The Alaska Contractor - Summer 2008

The Alaska Contractor - Summer 2008

The Alaska Contractor - Summer 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8005 Schoon St.<br />

Anchorage, AK 99518<br />

(907) 561-5354<br />

Fax: (907) 562-6118<br />

www.agcak.org<br />

<br />

Dick Cattanach<br />

Margaret Empie<br />

Roger Hickel<br />

Mary Killorin<br />

John MacKinnon<br />

Brook Mayfield<br />

Vicki Schneibel<br />

George Tuckness<br />

Lyn Whitley<br />

8537 Corbin Dr.<br />

Anchorage, AK 99507<br />

(907) 562-9300<br />

Fax: (907) 562-9311<br />

Toll Free: (866) 562-9300<br />

www.AQPpublishing.com<br />

<br />

Robert R. Ulin<br />

<br />

Heather A. Resz<br />

<br />

Susan Harrington<br />

<br />

Karen Copley<br />

<br />

Justin Ritter<br />

<br />

Clem E. Mewmaw<br />

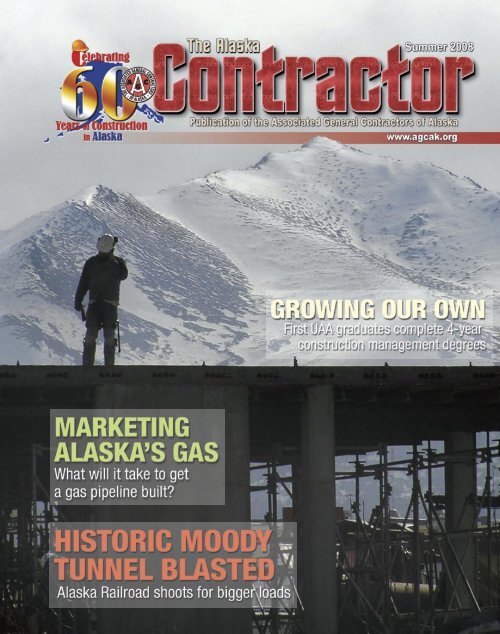

On the cover:<br />

AGC member Graff Contracting LLC<br />

poured the concrete for the new<br />

Crown Plaza Hotel on the corner of<br />

International Airport Road and<br />

C Street in Anchorage.<br />

<br />

<br />

<strong>The</strong> Official Publication of the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong><br />

<br />

Table of Contents<br />

<br />

by John MacKinnon<br />

by Tracy Kalytiak<br />

by Eowyn LeMay Ivey<br />

by Heather A. Resz<br />

by Tracy Kalytiak<br />

by Tracy Kalytiak<br />

by Heather A. Resz<br />

by Rob Stapleton<br />

by Heather A. Resz<br />

by Patricia Liles<br />

by Patricia Liles<br />

by Nancy Erickson<br />

Photo essay<br />

by Heidi Bohi<br />

by Ginger Cooley<br />

by U.S. Sen. Lisa Murkowski<br />

<br />

by Brook Mayfield<br />

<br />

by Heidi Bohi<br />

by Heidi Bohi<br />

by Nancy Pounds<br />

by Heather A. Resz<br />

by Victoria Naegele<br />

<br />

<br />

by Roger Hickel<br />

by John MacKinnon<br />

by John MacKinnon<br />

by Larry Wilson<br />

<br />

<br />

<br />

by Robert Cress<br />

by Robert J. Dickson<br />

by Rep. Craig Johnson<br />

<br />

<br />

Senior Editor Note<br />

<strong>The</strong> <strong>Alaska</strong> Supreme Court<br />

granted a joint motion to dismiss<br />

all appeals to Clean Water 1 on<br />

June 9. According to a press release<br />

from Lt. Gov. Sean Parnell’s<br />

office, the court’s action means<br />

the initiative will not appear on the<br />

Aug. 26 ballot, in accordance with<br />

a lower court ruling by Judge Blankenship<br />

in a Fairbanks case. <strong>The</strong><br />

Supreme Court was scheduled<br />

to hear oral arguments on the<br />

remaining water initiative – Ballot<br />

Measure 4 – on June 16.

