR, JF-E<br />

19610 BEARING, ALUM/BRZ, 5/8” SHAFT X 1.44” WIDE<br />

20300 BRACKET, FEEDER SUPPORT, JF, LEFT<br />

20301 BRACKET, FEEDER SUPPORT, JF, RIGHT<br />

20312 SUPPORT, BEARING, <strong>CE</strong>NTER, JF-E - WLDMT<br />

20417 SHIELD, PATTY WARMER, JF - WLDMT<br />

20419 SUPPORT, BELT (1/8” SS PIPE, 2” LONG)<br />

20309 BRACKET, REFLECTOR/SCRAPER, JF-E - WLDMT<br />

FEEDER<br />

22214 FEEDER W/DRIVES, DUAL 13”, PB/WB, JF<br />

22353 DRIVE UNIT, WIREBELT, 13” BELT, RH - ASSY<br />

22298 SHAFT, DRIVE, PB/WB, 14.53” L, 13” ROD BELT<br />

22297 TENSIONER, PUSH BAR, PTFE, RIGHT - ASSY<br />

22296 TENSIONER, PUSH BAR, PTFE, LEFT - ASSY<br />

20883 SPROCKET, ROLLER CHAIN, 12T, 3/8” BORE<br />

15617 PUSH-BAR, 13“ ROD BELT - WLDMT<br />

11478 BUSHING, FLANGED, 3/8” SHAFT, W/FLAT<br />

11381 CHAIN,LADER,353” PITCH, 13 GA<br />

11194 COUPLER, DRIVE, 1/4” SQ X 3/8” ID<br />

22347 PLATFORM, TRIPLE PUSH-BAR, 13“ BELT<br />

22353 DRIVE UNIT, WIREBELT, 13” BELT, RH - ASSY<br />

22352 SHAFT, Ø1/2”, 1/4-20 TAPPED X 12.88”<br />

22351 TENSIONER, WIREBELT, 13” BELT - WLDM<br />

20882 SPROCKET, WIREBELT, 24T, Ø3/8” BORE<br />

19913 BUSHING, FLANGED, Ø3^8’’ SHAFT X .275’’, W/FLAT<br />

17409 WIRE BELT, 72 X .050 MESH X 12” WIDE X 3 SPA<strong>CE</strong>S<br />

11114 ROLL PIN, Ø1/8 X 1”.SS<br />

6099 COLLAR, SHAFT, SET SCREW, 3/8” BORE<br />

22349 PLATFORM, WIREBELT, 13“ BELT, JF<br />

19762 FRAME, 1/2” TO 1“ PATTY, 13” BELT - ASSY<br />

17494 BRACKET, CLUTCH RESTRAINT, FEEDER DRIVE<br />

17066 COVER, FEEDER, DUAL 13” - MPB<br />

16691 COVER, FEEDER, 2 LANE, FLEX SIDE<br />

22295 ENCLOSURE, DUAL 13” FEEDER, JF - WLDMT<br />

20884 DRIVE ASSY W/CLUTCH, 15T FEEDER, UNIV<br />

20504 COVER, FEEDER DRIVE/CLUTCH ASSY, JF<br />

11608 KNOB, BLACK, INSERT, 10-32<br />

6053 OFFSET LINK, #35 ROLLER CHAIN<br />

6048 MASTER LINK, # 35 ROLLER CHAIN<br />

6037 SPROCKET, ROLLERCHAIN, 35B 15, 5/8” BORE<br />

6027 CHAIN, ROLLER, #35<br />

14900 SPROCKET, CLUTCHED, 13T, BELLEVILLE SPRING<br />

14896 BEARING, SHOULDER WASHER, LARGE, FEEDER DRIVE<br />

10627 BEARING CLIP, 1/2“ ID,12 THK<br />

37 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

G. PARTS REPLA<strong>CE</strong>MENT LIST<br />

MIS<strong>CE</strong>LLANEOUS<br />

20860 IN<strong>CE</strong>NDALYST, 15.19“ X 8“ X 1.5“, 29 CPI<br />

22400 SPARE KIT<br />

22342 HEAVY DUTY SPARES KIT<br />

38 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong>

REV. DESCRIPTION DATE BY<br />

A Initial Release 8-Jul-11 PB<br />

B Updated flex (right) side 12-Aug-11 PB<br />

element w iring<br />

C Replaced Broil Stabilizer, w as 16035 26-Sep-11 PB<br />

D Corrected main side element w iring. 29-Sep-11 PB<br />

E Corrected flex side element w iring. 6-Oct-11 PB<br />

F Changed Main Side element w iring.16-Nov-11 PB<br />

G, H Changed Flex element w iring. 3-Dec-11 PB<br />

J Changed Flex element w iring. 6-Jan-12 KK<br />

K Changed Main & Warming Elements 6-Feb-12 KK<br />

