The Alaska Contractor - Spring 2011 - Keep Trees

The Alaska Contractor - Spring 2011 - Keep Trees

The Alaska Contractor - Spring 2011 - Keep Trees

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Associated General<br />

<strong>Contractor</strong>s of <strong>Alaska</strong><br />

8005 Schoon St.<br />

Anchorage, AK 99518<br />

(907) 561-5354<br />

Fax: (907) 562-6118<br />

www.agcak.org<br />

<strong>Contractor</strong>@agcak.org<br />

Editorial Board<br />

Dick Cattanach<br />

Margaret Empie<br />

Mary Killorin<br />

John MacKinnon<br />

Brook Mayfield<br />

April Reilly<br />

Vicki Schneibel<br />

George Tuckness<br />

Lyn Whitley<br />

8537 Corbin Dr.<br />

Anchorage, AK 99507<br />

(907) 562-9300<br />

Fax: (907) 562-9311<br />

Toll Free: (866) 562-9300<br />

www.AQPpublishing.com<br />

Publisher<br />

Robert R. Ulin<br />

Editor<br />

Rachael Fisher<br />

Graphic Designer<br />

Justin Ritter<br />

Project Sales Manager<br />

Clem E. Mewmaw<br />

Advertising Coordinator<br />

Carol Choi<br />

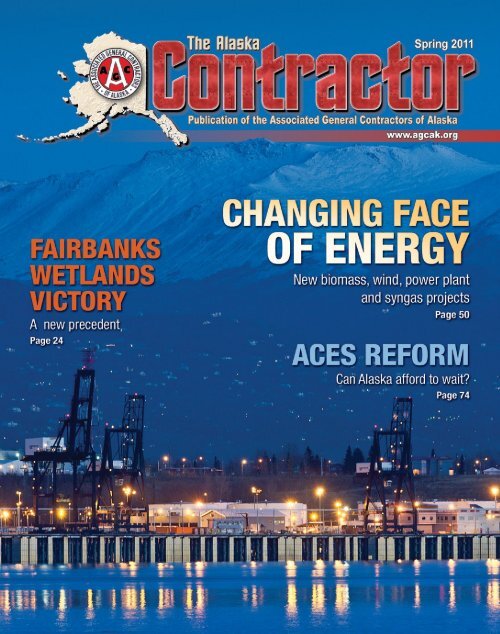

On the cover: Port of Anchorage.<br />

Cover photo by<br />

© Ken Graham photoGr aphy.Com<br />

Features<br />

Table of Contents<br />

12 <strong>Alaska</strong> Construction Spending <strong>2011</strong> Forecast excerpts<br />

by Scott Goldsmith and Mary Killorin<br />

20 Project Update: West Construction Company by Jessica Bowman<br />

34 AVTEC’s new wind turbine offers more than power by Nancy Erickson<br />

45 Legislative Fly-In photo essay<br />

46 Energy efficiency programs keep contractors busy by Jody Ellis-Knapp<br />

50 <strong>The</strong> Changing Face of Energy in <strong>Alaska</strong> by Rindi White<br />

56 Hydroelectric project on the Susitna River gains momentum by E. Colleen Kelly<br />

59 14th Annual Fairbanks Bowl-A-Thon photo essay<br />

60 Eklutna Inc. Anchorage’s largest private landowner by Carly Horton Stuart<br />

70 Department of Transportation partners with AGC by Commissioner Marc Luiken<br />

74 Back to the future ACES reform by Rachael Fisher<br />

77 A perfect par Neeser Construction and <strong>The</strong> First Tee of <strong>Alaska</strong> by Colleen Madonna Flood<br />

78 Oil Pumps <strong>Alaska</strong>’s Economy to Twice the Size—But What’s Ahead? by Scott Goldsmith<br />

84 Under Canstruction Industry seeks to construct an <strong>Alaska</strong><br />

without hunger through design/build competition by Rachael Fisher<br />

86 2010 Winners of AGC’s Excellence in Construction Awards photo essay<br />

ProFiles<br />

16 Florcraft Carpet One by Rachael Kvapil<br />

30 Cowater <strong>Alaska</strong> Inc. by Bambi Childs<br />

40 R&M Consultants Inc. by Sharon Stockard<br />

66 Crowley Petroleum Distribution Inc. compiled by Tracy Kalytiak<br />

DePartments<br />

4 Winning Bids and Construction Trends<br />

8 President’s Message by George Tuckness<br />

10 Executive Director’s Message by John MacKinnon<br />

24 <strong>Contractor</strong>s & the Law by Robert J. Dickson<br />

38 Safety Report by Chris Ross<br />

44 Financial Services & <strong>Contractor</strong>s by Bill Cessnun<br />

65 Human Resources Update by Barbara Stallone<br />

69 Beacon/WorkSafe by Chris Williams<br />

95 Member News<br />

<strong>The</strong> <strong>Alaska</strong> <strong>Spring</strong> <strong>2011</strong><br />

Publication of the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong><br />

www.agcak.org<br />

Editor’s note: We’ve begun to profile two Associate Members in each issue to shorten the length of time these valued<br />

members wait to be featured in <strong>The</strong> <strong>Alaska</strong> <strong>Contractor</strong>.<br />

Corrections: A column on page 8 of Winter <strong>2011</strong> incorrectly said the overall unemployment rate nationally hovered<br />

around 1 percent in 2009. <strong>The</strong> overall unemployment rate nationally hovered around 10 percent in 2009.<br />

A photo caption on page 44 of Winter <strong>2011</strong> incorrectly identified AGC Vice President Tony Johansen, who was not pictured.<br />

<strong>The</strong> <strong>Alaska</strong> <strong>Contractor</strong> is published by AQP Publishing Inc. for the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong>. Contents of the magazine are not necessarily endorsed by AGC of <strong>Alaska</strong> or AQP Publishing Inc. All rights reserved.<br />

Copyright <strong>2011</strong> by the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong>. For information about articles in this edition or for permission to reproduce any portion of it, contact AQP Publishing Inc.<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 3

Note: Winning Bids and<br />

Construction Trends<br />

1) Source from projects advertised<br />

in the AGC of <strong>Alaska</strong> Bulletin<br />

2) Calculations based<br />

on date of bid<br />

3) Supply/Service; Non-Construction<br />

bid results are not always<br />

advertised in the bulletin<br />

4) RFP results are not always<br />

advertised in the bulletin<br />

ARCTIC & WESTERN<br />

BETHEL MATERIAL SUPPLY<br />

$4,638,000<br />

Specialty Supply Inc.<br />

SAND POINT SCHOOL LOOP ROAD<br />

$4,599,790<br />

Brechan Enterprises Inc.<br />

NOME COUNCIL HWY RESURFACE<br />

$4,359,365<br />

Phillip & Jordan Inc.<br />

NOME HIGHWAY BRIDGE<br />

IMPROVMENTS<br />

$2,233,855<br />

Twin Peaks Construction Inc.<br />

ST MARYS TEACHER HOUSE TRIPLEX<br />

$1,199,500<br />

Tunista Construction LLC<br />

AK YUKON RIVER BRIDGE REHAB<br />

$789,000<br />

MKB Constructors<br />

BETHEL PILING INSTALL<br />

$753,604<br />

Salzburn Services & Drilling<br />

NUIQSUT FIRE STATION<br />

FLOOR REPLACE<br />

$571,000<br />

Concor Construction Inc.<br />

DILLINGHAM FUEL TANKS FAB<br />

$530,675<br />

Brown Minneapolis Tank NW<br />

NOME ANVIL CORRECTIONAL ROOF<br />

$424,761<br />

Silver Bow Construction<br />

KAKTOVIK LIGHTING UPGRADES<br />

$275,083<br />

Tanik Construction Co. Inc.<br />

INTERIOR<br />

FBKS NORTH POLE<br />

WELLER SCHOOLS LIGHTING<br />

$4,095,347<br />

Johnson River Enterprises LLC<br />

DALTON HWY AGGREGATE<br />

$544,500<br />

Exclusive Paving<br />

SOUTHCENTRAL<br />

ANCH AIA RUNWAY 7R/25L REHAB/EXT<br />

$32,191,812.22<br />

QAP<br />

WHITTIER HARBOR PHS I<br />

$3,909,000<br />

Harris Sand & Gravel Inc.<br />

KODIAK UV DISINFECTION FACILITY<br />

$3,540,794<br />

Jay-Brant General <strong>Contractor</strong>s<br />

EAGLE RIVER CLARIFIER/ASH IMPROVE<br />

$1,591,186<br />

MKB Constructors<br />

ANCH ASD HUFFMAN SITE IMPROVE<br />

$1,583,777<br />

Roger Hickel Contracting Inc.<br />

ANCH ASD SOUTH HS TURF FIELD<br />

INSTALL<br />

$1,401,265<br />

Roger Hickel Contracting Inc.<br />

ANCH PINE/4TH AVE STORM PHI<br />

$1,365,449<br />

Pruhs Construction Co. LLC<br />

MAT-SU PHYSICAL SECURITY PCKG<br />

$1,322,364<br />

Howdie Inc.<br />

CHUGIAK ASD ROOF UPGRADES<br />

$1,087,000<br />

Wolverine Supply Inc.<br />

AK AIA/FIA CUPPS GATE/TICKET<br />

COUNTER IMPROVE<br />

$1,002,777<br />

Consolidated Contracting & Engineering<br />

ANCH CAMPBELL LK<br />

SEDIMENTATION REDUCTION<br />

$931,450<br />

Territory North Constructors LLC<br />

4 <strong>The</strong> <strong>Alaska</strong> CONTRACTOR <strong>Spring</strong> <strong>2011</strong>