Category January<br />

February<br />

March<br />

April<br />

May<br />

June<br />

July<br />

August<br />

September<br />

October<br />

November<br />

December<br />

Total<br />

Building<br />

Military<br />

Other<br />

Trans<br />

Low Bids for <strong>2008</strong><br />

TOTAL<br />

<br />

RUSSIAN MISSION K-12<br />

REPLACEMENT SCHOOL<br />

$22,200,000.00<br />

SKW/Eskimo Inc.<br />

RUSSIAN MISSION K-12 SCHOOL RE-BID<br />

$20,832,900.00<br />

Bering Pacific Construction<br />

ATKA AIRPORT RUNWAY<br />

EXTENSION/RESURFACE<br />

$17,956,915.00<br />

Brice Inc.<br />

ST MARY SCHOOL COMPLEX RENOVATION<br />

$14,296,461.00<br />

Mantech Mechanical Inc.<br />

BETHEL AIRPORT IMPROVEMENTS<br />

PHS 3 STAGE 2<br />

$9,743,265.00<br />

Knik Construction Co. Inc.<br />

KAKTOVIK WARM STORAGE BUILDING<br />

$8,076,000.00<br />

Kaktovik Constructors<br />

POINT LAY WARM STORAGE BLDG<br />

$7,442,000.00<br />

SKW/Eskimo Inc.<br />

KIPNUK/KWIGILLINGOK<br />

WATERSORAGE PORJECTS<br />

$6,775,000.00<br />

Bering Pacific Construction<br />

BETHEL YUUT ELITNAURVIAT<br />

TESS COMPLETION<br />

$4,913,900.00<br />

TBI Construction Co.<br />

DILLINGHAM HOSPITAL NEW BOILER<br />

PLANT FACILITY<br />

$4,835,116.00<br />

F & W Construction Co. Inc.<br />

KING SALMON AIRPORT IMPROVEMENTS<br />

$4,751,265.00<br />

Knik Construction Co. Inc.<br />

ATMAUTLUAK ALEXIE SCHOOL<br />

WASTEWATER TREATMENT FACILITY<br />

$4,570,000.00<br />

SKW/Eskimos Inc.<br />

$14,629,542.45 $96,819,173.00 $72,830,508.83 $34,641,707.66 $20,799,578.50<br />

$0.00 $0.00 $14,394,350.00 $195,858.00 $76,600.00<br />

$7,268,077.22 $3,299,783.22 $30,616,160.80 $54,813,210.56 $25,601,215.47<br />

$16,462,545.97 $2,311,158.00 $57,717,618.89 $66,462,654.08 $80,942,828.11<br />

KOTZEBUE FRONT ST WATER<br />

LOOP IMPROVEMENTS<br />

$3,696,040.00<br />

Drake Construction<br />

NOME WARM STORAGE BUILDING<br />

$2,476,587.00<br />

Pro West <strong>Contractor</strong><br />

BETHEL WATERFRONT IMPROVEMENT<br />

$1,938,000.00<br />

Ridge Contracting Inc.<br />

BETHEL UAF KUSKOKWIM CAMPUS<br />

SIDING/ROOFING<br />

$1,594,000.00<br />

Concor Construction Inc.<br />

EKWOK AIRPORT SNOW REMOVAL<br />

EQUIPMENT BLDG<br />

$1,228,450.00<br />

Pro West <strong>Contractor</strong>s<br />

DALTON HIGHWAY MP334.5 HAPPY<br />

VALLEY STOCKPILE<br />

$1,097,000.00<br />

Cruz Construction<br />

NOME FRONT STREET STORM DRAIN<br />

IMPROVEMENTS<br />

$1,057,500.00<br />

QAP<br />

<br />

AK ALASKA HIGHWAY<br />

MP-1267-MP1314 REHAB<br />

$18,961,688.50<br />

Great Northwest Inc.<br />

RICHARDSON HWY MP267-MP276 REHAB<br />

$3,638,047.75<br />

HC <strong>Contractor</strong>s Inc.<br />

DENALI PARK ROAD 4 MILE SLUMP/<br />

AUFEIS SECTION<br />

$2,401,807.70<br />

D & L Construction LLC<br />

ESTER FSA FIRE STATION ADDITION<br />

$1,481,954.00<br />

Chugach Industries Inc.<br />

NORTH POLE MS TRAFFIC SAFETY/SITE<br />

UPGRADE<br />

$1,270,000.00<br />

Great Northwest Inc.<br />

DELTA JUNCTION <strong>2008</strong> ROAD SURFACING<br />

$1,015,582.00<br />

HC Contracting Inc.<br />

<br />

ANCH AIA T/W RELO/RECONSTRUCT<br />

$18,991,930.00<br />

QAP<br />

ELMENDORF 176TH ANG PARARESCUE<br />

OPS FAC<br />

$15,263,800.00<br />

ASRC Construction Inc.<br />

ELMENDORF AIRCRAFT<br />

MAINTENANCE COMPLEX<br />

$14,394,350.00<br />

Alcan General Inc.<br />

ANCH GAMBELL ST/AIRPORT HEIGHT<br />

RECONSTRUCTION<br />

$13,602,690.40<br />

<strong>Alaska</strong> Interstate Construction LLC<br />

ANCH 80TH/72ND/SPRUCE ST/LORE ROAD<br />

UPGRADES<br />

$10,991,576.00<br />

QAP<br />

EAGLE RIVER LOOP ROAD<br />

REHABILITATION<br />

$10,612,237.65<br />

Wilder Construction Co. Inc.<br />

PALMER OLD GLENN HWY<br />

REHAB/CHANNELIZATION<br />

$9,884,337.53<br />

Pruhs Corp.<br />

ANCH UAA PARKING<br />

GARAGE/AMENITY BLDG<br />

$9,757,000.00<br />

Roger Hickel Contracting Inc.<br />

ANCH E STREET COORIDOR<br />

ENHANCEMENTS PHS I<br />

$9,006,690.50<br />

Construction Unlimited Inc.<br />

$38,360,165.64 $102,430,114.22 $175,558,638.52 $156,113,430.30 $127,422,222.08 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00<br />

$239,720,510.44<br />

$14,668,808.00<br />

$121,598,447.27<br />

$223,896,805.05<br />

$599,884,570.76

HOMER WATER TREATMENT PLANT<br />

PROJECT<br />

$8,639,359.00<br />

Udelhoven Oilfield Systems Service<br />

ANCH 100TH/POINTE RESOLUTION/<br />

VICTOR RD REHAB/UPGRADES<br />

$6,601,406.40<br />

Annette’s Trucking Inc.<br />

ANCH CHESTER CRK AQUATIC<br />

ECOSYSTEM RESTORATION<br />

$5,864,668.28<br />

Hamilton Construction<br />

ANCH BAYSHORE SUBDIVISION AREA<br />

RECONSTRUCT RID<br />

$5,308,488.60<br />

<strong>Alaska</strong> Frontier Services LLC<br />

CORDOVA AIRPORT IMPROVEMENTS<br />

STAGE I<br />

$4,698,412.00<br />

Swanson General <strong>Contractor</strong>s<br />

CHUGIAK S BIRCHWOOD LP SEWER<br />

IMPROVE<br />

$4,060,331.00<br />

Pruhs Corp.<br />

ANCH CREEKSIDE TOWN CENTER ROAD<br />

IMPROVEMENT<br />

$3,299,592.64<br />

Neeser Construction Inc.<br />

ANCH TOWN/COUNTRY ESTATES STREET<br />

RID/RECONSTRUCT<br />

$2,804,425.00<br />

Annette’s Trucking Inc.<br />

ANCH RESIDENTIAL SOUND INSULATION<br />

PACK 10<br />

$2,437,151.00<br />

Koch Corp.<br />

ANCH MERRILL FIELD REHAB BLOCK 5<br />

PHS III<br />

$2,034,046.00<br />

AIC <strong>Alaska</strong> Interstate Construction LLC<br />

WASILLA HIGH SCHOOL REMODEL PHS III<br />

$1,750,000.00<br />

Pinnacle Construction<br />

WASILLA MIDDLE SCHOOL CAFETERIA<br />

ADDITION<br />

$1,692,122.00<br />

CYS Management Services Inc.<br />

ANCH G/H ALLEY 10TH/13TH WATER<br />

UPGRADES<br />

$1,365,628.00<br />

Tam Construction Inc.<br />

ANCH SAN ERNESTO WATER/SEWER<br />

UPGRADES<br />

$1,293,486.00<br />

North Star Paving & Construction Inc.<br />

ANCH 58TH/ARCTIC/SILVERADO WAY RID<br />

RECONSTRUCT<br />

$1,245,299.00<br />

Roger Hickel Contracting Inc.<br />

ANCH UAA JOINT PSYCHOLOGY<br />

RENOVATION<br />

$1,163,000.00<br />

SR Bales Construction Inc.<br />

<br />

JUNEAU HARBORVIEW ELEMENTARY<br />

RENOVATION<br />

$16,543,421.00<br />

McGraw’s Custom Construction<br />

HAINES FERRY TERMINAL/UNION ST<br />

$12,910,339.10<br />

Southeast Road Builders<br />

JUNEAU GLACIER VALLEY ES RENO PHS II<br />

$11,497,000.00<br />

Dawson Construction Inc.<br />

PETERSBURG MITKOF HWY UPGRADE<br />

PHS II/ISLAND PAVING<br />

$5,987,248.00<br />

SECON Inc.<br />

SKAGWAY COMMUNITY HEALTH CLINIC<br />

$5,930,000.00<br />

Dawson Construction Inc.<br />

YAKUTAT MULTI PURPOSE DOCK<br />

$5,802,000.00<br />

West Construction Co. Inc.

