Annex 1 To 3. Scope Of Work, Specifications - Alliance for Mindanao ...

Annex 1 To 3. Scope Of Work, Specifications - Alliance for Mindanao ...

Annex 1 To 3. Scope Of Work, Specifications - Alliance for Mindanao ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Annex</strong> 1 <strong>Scope</strong> of <strong>Work</strong><br />

<strong>Annex</strong> 2 Technical <strong>Specifications</strong><br />

and Standards<br />

<strong>Annex</strong> 3 General Requirements and<br />

specifications <strong>for</strong> solar<br />

photovoltaic home systems

Table of Contents<br />

ANNEX 1: SCOPE OF WORK...............................................................................4<br />

1.1 Installation of solar PV systems at public facilities .............................5<br />

1.1.1 System descriptions ...................................................................5<br />

1.1.2 Number and location of systems to be installed........................7<br />

1.1.3 Documentation and training ......................................................9<br />

1.1.4 Delivery schedule ......................................................................9<br />

1.2 After-sales services <strong>for</strong> solar PV systems at public facilities ..............9<br />

1.2.1 System Warranty .......................................................................9<br />

1.2.2 Maintenance.............................................................................10<br />

1.3 Sales and services to private customers .............................................10<br />

ANNEX 2: TECHNICAL SPECIFICATIONS AND STANDARDS ..................12<br />

2.1 Load assessment and sizing ...............................................................12<br />

2.1.1 Minimum sizes ........................................................................12<br />

2.2 Project requirements <strong>for</strong> private customers .......................................12<br />

2.3 Project requirements <strong>for</strong> public facilities...........................................12<br />

2.<strong>3.</strong>1 Applicable standards................................................................12<br />

2.<strong>3.</strong>2 PV modules..............................................................................13<br />

2.<strong>3.</strong>3 Batteries...................................................................................14<br />

2.<strong>3.</strong>4 Solar charge controllers...........................................................14<br />

2.<strong>3.</strong>5 Inverters...................................................................................14<br />

2.<strong>3.</strong>6 Interior luminaires ...................................................................15<br />

2.<strong>3.</strong>7 Exterior luminaires ..................................................................15<br />

2.<strong>3.</strong>8 Streetlight.................................................................................15<br />

2.<strong>3.</strong>9 LCD/DVD ...............................................................................16<br />

2.<strong>3.</strong>10 Public Address system.............................................................16<br />

2.<strong>3.</strong>11 Portable Lanterns.....................................................................16<br />

2.4 Project specific technical specifications <strong>for</strong> Public Systems .............17<br />

2.4.1 PV School Electrification System ..........................................17<br />

2.4.2 PV Streetlight ..........................................................................18<br />

2.4.3 Example bill of quantities........................................................18<br />

2.4.5 Code of practice <strong>for</strong> installation ..............................................20<br />

2.4.6 Spares.......................................................................................23<br />

2.4.8 Training code...........................................................................24<br />

2.4.9 Documentation to be provided ................................................24<br />

2.5 Technical specifications: Maintenance ..............................................26<br />

2.5.1 Routine maintenance ...............................................................26<br />

2.5.2 Breakdown repair maintenance service...................................27<br />

2.5.3 Maintenance log sheets............................................................27<br />

2.6 Product range <strong>for</strong> the private market .................................................33<br />

2.6.1 Solar home systems .................................................................33<br />

2.6.2 Business systems .....................................................................33<br />

2.7 Experience, organisational and competence requirements ................33

ANNEX 3: GENERAL REQUIREMENTS AND SPECIFICATIONS FOR SOLAR<br />

PHOTOVOLTAIC HOME SYSTEMS .......................................................35<br />

<strong>3.</strong>1 Solar Home System Hardware Description .......................................35<br />

<strong>3.</strong>2 Certification Requirements ................................................................36<br />

<strong>3.</strong>3 Recommended Best Practices ............................................................36<br />

<strong>3.</strong><strong>3.</strong>1 PV Module Installation............................................................37<br />

<strong>3.</strong><strong>3.</strong>2 Circuit Protection and Charge Controls...................................38<br />

<strong>3.</strong><strong>3.</strong>3 System Monitoring ..................................................................38<br />

<strong>3.</strong><strong>3.</strong>4 Batteries...................................................................................39<br />

<strong>3.</strong><strong>3.</strong>5 DC/AC Inverters......................................................................40<br />

<strong>3.</strong><strong>3.</strong>6 Equipment Enclosure...............................................................40<br />

