THE COTTON CORPORATION OF INDIA LIMITED NO - Tenders India

THE COTTON CORPORATION OF INDIA LIMITED NO - Tenders India

THE COTTON CORPORATION OF INDIA LIMITED NO - Tenders India

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CCI<br />

<strong>THE</strong> <strong>COTTON</strong> <strong>CORPORATION</strong> <strong>OF</strong> <strong>INDIA</strong> <strong>LIMITED</strong><br />

(A GOVERNMENT <strong>OF</strong> <strong>INDIA</strong> UNDERTAKING)<br />

BRANCH <strong>OF</strong>FICE: PRAMILA NIWAS, MAIN ROAD<br />

RAYAGADA – 765001 (ORISSA)<br />

Phone: 06856-236616: Fax-236013<br />

<strong>NO</strong>: CCI/RGD/G&P/2012-13 Date: 21.08.2012<br />

TENDER <strong>NO</strong>TICE<br />

The Cotton Corporation of <strong>India</strong> Ltd, Rayagada invites Sealed<br />

<strong>Tenders</strong> from reputed Ginning & Pressing Factories for the Cotton Season<br />

2012-2013 in respect of Ginning & Pressing work at the following proposed<br />

centers: Rayagada, Gunupur, Kesinga, Kantabanji, Bolangir & Titlagarh.<br />

Tendered should ensure the holding of Provident Fund Code No. from<br />

the appropriate authority.<br />

The prescribed tender forms along with the terms & conditions can be<br />

obtained from the Branch Office during working hours on any working day,<br />

on payment of Rs.100/- (Rupees One Hundred only) upto 07.09.12 and the<br />

same is also available at CCI’s website:http://www.cotcorp.gov.in and<br />

government portal http://tenders.gov.in. The Tender Form duly completed in<br />

all respects in sealed cover inscribed as "Ginning & Pressing tender for<br />

cotton season 2012-2013" addressed to the Branch Manager, should reach<br />

the Branch Office on or before 3.30pm hours on 07.09.12. The sealed<br />

tenders received within the stipulated time, shall be opened on the same day<br />

at 4.00pm in the presence of tenderers who may wish to remain present.<br />

The Corporation reserves the right to accept or reject any tender<br />

without assigning any reason thereof.<br />

(BRANCH MANAGER)

CCI<br />

(A Government of <strong>India</strong> Undertaking)<br />

Branch Office, Pramila Niwas, Main Road, Rayagada -765001(Orissa)<br />

Phone-06856-236616 & Fax 06856-236013<br />

Website:- www.cotcorp.gov.in .<br />

E-Mail: rayagada@cotcorp.com________________________________<br />

Tender Form No. : ______________ Tender form fees : Rs.100/-<br />

(Rupees One Hundred only)<br />

Date of issue : 21.08.2012<br />

Last date of submission : 07.09.2012 upto 3.30 P.M.<br />

Date of opening of Tender : 07.09.2012 at 4.00 P.M.<br />

TENDER FOR JOB WORK <strong>OF</strong> GINNING & PRESSING<br />

FOR <strong>COTTON</strong> SEASON : 2012-13.<br />

PART-I<br />

1. Name of the centre : ________________________________<br />

2. Full Name of the factory, Address with Pin<br />

code, Telephone/Mobile/ Fax Numbers<br />

E-mail (If any):<br />

3. Status of the Factory :<br />

(Please tick () whichever is applicable)<br />

4. Category of Ginning & Pressing factory<br />

(Please tick () whichever is applicable)<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