JUNEAU LOWER BASIN ROAD<br />

RECONSTRUCTION<br />

$5,516,324.00<br />

Arete Construction Corp.<br />

THORNE BAY SEA LEVEL ROADS<br />

$4,624,746.00<br />

Southeast Road Builders<br />

SITKA AIRPORT ACCESS IMPROVEMENTS<br />

$3,856,912.00<br />

S & S General <strong>Contractor</strong>s<br />

JUNEAU THUNDER MOUNTAIN HS TRACK/FIELD<br />

$3,482,680.00<br />

Miller Construction Equipment Sales<br />

HOONAH MARINE INDUSTRIAL CENTER PHS III<br />

$3,011,500.00<br />

Kelly Ryan Inc.<br />

ZAREMBO ISLAND BAHT ROADS<br />

$2,858,190.00<br />

Ketchikan Ready Mix & Quarry Inc.<br />

HAINES YOUNG ROAD IMPROVEMENTS/WATER<br />

TANK<br />

$1,700,000.00<br />

Southeast Earthmovers Inc.<br />

JUNEAU MENDENHALL VALLEY SEWER LID 98 PHS I<br />

$1,631,892.00<br />

Southeast Earthmovers Inc.<br />

ACTIVITY<br />

Highway<br />

$500,000,000<br />

$500,000<br />

$450,000<br />

$400,000<br />

$350,000<br />

$300,000<br />

$250,000<br />

$200,000<br />

$150,000<br />

$100,000<br />

$50,000<br />

$500,000<br />

$450,000<br />

$400,000<br />

$350,000<br />

$300,000<br />

$250,000<br />

$200,000<br />

$150,000<br />

$100,000<br />

$50,000<br />

$1,200,000,000<br />

$1,000,000,000<br />

$800,000,000<br />

$600,000,000<br />

$400,000,000<br />

$450,000,000<br />

$200,000,000<br />

$400,000,000<br />

JANUARY<br />

JANUARY<br />

JANUARY<br />

$350,000,000<br />

WRANGELL SCHOOLS RENOVATION PHS II<br />

$1,460,000.00<br />

McGraw’s Custom Construction<br />

JUNEAU SOB PARKING GARAGE<br />

LEVEL 4 UPGRADE<br />

$1,389,850.00<br />

McGraw’s Custom Construction<br />

JUNEAU EAGLECREST CHAIRLIFT/ACCESS RD.<br />

$1,282,400.00<br />

Arete Construction Corp.<br />

JUNEAU NORTH DOUGLAS SEWER PHS III LID<br />

95<br />

$1,204,452.00<br />

Miller Construction Equipment Sales<br />

JUNEAU CAPITOL FIRE<br />

ALARM/SPRINKLER SYSTEM<br />

$1,045,000.00<br />

McGraw’s Custom Construction<br />

<br />

SHAKWAK HWY PERMAFROST TEST<br />

SECTIONS<br />

$1,948,290.00<br />

Golden Hill Ventures Ltd.<br />

<br />

FEBRUARY<br />

FEBRUARY<br />

FEBRUARY $300,000,000<br />

<br />

$250,000,000<br />

MARCH<br />

<br />

MARCH<br />

<br />

MARCH<br />

$200,000,000<br />

APRIL<br />

APRIL<br />

APRIL $150,000,000<br />

MAY<br />

MAY<br />

$100,000,000<br />

MAY<br />

$50,000,000<br />

JUNE<br />

JUNE<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

$-0<br />

2004<br />

2005<br />

2006<br />

2007<br />

<strong>2008</strong><br />

JUNE<br />

JULY<br />

JULY<br />

building<br />

JULY $450,000,000<br />

AUGUST<br />

AUGUST<br />

$400,000,000<br />

AUGUST<br />

$350,000,000<br />

SEPTEMBER<br />

SEPTEMBER<br />

SEPTEMBER<br />

$300,000,000<br />

OCTOBER<br />

OCTOBER<br />

OCTOBER $250,000,000<br />

NOVEMBER<br />

NOVEMBER<br />

$200,000,000<br />

NOVEMBER<br />

$150,000,000<br />

DECEMBER<br />

DECEMBER<br />

DECEMBER<br />

$100,000,000<br />

$50,000,000<br />

$-0<br />

2004<br />

2005<br />

2006

PRESIDENT’S MESSAGE<br />

New issues face industry<br />

I’d like to review some of the highlights of my first six months<br />

as your AGC Chapter President. So far it has been an educational<br />

and interesting time. I’ve had the opportunity to attend<br />

the Western Chapters Conference in February, the National Convention<br />

in March and the National and Chapter Leadership Conference<br />

in Washington, D.C., in April. At these events I’ve met with<br />

numerous construction professionals and attended many sessions<br />

regarding issues challenging our industry. Collectively our industry<br />

is trying to improve its image. We need to refer to our construction<br />

managers as “professionals.” Architects and engineers are referred<br />

to as professionals and many construction managers have degrees<br />

that are no less important than theirs. Our many years of practical<br />

experience add incredible value to a project. Some important new<br />

issues relating to our industry are as follows.<br />

AGC’s Contracts and Construction Law Area provides a single<br />

source for construction contract knowledge for all building methods.<br />

AGC is one of the key organizations in ConsensusDOCS,<br />

which has 21 participating organizations that represent designers,<br />

owners, contractors, subcontractors and sureties. <strong>The</strong> groups<br />

worked together to draft contracts that are in the best interests of<br />

the project, rather than representing only one association’s constituency.<br />

<strong>The</strong> unprecedented buy-in for these contracts reflects<br />

a genuine effort to identify and employ best practices to better<br />

the industry. American Institute of Architects chose not to participate<br />

in ConsensusDOCS. AGC endorses ConsensusDOCS<br />

and we hope that they will replace AIA documents, which have<br />

dominated the industry for many years. We also hope that public<br />

agencies and private owners will revise their contracts to incorporate<br />

many provisions contained in ConsensusDOCS. For the<br />

first time AGC has not endorsed the new versions of the AIA<br />

documents because they are shifting an unreasonable amount of<br />

risk from the designers and owners to the contractor. Please visit<br />

the AGC Web site for free samples.<br />

Building Information Modeling, “BIM,” is the process of generating<br />

and managing a building information model through the<br />

use of three-dimensional, intelligent design information. Technology<br />

improvements and integration fostered by expanded use<br />

of BIM are dramatically increasing efficiency in the industry. <strong>The</strong><br />

U.S. Army Corp of Engineers recently adopted the Bentley platform<br />

as its standard. <strong>The</strong>re are several other competing platforms<br />

in the industry. BIM is not only beneficial for contractors who are<br />

trying to coordinate many disciplines in a confined space but it is<br />

also useful after occupancy for facility management and maintenance.<br />

Recently AGC added the Building Information Modeling<br />

Addendum to the ConsensusDOCS comprehensive catalog of<br />

contracts and forms, which address all project delivery methods.<br />

This addendum is the first and only industry standard document<br />

ROGER HICKEL<br />

President<br />

to globally address the legal uncertainties associated with using<br />

BIM. <strong>The</strong> BIM Addendum further establishes ConsensusDOCS’<br />

reputation as a leader in innovative construction contracts.<br />

Environmental issues are continually challenging contractors.<br />

It’s no coincidence that the largest office buildings in<br />

Washington, D.C., are occupied by the Environmental Protection<br />

Agency. Federal environmental policies seek to minimize and<br />

mitigate the environmental footprint of the construction process.<br />

Meeting environmental requirements has become a huge and<br />

growing responsibility for contractors, delaying if not threatening<br />

construction projects, and increasing the cost of doing business.<br />

To minimize the environmental barriers to business opportunities,<br />

environmental policies must be reasonable and achievable.<br />

AGC has partnerships with the U.S. Environmental Protection<br />

Agency and with the International Erosion Control Association.<br />

Our local chapter is very active in training Certified Erosion Sediment<br />

Control Leads, “CESCL.” We also have information on how<br />

to write and implement a SWPPP plan.<br />

Another environmental issue is the National Clean Diesel<br />

Campaign. So far it is voluntary, but the state of California is trying<br />

to make it mandatory in California. Federal and state agencies<br />

have had a tendency to adopt stricter California regulations<br />

in the past. Did you know that a 175 horsepower bulldozer emits<br />

as much particulate matter as 500 cars? <strong>The</strong> U.S. Environmental<br />

Protection Agency currently has available nearly $50 million<br />

in grant funding to reduce emissions from diesel engines nationwide,<br />

including those used in exiting fleets of construction<br />

equipment. <strong>The</strong>se funds are only available for voluntary compliance<br />

and not available for meeting new state or federal agency<br />

requirements. Visit the AGC Web site for more information.<br />

Another important issue facing our industry, especially in the<br />

southern states, is immigration reform. What is important to all<br />

contractors is the pending legislation that puts the burden of enforcement<br />

on employers and increases the penalties to $16,000<br />

for multiple violations. <strong>The</strong> Department of Homeland Security is<br />

expected to rule this year to amend the Federal Acquisition Regulations<br />

to require that contractors and subcontractors use the E-<br />

Verify system to verify immigration status of employees, not just on<br />

federal funded contracts but on the contractor’s entire workforce.<br />

<strong>The</strong>re are so many new regulations and requirements<br />

placed on contractors every day. Remember how much easier<br />

it was to build 10, 20 or 30 years ago? I often wonder why we<br />

do not value these new regulations and requirements in our<br />

bids. Does the added risk really justify working at margins that<br />

are historically lower than what they were 10 years ago? We all<br />

know that contractors are plagued by being very optimistic and<br />

competitive by nature!

EXECUTIVE DIRECTOR’S MESSAGE<br />

We all want clean water<br />

Voters in the primary election this August may still have<br />

the chance to offer their opinion on “<strong>The</strong> Clean Water<br />

Initiative.” Put forward by the Anchorage-based and nationally<br />

financed Renewable Resources Coalition, purportedly<br />

to protect the salmon runs of Bristol Bay, petitioners cleverly<br />

captured the attention of signers by characterizing the initiative<br />

as an effort to guarantee “clean water.” Consequently, they<br />

turned in more than 60,000 signatures.<br />

If passed, the initiative would override existing state and<br />

federal environmental requirements and scientific review of<br />

mine operations. It would prohibit storage or disposal of metallic<br />

mineral mining wastes and tailings on land and water. If<br />

neither land nor water can be used, then mining is impossible<br />

– just about anywhere in our state.<br />

Obviously, the coalition hopes <strong>Alaska</strong>ns won’t read beyond<br />

the title to learn what the initiative really means to our state.<br />

In truth, the initiative is an effort to stop the Pebble Mine from<br />

advancing to the extensive, exhaustive and lengthy permitting<br />

process. If passed by voters in August, it will have the effect of<br />

saying, “Stop now, do not proceed to permitting.”<br />

Many believe Pebble should be allowed to go through the<br />

regulatory process. Although all the rules and regulations that<br />

are currently on the books can safeguard the public’s interest in<br />

protecting the environment and the valuable fisheries resources<br />

of the region, the project must pass numerous tests and meet<br />

detailed requirements before it obtains the approvals necessary<br />

to operate. And for this particular project, the level of scrutiny to<br />

pass these tests will be done with a microscope. If Pebble can’t<br />

pass muster it will not and should not be allowed to go forward<br />

– but like every project, it deserves a chance to pass the test.<br />

Not every proposed mine gets developed through production.<br />

<strong>The</strong> list of prospects that began but never finished the<br />

arduous process of permitting and environmental compliance<br />

includes some big names.<br />

In the 1970s, U.S. Borax spent hundreds of millions of dollars<br />

on the Quartz Hill molybdenum deposit near Ketchikan. Borax<br />

even got approval from Congress for a marine tailings disposal<br />

in the deep waters of Wilson Arm. <strong>The</strong> claims have since become<br />

an in-holding in one of the many <strong>Alaska</strong> National Interest<br />

Land Claims Act Conservation Units that blanket <strong>Alaska</strong>.<br />

Echo Bay Mines spent more than $100 million trying to reopen<br />

the historic A-J mine in Juneau only to pull the plug because<br />

environmental compliance affected the project’s feasibility.<br />

In northern Southeast <strong>Alaska</strong>, Coeur d’Alene Mines has<br />

invested some $270 million in the Kensington gold mine and<br />

constructed a complete facility in a valley that had a handful of<br />

JOHN MACKINNON<br />

Executive Director<br />

mining operations 100 years ago. <strong>The</strong>y have yet to pour a single<br />

bar of gold because environmental groups sued over their previously<br />

permitted tailings disposal plan.<br />

If this initiative passes, every proposed large-scale mining<br />

operation in <strong>Alaska</strong> will be at risk. <strong>The</strong> targeted Pebble project<br />

could not move forward and Donlin Creek gold project would<br />

likely come to a screeching halt.<br />

If the initiative passes, the unintended consequences (are<br />

they really unintended?) are that all existing mining operations<br />

in <strong>Alaska</strong> would have to cease. Although the folks at the Renewable<br />