KODIAK FLOORING REPLACE<br />

$774,482<br />

Prosser-Dagg Construction Co. Inc.<br />

WASILLA POOL REMODEL<br />

$518,110<br />

Howdie Inc.<br />

ANCH TURNAGAIN BOOSTER<br />

STATION/RESVOIR<br />

$468,431<br />

<strong>Alaska</strong> Mechanical Inc.<br />

ANCH ASD EAST GYM HAVAC UPGRADES<br />

$453,895<br />

Consolidated Contracting and<br />

Engineering<br />

ANCH LIBRARY LIGHTING UPGRADES<br />

$449,340<br />

Electric Inc.<br />

ANCH ANTHC SERVER ROOM<br />

UPGRADES<br />

$367,815<br />

Eklutna Services LLC<br />

KODIAK MS GYM ROOF SEISMIC IMPROVE<br />

$334,158<br />

Alutiiq International Solutions LLC<br />

STERLING MORGANS LANDING<br />

PLATFORMS<br />

$331,001<br />

Orion Construction Inc.<br />

ANCH ASD CAMPBELL LIGHTING ECM<br />

$299,900<br />

Clemens Electric Inc.<br />

SoUTHEAST<br />

DOUGLAS GASTINEAU ES<br />

RENOVATIONS<br />

$8,792,700<br />

McGraw’s Custom Construction<br />

ANNETTE IS WALDEN PT PAVING<br />

$6,109,896<br />

Southeast Road Builders<br />

SKAGWAY WWTP UPGRADES<br />

$3,949,000<br />

McGraw’s Custom Construction<br />

AUKE BAY LOADING FACILITY PHS II<br />

$2,452,757<br />

Southeast Earth Movers Inc.<br />

PETERSBURG RUNWAY SAFETY PHS IV<br />

$2,437,750<br />

D & L Construction Co. Inc.<br />

COFFMAN COVE MAINT STATION<br />

$1,241,000<br />

McGraw’s Custom Construction<br />

JUNEAU DIXON/MAIN ST RECONSTRUCT<br />

$1,023,813.45<br />

Miller Construction Co. LTD<br />

JUNEAU WOOD DUCK AVE RECONSTRUCT<br />

$705,277<br />

Miller Construction Co. LTD<br />

JUNEAU SIDEWALK/DRAINAGE<br />

$567,592<br />

Cutting Edge Dev/N Lights Dev<br />

SKAKWAK HWY GEOTECH DRILLING SVCS<br />

$388,785<br />

Geoteck Drilling Services<br />

KETCHIKAN CRK ST BOARDWALK REPLACE<br />

$275,430<br />

CBC Construction Inc.<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 5

$650,000,000<br />

$600,000,000<br />

$550,000,000<br />

$500,000,000<br />

$450,000,000<br />

$400,000,000<br />

$350,000,000<br />

$300,000,000<br />

$250,000,000<br />

$200,000,000<br />

$150,000,000<br />

$100,000,000<br />

$50,000,000<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

$450,000,000<br />

$400,000,000<br />

$350,000,000<br />

$300,000,000<br />

$250,000,000<br />

$200,000,000<br />

$150,000,000<br />

$100,000,000<br />

$50,000,000<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

$1,200,000,000<br />

$1,050,000,000<br />

$900,000,000<br />

$750,000,000<br />

$600,000,000<br />

$450,000,000<br />

$300,000,000<br />

$150,000,000<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

$-0<br />

$-0<br />

$-0<br />

highway<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

building<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

annual<br />

TRENDS<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

6 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

PRESIDENT’S MESSAGE<br />

Long-term oil development<br />

needed to grow our<br />

construction economy<br />

L<br />

ast issue I brought you a good report on <strong>Alaska</strong>’s<br />

resourceful efforts to grow our <strong>Alaska</strong> construction<br />

economy. This was accomplished primarily by the<br />

effi cient use of state funding of a healthy capital budget<br />

and the Department of Transportation being shovel ready<br />

to receive federal stimulus funds. Granted these sources of<br />

funding did not constitute the entire winning formula but<br />

without them our economy would not have been nearly<br />

so robust. <strong>The</strong> question we should all ask is what to do<br />

about our future?<br />

<strong>Alaska</strong> has great representation in Washington D.C.,<br />

but we should prepare ourselves for a decline in federal<br />

funds. We already are the envy of every state because of<br />

how much funding we receive. With federal spending at<br />

an all time high, can we expect it to continue? At a time<br />

when all states are crying out for help and the national<br />

debt is more than $14 trillion, our portion will inevitably<br />

be reduced. What can we do to replace these declining<br />

funds? Can we continue to take from our savings to stimulate<br />

our economy indefi nitely? No, we need a long-term<br />

plan to grow private industry. We must become a better<br />

partner to the resource industry and in particular, oil.<br />

<strong>The</strong> oil industry accounts for one-third of <strong>Alaska</strong>’s<br />

economy and more than 85 percent of the state’s general<br />

fund revenue—oil is king. We see declining production<br />

and an even greater decline in exploration. ConocoPhillips,<br />

one our largest investors in exploration, did not drill one<br />

exploration well last year and won’t again this year. We<br />

are seeing many good <strong>Alaska</strong> companies specializing in<br />

oil fi eld services moving their operations to new oil fi elds<br />

in North Dakota, Texas and Alberta, Canada. <strong>The</strong>se are<br />

good-paying jobs that could be in <strong>Alaska</strong> if we become<br />

more competitive. We do not have a monopoly in the oil<br />

market, and we must turn this trend around.<br />

Some experts are saying our tax structure is no longer<br />

competitive. I believe we should support Gov. Parnell’s<br />

plan for reform. Our oil tax law called ACES stands for<br />

<strong>Alaska</strong>’s Clear and Equitable Share. It could more appropriately<br />

be called <strong>Alaska</strong>’s Clear and Excessive Share.<br />

We have received a nice, fat windfall from this tax which<br />

has helped replenish our savings and sustain us through<br />

the crash of the American economy. But there are more<br />

GE O R G E TU C K N E S S<br />

President<br />

profi table opportunities for the oil companies to invest in<br />

outside of <strong>Alaska</strong>. We need to bring the exploration dollars<br />

back to <strong>Alaska</strong>.<br />

Not only are the taxes higher in <strong>Alaska</strong>, the costs associated<br />

with remote locations and the environmental regulation<br />

of Arctic exploration makes a stronger headwind.<br />

With oil’s current prices, the state takes more than 80<br />

percent of the revenue—this is twice the tax of any other<br />

state. It is very short-sighted to think the oil industry will<br />

continue to invest in <strong>Alaska</strong> when our tax structure is the<br />

highest in the nation. If it was your business, would you<br />

promote new investment where the taxes are so high?<br />

AGC of <strong>Alaska</strong> is supporting one of the newest efforts<br />

promoting tax reform, the Make <strong>Alaska</strong> Competitive<br />

Coalition or MACC. <strong>The</strong> new group, a coalition of <strong>Alaska</strong><br />

individuals and businesses, is funded by donations from<br />

supporters, but is not accepting any funds from the oil<br />

industry. <strong>The</strong> coalition is waging war on ACES. <strong>The</strong>ir<br />

