PV7005 PV7010 TN6010 - Kyocera

PV7005 PV7010 TN6010 - Kyocera

PV7005 PV7010 TN6010 - Kyocera

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

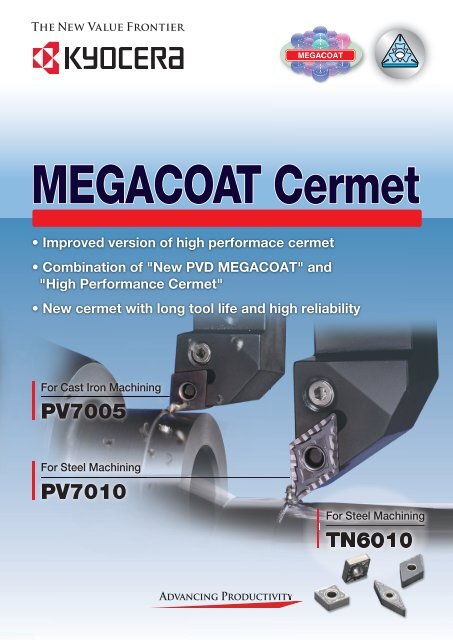

MEGACOAT Cermet<br />

New MEGACOAT PVD technology<br />

• MEGACOAT produces excellent wear resistance and heat resistance<br />

• Achieves beautiful finished surfaces with high temperature<br />

stability plus surface smoothness<br />

Wear resistant and heat resistant<br />

MEGACOAT<br />

• Nitride solid solution of high melting<br />

point metal<br />

• High hardness and oxidation resistant<br />

• Superior surface roughness<br />

• Superior crater wear resistance<br />

MEGACOAT CERMET for steel machining<br />

<strong>PV7010</strong><br />

Feature<br />

Surface reforming Cermet<br />

• Surface structure has high hardness and high wear resistance and<br />

inner structure has high toughness and high fracture resistance.<br />

Inner structure<br />

Nose Wear(mm)<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

Hardness<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

400 600 800 1000 1200<br />

Competitor A<br />

0.00<br />

0 30 80 90120 150<br />

Cuttig Time(min)<br />

cutting conditions<br />

SCM435, Vc=250m/min, ap=1.0mm,<br />

f=0.20mm/rev, WET, CNMG120408<br />

Oxidation temperature<br />

• Achieves long tool life and stable machining with two new technologies, MEGACOAT plus<br />