Resources Coalition say this will not affect existing permitted<br />

large-scale mines – that is not true. <strong>The</strong> lifecycle of every mine<br />

consists of a continuous process of permitting, amending permits,<br />

re-permitting and compliance with a myriad of ever-changing<br />

laws and regulations. <strong>The</strong> permitted mine of today will be applying<br />

for new permits tomorrow. Existing mines like Greens Creek, Red<br />

Dog, Fort Knox and Pogo would soon fall under the requirements<br />

of the Initiative. In the hands of a zealous regulator (not even an<br />

overzealous regulator) this new law, if passed, could even impact<br />

sand and gravel operations, which by definition, are mining.<br />

<strong>The</strong> initiative as written prohibits any discharge or potential<br />

discharge of “toxic pollutants” into any groundwater, surface<br />

water or stream. It’s not just major streams, but every tributary<br />

to every stream that may be used for human consumption or<br />

support salmon for survival or propagation. That sounds like<br />

just about every stream to me.<br />

Looking at the list of chemicals defined in the initiative as<br />

“toxic pollutants” one notices a long list – benzene, carbon tetrachloride,<br />

dieldrin, DDT, PCBs – to name a few of the more common<br />

and pronounceable ones. <strong>The</strong>se are already highly regulated,<br />

and who would argue with preventing their discharge and<br />

release into our water? I certainly don’t want them in my water.<br />

Also on the list of “toxic pollutants” are metals, such as silver,<br />

lead, nickel, copper and zinc. Natural waters contain many<br />

of these trace metals. <strong>The</strong>se metals are also found in the outfalls<br />

of most municipal sewage treatment plants. Fortunately, municipal<br />

sewage systems don’t involve mining or the initiatives<br />

could jeopardize them, too.<br />

We all want clean water. This initiative is not about clean<br />

water; it is aimed at stopping one proposed mine and would<br />

impact many more. <strong>Alaska</strong>’s exemplary record of responsible<br />

development and stewardship of our lands and resources is the<br />

envy of every other state and unequaled anywhere in the world.<br />

In <strong>Alaska</strong>, we have worked very hard over the past few years<br />

to hang out the sign that says “We’re Open for Business.” Why<br />

turn out the lights on that sign now?

Associated General <strong>Contractor</strong>s of <strong>Alaska</strong><br />

<strong>2008</strong> Legislative Session Report<br />

In mid-February, AGC made a trip to the Capitol<br />

as part of its annual “Legislative Fly-In” to discuss<br />

issues of importance with the <strong>Alaska</strong> Legislature.<br />

By JOHN MACKINNON, Executive Director<br />

<br />

Integral to this effort were more than 22 AGC members<br />

who made the trip on their own time and expense to<br />

participate in the process. During the two-day event,<br />

<br />

we split into teams, met with almost all 60 legislators,<br />

shared a reception with the <strong>Alaska</strong> Trucking Association<br />

and the <strong>Alaska</strong> Miners Association, and met with Gov.<br />

Sarah Palin. As has been AGC policy, we brought with<br />

us just three of the most important issues facing our<br />

members and the state.<br />

Our top three<br />

Gas line contract – <strong>Alaska</strong> can’t afford to delay this<br />

project any longer while a perfect contract is produced.<br />

A good contract timely executed is better than the best<br />

<br />

contract never executed. As this is being written, the<br />

Legislature is getting ready to go into special session<br />

to consider the TransCanada proposal under the <strong>Alaska</strong><br />

Gasline Inducement Act and the Denali Project brought<br />

by BP and Conoco Phillips. <strong>The</strong>y do not have an easy<br />

task ahead of them.<br />

A state funded transportation program – <strong>The</strong> current<br />

transportation infrastructure of <strong>Alaska</strong> is inadequate<br />

and requires continued planning, upgrades and expenditures<br />

to assure the citizens of <strong>Alaska</strong> are provided with<br />

essential services. To address its needs and realize its<br />

potential, <strong>Alaska</strong> needs a transportation program that is<br />

adequately and predictably funded, provides continuity<br />

between succeeding administrations and considers all<br />

modes of transportation.<br />

<strong>The</strong> Associated General <strong>Contractor</strong>s of <strong>Alaska</strong> supported<br />

the establishment of the governor’s $1 billion<br />

Transportation Endowment Trust Fund as a “good start,”<br />

but only if there were assurances of future deposits into<br />

the trust so that it could support an annual construction<br />

program of at least $250 million. As an alternate, if it were<br />

to be only funded as proposed, we suggested the fund<br />

spend down like an annuity over the next 10 years to address<br />

the important transportation needs that are here<br />

and now. <strong>The</strong>re was a healthy debate and the bill did not<br />

advance for passage, but the good news is the Legislature<br />

is very cognizant of the pressing transportation needs in<br />

<strong>Alaska</strong>. <strong>The</strong>y built upon the original capital budget and<br />

constructed a healthy list of good projects dealing with<br />

congestion improvements and deferred maintenance<br />

that the governor approved in her signing the bill.<br />

Funding for vocational/technical education – <strong>The</strong><br />

AGC and its partners have long worked for increased<br />

funding for vocational training at the secondary level<br />

and an emphasis at the post-secondary level to capture<br />

those who did not receive such training. For the<br />

last several years we have been successful. In 2006 and<br />

2007, the Legislature took the initial steps to address the<br />

problem and funded a pilot program at the King Career<br />

Center in Anchorage, and then expanded to five similar<br />

programs in other urban areas. Initially, these funds<br />

were in the capital budget and had to be secured every<br />

year. This year the Legislature moved the $3.5 million to<br />

the operating budget, which is a clear recognition that<br />

it is an ongoing program. <strong>The</strong> program represents a true<br />

public/private partnering effort and initial indications<br />

are that the model will help address the long-term labor<br />

needs of the construction industry.<br />

Other bills in the works that were of concern to the<br />

AGG were:<br />

House Bill 2/Senate Bill 124 – vocational education<br />

– In the last two days of the regular legislative<br />

session, these two bills regarding vocational education<br />

were melded into one. Senate Bill 124 was stuck in the<br />

House Finance Committee with no prospect of further<br />

action. HB 2, which established a vocational education<br />

fund and its beneficiaries, was in Senate Finance. SB 124<br />

increased the percentage of wages employees contribute<br />

for the <strong>Alaska</strong> technical and vocational education<br />

program from 0.01 percent to 0.015 percent. <strong>The</strong> Senate<br />

Finance Committee amended HB 2 to included SB 124<br />

and changed the program beneficiaries. <strong>The</strong> governor<br />

signed the bill May 28.<br />

HB 61 – voc ed tax relief – Beginning Jan. 1, 2009,<br />

businesses can get a credit against state taxes for cash

contributions to high school and state operated vocational<br />

education programs. A 50 percent tax credit is available<br />

on donations up to $100,000. Donations between<br />

$100,000 and $200,000 are given 100 percent tax credit.<br />

<strong>The</strong> maximum credit is $150,000. <strong>The</strong> governor signed<br />

the bill May 28.<br />

HB 314 – general obligation bond package – <strong>The</strong><br />

governor’s original general obligation bond bill grew from<br />

$220.6 million to $315.05 million after moving through<br />

the Senate. This was one of the last pieces that passed<br />

before adjournment. This package will be put before the<br />

voters in the general election on Nov. 4 this year. Like<br />

the capital budget, this represents projects throughout<br />

the state that will address some of our many needs. <strong>The</strong><br />

governor signed the bill May 22.<br />

SB 120 – unemployment insurance – AGC did not<br />

support the original version of SB 120. AGC’s position<br />

paper stated that we would support an increase in UI<br />

benefits only if it could be accomplished with no increase<br />

in cost to the employer. In the end, this was accomplished<br />

by reducing the employer share of the UIC premium and<br />

increasing the eligibility level. <strong>The</strong> bill will allow a poten-<br />

tial maximum weekly benefit of $370 per week, up from<br />

the current $248. This is the first increase in 11 years. <strong>The</strong><br />

governor signed the bill May 28.<br />

SB 59 – gaming bill – AGC participated in a flurry<br />

of activity at the end of session in 2007 to remove an<br />

amendment to SB 59 that would have prohibited the use<br />

of funds raised through raffles for Political Action Committees<br />

such as AGC-PAC. We were successful in getting<br />

the Senate not to concur with the House changes. <strong>The</strong><br />

conference committee met on the bill several times and<br />

ultimately removed the offending section. <strong>The</strong> governor<br />

signed the bill April 21.<br />

<strong>The</strong> <strong>2008</strong> session was a very successful for the AGC. I<br />

believe the success we achieved – especially in a 90-day<br />

session, would not have happened without the enthusiasm<br />

and decorum of the AGC members who took part<br />

in the fly-in. For some members, it was their first fly-in,<br />

other members had been before and for all who attended<br />

it was an educational and informative trip. Every year the<br />

fly-in gets a little bigger and better. I encourage all members<br />

interested in participating to keep an eye out for the<br />

announcement next January and join the fly-in.