message is to stop looking for how much revenue we can<br />

get now from the oil, but rather let’s help to build a stable<br />

future with sustainable reinvestment in oil development.<br />

It is easy for those of us who don’t work in the oil fi eld<br />

to think that this issue is not so important. But we need<br />

only look a little way down the road before we realize<br />

much of the growth of our economy will depend on <strong>Alaska</strong>’s<br />

ability to continue to receive a stable income from oil.<br />

Let’s not kill the golden goose, when so much is to be<br />

gained from being a good partner and working toward a<br />

long-term plan.<br />

<strong>The</strong> most important thing we can do as businesses<br />

and individuals is to get involved. Help spread the<br />

message of how important it is for us to keep the oil<br />

fl owing. I don’t know the exact formula to reform ACES,<br />

but I know we went too far when it was passed three<br />

years ago. We cannot afford to let our resources dry up.<br />

Talk to your friends and neighbors, write your legislators.<br />

Help everyone you know, young and old, to understand<br />

how important oil is to <strong>Alaska</strong>. Become an advocate to<br />

help change and create a more competitive environment<br />

for oil development. I encourage our entire membership<br />

to support this effort.<br />

8 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

EXECUTIVE DIRECTOR’S MESSAGE<br />

A couple things ...<br />

I<br />

n this issue you’ll read about ACES, <strong>Alaska</strong>’s oil tax<br />

regime, and how it’s driving investment away from<br />

our state. Many <strong>Alaska</strong> businesses have experienced<br />

a signifi cant drop in business volume as a result of the<br />

tax structure and change in the industry investment on<br />

the North Slope. <strong>The</strong> current progressivity tax regime is<br />

driving investment to other countries and other states. We<br />

complain about the number of non-residents working in<br />

<strong>Alaska</strong>, and our own tax policy is making <strong>Alaska</strong>ns work<br />

as non-residents in other states.<br />

Our industry and all of <strong>Alaska</strong> has benefi tted from<br />

the large capital budget made possible by the high taxes,<br />

but we are concerned that the short-term gain of greater<br />

revenue now may result in a longer-term<br />

loss for the state. Many business leaders<br />

in <strong>Alaska</strong> are concerned that if ACES is<br />

not addressed and adjusted, then our<br />

<strong>Alaska</strong> economy could suffer. <strong>The</strong> Make<br />

<strong>Alaska</strong> Competitive Coalition was formed<br />

by a group of civic and business leaders<br />

who have a compelling message and are<br />

pushing the state to adopt a tax structure<br />

that encourages jobs and investment in<br />

<strong>Alaska</strong>. You can fi nd out more at www.<br />

Make<strong>Alaska</strong>Competitive.com.<br />

Presently there is legislation being<br />

considered that will fi x some of the problems<br />

in ACES. As they weigh the matter<br />

of capping progressivity, lawmakers must ask themselves,<br />

are they managing the state for just two years into the<br />

future, or are they concerned about what’s on the horizon?<br />

You need to get involved.<br />

You’ll also read the latest ISER report by Scott<br />

Goldsmith, “Oil Pumps <strong>Alaska</strong>’s Economy to Twice the<br />

Size—But What’s Ahead.” It discusses the importance of<br />

oil on <strong>Alaska</strong>’s economy and looks at our state in 1960<br />

and today—today both with oil and without oil. An<br />

excellent article that details just how oil has benefi tted<br />

the state. In addition to a number of thought-provoking<br />

facts and analyses, it should incite the question in most<br />

reader’s minds: Without oil in <strong>Alaska</strong>’s economy, where<br />

would you be? <strong>The</strong> answer in the article is that half of us<br />

wouldn’t be here.<br />

We have an article about wetlands and the legal victory<br />

of a Fairbanks gravel pit owner, Great Northwest, over the<br />

Many business<br />

leaders in <strong>Alaska</strong><br />

are concerned<br />

that if ACES is<br />

not addressed and<br />

adjusted, then our<br />

<strong>Alaska</strong> economy<br />

could suffer.<br />

JO H N MA CKI N N O N<br />

Executive Director<br />

Corps of Engineers. <strong>The</strong> Corps wanted to extract $55,000<br />

from them in exchange for permission to fi ll part of a<br />

gravel pit Great Northwest had previously dug out. <strong>The</strong><br />

article takes you through the history of the Clean Water<br />

Act and all the subsequent interpretations and rulings and<br />

discusses the legal aspects of the case relative to a couple<br />

of recent Supreme Court decisions. It discusses the merits<br />

and precedents of the recent court case won on behalf<br />

of Great Northwest by the Pacifi c Legal Foundation.<br />

With statehood in 1959, Congress granted <strong>Alaska</strong> title<br />

to 103 million acres so that we could build and sustain a<br />

resource-based economy. Ten years later, Congress passed<br />

the Clean Water Act that said “That land we gave you—<br />

most of it is wetlands and we won’t let<br />

you do anything with it.” Does “breach of<br />

contract” come to mind?<br />

Finally, not related to an article in<br />

this issue, but bears repeating, Gov. Sean<br />

Parnell spoke at the National Press Club<br />

on Feb. 25. <strong>The</strong> Department of Interior<br />

and the Environmental Protection Agency<br />

are now actually driving our domestic and<br />

foreign policy. This is because these agencies<br />

have locked down America’s resources,<br />

forcing our country to be dependent on an<br />

increasingly hostile Middle East.<br />

Gov. Parnell said, “<strong>The</strong>se are agencies<br />

that can lock down domestic oil with no<br />

responsibility for the consequences. <strong>The</strong>y can force America<br />

to depend ever more heavily on Middle East oil, at enormous<br />

cost of lives, tax dollars and economic opportunity. <strong>The</strong>y do<br />

this by delaying leasing, delaying permitting for exploration<br />

and development, and by attempting sweeping lock-ups of<br />

lands without congressional approval or authority.<br />

“<strong>The</strong> Department of Interior in the past few years has<br />

acted like a shopaholic with a stolen credit card and a taste for<br />

empire building. Recently, U.S. Interior Secretary Ken Salazar<br />

decided to evaluate 87 million acres of federal land in <strong>Alaska</strong><br />

and millions elsewhere in the West as potential ‘wild lands.’<br />

That designation, if implemented, would lock up <strong>Alaska</strong>n oil<br />

without Congress having any input at all.”<br />

It seems like there’s a lot of pushing back against<br />

government overreach, both by businesses and by states<br />

like Wisconsin, New Jersey and <strong>Alaska</strong>. That sends a<br />

message. Is Washington listening?<br />

10 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

Forecast predicts <strong>Alaska</strong> construction<br />

spending will increase 4 percent<br />

Excerpts from “<strong>Alaska</strong>’s Construction Spending <strong>2011</strong> Forecast”<br />