special surface reforming Cermet<br />

Inner side of cermet Surface of cermet<br />

[High toughness cermet]<br />

Resistant to chipping and<br />

thermal shock<br />

wear resistance<br />

<strong>PV7010</strong><br />

fracture resistance<br />

Surface structure<br />

[High hardness cermet]<br />

High wear resistance<br />

PV7020<br />

TiN<br />

Comparison of wear Resistance<br />

<strong>PV7010</strong><br />

MEGACOAT<br />

TiAIN<br />

Comparison of fracture resistance<br />

<strong>PV7010</strong><br />

Competitor B<br />

Competitor C<br />

<strong>PV7010</strong><br />

Competitor A<br />

0 500 1000 1500 2000<br />

hits<br />

cutting conditions<br />

S45C, Vc=250m/min, ap=1.5mm, f=0.20mm/rev, DRY, CNMG120408

Nose Wear(mm)<br />

MEGACOAT CERMET for cast iron machining<br />

<strong>PV7005</strong><br />

Feature<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

0.00<br />

0 5 10 15<br />

Cuttig Time(min)<br />

cutting conditions<br />

FCD450, Vc=250m/min, ap=1.0mm,<br />

f=0.20mm/rev, WET, TNGA160408<br />

<strong>PV7005</strong><br />

Competitor F<br />

Workpiece<br />

material<br />

Carbon Steel<br />

Alloy Steel<br />

• Improved wear resistance for cast iron machining through<br />

the use of MEGACOAT<br />

• Controls deterioration of the cutting edge due to progressive<br />

crater wear, enabling stable machining<br />

• The substrate is a special TiC-TiN Cermet exclusively for cast<br />

iron machining<br />

Comparison of wear Resistance (FCD450)<br />

Insert Grade (Vc:m/min)<br />

<strong>PV7010</strong><br />

200-250-300<br />

150-200-250<br />

<strong>PV7005</strong><br />

0.15<br />

Competitor D Competitor F<br />

<strong>PV7005</strong><br />

Comparison of fracture resistance<br />

0.05 0.10 0.15 0.20<br />

f (mm/rev)<br />

0.25 0.30 0.35<br />

CERMET for steel machining<br />

<strong>TN6010</strong><br />

Competitor D<br />

• Special surface reforming cermet with high wear<br />

resistance and anti chipping<br />

• Cost effective performance non coated cermet<br />

Recommended Cutting Conditions<br />

Workpiece<br />

material<br />

Carbon Steel<br />

Alloy Steel<br />

Nose Wear(mm)<br />

Comparison of wear Resistance (FC250)<br />

0.20<br />

0.10<br />

0.05<br />

0.00<br />

0 10 20<br />

Cuttig Time(min)<br />

30 40<br />

cutting conditions<br />

FC250, Vc=350m/min, ap=1.0mm,<br />

f=0.20mm/rev, WET, CNGA120408<br />

cutting conditions<br />

Vc=100m/min, ap=2.0mm, Dry,<br />

S45C 5mm×4, CNGA120408<br />

* Toughness evaluation performed with S45C<br />

Insert Grade (Vc:m/min)<br />

<strong>TN6010</strong><br />

150-200-250<br />

100-150-200<br />

wear resistance<br />

<strong>PV7005</strong><br />

Workpiece<br />

material<br />

Gray Cast Iron<br />

<strong>TN6010</strong><br />

Nodular Cast Iron<br />

<strong>PV7005</strong><br />

fracture resistance<br />

Competitor E<br />

TN6020<br />

Insert Grade (Vc:m/min)<br />

<strong>PV7005</strong><br />

300-350-400<br />

150-250-300<br />

2

3<br />

Stock Items<br />

Insert<br />

Handed insert<br />

shows Right-Hand<br />

Finishing With<br />

Wiper Edge<br />

Finishing<br />

Finishing-Medium<br />

Roughing<br />

Low Carbon<br />

Steel Finishing<br />

Description<br />

Dimension (mm)<br />

I.C. Thickness Hole<br />

CNMG 120404WP<br />

12.70 4.76 5.16<br />

120408WP<br />

CNMG 120404WQ<br />

12.70 4.76 5.16<br />

120408WQ<br />

Finishing-Medium<br />

With Wiper Edge<br />

Finishing-Medium<br />

/ Up facing<br />

Medium-Roughing<br />

Low Carbon Steel<br />

Medium Finishing<br />

Without Chipbreaker<br />

CNMG 120402GP<br />

120404GP 12.70 4.76 5.16<br />

120408GP<br />

CNMG 120404HQ<br />

12.70 4.76 5.16<br />

120408HQ<br />

CNMG 120404CQ<br />

12.70 4.76 5.16<br />

120408CQ<br />

CNMG 120404PS<br />

12.70 4.76 5.16<br />

120408PS<br />

CNMG 120404<br />

120408<br />

120412<br />

12.70<br />

12.70<br />

4.76<br />

4.76<br />

5.16<br />

CNMG 120404XP<br />

12.70 4.76 5.16<br />

120408XP<br />

CNMG 120404XQ<br />

12.70 4.76 5.16<br />

120408XQ<br />

CNGA 120404<br />

120408<br />

5.16<br />

DNMG 150402GP<br />

12.70 4.76<br />

150404GP<br />

DNMG 150602GP<br />

5.16<br />

150604GP 12.70 6.35 5.16<br />

Finishing<br />

150608GP<br />

DNMG 150404HQ<br />

12.70 4.76<br />

150408HQ<br />

DNMG 150604HQ<br />

5.16<br />

150608HQ 12.70 6.35 5.16<br />

Finishing-Medium 150612HQ<br />

DNMG 150408CQ 12.70 4.76 5.16<br />

Finishing-Medium<br />

⁄ Up facing<br />

DNMG 150604CQ 12.70 6.35 5.16<br />

Corner Relief<br />

-R (r ) Angle<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

1.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

1.2<br />

0.8<br />

0.4<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Stock Grades<br />

PVD Cermet Cermet<br />

<strong>PV7005</strong><br />

•<br />

•<br />

<strong>PV7010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>TN6010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Insert<br />