Behavior-based safety<br />

and the construction industry<br />

Although thousands of companies<br />

worldwide have dramatically reduced<br />

their injuries, improved participation<br />

levels in safety programs, and improved<br />

employee morale by implementing a<br />

behavior-based safety process, the construction<br />

industry has been reluctant to<br />

follow suit.<br />

Why? <strong>The</strong>re are two main obstacles<br />

to running successful behaviorbased<br />

safety processes in construction<br />

environments.<br />

• Until recently, behavior-based safety<br />

was considered a long-term payback<br />

process, possibly taking three to five<br />

years, and most construction projects<br />

do not last that long.<br />

• Implementing a behavior-based safety<br />

program in a construction environment<br />

is expensive and time consuming. It<br />

takes time and money to implement<br />

a behavior-based safety program, and<br />

construction contracts are usually rewarded<br />

for reducing costs and minimizing<br />

completion times.<br />

Unless these problems are overcome<br />

or sidestepped, it will be a long time<br />

before behavior-based safety is as common<br />

in the construction industry as it is<br />

in other industries.<br />

This is not to say that there have not<br />

been successes. One construction project<br />

at a power plant went 18 months<br />

without a serious (lost-time) injury, with<br />

more than 2,000 workers on the project.<br />

Another construction company had a<br />

lower injury rate for a three-year project<br />

than the host petrochemical company.<br />

So it is possible to have successful behavior-based<br />

safety processes in a construction<br />

environment. And although<br />

there is no methodology that is guaranteed<br />

to bring success, here is what some<br />

construction companies have done:<br />

Because of the workforce’s transient<br />

nature, a company may choose only to<br />

SAFETY REPORT<br />

train managers, superintendents, general<br />

foremen and foremen. For some companies,<br />

training costs can be minimized by<br />

the fact that foremen devoted most of their<br />

time to the company providing the training.<br />

When all levels of management make<br />

observations, give positive feedback and<br />

encourage people to work safely, behavior-based<br />

safety activities go a long way.<br />

Although not as effective as peer-to-peer<br />

feedback in real-time, supervisor observation<br />

and feedback can still be very effective<br />

at reducing injuries. Once the workforce<br />

understands that behavior-based safety<br />

is not designed to punish employees, it<br />

becomes easier to gain buy-in for the<br />

system. In addition, training sessions give<br />

management an opportunity to encourage<br />

employees to think more about their<br />

own safety and the hazards present.<br />

Some companies have even taken<br />

these training sessions further by including<br />

advanced safety awareness concepts<br />

and techniques. Advanced awareness<br />

training looks at all of the necessary<br />

ingredients for an accidental injury: the<br />

hazard, something unexpected happening,<br />

and the hazard contacting the worker<br />

or the worker contacting the hazard.<br />

Although hazards are usually the<br />

focus of safety programs, the “source of<br />

the unexpected” should be given more<br />

attention. A worker does something unexpectedly,<br />

a coworker does something<br />

unexpectedly, or the equipment activates<br />

unexpectedly.<br />

Surprisingly, more than 90 percent<br />

of all injuries are caused by the individual<br />

doing something unexpectedly,<br />

rather than as a result of a coworker or<br />

the equipment doing something unexpectedly.<br />

<strong>The</strong>se unexpected occurrences<br />

by the individual are mistakes or errors<br />

(which are always unexpected).<br />

<strong>The</strong> following mistakes cause more<br />

than 90 percent of injuries:<br />

By Larry Wilson<br />

• Eyes not on task<br />

• Mind not on task<br />

• Moving into or being in the<br />

line-of-fire<br />

• Losing balance, traction, or grip<br />

<strong>The</strong>re are also human factors that<br />

contribute to errors. <strong>The</strong> four states that<br />

cause more than 90 percent of the four<br />

critical errors above are:<br />

• Rushing and frustration<br />

• Fatigue and complacency<br />

While mistakes will happen, it is<br />

possible to teach people to recognize<br />

when they are in one of these four states<br />

before they make a critical error.<br />

<strong>The</strong>re are four techniques to reduce<br />

critical errors:<br />

• Recognize the state or hazard to avoid<br />

a critical error.<br />

• Analyze close calls and small errors to<br />

prevent big ones.<br />

• Look for the patterns that increase the<br />

risk of injury with other people.<br />

• Implement good habits that reduce<br />

the risk of injury.<br />

Training employees to handle critical<br />

errors and then following up with on-thejob<br />

observations drives injuries down dramatically<br />

and swiftly. Some companies report<br />

injury reductions of 80 percent within<br />

four months, although typical reductions<br />

are 60 to 90 percent within a six- to 12month<br />

period.<br />

Is that quick enough for the construction<br />

industry? In some cases yes<br />

and in others no, but at least it gives<br />

the construction industry a model to<br />

improve safety through behavior-based<br />

safety programs.<br />

Guest columnist Larry Wilson is<br />

the author of SafeStart: An Advanced<br />

Safety Awareness Training Program, a<br />

common sense approach to working safely<br />

on and off the job. Go online to learn more:<br />

www.safestart-safetrack.com

You can’t win if you don’t enter.<br />

Yes, it’s that time of year again. THE ALASKA USA INSURANCE BROKERS EXCELLENCE IN CONSTRUCTION AWARDS<br />

and the MARSH USA EXCELLENCE IN SAFETY AWARDS deadlines are Sept. 5, <strong>2008</strong>. So start now to get<br />

your projects and programs submitted. Contact Kimberley at the AGC office and request the full award<br />

rules, category information, and entry forms. Your organization deserves the credit for its hard work and<br />

although not everyone will win an award, everyone receives the satisfaction of knowing their work was<br />

examined by a panel of their colleagues. Some of AGC’s best known names have entered and won, and<br />

now so can you.<br />

Here is what our members and previous winners are saying…<br />

CONSTRUCTION<br />

CALL FOR ENTRIES<br />

EXCELLENCE<br />

in Construction & Safety Achievements<br />

Brad West, WEST CONSTRUCTION<br />

<strong>The</strong> Excellence In Construction Award is the end result of the dedication, hard<br />

work and perseverance of all our employees. West Construction takes pride in<br />

receiving this annual award, working toward receiving one year after year. To us,<br />

there is no greater achievement than being recognized by our peers in the industry.<br />

Dick and Jennie Weldin, WELDIN CONSTRUCTION INC.<br />

Our company is not as “high profile” as many <strong>Alaska</strong> contractors because most of our<br />

work occurs on military installations, both in <strong>Alaska</strong> and the Pacific Rim. Submitting<br />

projects for awards packages lets our peers know what we’re up to. It is also a tremendous<br />

morale boost for our employees to know they were part of an award-winning project.