<strong>3.</strong><strong>3.</strong>7 Wiring......................................................................................40<br />

<strong>3.</strong>4 Documentation...................................................................................41<br />

<strong>3.</strong>4.1 Users Manual...........................................................................41<br />

<strong>3.</strong>4.2 Technicians Manual.................................................................42<br />

<strong>3.</strong>5 Packaging and Delivery .....................................................................43

<strong>Annex</strong> 1: <strong>Scope</strong> of <strong>Work</strong><br />

This procurement is to procure, install, commission and provide maintenance in<br />

thirty barangays of the DOE 30/WI-AMORE area 1 in the provinces of Zamboanga<br />

Peninsula, Central <strong>Mindanao</strong>, Basilan, and Sulu as well as to commercially<br />

market, sell, install, and provide after sales service <strong>for</strong> a number of solar home<br />

systems (SHS), i.e. 900, <strong>for</strong> private customers in the same DOE 30/WI-AMORE<br />

area.<br />

AMORE Project. Winrock International (WI), a US-based non-profit<br />

organization, is the implementer of the <strong>Alliance</strong> <strong>for</strong> <strong>Mindanao</strong> <strong>Of</strong>f-Grid<br />

Renewable Energy (AMORE) Project. AMORE seeks to improve the quality of<br />

life in poor, conflict-affected areas in <strong>Mindanao</strong> by providing off-grid<br />

electrification with the use of clean, renewable energy systems. A Memorandum<br />

of Agreement was signed between DOE and WI-AMORE to energize 21<br />

barangays <strong>for</strong> the purpose of introducing a number of comprehensive and<br />

innovative measures aimed at achieving the goal of 100% barangay electrification<br />

by 2008.<br />

AMORE provides a sustainable program by providing community organizing and<br />

capacity-building in its target area. AMORE organizes participating households<br />

in each community into a Barangay Renewable Energy and Development<br />

Associations (BRECDAs), which the program trains to operate and maintain their<br />

RE systems and expand their development<br />

The BRECDAs choose their own leaders, <strong>for</strong>mulate their own Constitution and<br />

By-laws, raise their own funds and register their organization with the appropriate<br />

government agency. These BRECDAs are further organized into provincial or<br />

municipality federations to foster cooperation among all the community recipients<br />

across the provinces. The BRECDA Federations are being developed by AMORE<br />

to take the lead in planning and implementing projects that would empower them<br />

and give them credibility as an organization <strong>for</strong> sustainable development.<br />

Rural Power Project. The Department of Energy is also implementing the<br />

World Bank and Global Environment Facility (GEF) financed Rural Power<br />

Project. This Project has supported the development of the Sustainable Solar<br />

Market Packages (SSMP) concept and supporting the commercial dissemination<br />

of solar PV systems in the Philippines. Specifically, the Project may provide the<br />

following incentives to the DOE 30 Contractor:<br />

1 Refer to Instructions to Bidders <strong>for</strong> definition of ”DOE 30/AMORE” and ”DOE 30/AMORE Area”<br />

4

For sales in the private market within a DOE 30 Area, output-based subsidies and<br />

financial incentives, paid upon verification of installations, are available<br />

depending on the type and size of the PV Systems Installed in accordance with the<br />

following table:<br />

Subsidy<br />

level<br />

Government Subsidy GEF Financial Incentives<br />

≥ 20 Wp & ≤ 30<br />

Wp<br />

> 30 Wp & ≤ 50<br />

Wp<br />

P8,000 per<br />

system<br />

P5,000 per<br />

system<br />

≥ 10 Wp & ≤ 50<br />

Wp<br />

> 50 Wp & ≤ 100<br />

Wp<br />

$2.5 per Wp<br />

$1.5 per Wp<br />

For installations at public facilities within a DOE 30 Area, including those<br />

installations covered under this bid, a GEF subsidy is available of $1.5 per Wattpeak<br />

up to a maximum of $450 per system.<br />

Companies accredited by the Department of Energy <strong>for</strong> commercial sales of PV<br />

Systems to the private market can claim these subsidies and financial incentives<br />

through the Rural Power Project – Project Management <strong>Of</strong>fice. Companies not<br />

already accredited can apply to the Department of Energy <strong>for</strong> accreditation and<br />

enter into a Memorandum of Agreement with the Department of Energy<br />

simultaneously or subsequent to submitting a bid <strong>for</strong> the DOE 30.<br />