Medium cutting<br />

Medium-Roughing<br />

Medium-Roughing<br />

Roughing<br />

Without Chipbreaker<br />

Description<br />

Handed insert<br />

shows Right-Hand<br />

DNMG 150404PS<br />

150408PS<br />

DNMG 150604PS<br />

150608PS<br />

Medium-Roughing 150612PS<br />

Roughing<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon Steel<br />

Medium Finishing<br />

Finishing-Medium<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon Steel<br />

Medium Finishing<br />

DNMG 150408<br />

DNMG 150608<br />

Dimension (mm)<br />

I.C. Thickness Hole<br />

12.70<br />

12.70<br />

12.70<br />

12.70<br />

12.70<br />

4.76<br />

6.35<br />

4.76<br />

6.35<br />

4.76<br />

5.16<br />

5.16<br />

5.16<br />

5.16<br />

DNMG 150404XP<br />

150408XP<br />

12.70 4.76 5.16<br />

DNMG 150604XP<br />

150608XP<br />

12.70 6.35 5.16<br />

DNMG 150404XQ<br />

150408XQ<br />

12.70 4.76 5.16<br />

DNMG 150604XQ<br />

150608XQ<br />

12.70 6.35 5.16<br />

DNGG<br />

150404 R /L<br />

150408 R /L<br />

RNMG 090300<br />

RNMG 120400<br />

5.16<br />

9.525 3.18 3.81<br />

12.70 4.76 5.16<br />

SNMG 120404HQ<br />

12.70 4.76 5.16<br />

120408HQ<br />

SNMG 120408PS 12.70 4.76 5.16<br />

SNMG 120404<br />

120408<br />

12.70 4.76 5.16<br />

SNMG 120408XP 12.70 4.76 5.16<br />

SNMG 120408XQ 12.70 4.76 5.16<br />

SNGA 120408<br />

12.70 4.76 5.16<br />

SNGG 090304 9.525 3.18 3.81<br />

R /L-B<br />

SNGG 120404<br />

12.70 4.76 5.16<br />

R /L-C<br />

120408 R '-B:Finishing-Medium<br />

'-C:Medium-Roughing<br />

/L-C<br />

Corner Relief<br />

-R (r )<br />

Angle<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

1.2<br />

0.8<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

-<br />

-<br />

0.4<br />

0.8<br />

0.8<br />

0.4<br />

0.8<br />

0.8<br />

0.8<br />

0.8<br />

0.4<br />

0.4<br />

0.8<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Stock Grades<br />

PVD Cermet Cermet<br />

<strong>PV7005</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>PV7010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>TN6010</strong><br />