SAFETY<br />

Kevin P. Welker, KIEWIT BUILDING GROUP.<br />

Safety is job one at Kiewit, and acknowledgement of our safety program assures<br />

our clients that every employee will go home safely at the end of every work day.<br />

Our employees take personal pride in our excellent safety record and appreciate the<br />

recognition of our peers at AGC. <strong>The</strong> three aspects of attitude, family responsibility<br />

and good work plans is the road map we use to this safety success.<br />

Richard Podobnik, INTERIOR ALASKA ROOFING INC.<br />

Regardless of a company’s size, employee, job site and customer safety should<br />

always be the number one priority in our industry. Creating and implementing a<br />

quality safety program takes a lot of time, effort, and money which is returned many<br />

times over. Winning the Marsh 2006 Excellence Award for <strong>Contractor</strong>s Safety Program<br />

and being recognized by our industry was a great honor.<br />

Brad West, WEST CONSTRUCTION<br />

Receiving the AGC Safety Award was no accident. Pun on words aside, receiving<br />

this award was actually the result of each and every West Construction employee<br />

diligently making safety in our workplace priority number one on a daily basis. <strong>The</strong>re<br />

is no award taken in such high regard by us than one that rewards the safety of our<br />

employees.<br />

Thomas Ulrich, Vice President, AMERICAN MARINE CORPORATION<br />

When competing in a competitive bid process and work is awarded to the<br />

lowest bidder, many times safety is one of the areas that is compromised in order<br />

to win projects. It’s gratifying to be recognized by the AGC and my peers for safety<br />

achievements – It shows my clients and competitors that we can get the job done on<br />

time, within budget and while still maintaining the highest safety standards.<br />

HOW TO ENTER<br />

So what are you waiting for? <strong>The</strong> time to enter is now.<br />

Award rules and categories are available on the<br />

AGC Web site http://www.agcak.org under Hot Topics,<br />

mailed to all member companies in early July.<br />

<strong>The</strong> DEADLINE to enter is 5 p.m. Sept. 5, <strong>2008</strong>, at the<br />

AGC of <strong>Alaska</strong> Anchorage office on 8005 Schoon Street.<br />

Call Kimberley at 561-5354 or e-mail Kimberley@agcak.org for more information.

By Heidi Bohi<br />

AGC of <strong>Alaska</strong> Legacy Members<br />

Hector’s Welding offers fast, quality<br />

fabrication and design services<br />

When a livelihood has been a part of your day-to-day existence for almost your entire<br />

life, Ken <strong>The</strong>rriault of Hector’s Welding says it gets to the point where you’re never quite<br />

sure if you’ve learned something or if you just know it<br />

simply because the business has always been at your<br />

front door.<br />

He’s vice president and general manager of this North<br />

Pole-based welding company,<br />

now in its 51st year of operation,<br />

that his late father Hector<br />

and his mother Jeanette<br />

started in 1956 after moving<br />

to the Fairbanks area from<br />

Los Angeles, Calif., where his<br />

father had worked for North<br />

American Aviation during<br />

World War II.<br />

At first, Hector spent<br />

summers working for various<br />

general contractors in<br />

equipment maintenance and<br />

repair for the Richardson<br />

Highway and Eielson Air<br />

Force Base, while taking on<br />

moonlighting welding jobs<br />

during the winter months.<br />

When it became apparent<br />

to him there was enough<br />

business for him to be able<br />

to make it on his own, he<br />

opened a storefront in 1969,<br />

purchasing some land and<br />

a shop building. Since then,<br />

<strong>The</strong>rriault says, this second-generation family business<br />

has operated in five different shops in the North Pole<br />

area, continuing to expand and grow everything from<br />

inventory and equipment to personnel.<br />

Today, Hector’s Welding is known statewide for its<br />

fast, quality fabrication and design services, employing<br />

the best craftsmen in the industry to take on small and<br />

large retail and commercial projects ranging from repairing<br />

a bicycle or broken parts and equipment to custom<br />

built parts, new school installations, oil field development<br />

projects and developing clients’ custom designs. Although<br />

welding is the biggest part of the business, the company is<br />

also one of the largest suppliers of steel for wholesale and<br />

retail markets, offers heavy equipment rental and spe-<br />

Ken <strong>The</strong>rriault stands in front of one of the many custom built<br />

sluice boxes that the company fabricated for miners during a<br />

15-year period when gold mining in the Interior was booming.<br />

cializes in manufacturing and rebuilding mining equipment<br />

and parts such as sluice boxes, grizzlies, trommels,<br />

blade and truck liners, cutting edges and ripper shanks.<br />

Hector’s also custom builds aluminum and steel water,<br />

chemical and fuel tanks, or<br />

modifies existing tanks for<br />

homes, businesses, trucks,<br />

boats, planes and job sites.<br />

Many clients have been<br />

using Hector’s for 20 to 25<br />

years, <strong>The</strong>rriault says, because<br />

they appreciate what he says<br />

is the company’s prime area<br />

of specialization: knowing<br />

what the customer needs or<br />

what they should have. This<br />

is especially important in an<br />

industry where people don’t<br />

typically realize what welding<br />

involves, he says.<br />

“A lot of people don’t<br />

understand what it takes to<br />

mend two broken pieces,” he<br />

says. “<strong>The</strong>y think it’s bubble<br />

gum and that ain’t gonna<br />

make it – if something isn’t<br />

going to work we’ll tell<br />

them, or they’ll go someplace<br />

else.”<br />

Although most clients<br />

are in the Fairbanks area, several come from across<br />

the state. Clients include Cruz Construction (Palmer),<br />

<strong>Alaska</strong> Frontier Constructors (Anchorage), Colville, Inc.<br />

(Prudhoe Bay), Flowline <strong>Alaska</strong> (Fairbanks), and ATEC<br />

Industries in Elkridge, Md.<br />

<strong>The</strong> oldest of seven siblings – who have all worked<br />

in the business at one time or another – Ken <strong>The</strong>rriault<br />

oversees day-to-day operations that include five<br />

other employees. His mother and middle sister Donna<br />

share administrative and bookkeeping responsibilities,<br />

and his youngest brother Ron is a welder and machine<br />

operator. His sister Laura is president and lives in Valdez,<br />

and the remaining siblings are also co-owners so<br />

that everyone is involved in the family corporation. At

55, Ken says he has worked for the<br />

business on and off since junior high<br />

school, 30 years total, and of that time<br />

20 years was spent working under<br />

his father’s direction before Hector<br />

passed away four years ago. He assumed<br />

the managerial responsibilities<br />

in the early ‘80s when his father<br />

retired and the business became a<br />

family corporation.<br />

Although working with family has<br />

advantages and disadvantages, he<br />

says, the trade-off of having control<br />

over the business and their personal<br />

livelihoods is worth working through<br />

any sibling conflicts that ever arise.<br />

At the same time, he says, he doesn’t<br />

have anything to compare it to.<br />

Whether he was sweeping floors,<br />

“cutting stuff,” or drilling, “the company<br />

has always been at the front<br />

door,” <strong>The</strong>rriault says, adding that the<br />

only two breaks he has taken from<br />

the family business were to earn his<br />

civil engineering degree at the University<br />

of <strong>Alaska</strong> Fairbanks – he is<br />

also a welder himself – and to work<br />

seasonal construction for about four<br />

years, before realizing that his family’s<br />

business was some of the most<br />

interesting work and probably one of<br />

the best opportunities.<br />

Although his father was one of<br />

his greatest influences, especially in<br />

the area of work ethics and employee<br />

and customer relations, <strong>The</strong>rriault says<br />

a lot of what he learned was simply<br />

from being exposed to the industry<br />

and the business for so many years. It<br />

becomes so second nature, he says, it<br />

is difficult to discern between what he<br />

naturally knows and what he continues<br />

to learn.<br />

Even after more than 50 years in<br />

business, Hector’s Welding contin-<br />

<br />

Hector and Jeanette<br />

<strong>The</strong>rriault and their<br />

seven children have all<br />

worked for the family<br />

business at different<br />

times over the past 51<br />

years. Ken’s dog Ginger<br />

was responsible for<br />

greeting customers as<br />

they entered the shop<br />

and had a special<br />

bond with a few, select<br />

customers.<br />

Back row, from left: Ken,<br />

Bonne, Laura, Donna,<br />

Eugene<br />

Middle row, from left:<br />

Dwayne, Jeannette,<br />

Hector, Ron<br />

Front row, Ginger<br />

ues to look for new ways to improve<br />

and grow the business. In addition to<br />

investing in new technology and shop<br />

processes, <strong>The</strong>rriault says, Hector’s<br />

Welding also joined Associated General<br />

<strong>Contractor</strong>s six years ago and especially<br />

values the opportunities to network<br />

with other businesses in the industry<br />

and to track industry bids by using <strong>The</strong><br />

Plans Room.<br />

Heidi Bohi is a freelance writer and<br />

marketing professional who divides her<br />

time between Anchorage and Arizona.