A Market Development Support Facility is also available which provides costshared<br />

grants (up to 50 percent of the costs) to support specific activities such as<br />

training, technical assistance, market entry cost, etc to Companies accredited by<br />

the Department of Energy.<br />

Guidelines <strong>for</strong> the Market Development Support Facility and subsidy availment<br />

(PV Guidelines) can be downloaded from the Department of Energy website<br />

(www.doe.gov.ph) under the RPP link.<br />

1.1 Installation of solar PV systems at public facilities<br />

Solar PV systems are to be installed at selected public facilities within the DOE<br />

30/WI-AMORE area. Each installation shall be undertaken according to the<br />

technical specifications provided, including user-training and provision of<br />

documentation.<br />

1.1.1 System descriptions<br />

Technical specifications are provided <strong>for</strong> solar electricity systems <strong>for</strong> the<br />

following applications in barangay public facilities:<br />

• SYSTEM A - PV School Electrification – lighting (indoor, and outdoor),<br />

public address/karaoke systems, LCD/DVD and small appliances<br />

• SYSTEM B - PV Streetlight – streetlights, path lighting, pier lighting,<br />

public areas such as basketball / drying areas<br />

5

The recommended system configuration <strong>for</strong> the identified solar PV packages in<br />

the DOE 30/WI-AMORE project is a small DC-bus system providing 12 V DC<br />

electricity <strong>for</strong> lighting and 220 - 240 V AC electricity <strong>for</strong> energy efficient<br />

appliances such as LCD/DVD, karaoke system, cell phone charger. This system<br />

would be provided with two portable solar lantern which con<strong>for</strong>ms and preapproved<br />

by RPP. The exception to this standardised configuration is the<br />

standalone 12 V DC system <strong>for</strong> public lighting.<br />

A typical system diagram <strong>for</strong> the DC / AC system is shown in Figure 1 and Figure<br />

2, and the categories of systems detailed in the attached Technical <strong>Specifications</strong><br />

are presented in Table 1.<br />

All bidders must produce technical drawings of all the systems herein <strong>for</strong><br />

reference and review to Winrock International – AMORE. For details, please<br />

refer to page Table 1 page 7 and Table 4 page 12.<br />

Figure 1: System diagram <strong>for</strong> typical solar PV package<br />

Solar Modules<br />

+ - + -<br />

Array Junction Box<br />

+<br />

+<br />

Charge Controller<br />

+ - + - + -<br />

Fuse<br />

Battery<br />

Battery<br />

-<br />

-<br />

+ -<br />

+ - + - + -<br />

DC Distribution Box<br />

DC/AC<br />

Inverter<br />

Switch<br />

DC Chargers<br />

AC Pannel Board<br />

DC Lights (12V CFL)<br />

AC Loads<br />

Sound System<br />

TV & DVD Player<br />

Nebulizer<br />

Fan<br />

AC Cellphone Charger<br />

AC NiCd Battery Charger<br />

AC Portable Lantern Charger<br />

Plugs<br />

Lights (in future)<br />

6

Figure 2: Typical schematic of system installation<br />

solar modules on<br />

polemount<br />

Note<br />

Pole against wall<br />

and through roof<br />

SIDE VIEW<br />

distribution box pull switch<br />

DC light<br />

metal enclosure<br />

charge<br />

controller<br />

battery box<br />

fuse<br />

battery battery<br />

Table 1: System descriptions<br />

dc/ac inverter<br />

AC pannel board<br />

AC Appliances<br />

Solar<br />

Modules<br />

CFL 5<br />

Outdoor<br />

Light<br />

Charge Controller<br />

& Inverter Box<br />

Battery Box<br />

CFL 1<br />

TOP VIEW<br />

Distribution<br />

Box<br />

CFL 2<br />

CFL 3 CFL 4<br />

Ref Application Description<br />

A System A<br />

12 V DC and 220 V AC system; a total of 720 Wh/day or<br />

- PV School<br />

Electrification<br />

System<br />

60 Ah @ 12 V DC – <strong>for</strong> 12 V indoor and outdoor lighting,<br />

and 220 V – <strong>for</strong> small AC appliances such as a<br />

karaoke/LCD and DVD and 2 PV solar lanterns<br />

B System B<br />

12 V DC system; 192 Wh/day or 16 Ah/day @ 12 V – <strong>for</strong><br />

- PV Street light 12 V DC lighting using an 15W pole mounted luminaire.<br />

1.1.2 Number and location of systems to be installed<br />

Systems are to be installed at the public facilities in the barangays within the DOE<br />