•<br />

•<br />

•

Insert<br />

Handed insert<br />

shows Right-Hand<br />

Finishing<br />

Finishing-Medium<br />

Finishing-Medium<br />

Medium-Roughing<br />

Roughing<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon Steel<br />

Medium Finishing<br />

Without Chipbreaker<br />

Finishing / Surface<br />

Roughness Oriented<br />

Description<br />

Dimension (mm)<br />

I.C. Thickness Hole<br />

TNMG 160402GP<br />

0.2<br />

160404GP 9.525 4.76 3.81 0.4<br />

160408GP<br />

0.8<br />

TNMG 160404HQ<br />

9.525 4.76 3.81<br />

160408HQ<br />

TNMG 160404CQ<br />

9.525 4.76 3.81<br />

160408CQ<br />

9.525 4.76 3.81<br />

9.525 4.76 3.81<br />

TNGG 160402<br />

9.525 4.76 3.81<br />

R /L-B<br />

160404 R /L-B<br />

160408<br />

9.525 4.76 3.81<br />

R /L-C<br />

160412 R /L-C<br />

TNGG 220404<br />

12.70 4.76 5.16<br />

R /L-C<br />

220408 R '-B:Finishing-Medium<br />

'-C:Medium-Roughing<br />

/L-C<br />

Finishing<br />

Finishing-Medium<br />

Corner Relief<br />

-R (r ) Angle<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

TNMG 160404PS<br />

0.4<br />

9.525 4.76 3.81<br />

160408PS<br />

0.8<br />

TNMG 160404<br />

160408<br />

0.4<br />

0.8<br />

TNMG 160404XP<br />

0.4<br />

9.525 4.76 3.81<br />

160408XP<br />

0.8<br />

TNMG 160404XQ<br />

0.4<br />

9.525 4.76 3.81<br />

160408XQ<br />

0.8<br />

TNGA 160404<br />

160408<br />

TNGG 160402 R /L-S<br />

160404 9.525 4.76 3.81<br />

R<br />

/L-S<br />

160408 R<br />

/L-S<br />

TNGG 160404 R /L-C<br />

160416 R /L-C<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.4<br />

0.8<br />

1.2<br />

1.6<br />

0.4<br />

0.8<br />

VNMG 160402GP<br />

0.2<br />

160404GP 9.525 4.76 3.81 0.4<br />

160408GP<br />

0.8<br />

VNMG 160404VF 9.525 4.76 3.81<br />

0.4<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Stock Grades<br />

PVD Cermet Cermet<br />

<strong>PV7005</strong><br />

•<br />

•<br />

• R<br />

•<br />

<strong>PV7010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

R<br />

•<br />

•<br />

•<br />

<strong>TN6010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Insert<br />

Handed insert<br />

shows Right-Hand<br />

Finishing-Medium<br />

/ Up facing<br />

Description<br />

Dimension (mm)<br />

I.C. Thickness Hole<br />

VNMG 160404HQ<br />

160408HQ<br />

9.525 4.76 3.81<br />

Finishing-Medium<br />

Roughing<br />

Medium cutting<br />

Without Chipbreaker<br />

Finishing With<br />

Wiper Edge<br />

VNMG 160408<br />

VNGG<br />

160402 R<br />

/L<br />

160404 R /L<br />

160408 R /L<br />

VNGA 160404<br />

160408<br />

9.525<br />

9.525<br />

9.525<br />

12.70<br />

12.70<br />

12.70<br />

4.76<br />

4.76<br />

4.76<br />

4.76<br />

4.76<br />

4.76<br />

3.81<br />

3.81<br />

3.81<br />

WNMG 080404WP<br />

12.70 4.76 3.81<br />

080408WP<br />

WNMG 080404WQ<br />

12.70 4.76 3.81<br />

080408WQ<br />

Finishing-Medium<br />

With Wiper Edge<br />

Finishing<br />

Finishing-Medium<br />

Medium-Roughing<br />

Roughing<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon Steel<br />

Medium Finishing<br />

WNMG 080404GP<br />

12.70 4.76 3.81<br />

080408GP<br />

WNMG 080404HQ<br />

12.70 4.76 3.81<br />

080408HQ<br />

WNMG 080404CQ<br />

12.70 4.76 3.81<br />

080408CQ<br />

WNMG 080404PS<br />

080408PS<br />

WNMG 080408<br />

WNMG 080404XP<br />

080408XP<br />

3.81<br />

3.81<br />

3.81<br />

WNMG 080404XQ<br />

12.70 4.76 3.81<br />

080408XQ<br />

Corner Relief<br />

-R (r )<br />

Angle<br />

0.4<br />

0.8<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Stock Grades<br />

PVD Cermet Cermet<br />

<strong>PV7005</strong><br />

•<br />

•<br />

•<br />

<strong>PV7010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>TN6010</strong><br />