Asphalt oil is almost as<br />

valuable as fuel oil<br />

BY JOHN MACKINNON<br />

I had always been under the impression<br />

that asphalt oil was the bottom of<br />

the barrel in the refining process, almost<br />

a waste product that the refiners were<br />

happy to get rid of. This may have been<br />

the case years ago, but today it is almost<br />

as valuable as fuel oil.<br />

<strong>The</strong> end product or base material that<br />

is used for asphalt road oil can be further<br />

refined with minor effort and sold as<br />

“Bunker C” oil, the fuel that powers most<br />

of the world’s merchant fleet. In Puget<br />

Sound, there is a good market for Bunker<br />

C. Asphalt oil markets there are competing<br />

with the market for fuel for the merchant<br />

fleet.<br />

Some refineries have installed new<br />

coking towers that can take the asphalt<br />

oil material and refine it into fuel oil and<br />

market it for heating oil for the commercial<br />

market. In areas where coking towers<br />

are refining the product further, they<br />

Fairbanks International Airport<br />

R/W 1L-19R Reconstruction<br />

• Bids Opened – July 18, 2007<br />

• Contract Amount - $32,987,400<br />

– Electrical - $10,816,000<br />

– HAP – 112,000 tons – $4,699,350<br />

– Asphalt Cement and Tack Coat – 6,248 tons<br />

– $5,072,627<br />

• <strong>Alaska</strong> Asphalt Material Price Index at Bid Opening<br />

– $376.67<br />

• Paving during summer of 2009<br />

• Bid Opening to Paving – 2+ years<br />

• Average (65% Increase)<br />

– Increase - $238.99/ton<br />

– Total Increase for 6,248 tons – $1,493,181<br />

• High Increase (260% Increase)<br />

– Increase - $979.34/ton<br />

– Total Increase for 6,248 tons – $6,118,891<br />

• Low (36% Decrease)<br />

– Decrease - $135.60/ton<br />

– Total Decrease for 6,248 tons – $847,229<br />

Annual Crude Oil Price<br />

June <strong>2008</strong>

are producing little to no asphalt oil,<br />

and have to import it from refineries<br />

where coking towers are not installed.<br />

<strong>The</strong> whole supply cycle has changed<br />

while demand for asphalt continues to<br />

increase.<br />

Simply put, the raw material can<br />

be refined into more valuable product<br />

than asphalt oil, thus the price of asphalt<br />

has to go up to compete with the<br />

other more expensive products.<br />

<strong>The</strong> two state refineries that supply<br />

<strong>Alaska</strong> – Tesoro and Flint Hills – are not<br />

producers. <strong>The</strong>y buy oil from the producers,<br />

refine it and market the refined<br />

products, working on a thin margin between<br />

the price of raw material per barrel<br />

(>$125) and the wholesale (or retail)<br />

price for gasoline, heating oil, etc.<br />

If you look at the profits of the refining<br />

companies such as Tesoro and<br />

Valero, you won’t see stellar results. It<br />

is the producers that have billions of<br />

dollars in quarterly profits because they<br />

own the raw material in the ground.<br />

For asphalt oil, <strong>Alaska</strong>ns are victims<br />

of the marketing and refining<br />

efficiency of the refiners. This affects<br />

some, but not all of the contractors.<br />

Some buy the oil at the time of bid,<br />

locking in their bid price. <strong>The</strong>y can<br />

do this only if they have the capacity<br />

to store quantities of oil. This is<br />

something few can do. Most contractors<br />

are subject to market exigencies<br />

or vagaries. Since asphalt is a long<br />

lead-time item, contractors face the<br />

risk of price variations that make bidding<br />

perilous and only for the most<br />

adventurous.<br />

John MacKinnon is the executive director<br />

of the Associated General <strong>Contractor</strong>s of<br />

<strong>Alaska</strong>.

By Heidi Bohi<br />

AGC of <strong>Alaska</strong> Legacy Members<br />

SENCO <strong>Alaska</strong> sells, services<br />

air-powered fastening systems<br />

How a company gets the name SENCO Products out of what was originally called Springtramp<br />

Eliminator Company is a mystery to Teri Gunter and her sister Jackie Glatt, owners of the<br />

<strong>Alaska</strong> division of one of the world’s leading manufacturers<br />

of air-powered fastening systems. In fact, it’s a<br />

mystery to the parent company.<br />

But as these second generation owners celebrate 40<br />

years of doing business in Anchorage, what is certain,<br />

the two sisters will tell you, is that they are proud to<br />

continue to serve the construction trade and do-it-yourselfer<br />

with the most innovative, quality merchandise in<br />

the tools and fastening industry. <strong>The</strong> “service what we<br />

sell” repair department and the all-customer-service, allthe-time<br />

philosophy is what keeps the building trade<br />

coming back, including customers who are referred by<br />

their competition, Gunter says proudly.<br />

Founded in Cincinnati 50 years ago, SENCO Products<br />

Inc. has a network of authorized dealers, distributors and<br />

sales representatives in North and South America, Europe,<br />

Asia and Australia, as well as worldwide manufacturing<br />

operations in Australia, Colombia, France, Germany, Italy,<br />

Korea, <strong>The</strong> Netherlands, South Africa and Spain.<br />

Originally known as a hammer and nails company,<br />

today, in addition to having the widest selection of staples,<br />

nails and screws in the industry, it is also known<br />

for leading the market by carrying the newest innovations<br />

in products and materials: the extended line includes<br />

Max Rebar Tiers, FOMO insulation applications,<br />

and the newer space-efficient, noise-reduced compressors.<br />

SENCO is also known as the leader in fastening<br />

solutions for use in the residential home construction<br />

market; framing, interior finish and trim carpentry, drywall<br />

installation, exterior residential decks, roofing, siding<br />

and fencing. It also produces fastening solutions for<br />

industrial markets; in-plant housing, cabinets, pallets,<br />

furniture, bedding and recreational vehicles.<br />

Originally, a prominent homebuilder in Anchorage,<br />

Jack and Barbara Butt purchased SENCO <strong>Alaska</strong> in 1968<br />

from a construction associate after he introduced the<br />

line of tools to Gunter and Glatt’s father and then approached<br />

him about becoming the exclusive distributor<br />

in Anchorage. It began in small quarters and moved to its<br />

present location near the corner of Old Seward Highway<br />

and Dowling Road in Anchorage in 1974, which includes<br />

more than 7,000 square feet of warehouse and shop,<br />

1,600 square feet of office space, and a newly remodeled<br />

showroom. In addition to the Anchorage office, there is a<br />

Wasilla location and seven dealers in Fairbanks, Kodiak,<br />

Seward, Soldotna, Nome, Bethel and Delta Junction.<br />

As SENCO <strong>Alaska</strong> continues to grow – last year<br />

alone there was more than a 6 percent increase in new<br />

business – besides the residential market, the company<br />

is focusing on securing more commercial accounts and<br />

getting large housing contracts on local military bases<br />

in Anchorage and Fairbanks. Today, 75 percent of the<br />

company’s clientele is in the commercial sector including<br />

F & W Construction, Builders Choice Inc. and FM<br />

Construction. One of their primary sources of customers<br />

is the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong> organization,<br />

Gunter says, and almost every contractor associated<br />

with AGC is a client of SENCO’s.<br />

Gunter says her father ran SENCO <strong>Alaska</strong> as a family<br />

style business from the beginning, including his wife,<br />

who was the company’s secretary, and daughters, sonsin-law<br />

and grandchildren who worked in various capacities<br />

before Gunter and Glatt purchased it. Although<br />

their father passed away five years ago, Gunter says they<br />

still have many customers who attribute part of their<br />

success to him for his generosity and trust.<br />

It was not uncommon for him to sell customers a tool<br />

for a handshake and tell them to pay him when they<br />

had the money. Although that was a sign of the times<br />

and she and her sister don’t run the business quite that<br />

way today, Gunter says laughing, they still turn to the<br />

business ethics and examples of integrity and leadership<br />

their father taught them.<br />

“We were raised in a wonderful learning situation<br />

where we were able to see first-hand the day-to-day<br />

requirements needed to run a successful company,”<br />

Gunter says.<br />

After growing up with the business for 30 years, as<br />

general manager, Gunter works with the financial and<br />

marketing divisions of the company, and as office manager,<br />

Glatt, who has worked for the family business for<br />

29 years, focuses on the sales and product areas.<br />

Having grown up with the business – as a small child<br />

Gunter started sweeping floors then worked her way<br />

up – she says that while she understands that working<br />

with family isn’t for everyone, she enjoys every moment<br />

with her sister, who she has worked with for 28 years.<br />

When they are not working they spend free time to-

gether at one of the family cabins and<br />

if they are not together, they are talking<br />

on the phone.<br />

One of the keys to their success,<br />

Gunter says, is that they also consider<br />

the other seven employees family, too,<br />

and in turn the employees invest in<br />

the company with the same heart and<br />

soul she and her sister do.<br />

“We view our staff as a team that<br />

works together. In this sense, we are<br />

carrying on the values which our<br />

parents instilled in us – the strong<br />

work ethic and hands on approach<br />

are the foundation to our success,”<br />

Gunter says. “We believe our staff to<br />

be the finest available and are proud<br />

of the service they provide to our<br />

customers.”<br />

Although there are several children<br />

in the family who may one day work<br />

for the company, Gunter says, right<br />

now it’s too soon to tell if the next<br />

generation of leadership will come<br />

from within the family.<br />

SENCO <strong>Alaska</strong> has been a member<br />

of AGC for 33 years. Gunter says<br />

her father joined in 1975 because he<br />

believed that the growing Anchorage<br />

SENCO’s store in the Mat-Su Valley is located at 420 E. Snider at Mile 1 of the<br />