By sC o t t Go l d s M i t h a n d Ma Ry Ki l l o R i n<br />

T<br />

he total value of construction<br />

spending “on the street”<br />

in <strong>Alaska</strong> in <strong>2011</strong> will be $7.1<br />

billion, up 4 percent from 2010.<br />

Excluding the oil and gas sector—<br />

which accounts for 41 percent of the<br />

total—construction spending will be<br />

$4.2 billion—up 5 percent from 2010.<br />

Uncertainty is particularly signifi -<br />

cant in the forecast this year, especially<br />

in the oil and gas sector—in spite of<br />

high oil prices. In January <strong>2011</strong>, uncertainty<br />

surrounds most of the largescale<br />

petroleum projects on the North<br />

Slope and in Cook Inlet. Uncertainty<br />

about future developments in the oil<br />

industry underscores the continued<br />

sense of caution within the business<br />

community about the prospects for<br />

the economy.<br />

Private spending<br />

<strong>The</strong> private sector will spend<br />

$4.5 billion on construction-related<br />

activities in <strong>Alaska</strong> in <strong>2011</strong>. That is 63<br />

percent of total construction spending<br />

and an increase of 6 percent compared<br />

with 2010.<br />

Oil and gas industry spending<br />

is expected to be up about 3 percent<br />

from last year’s revised projections—if<br />

most projects are able to move forward<br />

as planned. None of the three major<br />

producers on the North Slope—British<br />

Petroleum (BP), ConocoPhillips and<br />

Exxon—will be exploring.<br />

BP will concentrate on bringing the<br />

Liberty fi eld into production, developing<br />

existing reserves and maintaining<br />

infrastructure. ConocoPhillips<br />

will also concentrate on developing<br />

existing reserves, particularly the<br />

Alpine West prospect in the National<br />

Petroleum Reserve <strong>Alaska</strong>. However,<br />

all these projects face environmental<br />

or legal hurdles that have slowed their<br />

development, and in the current environment<br />

it is diffi cult to predict how<br />

much further their timetables will slip<br />

over the next year.<br />

Eni, Pioneer and Shell will have<br />

large North Slope budgets this year.<br />

Eni will bring the Nikaitchuq fi eld<br />

into prospects, and Savant will be<br />

re-starting the Badami fi eld, which has<br />

been shut-in for many years.<br />

Marathon, Chevron and Conoco-<br />

Phillips will all be active in Cook Inlet,<br />

as will a number of smaller companies<br />

like Armstrong Petroleum—which<br />

is leading a partnership to develop a<br />

North Fork gas fi eld—and Cook Inlet<br />

Energy, which has taken over the<br />

assets of bankrupt Pacifi c Energy.<br />

Spending by the mining industry—<br />

on exploration, development and<br />

upgrading existing mines—will be<br />

about the same as last year. <strong>The</strong> only<br />

signifi cant large scale mine development<br />

this year will be expansion of the<br />

Red Dog mine in northwest <strong>Alaska</strong><br />

into the adjacent Aqqaluk site. Capital<br />

spending at the other operating mines,<br />

including the recently opened Kensington<br />

Mine in southeast <strong>Alaska</strong>, will<br />

primarily be for normal maintenance<br />

and modest upgrades. Exploration and<br />

project planning will continue at the<br />

two large prospects—Donlin Creek<br />

and Pebble.<br />

Spending in the utilities category<br />

will be up 28 percent this year,<br />

because many Railbelt electric utilities<br />

are developing new generating facilities,<br />

and because telecommunications<br />

fi rms are expanding their networks<br />

in rural <strong>Alaska</strong>. Construction of the<br />

new gas-fi red electric generation<br />

facility by Chugach Electric Association<br />

and Anchorage Municipal Light<br />

and Power is moving forward, as are<br />

plans by Homer Electric Association<br />

to generate its own power with steam<br />

generation and gas turbines. Golden<br />

Valley Electric Association is plan-<br />

ning a wind project at Eva Creek near<br />

Healy, and Cook Inlet Region Inc.<br />

hopes to move forward with its Fire<br />

Island wind project, in Cook Inlet just<br />

west of Anchorage. Stimulus money<br />

is funding $88 million in grants and<br />

loans to United Utilities for installation<br />

of broadband service to 65<br />

communities in southwest <strong>Alaska</strong>,<br />

using fi ber-optic cable and a microwave<br />

network.<br />

Hospital spending will be considerably<br />

higher than it was last year<br />

(38 percent). Providence Hospital in<br />

Anchorage is embarking on its largest<br />

expansion program in 11 years—the<br />

modernization and enlargement of<br />

the newborn intensive care and maternity<br />

suites, and expansion of cardiac<br />

surgery capacity. Two other large<br />

continuing projects this year are the<br />

new hospitals in Nome and Barrow.<br />

In addition, work will begin this year<br />

on a new Chief Andrew Isaac Medical<br />

Center in Fairbanks.<br />

<strong>The</strong>re are no new large private<br />

commercial construction projects—<br />

12 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

such as new highrise office towers or<br />

shopping centers—planned for this year,<br />

and commercial construction is projected<br />

to fall 21 percent. <strong>The</strong> absence of large<br />

projects reflects the slowdown in the<br />

overall economy and the adequacy of the<br />

existing stock of retail, commercial and<br />

warehouse space in most communities.<br />

Medical office space is the one category<br />

where demand continues to grow.<br />

Although <strong>Alaska</strong> has been largely<br />

insulated from the national housing<br />

market crash—both in terms of prices<br />

and foreclosures— residential construction<br />

will decline slightly again this year,<br />

continuing a trend that began in 2007.<br />

Public spending<br />

Public construction spending will be<br />

up 1 percent, to $2.7 billion, due to the<br />

large FY <strong>2011</strong> state capital budget.<br />

Spending for national defense<br />

will be up 1 percent from last year,<br />

even though ARRA funds for military<br />

purposes have largely been spent.<br />

<strong>The</strong> largest share of the budget is<br />

for military construction at the main<br />

bases in the Anchorage and Fairbanks<br />

regions. Typical projects include<br />

aircraft hangers, housing replacement,<br />

training facilities, air support facilities<br />

and utility upgrades. <strong>The</strong> Corps<br />

of Engineers provides funds for civil<br />

works such as flood control and environmental<br />

remediation.<br />

Spending for highways and roads<br />

will be 5 percent lower than the revised<br />

total for last year. Highway projects<br />

funded by a portion of the deferred<br />

maintenance package in last year’s<br />

capital budget will cushion the decline.<br />

Spending for airports, ports and<br />

harbors will again be lower than the<br />

year before—down about 11 percent—<br />

because of the absence of new large<br />

projects and because most of the ARRA<br />

funds have been spent. <strong>The</strong> Anchorage<br />

and Point MacKenzie port development<br />

projects will continue, but at a modest<br />

level of effort because at this point they<br />

depend on state funding. <strong>The</strong> FY <strong>2011</strong><br />

state capital budget had only small<br />

appropriations for these projects.<br />

<strong>The</strong> capital construction program for<br />

modernizing and upgrading the <strong>Alaska</strong><br />

Railroad will continue this year at a<br />

slightly faster pace than last year. <strong>The</strong><br />

focus of the program continues to be<br />

track rehabilitation, siding extensions<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 13

and upgrades, bridge replacement and<br />

upgrades, passenger equipment and a<br />

collision-avoidance system. Construction<br />

of the Tanana River bridge, the first<br />

step in extending the railroad to Fort<br />

Greely, is underway, but is encountering<br />

design challenges that may delay the<br />

project timetable.<br />

<strong>The</strong> Denali Commission will spend<br />

about the same this year as last year.<br />

Major activities will include waterfront<br />

development and road projects, bulkfuel<br />

tank farms, rural power system<br />

upgrades, and renewable and alternative<br />

energy projects, as well as clinics<br />

and behavioral health projects.<br />

Education project funding will be up<br />

25 percent from last year, largely due<br />

to passage of the large state education<br />

general obligation bond package in late<br />

2010. <strong>The</strong> state capital budget allocation<br />

for school construction and maintenance<br />

will be about the same as last<br />

year, and we expect local school districts<br />

to spend about the same amount as in<br />

previous years on construction, renovations<br />

and upgrades.<br />

State and local government capital<br />

spending—excluding transportation,<br />

education and energy (electric utilities)<br />

—will be about 29 percent higher than<br />

last year, because of the large FY <strong>2011</strong><br />

state capital budget. <strong>The</strong> largest project<br />

will be continued construction of the<br />

new Goose Creek Correctional Center<br />

in the Mat-Su Borough.<br />

Construction spending is one of<br />

the important contributors to overall<br />

economic activity in <strong>Alaska</strong>. Annual<br />

wage and salary employment in the<br />

construction industry in 2010 was about<br />

16,000 workers, with average annual<br />

payroll of $60,000 per worker. This<br />

total does not account for construction<br />

workers who are self-employed—<br />

estimated to be about 9,000 in 2010. <strong>The</strong><br />

payrolls and profits from this construction<br />

activity support businesses in every<br />

community in the state. As this income<br />

is spent and circulates through local<br />

economies, it generates jobs in businesses<br />

as diverse as restaurants, dentists’<br />

offices and furniture stores.<br />

Visit www.agcak.org and click<br />

“News & Media” to view the full<br />

report which was generously<br />

underwritten by Northrim Bank.<br />

14 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

MEMBER PROFILE<br />

FLORCRAFT CARPET ONE By Ra C h a E l KVa p i l<br />

Gearing up to celebrate<br />

50 years in <strong>Alaska</strong><br />

F<br />

lorcraft Carpet One is excited for 2012. Next<br />

year marks the 50th anniversary of its Fairbanks<br />

store—a milestone that follows the<br />

Anchorage store’s 25th anniversary. Florcraft<br />

has come a long way from its beginnings as a small<br />

Fairbanks shop. <strong>The</strong> family-owned company’s reputation<br />

for quality earned it loyal customers and the<br />

ability to expand into the world of interior design,<br />

General Manager Patrice Case said.<br />

In 1962, Al Vacura, George Dujmovich, John<br />

Hajdukovich and Joe Carie founded Florcraft in Fairbanks.<br />

Back then it was a small shop that served only<br />

the Interior. Operations were simple—sell carpet, cut<br />

it at the warehouse and deliver it, Case said.<br />

Ownership changed in 1986 when Richard<br />

Wien and Robert Hanson purchased the business<br />

with John Hajdukovich. Hanson, Case’s father,<br />

worked as a Florcraft employee prior to becoming<br />

an owner. Case said her parents worked together<br />

in the Fairbanks corporate offi ce; and, as a teenager,<br />

she worked every Saturday during the school<br />

year and full-time in the summer fi ling paperwork.<br />

Later she worked in the Anchorage store until she<br />

Florcraft’s Anchorage store on Fifth Avenue celebrated its 25th anniversary last year.<br />