•<br />

R<br />

R<br />

R<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

• :Standard Stock R:R-hand Only<br />

4

5<br />

Stock Items<br />

Dimension (mm)<br />

I.C. Thickness<br />

Relief<br />

Angle<br />

Hole<br />

Stock Grades<br />

PVD Cermet Cermet<br />

Description<br />

Insert<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

• L<br />

L<br />

L<br />

L<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

6.35<br />

9.525<br />

12.70<br />

6.35<br />

9.525<br />

3.5<br />

4.3<br />

7.94<br />

9.525<br />

7.94<br />

9.525<br />

7.94<br />

9.525<br />

7.94<br />

9.525<br />

9.525<br />

6.35<br />

9.525<br />

6.35<br />

9.525<br />

2.38<br />

3.97<br />

4.76<br />

2.38<br />

3.97<br />

1.4<br />

1.8<br />

2.38<br />

2.38<br />

2.38<br />

3.18<br />

2.38<br />

3.18<br />

2.38<br />

3.18<br />

3.18<br />

2.38<br />

3.97<br />

2.38<br />

3.97<br />

2.8<br />

4.4<br />

5.5<br />

2.8<br />

4.4<br />

1.9<br />

2.3<br />

3.3<br />

4.5<br />

3.5<br />

4.5<br />

3.5<br />

4.5<br />

3.3<br />

4.5<br />

4.5<br />

2.8<br />

4.4<br />

2.8<br />

4.4<br />

7°<br />

7°<br />

7°<br />

7°<br />

7°<br />

7°<br />

7°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

7°<br />

7°<br />

7°<br />

7°<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

<strong>PV7005</strong><br />

<strong>PV7010</strong><br />

<strong>TN6010</strong><br />

Handed insert<br />

shows Left-Hand<br />

CCMT<br />

CCMT<br />

CCMT<br />

CCMT<br />

CCMT<br />

CCGT<br />

CCGT<br />

CPMT<br />

CPMT<br />

CPMH<br />

CPMH<br />

CPMH<br />

CPMH<br />

CPMT<br />

CPMT<br />

CPMT<br />

DCMT<br />

DCMT<br />

DCMT<br />

DCMT<br />

Finishing-Medium<br />

Finishing-Medium<br />

Finishing-Medium<br />

060202GK<br />

060204GK<br />

09T302GK<br />

09T304GK<br />

120404GK<br />

120408GK<br />

060202HQ<br />

060204HQ<br />

09T302HQ<br />

09T304HQ<br />

09T308HQ<br />

030102 R /L-F<br />

030104 R /L-F<br />

040102 R /L-F<br />

040104 R<br />

/L-F<br />

080204GP<br />

090304GP<br />

090308GP<br />

080204HQ<br />

080208HQ<br />

090304HQ<br />

090308HQ<br />

080204<br />

080208<br />

090304<br />

090308<br />

080204XP<br />

090304XP<br />

090308XP<br />

090304XQ<br />

090308XQ<br />

070202GP<br />

070204GP<br />

11T304GP<br />

11T308GP<br />

070202GK<br />

070204GK<br />

070208GK<br />

11T302GK<br />

11T304GK<br />

11T308GK<br />

Finishing<br />

Finishing<br />

Without Chipbreaker<br />