Composite G&P factory / Only Ginning factory /<br />

Only pressing factory.<br />

i) Modernised composite ginning & pressing<br />

factory through TMC assistance and certified<br />

by Textile Committee.<br />

ii) Modernised composite ginning & pressing<br />

factory other than TMC assistance and<br />

certified by Textile Committee.<br />

iii) Modernised composite ginning & pressing<br />

factory through TMC assistance.<br />

iv) Modernised composite ginning & pressing<br />

factory other than TMC assistance.<br />

v) Conventional ginning & pressing factory.<br />

5. Whether Modern Factory is online or not? Yes No<br />

6. Constitution – Company / Partnership /<br />

Sole Proprietary<br />

_______________________________

7. Name of the Directors/partners and their<br />

occupation.<br />

8. Name and address of the sister concern, if<br />

any.<br />

9. Name of Proprietor or Active Partner.<br />

10. Name of Factory Manager/Other Responsible<br />

person,<br />

if any alongwith Tel.No.<br />

11. P.F. Code No.<br />

(Please attach certificate issued by Regional<br />

Provident Fund Commissioner)<br />

1. _________________________________<br />

2. _________________________________<br />

3. _________________________________<br />

4. _________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

12. PAN from Income Tax Department _____________________________<br />

13. Location of Factory i) Distance from Market Yard ________KM<br />

ii) Distance from Railway station ________KM<br />

iii) Distance from SWC /CWC ________KM<br />

iv) Distance from Bus Stand ________KM<br />

PART-II<br />

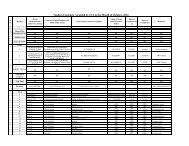

14.<br />

15.<br />

Installed capacity<br />

and its production<br />

Type<br />

Single Roller<br />

Double Roller<br />

Sawgin<br />

Pressing<br />

a) Manufacture & Installation of<br />

b) No. of Gallas<br />

c) Press marka<br />

Machine<br />

Nos/Sets<br />

Type<br />

SR<br />

DR<br />

Sawgin<br />

Press<br />

Machine Manufacturer<br />

Production in bales<br />

(on single shift of 8 hrs)<br />

Per day Per week<br />

Year of<br />

Installation<br />

16. a) Type of pressing : Hydraulic Mechanical<br />

b) No. of petti (box) :