Laminate is one of several fl ooring options offered by Florcraft.<br />

returned to Fairbanks. After her mother and father<br />

passed away in 2002 and 2006, respectively, Wien<br />

appointed Case as general manager and she now<br />

works alongside her husband.<br />

Florcraft employs 35 people in its Fairbanks<br />

and Anchorage stores. Residential and commercial<br />

divisions handle projects of all types and size. In<br />

16 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong><br />

photo: raChael Kvapil<br />

photo: Cour tesy of florCr aft Carpet one

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 17

photo: raChael Kvapil<br />

Florcraft employees from the Fairbanks offices.<br />

addition to carpeting, Florcraft sells<br />

hardwood and laminate floors, tiling<br />

and rugs. Its design services department<br />

works from start to finish on<br />

interior design projects, including<br />

paint, wallpaper, lighting, flooring and<br />

window treatments.<br />

“Really what Florcraft sells is<br />

service,” said Case. “Our staff is<br />

knowledgeable and takes care of the<br />

Florcraft’s Fairbanks store on Fox Avenue,<br />

off Phillips Field Road, will celebrate its 50th<br />

anniversary this year.<br />

customer. <strong>The</strong> commodity is important,<br />

but the service is really what the<br />

customer wants.”<br />

Denali State Bank President Jyotsna<br />

“Jo” Heckman has an extensive history<br />

with both Florcraft’s residential and<br />

commercial divisions. She remembers<br />

Hanson personally hauling oriental<br />

rugs up three flights of stairs so she<br />

could see them in the room firsthand.<br />

“Bob used to tell me don’t choose a<br />

carpet while it’s hanging in the store,”<br />

said Heckman in a phone interview.<br />

“He had a philosophy of personal<br />

customer service and attention to<br />

detail that are in-line with my values.<br />

And I think Patrice and her husband<br />

Jason are doing a fine job carrying on<br />

with that philosophy.”<br />

Recently Florcraft replaced carpet<br />

and blinds in Denali State Bank’s<br />

downtown branch. Last summer,<br />

Heckman also had the flooring<br />

replaced in every room of her new<br />

home, and again Florcraft lived up to<br />

her expectations. <strong>The</strong> crew began to<br />

remodel her home in June 2010 and<br />

asked when she would like the project<br />

completed. In jest, Heckman told<br />

them that her birthday is June 21. To<br />

her surprise, they worked every night<br />

on the installation so it would be done<br />

before then.<br />

“Who provides that kind of service<br />

anymore?” Heckman asked.<br />

Case attributes Florcraft’s success to<br />

the dedication of its employees, but also<br />

says that they wouldn’t be as effective<br />

without organizations such as Associated<br />

General <strong>Contractor</strong>s of <strong>Alaska</strong>.<br />

Florcraft joined AGC in September of<br />

‘92. Case said Florcraft finds value in<br />

its membership because AGC assists<br />

small businesses with the bigger<br />

picture, like lobbying and providing<br />

18 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong><br />

photo: Cour tesy of florCr aft Carpet one

up-to-date information about laws<br />

and regulations that affect the industry,<br />

as well as providing educational classes<br />

and helps members to provide health<br />

insurance for their employees.<br />

“<strong>The</strong>y have the best interest of<br />

the contractors at heart. <strong>The</strong>y provide<br />

services small businesses might not<br />

have the resources to do,” Case said.<br />

Case also appreciates the opportunities<br />

for community involvement<br />

offered by AGC. Most recently Florcraft<br />

participated in the first Operation<br />

Opening Doors project in Fairbanks,<br />

providing new carpet and flooring<br />

in the home of Sergeant Anthony<br />

Senecal. Community involvement is an<br />

important focus for Florcraft and last<br />

year the company won the Association<br />

of Fundraising Professionals Award for<br />

promoting philanthropy in the state.<br />

“It was truly an honor for me to<br />

nominate Florcraft for this award last<br />

fall and to watch proudly as Patrice<br />

accepted the award and dedicated it<br />

to her father,” Gretchen C. Gordon,<br />

CFRE, past president of AFP-<strong>Alaska</strong><br />

said in an e-mail.<br />

While Case appreciates Florcraft’s<br />

In addition to carpet, laminates, hardwood and<br />

tile, Florcraft also offers a selection of rugs.<br />

success, she has also set her sights<br />

on the company’s long-term growth.<br />

She hopes to expand market share in<br />

Anchorage and the Mat-Su Valley. At<br />

one time a Florcraft store existed in<br />

Wasilla and she said it would be nice to<br />

see one open there again. As a “forever<br />

optimist” Case sees the options for<br />

Florcraft recently carpeted the second floor of Denali<br />

State Bank’s downtown branch. <strong>The</strong>y are currently<br />

installing carpet in their fourth floor offices.<br />

growth as limitless and looks forward<br />

to the challenges ahead.<br />

Rachael Kvapil is a writer and<br />

photographer who lives in Fairbanks,<br />

<strong>Alaska</strong>.<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 19<br />

photos: raChael Kvapil

Project<br />

Update<br />

Port of Anchorage,<br />

Seward Breakwater Extension,<br />

Whittier Barge Ramp Upgrades<br />

By JE s s i Ca Bo W M a n<br />

PORT OF ANCHORAGE<br />

<strong>The</strong> Port of Anchorage, dubbed one of 19 U.S. “strategic<br />

ports” by the Department of Defense, underwent extensive<br />

renovations in 2010. WCC contracted with ICRC on the<br />

Port’s Intermodal Expansion Project. <strong>The</strong> $7 million effort<br />

began in January 2010 and consisted of vibrocompaction<br />

and soils densifi cation on-site.<br />

<strong>The</strong> second phase began six months later and included<br />

removal of sheet piling in areas that had seen more than<br />

fi ve decades of cargo infl ux and outfl ux. <strong>The</strong> OPEN CELL<br />

SHEET PILE® bulkhead design, developed by PND Engineers,<br />

required tail walls, which extend into the fi ll, to anchor<br />

the exposed sheet pile at the face of the dock. <strong>The</strong> composite<br />

soil and sheet pile structure behind the dock bulkhead face<br />

act as a high capacity structural unit.<br />

Six cranes working to install the Northern<br />

Extension of the Port of Anchorage.<br />

photo: GeorGe tipner<br />

With more than a decade of experience in <strong>Alaska</strong>, West Construction Company specializes in marine construction and<br />

recently fi nished three signifi cant local projects.<br />

“<strong>The</strong>re have been signifi cant challenges [at the Port],”<br />

said Brad West, owner of WCC. “<strong>The</strong> good news is that we<br />

fi gured out the work could be installed as designed, and we<br />

successfully installed half a dozen cells last year and demolished<br />

a few that had past issues. Every sheet extracted was<br />

measured, recorded, photographed, catalogued, marked,<br />

stacked [and] cleaned.”<br />

Another signifi cant challenge was an extensive Marine<br />

Mammal Monitoring Program to protect beluga whales.<br />

“We had a full-time plan,” said West. If the whales came too<br />

near, WCC had to cease operations on any pile driving or<br />

water work.<br />

<strong>The</strong> construction budget for this phase of the project was<br />

around $30 million and work was completed in December<br />

2010.<br />

20 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

SEWARD BREAKWATER EXTENSION<br />

In March 2010, WCC also began a $4.8 million project to<br />

shore up and extend the breakwater in Seward.<br />

“We had to take the nose off the existing breakwater and<br />

then tie into place the material. This was all constructed from<br />

barges because you couldn’t get to the site,” said West.<br />

photos: the al asKa sealife Center, universit y of al asKa anChor aGe and miCro speCialties inC.<br />

• 09.22.10 - <strong>The</strong> breakwater extension “breaks” the water line.<br />

• 10.28.10 - Excavator and barge placing rock on the breakwater extension.<br />

• 10.30.10 - First connection of the new extension with the existing breakwater.<br />

• 11.10.10 - Continued work with excavators and barge on the new breakwater extension.<br />

