Precision.

Precision.

Precision.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

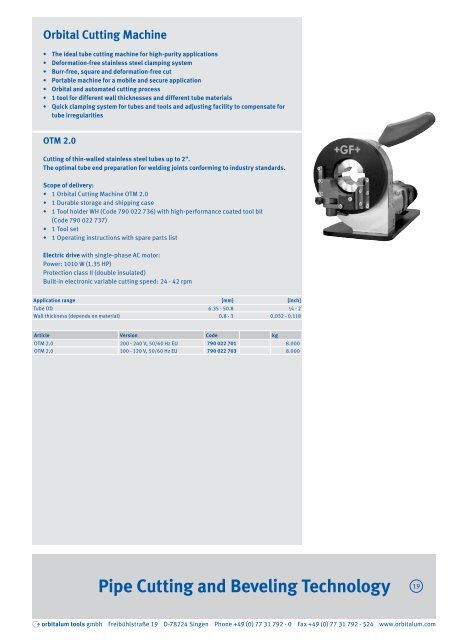

Orbital Cutting Machine<br />

• The ideal tube cutting machine for high-purity applications<br />

• Deformation-free stainless steel clamping system<br />

• Burr-free, square and deformation-free cut<br />

• Portable machine for a mobile and secure application<br />

• Orbital and automated cutting process<br />

• 1 tool for different wall thicknesses and different tube materials<br />

• Quick clamping system for tubes and tools and adjusting facility to compensate for<br />

tube irregularities<br />

OTM 2.0<br />

Cutting of thin-walled stainless steel tubes up to 2".<br />

The optimal tube end preparation for welding joints conforming to industry standards.<br />

Scope of delivery:<br />

• 1 Orbital Cutting Machine OTM 2.0<br />

• 1 Durable storage and shipping case<br />

• 1 Tool holder WH (Code 790 022 736) with high-performance coated tool bit<br />

(Code 790 022 737)<br />

• 1 Tool set<br />

• 1 Operating instructions with spare parts list<br />

Electric drive with single-phase AC motor:<br />

Power: 1010 W (1.35 HP)<br />

Protection class II (double insulated)<br />

Built-in electronic variable cutting speed: 24 - 42 rpm<br />

Application range [mm] [inch]<br />

Tube OD 6.35 - 50.8 ¼ - 2<br />

Wall thickness (depends on material) 0.8 - 3 0.032 - 0.118<br />

Article Version Code kg<br />

OTM 2.0 200 - 240 V, 50/60 Hz EU 790 022 701 8.000<br />

OTM 2.0 100 - 120 V, 50/60 Hz EU 790 022 703 8.000<br />

Pipe Cutting and Beveling Technology<br />

orbitalum tools gmbh Freibühlstraße 19 D-78224 Singen Phone +49 (0) 77 31 792 - 0 Fax +49 (0) 77 31 792 - 524 www.orbitalum.com<br />

19