Medium cutting<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon<br />

Steel Finishing<br />

Low Carbon Steel<br />

Finishing-Medium<br />

Low Carbon Steel<br />

Finishing-Medium<br />

Finishing<br />

Finishing-Medium<br />

Dimension (mm)<br />

I.C. Thickness<br />

Relief<br />

Angle<br />

Hole<br />

Stock Grades<br />

PVD Cermet Cermet<br />

Description<br />

Insert<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

6.35<br />

9.525<br />

6.35<br />

9.525<br />

9.525<br />

9.525<br />

9.525<br />

12.7<br />

9.525<br />

12.7<br />

5.56<br />

6.35<br />

5.56<br />

6.35<br />

9.525<br />

5.56<br />

6.35<br />

9.525<br />

5.56<br />

6.35<br />

9.525<br />

2.38<br />

3.97<br />

2.38<br />

3.97<br />

3.97<br />

3.97<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

2.38<br />

2.38<br />

2.38<br />

3.18<br />

3.18<br />

2.38<br />

3.18<br />

3.18<br />

2.38<br />

3.18<br />

3.18<br />

2.8<br />

4.4<br />

2.8<br />

4.4<br />

4.4<br />

4.4<br />

4.5<br />

5.5<br />

-<br />

-<br />

2.5<br />

2.8<br />

2.8<br />

3.3<br />

4.4<br />

2.8<br />

3.3<br />

4.4<br />

2.8<br />

3.3<br />

4.4<br />

7°<br />

7°<br />

7°<br />

7°<br />

7°<br />

7°<br />

11°<br />

11°<br />

11°<br />

11°<br />

7°<br />

7°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

<strong>PV7005</strong><br />

<strong>PV7010</strong><br />

<strong>TN6010</strong><br />

Handed insert<br />

shows Left-Hand<br />

DCMT<br />

DCMT<br />

DCMT<br />

DCMT<br />

DCMT<br />

SCMT<br />

SPGR<br />

SPGR<br />

SPGN<br />

SPGN<br />

TCMT<br />

TCMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

TPMT<br />

Finishing-Medium<br />

070202HQ<br />

070204HQ<br />

070208HQ<br />

11T302HQ<br />

11T304HQ<br />

11T308HQ<br />

070204XP<br />

11T302XP<br />

11T304XP<br />

11T308XP<br />

11T304XQ<br />

11T308XQ<br />

09T304HQ<br />

09T308HQ<br />

090304 R /L<br />

120308 R<br />

/L<br />

090304<br />

090308<br />

120304<br />

120308<br />

090202HQ<br />

090204HQ<br />

110202HQ<br />

110204HQ<br />

110208HQ<br />

090202GP<br />

090204GP<br />

110304GP<br />

110308GP<br />

160304GP<br />

090202HQ<br />

090204HQ<br />

110302HQ<br />

110304HQ<br />

110308HQ<br />

160304HQ<br />

160308HQ<br />

090204XP<br />

110304XP<br />

110308XP<br />

160304XP<br />

160308XP<br />

Finishing<br />

Finishing<br />

Finishing-Medium<br />

Finishing-Medium<br />

Finishing-Medium<br />

Corner<br />

-R (r )<br />

Corner<br />

-R (r )