Page 1 Left Side<br />

Control Box<br />

B<br />

Feed End<br />

B<br />

1<br />

Element Connection Wires 12 ga. TGGT<br />

8 7 R 6 5<br />

4 3 2<br />

R<br />

H. WIRING DIAGRAM - Main Side<br />

B<br />

R<br />

B<br />

B<br />

R<br />

Y<br />

R<br />

Heating Elements (9)<br />

P/N 20295<br />

Control Settings:<br />

Belt Speed Control<br />

B = 36<br />

P/N 13727-B<br />

G<br />

C = 450<br />

Socket Base<br />

5 4<br />

TLL = 1:00<br />

P/N 4136<br />

THH = 7:00 6<br />

3<br />

DIR = L<br />

7<br />

2<br />

B W<br />

8 1<br />

16 15 14 13 12 11 10 9<br />

R<br />

18 17<br />

B<br />

R<br />

R<br />

Y<br />

R<br />

B<br />

To Motor Reverse<br />

Button<br />

Y #12 TGGT<br />

Motor Reverse Switch<br />

P/N 13579<br />

G<br />

Br<br />

12<br />

B #10<br />

B #10<br />

B<br />

R<br />

Solid State Relay<br />

50A<br />

P/N 15329<br />

Broil<br />

Stabilizer Control<br />

P/N 19235<br />

17 16 11<br />

R<br />

B<br />

B<br />

R<br />

R<br />

B<br />

39<br />

Br<br />

G<br />

R<br />

W<br />

6<br />

7<br />

8<br />

9<br />

10<br />

L2 L3<br />

Circuit Breaker, 3 Pole 25A<br />

P/N 19161<br />

From Broil Stabilizer<br />

Control<br />

A2 A1<br />

(-) (+)<br />

13 14<br />

1<br />

2<br />

L1<br />

L1 T1<br />

3<br />

4<br />

18<br />

R<br />

11 12<br />

14<br />

R<br />

5<br />

To Motor Control, pin 3<br />

R<br />

B<br />

Pur<br />

W<br />

L2<br />

L1<br />

11<br />

10<br />

B<br />

B<br />

Thermocouple<br />

P/N 18861<br />

Green Light<br />

24V<br />

P/N 4402<br />

B #10<br />

9<br />

8<br />

4<br />

To Contactor Coil<br />

3<br />

B #10<br />

B #10<br />

B #10<br />

W<br />

Pur<br />

7<br />

6<br />

5<br />

Main Power<br />

Switch<br />

P/N 15480<br />

Or<br />

Bl<br />

1 2<br />

From Transformer<br />

24VAC from terminal<br />

block<br />

This document is the property of <strong>Nieco</strong><br />

Corporation. Reproduction or release without<br />

express permission is prohibited<br />

<strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

24VDC from rectifier<br />

Wiring Diagram<br />

Drawn Date Model Dwg No.<br />

Rev.<br />

PB 30Jun11 JF94/84E, <strong>CE</strong>, 380-400V 20110 K<br />

Page 1 of 3<br />

Motor Cable<br />

Low Voltage<br />

Conduit<br />

High Voltage<br />

Conduit

R<br />

Y<br />

Y<br />

Page 2 Right Side<br />

Control Box<br />

B<br />

Heating Elements (9)<br />

P/N 20295<br />

13 14<br />

15 16<br />

17 18<br />

12<br />

11<br />

Feed End<br />

Control<br />

Settings:<br />

B = 36<br />

C = 450<br />

TLL = 1:00<br />

THH = 7:00<br />

DIR = L<br />

Multi-Product<br />

Control<br />

P/N 15161-B<br />

B<br />

Y<br />

Y<br />

B<br />

B<br />

B<br />

R<br />

Element Connection Wires 12 ga. TGGT<br />

Burner<br />

24VAC<br />

Y<br />

Y<br />

Y<br />

H. WIRING DIAGRAM - Flex Side<br />

To motor Reverse<br />

Button<br />

Heater<br />