• 12.02.10 - Completed seamless extension of the breakwater.<br />

Marine construction in tough environments is what WCC<br />

is known for, but properly placing fi ll with an excavator from<br />

a fl oating barge is still no easy task.<br />

“We have a GPS system on our excavator so we always<br />

know exactly where the bucket is,” West said, but nonetheless<br />

the job proved diffi cult because the tolerances were<br />

extremely tight.<br />

“We were setting four-foot stone and the tolerance on<br />

the fi nished rock surface of the breakwater was minus zero<br />

plus six inches, so trying to fi t irregularly shaped 4-foot<br />

stones into that exact shape was a challenge,” West said.<br />

<strong>The</strong> project was completed in November 2010, and WCC<br />

worked with Brice Companies for the tug and barge, and<br />

TerraSond Limited provided surveying services.<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 21

<strong>Alaska</strong> Railroad wharf confi guration prior to<br />

rehabilitation.<br />

WHITTIER BARGE<br />

RAMP UPGRADES<br />

<strong>The</strong> <strong>Alaska</strong> Railroad Corporation’s<br />

rail barge ramp allows loaded railcars<br />

direct access to rail-equipped barges<br />

for transit to Seattle and Canada.<br />

<strong>The</strong> 120-foot ramp and lift structure<br />

was built by the railroad about 40 years<br />

ago. Its many cables, counterweights<br />

and “two tall lattice towers restricted<br />

the way they unloaded cargo,” said<br />

George Tipner, WCC project manager.<br />

<strong>Alaska</strong> Marine Lines desired to<br />

retrofi t the structure to allow access<br />

for its 53-foot containers. <strong>The</strong> project<br />

required replacement of the ramp<br />

counterweight system with a low-<br />

Distant view of refurbished “Tower-less” <strong>Alaska</strong> Railroad wharf. West crews installing the<br />

railroad rails on shore (inset photo).<br />

profi le hydraulic system; replacement<br />

of the deck with a higher capacity,<br />

fl exible structure; and installation of<br />

new lift beams, main girder reinforcement<br />

and bracing.<br />

<strong>The</strong> design details and construction<br />

of the project were tailored around the<br />

short work-windows dictated by the<br />

barge traffi c schedule to avoid any<br />

disruptions.<br />

This required a “complicated and<br />

clever plan,” said West. WCC placed<br />

two 15-inch bore hydraulic cylinders<br />

steel pile and caisson cradle foundation<br />

connected to two new lift beams<br />

threaded through reinforced openings<br />

cut in the existing girders of the ramp<br />

to actuate the required up-and-down<br />

movement to set the ramp on the stern<br />

of the barge.<br />

“We’ve done several other barge<br />

transfer ramp facilities, but this was<br />

the fi rst hydraulically-operated one<br />

I’ve done, and was very complicated<br />

due to the logistics of keeping the<br />

existing system operational throughout<br />

construction” said Dempsey Thieman,<br />

principal engineer at PND Engineers,<br />

the project designers.<br />

<strong>The</strong> $5 million project, led by<br />

WCC Project Manager Bryce Erickson,<br />

began in February 2010 and continued<br />

through the summer. <strong>The</strong> new hydraulic<br />

system is operated by a remote control,<br />

allowing the operator to stand on the<br />

ramp and have better visibility of the<br />

critical ramp setting process.<br />

With these projects WCC continues<br />

to expand their portfolio of complicated,<br />

unique and successful marine<br />

construction in <strong>Alaska</strong>.<br />

Jessica Bowman is a writer who lives<br />

in Anchorage, <strong>Alaska</strong>.<br />

22 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong><br />

photos: riChard Kr antZ

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 23

CONTRACTORS & THE LAW<br />

Fairbanks wetlands victory<br />

In a June 2010 decision, the <strong>Alaska</strong> Federal District Court<br />

handed a victory to a Fairbanks gravel pit owner over<br />

the Corps of Engineers in its effort to extract $55,000<br />

in exchange for permission to fi ll in part of the gravel pit.<br />

<strong>The</strong> dispute was over the extent of the Corps’ control over<br />

“wetlands,” and turned on the issue of whether the gravel<br />

pit was a wetland “adjacent” to a navigable river. <strong>The</strong> <strong>Alaska</strong><br />

District Court held that the Corps did not have jurisdiction<br />

over the gravel pit that was separated from the Tanana River<br />

by a third of a mile and (1) a berm supporting the <strong>Alaska</strong><br />

Railroad tracks; (2) a drainage channel; and (3) a man-made<br />

levy along the banks of the Tanana.<br />

Background<br />

To fully understand the signifi cance of the push-back<br />

against the Corps represented by this case, a little background<br />

is appropriate. In 1972, Congress enacted the Clear<br />

Water Act which prohibits the discharge of any dredged or<br />

fi ll materials into “navigable waters,” which are defi ned as<br />

“waters of the United States,” unless authorized by a permit<br />

issued by the Corps of Engineers. Traditionally federal jurisdiction<br />

existed over all rivers and streams upon which “a log”<br />

could be fl oated. <strong>The</strong> idea was that if the water body could<br />