17. Present working condition of the<br />

above machinery<br />

18. Whether factory has sufficient<br />

Managerial, Supervisory & Technical<br />

staff<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

Yes No<br />

19. Details of processing of bales during last<br />

three years<br />

2009-/10 2010-/11 2011-/12<br />

i) For CCI --------- --------- --------ii)<br />

Own --------- --------- --------iii)<br />

Other parties --------- --------- --------iv)<br />

Contamination free bales --------- --------- ---------

20. Whether total capacity is offered to CCI<br />

or part capacity on exclusive basis or on<br />

turn basis :<br />

21. If on part or turn basis, then details of<br />

capacity allotment to CCI<br />

22. Details of Palahouse and machinery<br />

installed for removing contaminants and<br />

trash<br />

23. Whether factory is having pacca compound<br />

wall or barbed wire fencing or otherwise<br />

24. Whether factory compound is pacca or<br />

kachha<br />

25. Whether rain water accumulates in the<br />

factory compound and if so, the approx.area<br />

26. Whether approach road to factory is pacca<br />

or not.<br />

27. Whether weighbridge/platform available at<br />

factory gate, if yes please mention the<br />

capacity.<br />

28. Whether all electrical wires are<br />

underground,<br />

installations.<br />

if not, place of open<br />

29. a. Whether the factory has diesel generator<br />

set?<br />

b. If yes, please indicate capacity of DG Set.<br />

30. Whether power supply in the factory is on<br />

express feeder?<br />

PART-III<br />

_________________________________<br />

Machinery Production in bales<br />

Per week Per month<br />

SR ------- -------- ---------<br />

DR ------- -------- ---------<br />

Sawgin ------- -------- ---------<br />

Pressing ------- -------- ---------<br />

i) Before Ginning _______________________<br />

_______________________<br />

ii) Before Pressing _______________________<br />

_______________________<br />

PART-IV<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

Yes No<br />

__________________________________<br />

Yes No

31. No. of Transformers/ Generators and their<br />

location from Gin/Press house and kapas<br />

heaps.<br />

32. Whether any HT/LT line passes through the<br />

factory compound or by the side of<br />

boundary wall.<br />

33. Details of fire-fighting arrangements<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

1) Tube well capacity _________________________________<br />

2) Over Head Tank Nos. ___________ Capacity (in litres)____________<br />

3) Underground Tanks Nos. ___________ Capacity (in litres)____________<br />

4) No.of Hydrants _________________________________<br />

5) No.of firex _________________________________<br />

34. Classification of the factory as per<br />

Insurance tariff rules.<br />

35. Details of fire accidents in the last 3<br />

years.<br />

36. Whether pucca kapas heap platforms<br />

are available ? If so give details of<br />

construction type i.e.cemented/<br />

pacca/ brick/ bolder / leveled with<br />

stones)<br />

37. Details of kapas heap platforms to<br />

be allotted to CCI, as per heap<br />

numbers under Srl.No.36<br />

38. Details of sheds/barracks/pala<br />

house/godowns available in the<br />

factory with their storage capacity<br />

and allotment to CCI free of cost.<br />

_________________________________<br />

Year Open compound Gin House Press House<br />

2009-/10- ________________________________<br />

2010-/11 ________________________________<br />

2011-/12 ________________________________<br />

PART-V<br />

Heap Height Type of Size Storage<br />

No. from constr- Capacity<br />

Ground uction (in Qtls)<br />

Level<br />

_____ ________ ________ _____ ______<br />

_____ ________ ________ _____ ______<br />

_____ ________ ________ _____ ______<br />

_____ ________ ________ _____ ______<br />

Heap Number Storage capacity (in Qtls)<br />

________ ________<br />

________ ________<br />

________ ________<br />

________ ________<br />

Availability Allotment to CCI<br />

No. Capacity No. Capacity<br />

Sheds ----- ---------- ----- ----------<br />

Barracks ----- ---------- ----- ----------<br />

Pallahouse ----- ---------- ----- ----------

39.<br />

Godowns ----- ---------- ----- ----------<br />

Location of pala Houses, its size capacity & type of construction<br />

Pala Distance Distance Size Roof Capacity (in Qtls)<br />

House from Gin from Press made of<br />

No. House House Tin/RCC Sheet<br />

-------- ------------ ------------- ----------- ----------- --------------<br />

-------- ------------ ------------- ----------- ----------- --------------<br />

-------- ------------ ------------- ----------- ----------- --------------<br />

-------- ------------ ------------- ----------- ----------- --------------

40. No.of weighing scales available for<br />

weighment of :<br />

i) Kapas<br />

_________________________________<br />

ii) Cotton seed _________________________________<br />

iii) FP bales _________________________________<br />

41. Please give details on the installation<br />

and working condition of the<br />

following :<br />

i) Kapas cleaner _________________________________<br />

ii) Lint opener<br />

_________________________________<br />

iii) Lint cleaner<br />

_________________________________<br />

iv) Pneumatic system for kapas heap<br />

to Gin Hall.<br />

_________________________________<br />

v) Pneumatic system from Gin Hall _________________________________<br />

to Pala/press hall.<br />

vi) Humidifier in Gin house, pala<br />

house/press house.<br />

42. If no pneumatic system from gin<br />

house to pala/press house,<br />

arrangements for carrying lint boras<br />

through trolly or otherwise.<br />

43. Details of facilities for CCI staff i.e.<br />

office with furniture, telephone and<br />

residence etc.<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

_________________________________<br />

PART-VI<br />

44. During cotton season 2011-12, cloth will not be supplied by CCI for packing of cotton bales<br />

therefore the factory should quote their rates including cost of cloth. Accordingly, your minimum<br />

acceptable ginning rates and pressing rates or ginning and pressing rates, to be quoted on the basis of<br />

all job work to be done by factory from kapas heap to ginning and carrying of lint upto press point in<br />

case of ginning and from gin house/pala house to pressing of bales including weighment and marka<br />

etc. in case of pressing with specific details of work requirements and inputs of material as under:<br />

