Cargo Airships Prospective - Faculty of Aerospace Engineering

Cargo Airships Prospective - Faculty of Aerospace Engineering

Cargo Airships Prospective - Faculty of Aerospace Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

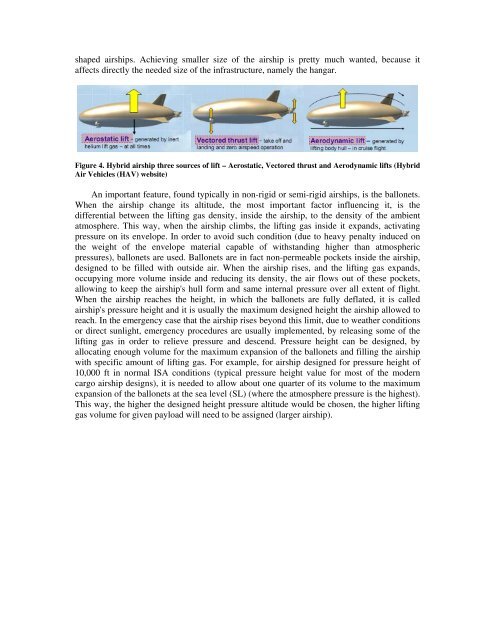

shaped airships. Achieving smaller size <strong>of</strong> the airship is pretty much wanted, because it<br />

affects directly the needed size <strong>of</strong> the infrastructure, namely the hangar.<br />

Figure 4. Hybrid airship three sources <strong>of</strong> lift – Aerostatic, Vectored thrust and Aerodynamic lifts (Hybrid<br />

Air Vehicles (HAV) website)<br />

An important feature, found typically in non-rigid or semi-rigid airships, is the ballonets.<br />

When the airship change its altitude, the most important factor influencing it, is the<br />

differential between the lifting gas density, inside the airship, to the density <strong>of</strong> the ambient<br />

atmosphere. This way, when the airship climbs, the lifting gas inside it expands, activating<br />

pressure on its envelope. In order to avoid such condition (due to heavy penalty induced on<br />

the weight <strong>of</strong> the envelope material capable <strong>of</strong> withstanding higher than atmospheric<br />

pressures), ballonets are used. Ballonets are in fact non-permeable pockets inside the airship,<br />

designed to be filled with outside air. When the airship rises, and the lifting gas expands,<br />

occupying more volume inside and reducing its density, the air flows out <strong>of</strong> these pockets,<br />

allowing to keep the airship's hull form and same internal pressure over all extent <strong>of</strong> flight.<br />

When the airship reaches the height, in which the ballonets are fully deflated, it is called<br />

airship's pressure height and it is usually the maximum designed height the airship allowed to<br />

reach. In the emergency case that the airship rises beyond this limit, due to weather conditions<br />

or direct sunlight, emergency procedures are usually implemented, by releasing some <strong>of</strong> the<br />

lifting gas in order to relieve pressure and descend. Pressure height can be designed, by<br />

allocating enough volume for the maximum expansion <strong>of</strong> the ballonets and filling the airship<br />

with specific amount <strong>of</strong> lifting gas. For example, for airship designed for pressure height <strong>of</strong><br />

10,000 ft in normal ISA conditions (typical pressure height value for most <strong>of</strong> the modern<br />

cargo airship designs), it is needed to allow about one quarter <strong>of</strong> its volume to the maximum<br />

expansion <strong>of</strong> the ballonets at the sea level (SL) (where the atmosphere pressure is the highest).<br />

This way, the higher the designed height pressure altitude would be chosen, the higher lifting<br />

gas volume for given payload will need to be assigned (larger airship).