support commerce, it was subject to federal jurisdiction.<br />

Initially after the 1972 enactment, the Corps of Engineers<br />

construed the Act to cover only waters that were<br />

“navigable in fact.” Wetlands were not even an issue at that<br />

point. <strong>The</strong>n, an environmental group sued, and a federal<br />

court held that the regulations were too narrow. As a<br />

result, the Corps issued fi nal regulations in 1975 redefi ning<br />

“waters of the United States” to include not only actually<br />

navigable waters, but also tributaries, interstate waters and<br />

their tributaries, non-navigable intra-state waters whose<br />

use or misuse could affect interstate commerce, and “all<br />

freshwater wetlands” that were “adjacent” to other covered<br />

waters. A “freshwater wetland” was defi ned as an area that<br />

was “periodically inundated” [fl ooded] and was “normally<br />

characterized by the prevalence of vegetation that requires<br />

saturated soil conditions for growth and reproduction.” In<br />

other words, if the soils were typically saturated either from<br />

periodic fl ooding or otherwise, it was a wetland, no matter<br />

where it was located nor who owned it. In 1977, the Corps<br />

broadened the defi nition by eliminating the need for periodic<br />

fl ooding.<br />

Following a 1985 U.S. Supreme Court decision that<br />

validated the Corps’ regulation that included “adjacent<br />

wetlands” within the coverage of the Act, the Corps again<br />

By ROBERT J. DI C K S O N<br />

expanded its regulations to create the so-called “Migratory<br />

Bird Rule,” in which the Corps purported to extend its<br />

jurisdiction over any marsh where migratory birds had been<br />

seen, or that an endangered species “would” [not necessarily<br />

did] use as a habitat.<br />

By that time, the Corps defi ned wetlands subject to its<br />

jurisdiction as “wetlands adjacent to [navigable waters]<br />

and tributaries to such waters.” “Adjacent” was defi ned to<br />

mean wetlands that were “bordering, contiguous [to], or<br />

neighboring” navigable waters. Even if wetlands were separated<br />

from navigable waters “by manmade dikes or barriers,<br />

natural river berms, beach dunes and the like,” they were<br />

still “adjacent wetlands.” <strong>The</strong> Corps interpreted its own<br />

regulation to include “ephemeral streams” and “drainage<br />

ditches,” “tributaries” as “waters of the United States” even<br />

though they were dry most or part of the time. In other<br />

words, even streams or drainage ditches that were dry most<br />

of the time were still considered subject to the Corps’ jurisdiction,<br />

and wetlands adjacent to them were also subject to<br />

Corps’ control.<br />

<strong>The</strong> lower federal courts enforced these positions by<br />

holding that “storm sewers,” irrigation ditches and drains<br />

were subject to Corps jurisdiction. Even “dry arroyos<br />

connected to remote waters through the fl ow of ground<br />

water,” and which were in the middle of the desert but<br />

carried waters in a rain, were also considered “adjacent<br />

wetlands.” A “roadside ditch” that took water over a winding<br />

32-mile path to the Chesapeake Bay was considered subject<br />

to Corps jurisdiction.<br />

Between 1985 and 2006, three U.S. Supreme Court cases<br />

interpreted the Corps’ power under the Clean Water Act. In<br />

1985, the U.S. Supreme Court in Riverside Bayview Homes<br />

approved the imposition of Corps control over a low-lying<br />

marsh near the shores of Lake St. Clair in Michigan, a lake<br />

through which the international boundary runs. A developer<br />

was prevented from building homes on 80 acres because the<br />

Corps denied a permit. <strong>The</strong> court held that the land was a<br />

“wetland” because the land was saturated, no matter what<br />

the source of water; and the land was an “adjacent wetland”<br />

because the vegetation that existed on the developer’s land<br />

extended beyond the boundary of the developer’s land all<br />

the way to a creek that was a tributary to a “navigable water<br />

way.” In other words, because the vegetation that defi ned<br />

the “wetland” extended from a tributary of the lake all the<br />

way onto the developer’s land, even though the land did not<br />

abut the tributary creek, the Corps could validly treat the<br />

developer’s land as an “adjacent wetland.”<br />

24 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

Sixteen years later, in 2001, the Court<br />

held that the Corps’ effort to extend<br />

its jurisdiction through its so-called<br />

“Migratory Bird Rule” was invalid. In<br />

that case, several suburban cities and<br />

villages had purchased a 30-year old,<br />

long abandoned gravel pit far removed<br />

from any tributaries to any lake or rivers<br />

to be developed into a non-hazardous<br />

solid waste disposal site. <strong>The</strong> bottom of<br />

the pit had developed seasonal ponds of<br />

varying size which were going to have<br />

to be filled in as part of the landfill site.<br />

Because some migratory birds had been<br />

seen on the site, the Corps denied the<br />

permit. <strong>The</strong> U.S. Supreme Court case,<br />

called SWANCC for Solid Waste Agency<br />

of Northern Cook County, held that<br />

the Clean Water Act did not cover nonnavigable,<br />

isolated, intra-state waters;<br />

and the presence of migratory birds did<br />

not bestow jurisdiction.<br />

Following SWANCC, which undercut<br />

the Corps’ reach substantially, the Corps<br />

remarkably continued on with its regulations<br />

essentially in a “business as usual”<br />

pattern. <strong>The</strong>n in 2006, the U.S. Supreme<br />

Court decided the Rapanos case, in an<br />

opinion by Scalia, Roberts, Thomas and<br />

Alito. Justice Kennedy agreed with the<br />

result in a separate opinion. Justices<br />

Stevens, Souter, Ginsberg and Breyer<br />

dissented.<br />

Four members of the court opined<br />

that the term “navigable waters” under<br />

the Clean Water Act, and thus the extent<br />

of the Corps’ jurisdiction, included<br />

“only relatively permanent, standing or<br />

flowing bodies of water, not intermittent<br />

or ephemeral flows of water;” and<br />

that “adjacent wetlands” under the CWA<br />

included “only those wetlands with a<br />

continuous surface connection to bodies<br />

that are waters of the United States<br />

in their own right.” In other words,<br />

there had to be permanent, continuous<br />

standing or flowing water between the<br />

so-called “adjacent” wetland and the<br />

navigable water, meaning that there had<br />

to be no clear demarcation between the<br />

two to be considered adjacent. Justice<br />

Kennedy adopted a different, looser rule<br />

which he called “the significant nexus”<br />

rule. Nevertheless, even applying his<br />

much looser, “significant nexus” rule,<br />

Kennedy concluded that in that case,<br />

the Clean Water Act did not apply to the<br />

developments in question.<br />

<strong>The</strong> developments in question<br />

involved a site that abutted a manmade<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 25