For Ginning For Pressing<br />

Providing of required number of labourers for<br />

all stages of work beginning from kapas heap<br />

to gin house, feeding on machines, bura<br />

picking from heap to gin house, platform<br />

cleaning, rool picking, cowdy and YP pickings<br />

on machine, lint picking from front and back<br />

side of machines, cotton seed cleaning and all<br />

other allied works of bora filling and its<br />

Providing of required number of labourers for<br />

mixing as well as cleaning of lint before feeding in<br />

the opener and pressing of bales with standard<br />

weight of 170 kg net lint with tolerance limit of +<br />

5 kgs for all months except during March to June<br />

when the tolerance shall be of + 7 Kgs. fully<br />

covered with new iron hoops(18/19 gauge, 1/2”<br />

width) with 100% cotton cloth (20X20 count,

carrying / transportation upto pala house/press<br />

house in the same factory or another factory at<br />

the same centre or another centre<br />

48X40 R&P, 127 cm width, weight 122 gms per<br />

Sq Metres) to be arranged by G&P factory, with<br />

stitching and covering of bales from all sides<br />

including top and bottom, besides handling of lint<br />

stocks beginning from opening of lint<br />

boras/boundaries till stacking of bales after marka<br />

and weighment and all other allied work during the<br />

course of pressing of lint into bales including lint<br />

opener.<br />

45. The net weight of a fully pressed bale should not be less than 170 kgs However, tolerance limit of<br />

+ 5 kg may be allowed for all the months except during March to June when the tolerance shall be<br />

of + 7 kg. subject to the condition that the average net weight of a lot of 100 bales should not be less<br />

than 165 quintals. Suitable deductions will be made from pressing charges if the average net weight<br />

of a lot is less than 165 quintals per lot of 100 bales. However, no extra payment will be made for<br />

excess weight in the lot.<br />

46. Rates may be specifically quoted both in numeric form and in words clearly. <strong>Tenders</strong> without<br />

quoting specific rates or with indications of negotiations on CCI rates/Government rates etc. may be<br />

rejected at the discretion of the Corporation.<br />

47. During cotton season 2011-12, cloth will not be supplied by CCI for packing of cotton bales<br />

therefore the factory should quote their rates including cost of cloth. In case some stocks of<br />

cloth/Hessian procured by CCI is available, such stocks will be consumed first and for such<br />

eventualities, G&P rates without including cost of cotton cloth may be quoted by G&P factories<br />

separately. Thus based on the indicative job requirement and inputs of labour and material, our<br />

lowest acceptable ginning and pressing rates are as under:<br />

Particulars<br />

i) Combined ginning & pressing rates per bale with iron hoops including cost of<br />

cloth<br />

(Modern Factory/Conventional)<br />

Processing Type<br />

Roller Sawgin<br />

Rs._____ Rs.____<br />

ii) Ginning rate per quintal of kapas/lint<br />

(Modern Factory/Conventional)<br />

Rs._____ Rs.____<br />

iii) Pressing rate per bale with iron hoops and with cost of 100% cotton cloth to be<br />

arranged by the factory.<br />

Rs._____ Rs.____<br />

iv) Pressing rate per bale with iron hoops but without including cost of cloth.<br />

Note:<br />

Rs._____ Rs.____<br />

♦ The specifications for iron hoops (18/19 gauge, 1/2” width) and specification of 100%<br />

cotton cloth (20X20 count, 48X40 R&P, 127 cm width, weight 122 gms per Sq Metres)<br />

should be considered while quoting above rates.<br />

♦ It must be clearly indicated whether above rates are for Modern factory or for<br />

Conventional factory.<br />

♦ Please strike out whichever is not applicable.

I/We have gone through the detailed terms and conditions for hiring of G&P factories<br />

by the Corporation and agree to carry out the complete processing work as per standards and<br />

requirements of the Corporation.<br />

Name of the Authorised Signatory<br />

Address of the<br />

factory with seal<br />

Date:

Annexure-III<br />

-1-<br />

<strong>THE</strong> <strong>COTTON</strong> <strong>CORPORATION</strong> <strong>OF</strong> <strong>INDIA</strong> <strong>LIMITED</strong>.<br />

BRANCH <strong>OF</strong>FICE : RAYAGADA<br />

MAIN TERMS AND CONDITIONS<br />

<<br />

i) The tender form duly filled in, in all respects and signed by the<br />

Authorized Signatory, should be submitted in a sealed cover inscribed<br />

"Ginning and Pressing tender for cotton season 2012-13" within the<br />

stipulated time and date. Tender forms received after the stipulated<br />

time and date, are likely to be rejected.<br />

ii) All columns in the tender form should be filled in clearly and legibly.<br />