Insert<br />

Low Carbon Steel<br />

Finishing-Medium<br />

Without Chipbreaker<br />

Description<br />

Handed insert<br />

shows Left-Hand<br />

TPMT 110304XQ<br />

110308XQ<br />

Finishing<br />

Medium cutting<br />

Finishing-Medium<br />

Medium cutting<br />

'-A:Finishing<br />

'-B:Finishing-Medium<br />

'-C:Medium cutting<br />

TPMT 160304XQ<br />

160308XQ<br />

TPGH<br />

TPGH<br />

TPGH<br />

TPGH<br />

TPGH<br />

080202 R /L<br />

080204 R /L<br />

090202 R /L<br />

090204 R<br />

/L<br />

110202 R /L<br />

110204 R /L<br />

110302 R /L<br />

110304 R /L<br />

110308 R /L<br />

160302 R /L<br />

160304 R /L<br />

160308 R /L<br />

TPGH 110302 R /L-H<br />

110304 R /L-H<br />

110308 R /L-H<br />

Dimension (mm)<br />

I.C. Thickness Hole<br />

6.35<br />

9.525<br />

4.76<br />

5.56<br />

6.35<br />

6.35<br />

9.525<br />

6.35<br />

5.56<br />

6.35<br />

9.525<br />

9.525<br />

9.525<br />

6.35<br />

9.525<br />

9.525<br />

6.35<br />

9.525<br />

3.18<br />

3.18<br />

2.38<br />

2.38<br />

2.38<br />

3.18<br />

3.18<br />

3.18<br />

TPGH 160304 9.525 3.18<br />

R /L-H<br />

TPGB 090204<br />

TPGB 110304<br />

110308<br />

TPGB 160304<br />

TPMR 160304HQ<br />

160308HQ<br />

TPMR 160304<br />

160308<br />

TPGR 110302R/L-A<br />

110304R/L-A<br />

TPGR 160302 R /L-B<br />

160304 R /L-B<br />

160308 R /L-B<br />

TPGR 160304 R /L-C<br />

TPGN 110304<br />

110308<br />

TPGN 160304<br />

Without Chipbreaker 160308<br />

2.38<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

3.18<br />

3.3<br />

4.4<br />

2.3<br />

3.0<br />

3.5<br />

3.3<br />

4.5<br />

3.3<br />

4.5<br />

3.0<br />

3.3<br />

4.5<br />

4.5<br />

4.5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Corner Relief<br />

-R (r ) Angle<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.8<br />

0.4<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

11°<br />

Stock Grades<br />

PVD Cermet Cermet<br />

<strong>PV7005</strong><br />

•<br />

•<br />

• •<br />

•<br />

•<br />

•<br />

•<br />

•<br />

L<br />

L<br />

L<br />

L<br />

L<br />

•<br />

•<br />

<strong>PV7010</strong><br />

•<br />

•<br />

•<br />

•<br />

L<br />

L<br />

L<br />

<strong>TN6010</strong><br />

•<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

•<br />

•<br />

L<br />

L<br />

L<br />

Insert<br />

Handed insert<br />

shows Left-Hand<br />

Finishing<br />

Finishing<br />

Finishing-Medium<br />

Finishing<br />

Finishing-Medium<br />

Finishing<br />

Finishing-Medium<br />

Finishing<br />

Finishing<br />

Finishing-Medium<br />

Description<br />

VBMT 110304GP<br />

VBMT 160404GP<br />

160408GP<br />

VBMT 110302VF<br />

110304VF<br />

110308VF<br />

VBMT 160402VF<br />

160404VF<br />

160408VF<br />

160412VF<br />

VBMT 110304HQ<br />

110308HQ<br />

VBMT 160404HQ<br />

160408HQ<br />

160412HQ<br />

VBGT 110302 R /L-F<br />

VBGT<br />

110302 R<br />

/L-Y<br />

110304 R /L-Y<br />

VBGT 160402 R /L-Y<br />

160404 R /L-Y<br />

VCMT 080202VF<br />

080204VF<br />

VCMT 080202HQ<br />

VCMT 080204HQ<br />

WBMT060102<br />

R /L-DP<br />

060104 R /L-DP<br />

WBMT080202<br />

R /L-DP<br />

080204 R /L-DP<br />

WBGT060102<br />

R /L-F<br />

060104 R /L-F<br />

WBGT080202<br />

R /L-F<br />

080204 R<br />

/L-F<br />

WPMT110204HQ<br />

WPMT160304HQ<br />

160308HQ<br />

Dimension (mm)<br />

I.C. Thickness Hole<br />

6.35<br />

9.525<br />

6.35<br />

9.525<br />

6.35<br />

9.525<br />

6.35<br />

6.35<br />

9.525<br />

4.76<br />

4.76<br />

3.97<br />

4.76<br />

3.97<br />

4.76<br />

6.35<br />

9.525<br />

3.18<br />

4.76<br />

3.18<br />

4.76<br />

3.18<br />

4.76<br />

3.18<br />

3.18<br />

4.76<br />

2.38<br />

2.38<br />

1.59<br />

2.38<br />

1.59<br />

2.38<br />

2.38<br />

3.18<br />

2.8<br />

4.4<br />

2.8<br />

4.4<br />

2.8<br />

4.4<br />

2.8<br />

2.8<br />

4.4<br />

2.3<br />

2.3<br />

2.3<br />

2.3<br />

2.3<br />

2.3<br />

2.8<br />

4.4<br />

Corner Relief<br />

-R (r ) Angle<br />

0.4<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

0.2<br />

0.4<br />

0.8<br />

1.2<br />

0.4<br />

0.8<br />

0.4<br />

0.8<br />

1.2<br />

0.2<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.2<br />

0.4<br />

0.4<br />

0.4<br />

0.8<br />

5°<br />

5°<br />

5°<br />

5°<br />

5°<br />

5°<br />

5°<br />

5°<br />

5°<br />

7°<br />

7°<br />

5°<br />

5°<br />

5°<br />

5°<br />

11°<br />

11°<br />

Stock Grades<br />

PVD Cermet Cermet<br />

<strong>PV7005</strong><br />

<strong>PV7010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

L<br />

L<br />

L<br />

L<br />

•<br />

•<br />

<strong>TN6010</strong><br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

L<br />

•<br />

•<br />

• :Standard Stock L:L-hand Only<br />

6