Palmer-Wasilla Highway. SENCO also has a store in Anchorage.<br />

Team SENCO poses with a selection of SENCO nail-guns at the Anchorage<br />

SENCO store, 817 E. Dowling. Pictured are: back row, Mary Wilts, Michael<br />

Springel, Jackie Glatt; bottom row: Greg Black, Jason Macrander, Teri Gunter.<br />

Not pictured are: David “Nick” Nichols – Wasilla facility and Michael Coles,<br />

IT staff – Anchorage facility.<br />

community would benefit from people<br />

in the contracting industry working<br />

together toward a common goal.<br />

She and her sister continue to stay<br />

involved with the organization; one<br />

more way they carry on their father’s<br />

legacy. When they decided to diversify<br />

the company from the residential<br />

market to also include products for<br />

commercial and industrial customers,<br />

she says the company relied on the<br />

networking and educational opportunities<br />

offered through the organization<br />

and this involvement encouraged<br />

her to take on a more active role in<br />

AGC. In addition to attending events,<br />

she is also the co-chair for the annual<br />

conference.<br />

“We have already seen the benefits<br />

of making connections and staying<br />

current with the evolving industry,”<br />

Gunter says. “<strong>The</strong> members are the key<br />

to this great networking opportunity<br />

because they work together to make<br />

the industry, as a whole, stronger.”<br />

Heidi Bohi is a freelance writer and<br />

marketing professional who divides her<br />

time between Anchorage and Arizona.

Urban <strong>Alaska</strong><br />

EDUCATION, TRAINING &<br />

WORKFORCE DEVELOPMENT REPORT<br />

“Our Mission: through <strong>Alaska</strong> Construction Academy<br />

effort, <strong>Alaska</strong>n students and adults will be recruited, trained<br />

and placed into jobs in the construction industry.”<br />

– Kathleen Castle, Executive Director<br />

of the <strong>Alaska</strong> Construction Academy<br />

This year, <strong>2008</strong>, Construction Academies statewide will<br />

teach basic skills to 1,000 high school students and 300<br />

adults to prepare them for jobs in construction. Through<br />

$3.5 million appropriated by Gov. Sarah Palin and the Legislature,<br />

Construction Academies were established in urban<br />

communities that had a local chapter of the <strong>Alaska</strong> State<br />

By ROBERT CRESS,<br />

Training Director<br />

Together with the effective efforts of our many partners in industry, government, and education, AGC of <strong>Alaska</strong> continues to see<br />

substantial gains in workforce development and specialized contractor training throughout <strong>Alaska</strong>.<br />

In Ketchikan, nine adult students recently<br />

completed the academy’s first class, held<br />

at the University of <strong>Alaska</strong> Southeast Ketchi-<br />

BY PAM ROTH<br />

kan campus. Basic Construction Techniques,<br />

a 50-hour class, used classroom teaching and hands-on experiences<br />

that provided an overview of tool usage, building procedures<br />

and codes, job site planning, layout and foundation,<br />

floor, wall and roof framing methods.<br />

“It’s a great way to train a workforce in the community<br />

where they’ll live and work,” says Wendy Gierard, assistant<br />

director of workforce development at UAS-Ketchikan.<br />

“We’re teaching them what is expected from an entry<br />

level laborer on the job,” says Charles “Chas” Edwardson, a<br />

UAS adjunct professor and a general contractor in Ketchikan<br />

for the past 14 years.<br />

<strong>The</strong> Southern Southeast <strong>Alaska</strong> Building Industry Association,<br />

SSEABIA, is working to place the students into<br />

on-the-job training summer work with local builders, and<br />

is working in partnership with the Ketchikan Gateway Borough<br />

School District to make sure the curriculum being<br />

taught meets the needs of the local industry.<br />

Additional courses will be offered at UAS-Ketchikan. A<br />

unique aspect of the academy is that there is no cost to the<br />

participants – the academy pays for all tuition, books, tools<br />

and supplies.<br />

Similar to other academies, Ketchikan reaches out to<br />

high school students as well as adult learners. Construction<br />

Academy grant funding is provided to hire an additional<br />

construction trades teacher at the high school. <strong>The</strong> academy<br />

is setting up a “tech-prep agreement” for dual credit.<br />

Chas Edwardson said he believes the focus on high<br />

Home Builders Association. Construction Academy training<br />

is offered in two components: high school students and<br />

adult learners. High school students receive high school<br />

credit and in some cases, college credit for the courses (dual<br />

credit). <strong>The</strong> adult component offers training in the evenings<br />

and Saturdays. Both receive hands-on training by experts in<br />

the construction trades.<br />

While you will find similarities and differences among<br />

the individual academies, all share the same mission: giving<br />

student and adult participants new opportunities to explore<br />

one or more construction trades that may lead to rewarding<br />

careers in construction.<br />

Academy adult students working on their shed project being built at the<br />

Ketchikan Indian Community parking lot.<br />

school students is especially important.<br />

“We’re getting older and the younger people are not<br />

stepping in,” he said. “We need to focus more on vocational<br />

training in the high schools. Hopefully, the academy will<br />

help generate more students from the high school.”<br />

Partners include the SSEABIA, UAS-Ketchikan, Ketchikan<br />

Gateway Borough School District, AGC of <strong>Alaska</strong>, Ketchikan<br />

Job Center, Ketchikan Indian Community, Ketchikan<br />

Youth Initiatives and <strong>Alaska</strong> Works Partnership.<br />

Pam Roth is the executive officer for Southern Southeast<br />

Building Industry Association.

Juneau’s “in school” program of the Juneau Construction<br />

Academy, served more than 422 students in construction and<br />

construction-related classes this school year. <strong>The</strong>se classes included:<br />

Creative Woods, Computer-Assisted Drafting, Basic Construction,<br />

Metals and Small Engine Repair. Some 43 students participated in after<br />

school classes in Basic Construction, Computer-Assisted Drafting and Welding.<br />

In February, a select team of five Juneau Douglas High School students won<br />

first place in the National Residential Construction Competition in Orlando, Fla.<br />

(See <strong>Alaska</strong> <strong>Contractor</strong> Spring <strong>2008</strong>, Pg. 69)<br />

<strong>The</strong> Southeast Regional Resource Center, SERRC, facilitated the adult training<br />

program. SERRC screened 98 applicants and trained 32 adults in Basic Construction,<br />

Drywall, Welding, Plumbing and Heating, First Aid and CPR, OSHA 10,<br />

Scaffolding and Forklift Safety classes. Training was coordinated with UAS-Juneau,<br />

BY CARIN SMOLIN<br />

Adult student Alphonozo Hampton grinding<br />

away in the academy’s welding program. He is<br />

now employed with Channel Construction at<br />

the Greens Creek Mine.<br />

<strong>Alaska</strong> Works Partnership and local<br />

unions. <strong>The</strong> program provided assistance<br />

with job placement and apprenticeship<br />

applications. Charlie Carlson is<br />

the SERRC admissions coordinator.<br />

As a residential contractor and former<br />

SEABIA president, Russ McDougal has<br />

already experienced the benefit of hiring<br />

a Construction Academy graduate.<br />

“I was very pleased with his attitude,<br />

desire to learn and his work ethic,”<br />

he said.<br />

Juneau Construction Academy partners<br />

include the Juneau School District,<br />

SERRC, UAS-Juneau AWP, AGC of<br />

<strong>Alaska</strong>, Southeast <strong>Alaska</strong> Building Industry<br />

Association, <strong>Alaska</strong> Department<br />

of Labor and Workforce Development,<br />

<strong>Alaska</strong> Plumbers and Pipefitters Local<br />

262 and Juneau Building Trades Council/IBEW<br />

1547.<br />

Carin Smolin is the career and technical<br />

education coordinator for the Juneau School<br />

District.<br />

Bob Hammer,<br />

president of the<br />

<strong>Alaska</strong> State Home<br />

BY BARB ROPER<br />

Building Association,<br />

ASHBA, and a Kenai contractor,<br />

remembers a time when vocational<br />

education students built an entire<br />

house with the guidance of a master<br />

journeyman in the construction trades.<br />

That memory has become a vision<br />

for the future as Construction Academy<br />