Tender form found as incomplete in any respect, may be rejected at the<br />

discretion of the Corporation.<br />

iii) Mere submission of the tender form does not entitle any factory to be<br />

engaged by the Corporation. The Corporation reserves the right to<br />

accept or reject any tender without assigning any reason thereof.<br />

iv) Other things being equal and meeting the requirements of the<br />

Corporation, preference will be given to factories offering the lowest<br />

ginning and pressing rates. However, rates shall not be the sole<br />

criteria for engagement of factories and other factors like quality of<br />

work by the factory, extent of modernization and past performance<br />

etc., shall also be considered.<br />

v) The Corporation will consider hiring of ginning and pressing factories<br />

in the following order of preference :<br />

(a) Modernized composite G&P factories with adequate fire fighting<br />

arrangements and having certification of Textile Committee<br />

(b) Modernized composite G&P factories with adequate fire fighting<br />

arrangements<br />

(c) Composite G&P factories in MSEs / Co-operative sector / other<br />

institutions<br />

(d) Composite G&P factories with track record of good performance.<br />

(e) G&P factories willing to give their full capacity on exclusive basis to<br />

CCI.<br />

Note : Online Modern Factories, Factories having power supply through express feeder<br />

and the Factories having diesel generator sets shall have added advantage.

vi) Ginning & Pressing rates announced by the State Government, if any,<br />

under any act in force are the maximum rates. Hence it is made clear to<br />

all the parties that the CCI will pay the rate finalized with CCI or the<br />

rates fixed by State Govt. whichever is lower.<br />

vii) In the event of Corporation finalizing to hire the ginning and pressing capacity, the<br />

concerned factory will have to enter into an agreement with the Corporation in the<br />

prescribed form with acceptance of all its terms and conditions. The factory will<br />

also submit a copy of partnership deed/ memorandum of article/ memorandum of<br />

association as the case may be.<br />

viii) In case the L1 tenderer refuse to work at the rates quoted by him, such<br />

factories shall not be awarded any work for at least one year i.e. next<br />

cotton season.<br />

ix) Ginning rates to be quoted by parties must be inclusive of all the work<br />

and the various stages of work specified as under :-<br />

a) Carrying of graded kapas from the grading hall/heap to gin hall.<br />

b) Feeding of kapas to the gins.<br />

c) Cleaning of lint, filling into the lint boras, weighment of lint boras<br />

if any, and stacking of boras.<br />

d) Picking of roll touch and yellow picking from the lint at the time of<br />

ginning.<br />

e) Transportation of lint to the press hall and in case of Ginning unit<br />

only to Press Hall of pressing factory at the same centre or another<br />

centre.<br />

f) Carrying of seeds from the gin hall to seed godown.<br />

g) Sweeping of lint in ginning hall / factory and removing gin waste<br />

and miscellaneous items etc. to storing points.<br />

h) Weighment of lint if required.<br />

i) Any extra labour required to be deployed in the case of ginning of<br />

kapas and in emergencies and natural calamities like rain, thunder,<br />

cyclone etc.<br />

ix) In case of pressing of bales, the rates quoted should be inclusive of the<br />

following:<br />

a) Unloading, carrying and stacking of the lint boras from within the<br />

factory or to be received from outside.<br />

b) Carrying and opening of lint in the lint hall.<br />

c) Pala making<br />

d) Feeding of cleaned lint into the press box.<br />

e) Removing of bales from press platforms to stacking point.

f) Marking of bales.<br />

g) Weighment of bales.<br />

h) Any extra labour required to be deployed in the case of pressing of<br />

bales and in emergencies and natural calamities like rain, thunder,<br />

cyclone etc.<br />

x) All the pages of the Tender Form as well the Terms & Conditions should<br />

be signed by the factory owner.<br />

xi) The time and date of finalization of the tender shall be intimated<br />

separately.<br />

D E C L A R A T I O N<br />

I/We hereby confirm that the above clauses have been read and noted<br />

and we agree to abide by all the above Terms and Conditions.<br />

Name of the :<br />

____________________________<br />

Factory owner<br />

Seal of<br />

Signature : __________________________<br />

Factory : __________________