24VDC<br />

+<br />

-<br />

Or<br />

B<br />

10<br />

3 4<br />

5 6<br />

7 8<br />

9<br />

2<br />

1<br />

B<br />

Y<br />

Y<br />

1<br />

7 6 5 4 3 2<br />

R<br />

Motor Reverse Switch<br />

P/N 13579<br />

Br<br />

W<br />

B<br />

G<br />

R<br />

W<br />

R<br />

B<br />

Circuit Breaker, 20A<br />

P/N 11965<br />

To Multi Product<br />

Control, pin 3<br />

Circuit Breaker, 3 Pole 25A<br />

P/N 19161<br />

Warmer Element<br />

P/N 20418<br />

19 20<br />

Bl<br />

Y<br />

20<br />

Broil<br />

Stabilizer Control<br />

P/N 19235<br />

19<br />

18<br />

Bl<br />

24V Relay<br />

For blower<br />

Relay P/N 18093<br />

Base P/N 18092<br />

R<br />

Y<br />

B #10<br />

B #10<br />

B<br />

B<br />

Br<br />

W<br />

R<br />

Y<br />

R<br />

B<br />

R<br />

B<br />

Or<br />

B<br />

Or<br />

W<br />

R<br />

Solid State Relay<br />

20A (3)<br />

P/N 20724<br />

A2 A1<br />

(-) (+)<br />

A2 A1<br />

(-) (+)<br />

A2 A1<br />

(-) (+)<br />

6<br />

7<br />

8<br />

9<br />

10<br />

13 14<br />

1<br />

2<br />

N<br />

L1 L2 L3<br />

T1 L1<br />

Terminal Blocks (7)<br />

P/N 18686<br />

B #12 TG G T<br />

T1 L1<br />

10<br />

Y #12 TG G T<br />

T1 L1<br />

Y<br />

Bl<br />

3<br />

Y #12 B<br />

3<br />

4<br />

11 12<br />

5<br />

Y #12 TG G T<br />

Thermocouple<br />

P/N 18861<br />

9<br />

Bl<br />

Y<br />

B #10<br />

R<br />

B<br />

B<br />

Bl<br />

Y<br />

Y #12<br />

R<br />

Or<br />

Br<br />

Y<br />

Bl #12<br />

B #10<br />

B #10<br />

B #10<br />

16<br />

15<br />

18<br />

17<br />

14<br />

13<br />

12<br />

40 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

24VAC from transformer<br />

24VDC from rectifier<br />

Low Voltage<br />

Conduit Motor Box<br />

Motor Cable<br />

High Voltage<br />

Conduit<br />

This document is the property of <strong>Nieco</strong><br />

Corporation. Reproduction or release without<br />

express permission is prohibited<br />

Wiring Diagram<br />

Drawn Date Model Dwg No.<br />

Rev.<br />

PB 30Jun11 JF94/84E, <strong>CE</strong>, 380-400V 20110 K<br />

Page 2 of 3<br />

To High Pressure Blower

Page 3 Motor Box<br />

H. WIRING DIAGRAM - Motor Box<br />

To Left Side<br />

Control Box pg. 1<br />

To Right Side<br />

Control Box pg. 2<br />

24VDC to left control box<br />

High Voltage<br />

Conduit<br />

Low Voltage<br />

Conduit<br />

Low Voltage<br />

Conduit<br />

24VAC to left control box<br />

High Voltage<br />

Conduit<br />

14<br />

13<br />

12<br />

To Main Switch<br />

10 ga. Black<br />

12 ga. Blue<br />

to Right Side<br />

Circuit Breakers<br />

24VAC to right<br />

control box<br />

From Main Switch<br />

24VDC to right<br />

control box<br />

W<br />

Pur<br />

Bl #12<br />

7<br />

6<br />

5<br />

4<br />

3<br />

B<br />

10 ga. Black to Left Side<br />

Circuit Breakers<br />

B #10<br />

B #10<br />

B #10<br />

Motor (2)<br />