drain which drained into a creek which<br />

flowed into a river that in turn emptied<br />

into Saginaw Bay and Lake Huron.<br />

<strong>The</strong> other site involved a parcel of land<br />

one mile from Lake St. Claire, along<br />

which a manmade drainage ditch ran,<br />

though a four-foot wide man-made<br />

berm ran between the parcel and the<br />

drainage ditch. <strong>The</strong> berm was impermeable<br />

to water, and therefore blocked<br />

drainage from the parcel, though there<br />

was occasional overflow into the ditch.<br />

<strong>The</strong> ditch emptied into another ditch<br />

that then connected to a creek, which<br />

in turn emptied into Lake St. Claire.<br />

<strong>The</strong> court held that the CWA, and thus<br />

the Corps’ power, did not extend to<br />

these sites.<br />

<strong>The</strong> court expressly excluded sites<br />

where there was only ephemeral or<br />

intermittent flow between the site<br />

and some navigable body of water.<br />

Drainage ditches that were only<br />

intermittently filled with water and<br />

dry otherwise could not be considered<br />

“tributaries” to “waters of the<br />

United States.” <strong>The</strong> simple fact that<br />

there was some “ecological connection”<br />

between the site in question and<br />

the navigable water was not an independent<br />

basis for considering the site<br />

to be “adjacent” to the navigable water.<br />

<strong>The</strong> Corps’ regulations and its interpretations<br />

of its regulations were thus<br />

considered invalid.<br />

Because only four members of the<br />

court adopted the opinion, it is not<br />

considered binding precedent. Because<br />

Kennedy provided the fifth vote needed<br />

to vacate the lower courts’ decisions<br />

favoring the Corps, his “significant nexus”<br />

rule became the “de facto” standard that<br />

is now applied by the lower courts.<br />

<strong>The</strong> Fairbanks Case<br />

Great Northwest had operated<br />

since 1993, an approximately 300 acre<br />

gravel pit near the Fairbanks airport. Its<br />

southern boundary bordered the <strong>Alaska</strong><br />

Railroad tracks which were situated<br />

atop a large berm. On the other side of<br />

the railroad berm was what was referred<br />

to as “Channel A,” which was a drainage<br />

ditch that did not flow regularly. When<br />

it carried water, it flowed in a westerly<br />

direction south of the railroad and on<br />

the other side of the railroad from the<br />

pit. South of the east-west Channel<br />

A was a flood control levee that ran<br />

along the banks of the Tanana. <strong>The</strong><br />

Tanana which ran in a westerly direction<br />

parallel to the pit and was south of<br />

the levee, was about one-third of a mile<br />

from the southern border of the gravel<br />

pit property. Thus between the gravel<br />

pit and the Tanana were (1) the railroad<br />

berm; (2) the sometimes dry Channel A;<br />

and (3) the flood control levee. When<br />

it carried water, Channel A emptied<br />

into the Tanana, past and to the west of<br />

the gravel pit property. Channel A also<br />

caught the southeast corner of the gravel<br />

pit property. Although the Corps took<br />

the position that Channel A ran continuously,<br />

it could never document that and<br />

ultimately admitted that Channel A was<br />

not “a relatively permanent waterway.”<br />

In that sense Channel A was very much<br />

like one of the drainage ditches in the<br />

Rapanos case.<br />

<strong>The</strong> Corps was willing to grant a<br />

permit to Great Northwest to clear land<br />

on 170 acres and to fill in 62 acres of<br />

the pit. But the Corp also required as a<br />

condition to the permit the payment of<br />

$55,000 to be deposited in “the Conser-<br />

26 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

vation Fund,” a fund apparently used by<br />

the Corps for conservation purposes.<br />

Great Northwest objected to the Corps’<br />

exercise of jurisdiction over the pit.<br />

<strong>The</strong> judge held that there was no<br />

question that under the Rapanos opinion<br />

of the plurality of four, the gravel pit<br />

could not be regulated by the Corps. But<br />

because the Rapanos case did not have a<br />

single opinion shared by five justices, the<br />

<strong>Alaska</strong> federal judge had to apply Justice<br />

Kennedy’s “significant nexus” test. Even<br />

applying Kennedy’s “significant nexus”<br />

test, the court concluded that the gravel<br />

pit was not subject to the Corps’ jurisdiction.<br />

A critical fact was that Channel<br />

A did not have year-round surface flow<br />

throughout its length. Thus Channel A<br />

could not be considered a “tributary” to<br />

the Tanana River.<br />

<strong>The</strong> court accepted that the gravel<br />

pit, devoid of vegetation and migratory<br />

birds, was still considered “a wetland”<br />

because apparently it was saturated.<br />

But the court ruled that the Corps had to<br />

either (1) establish a “significant nexus”<br />

between the gravel pit and the Tanana;<br />

or (2) establish that the gravel pit was<br />

“adjacent” to the Tanana River, using the<br />

Corps’ definitions of “adjacent.” Because<br />

the Corps had never conducted a “nexus<br />

assessment” and ultimately admitted<br />

that Channel A did not flow continuously,<br />

there was no “significant nexus”<br />

between the pit and the Tanana. That<br />

left the Corps to argue that the pit was<br />

simply “adjacent” to the Tanana using<br />

the Corps’ own regulations.<br />

Relying on the Corps’ regulations,<br />

the judge concluded that where a<br />

wetland covered by the CWA is separated<br />

from another wetland by a manmade<br />

barrier, the Corps will be able to<br />

exercise jurisdiction over the far wetland<br />

(i.e., making it adjacent) only if the<br />

wetlands on both sides of the barrier are<br />

in continuous contact with each other<br />

such that they can be considered the<br />

same wetland. That was not the case<br />

with Great Northwest’s gravel pit and<br />

the Tanana, and thus the gravel pit was<br />

not adjacent. <strong>The</strong> judge held that the<br />

Corps had no jurisdiction over the pit.<br />

Although the Corps appealed the<br />

District Court’s decision to the Ninth<br />

Circuit in San Francisco, the Corps<br />

dropped its appeal on Feb. 15, <strong>2011</strong>. No<br />

doubt the Supreme Court’s decision in<br />

Rapanos heavily influenced the government<br />

lawyers’ evaluation.<br />

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 27

<strong>The</strong> Significance of the Case<br />

According to the U.S. Fish & Wildlife<br />

Service, 43.3 percent of <strong>Alaska</strong>’s<br />

surface area (more than 403 million<br />

acres including offshore areas studied)<br />

is what it calls wetlands. <strong>The</strong> <strong>Alaska</strong><br />

wetlands account for 63 percent of<br />

the total wetlands and acreage in the<br />

entire United States excluding Hawaii.<br />

Wetlands in the Lower 48 constitute<br />

only 5.2 percent of its surface area.<br />

<strong>The</strong> Fish & Wildlife Service consider<br />

“wetlands” to include forest, bogs and<br />

swamps which are forested with Black<br />

Spruce, muskeg and other substantial<br />

vegetation. More than three-quarters<br />

of the total wetland acreage in <strong>Alaska</strong><br />

is found in the Arctic, Western and Interior<br />

<strong>Alaska</strong> regions, i.e., in the rural and<br />

Bush areas. Only 2.6 million of the total<br />

403 million acres (about one-half of 1<br />

percent), are found in the Cook Inlet,<br />

Susitna lowland areas, i.e., in the southcentral<br />

urban areas. Consequently the<br />

designation of wetlands is far more<br />

important to <strong>Alaska</strong> than it is generally<br />

to the other Lower 48 states.<br />

<strong>The</strong> Corps’ effort to control over<br />

40 percent of the total land surface<br />

of <strong>Alaska</strong>, particularly when an antidevelopment<br />

administration is in office,<br />

therefore carries a far greater adverse<br />

impact on <strong>Alaska</strong>’s economy than similar<br />

restrictions in the Lower 48. <strong>The</strong> local<br />

district court’s decision in this case is a<br />

major setback to the government’s ability<br />

to obstruct responsible and common<br />

sensical urban development. <strong>The</strong> fact<br />

that the Corps dropped its appeal to<br />

the Ninth Circuit leaves the Fairbanks<br />

decision for all practical purposes as<br />

the controlling precedent for all <strong>Alaska</strong><br />

“wetlands.”<br />

This column provides information<br />

about the law to help users competently<br />

cope with their legal needs. But legal information<br />

is not the same as legal advice—<br />

the application of law to an individual’s<br />

specific circumstances. Although we go to<br />

great lengths to ensure accurate and useful<br />

information, we recommend consulting a<br />

lawyer for professional assurance and your<br />

interpretation of a particular situation.<br />

Robert J. Dickson is a partner of the<br />

Anchorage law firm Atkinson, Conway<br />

and Gagnon Inc.<br />

28 <strong>The</strong> <strong>Alaska</strong> conTrAcTor <strong>Spring</strong> <strong>2011</strong>

<strong>Spring</strong> <strong>2011</strong> <strong>The</strong> <strong>Alaska</strong> conTrAcTor 29

MEMBER PROFILE<br />

COWATER ALASKA INC. By BA M B I CH I L D S<br />

Banishing the bucket<br />

Need for sanitary services in rural <strong>Alaska</strong><br />

keeps contractor fl ush with jobs<br />

For many outdoor enthusiasts in <strong>Alaska</strong> a<br />

honey bucket is a mildly offensive and familiar<br />

luxury one appreciates when spending<br />

time in the state’s great outdoors. But for<br />

other <strong>Alaska</strong>ns it is a burdensome fact of life, and<br />

an important necessity. In rural communities residents<br />

operate daily without the benefi t of fl ushing<br />

toilets, running tap water or private and sanitary<br />

bathing areas. <strong>The</strong> permafrost-ridden terrain and<br />

low temperatures in many of the state’s remote<br />

locations simply will not allow for a traditional<br />

sewage system, with its underground piping and<br />

septic tanks.<br />

After realizing the need for a system that could<br />

withstand the challenging conditions of <strong>The</strong> Last<br />

Frontier, Mark Baron, as president of Cowater<br />

<strong>Alaska</strong> Inc., partnered with the <strong>Alaska</strong> Village Safe<br />

Water Program, the <strong>Alaska</strong>n Native Tribal Health<br />

Consortium, and the Department of Environmental<br />

Conservation to create the Flush Tank and Haul<br />

(FTH®) system.<br />

Cowater <strong>Alaska</strong>, an offshoot<br />

of Cowater International, developed<br />

a system that embraces<br />

the challenges of the Arctic and<br />

introduced the Flush Tank and<br />

Haul System® in 1989 on the<br />

island of Mekoryuk, in southwest<br />

<strong>Alaska</strong>.<br />

“<strong>The</strong> community of Mekoryuk<br />

was willing to try a prototype<br />

in the city hall for one year<br />

before moving onto residential,”<br />

said James Patterson, a P.E.,<br />

project administrator (retired) for<br />

the Village Safe Water Program.<br />

Residents welcomed<br />

Cowater <strong>Alaska</strong> into their<br />

community to test, install and<br />

eventually develop the system<br />

into what it is today. In doing<br />

this, the company encountered<br />

and defeated many obstacles<br />

but it was the permafrost that<br />

presented the biggest challenge.<br />

“With the melting and freezing of the permafrost,<br />

comes sinking and heaving of the ground. Sewage<br />

systems are constantly submitted to relative movement<br />

which destroys traditional piped systems,” said<br />

Tim Allen, general manager of Cowater <strong>Alaska</strong>.<br />

Sewage holding tank installation<br />

30 <strong>The</strong> <strong>Alaska</strong> CONTRACTOR <strong>Spring</strong> <strong>2011</strong><br />

PHOTOS: COURTESY OF CO W A T E R ALASKA<br />

GRAPHIC: COURTESY OF CO W A T E R ALASKA

ANTHC workshop, in Kwigillingok, used for<br />

storage and fabrication.<br />

To address the issue of relative<br />

movement, necessary connections on<br />

the FTH® are above ground where a<br />

sewage holding tank can hold approximately<br />

120 gallons of waste. <strong>The</strong> tank<br />

is heavily insulated to withstand<br />

extreme temperatures and is mounted<br />

off the ground to minimize thawing<br />

and freezing of the permafrost. Once<br />

the tank is full, resident haul operators<br />

use a pump to transfer waste into<br />

a tank, which is then hauled to a pump<br />

station or sewage lagoon via fourwheeler<br />

or snowmachine. <strong>The</strong> blower<br />

pump, exclusive to Cowater <strong>Alaska</strong>, is a<br />

vacuum apparatus rather than a liquid<br />

pump and stays functional through<br />

<strong>Alaska</strong>’s harsh winters. “<strong>The</strong>se blower<br />

pumps operate well in -40ºF temperatures<br />

because they move air rather than<br />

liquid. <strong>The</strong> colder and more dense the<br />

air, the greater the vacuum and better<br />

system performance,” Allen said.<br />

Water conservation is also an important<br />

feature of these systems. Since rural<br />

<strong>Alaska</strong>ns have to haul or catch their<br />

potable water, using less is mandatory.<br />

So Cowater <strong>Alaska</strong> and affiliates<br />

conducted a survey to determine the<br />

amount of water residents could use<br />

each day. <strong>The</strong> results showed that three<br />

gallons is all that can be afforded, so to<br />

work with this extremely low amount,<br />

the FTH® uses a “pint flush” toilet<br />

which is designed to use a minimal<br />

amount of water.<br />

Cowater <strong>Alaska</strong>, a member of AGC<br />

of <strong>Alaska</strong> since 2003, is proud of the<br />

environmental rewards of the FTH®.<br />

<strong>The</strong>re is no digging with this completely<br />

above ground design which helps keep<br />