P/N 17932<br />

Bl #12<br />

Pur<br />

W<br />

15 10 16 11 17 8 18 9<br />

Y<br />

1<br />

Bl<br />

L3<br />

L2<br />

L1<br />

2<br />

Or<br />

Bridge Rectifier<br />

PRI SEC<br />

P/N 12725 6 12<br />

notch<br />

Fuseholder<br />

5 11<br />

+ ~<br />

P/N 4405-31<br />

2 Amp Fuse 4 10<br />

3 9<br />

~<br />

P/N 4621-02<br />

-<br />

2 8<br />

1 7<br />

Pur<br />

Bl<br />

W<br />

Y<br />

R<br />

Or<br />

B<br />

Br<br />

1L1 3L2 5L3 7L4<br />

N<br />

Coil<br />

8T4<br />

6T3<br />

4T2<br />

2T1<br />

Bl<br />

B<br />

Y<br />

R<br />

Note: Label terminal<br />

blocks<br />

10 mm Terminal Blocks<br />

Gray P/N 4405-16<br />

Blue P/N 4405-17<br />

Ground P/N 4405-18<br />

Bl #12<br />

Y<br />

B #10<br />

B #10<br />

B #10<br />

B<br />

Transformer<br />

P/N 19001<br />

Y<br />

Pur<br />

Bl<br />

W<br />

R<br />

Y<br />

B<br />

Note: Apply label with<br />

fuse rating next to<br />

fuseholder<br />

4 Pole Contactor<br />

50A, 24V Coil<br />

P/N 18889<br />

High Pressure Blower<br />

P/N 18447<br />

41 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

B<br />

R<br />

B<br />

R<br />

High Pressure Blower<br />

P/N 18447<br />

This document is the property of <strong>Nieco</strong><br />

Corporation. Reproduction or release without<br />

express permission is prohibited<br />

Wiring Diagram<br />

Drawn Date Model Dwg No.<br />

Rev.<br />

PB 30Jun11 JF94/84E, <strong>CE</strong>, 380-400V 20110 K<br />

Page 3 of 3

AUTOMATIC BROILER<br />

Model <strong>JF94E</strong><br />

DIMENSIONS INCH MM<br />

Length 35.48 901<br />

Height 64.02 1626<br />

Width 40.11 1019<br />

ENERGY<br />

Electrical connection (specify exact voltage)<br />

<strong>CE</strong> 380-415V 3Ø 25A 19kW<br />

Calculated average consumption: 16kW<br />

WEIGHT LBS KG<br />

Shipping 690 313<br />

Broiler on Stand 565 256<br />

CAUTION<br />

All electrical connections must be<br />

in accordance with local electrical<br />

codes and any other applicable<br />

codes.<br />

CAUTION<br />

Do not operate the broiler at gas<br />

pressures other than those stated<br />

here. Doing so will affect the operation<br />

of your broiler.<br />

I. SPECIFICATIONS<br />

1663<br />

65.47<br />

1626<br />

64.02<br />

853<br />

33.57<br />

ELT<br />

758<br />

29.83<br />

624<br />

24.57<br />

1076<br />

42.35<br />

1019<br />

40.11<br />

910<br />

35.82<br />

556<br />

21.91<br />

901<br />

35.48<br />

42 <strong>Nieco</strong> Corporation - Model <strong>JF94E</strong> <strong>CE</strong><br />

167<br />

6.58<br />

.<br />

.<br />

1378<br />

54.25<br />

BROIL BELT<br />

1

<strong>Nieco</strong> Corporation<br />

7950 Cameron Drive<br />

Windsor, CA 95492<br />

+1-707-284-7100<br />

+1-707-284-7430 Fax<br />

www.nieco.com<br />

sales@nieco.com • service@nieco.com<br />

© 2011 <strong>Nieco</strong> Corporation All Rights Reserved<br />

Printed in the U.S.A