30/WI-AMORE areas. The number and location of these systems are set out in<br />

Table 2.<br />

7

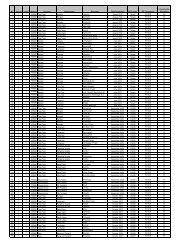

Table 2 Solar PV systems to be installed in DOE 30/AMORE Area in<br />

Zamboanga del Norte, Zamboanga del Sur, Basilan,<br />

Maguindanao, Shariff Kabunsuan, and Sulu<br />

Barangay , Municipality and Province* System A<br />

PV School Electrification System<br />

Basilan<br />

System B<br />

PV Streetlight<br />

1. Dasalan, Lantawan 1 2<br />

Maguindanao<br />

2. Ampuan, Buldon 1 2<br />

<strong>3.</strong> Tee, Datu Piang 1 2<br />

4. Kateman, Guindolungan (Talayan) 1 2<br />

5. Buterin, Kabuntalan 1 2<br />

6. Katidtuan, Kabuntalan (Tumbao) 1 2<br />

7. Talapas, Pagagawan 1 2<br />

8. Buliok, Pagalungan 1 2<br />

9. Kudal, Pagalungan 1 2<br />

10. Lambayao, Talayan 1 2<br />

11. Marader, Talayan 1 2<br />

12. Fukol, Talayan 1 2<br />

1<strong>3.</strong> Lapaken, Upi 1 2<br />

Shariff Kabunsuan<br />

14. Sabaken, Kabuntalan 1 2<br />

Sulu<br />

15. Gapas Tubig Tuwak, Lugus 1 2<br />

16. Larap, Lugus 1 2<br />

17. Pait, Lugus 1 2<br />

18. Sucuban, Luuk 1 2<br />

19. Lakit, Old Panamao 1 2<br />

20. Gata-Gata, Panglima Estino 1 2<br />

21. Lubuk-Lubuk, Panglima Estino 1 2<br />

22. Bulansing Tara, Siasi 1 2<br />

2<strong>3.</strong> Singko, Siasi 1 2<br />

24. Upper Laus, Talipao 1 2<br />

25. Pagatpat, Tapul 1 2<br />

26. Maligay, Patikul 1 2<br />

Zamboanga del Norte<br />

27. Guimotan, Baliguan 1 2<br />

28. Cusipan, Sebuco 1 2<br />

29. Pangian, Sebuco 1 2<br />

30. Puliran, Sebuco 1 2<br />

31. Santo Nino (Culabog), Sebuco 1 2<br />

8

32. Balagunan, Siocon 1 2<br />

3<strong>3.</strong> Tabayo, Siocon 1 2<br />

Zamboanga del Sur<br />

34. Canibugan, Dumingag 1 2<br />

TOTAL 30* 60*<br />

* 30 of these barangays will be selected based on the<br />

findings of the baseline survey presently being conducted<br />

1.1.3 Documentation and training<br />

Documentation, as set out in the Technical <strong>Specifications</strong>, shall be provided at<br />

each system installed.<br />

User training, as set out in the Technical <strong>Specifications</strong>, shall be provided to the<br />

users at each system installed.<br />

1.1.4 Delivery schedule<br />

All systems identified above must be delivered, installed and commissioned<br />

within three (3) months of contract effectiveness.<br />

1.2 After-sales services <strong>for</strong> solar PV systems at public<br />

facilities<br />

The DOE 30/AMORE Contractor will maintain at least one sales and service<br />

center in the DOE 30 Project area to serve the support needs of the public<br />

facilities as well as that of sales to households and other private sector facilities.<br />

The following after-sales services shall be provided <strong>for</strong> a period of five years from<br />

contact award date:<br />

• Warranty<br />

• Routine maintenance<br />

• Break-down repair service.<br />

1.2.1 System Warranty<br />

A five-year system warranty shall be provided <strong>for</strong> each system installed. This<br />

warranty will ensure the availability of the energy services provided by the<br />

systems supplied under this bid. The system warranty shall apply to the solar<br />

photovoltaic energy system, including light fittings and other end-use appliances<br />

supplied under this contract, but not the appliances supplied by other entities and<br />

used on the system.<br />

The following criteria will be used to determine the availability of the energy<br />

services:<br />

• The number of system breakdowns over five (5) years should be less than<br />

twenty-five per cent (25%) of the number of systems installed. A system<br />

breakdown is deemed to have occurred when a customer has no electricity<br />

9

service at all <strong>for</strong> more than five (5) working days due to electrical or<br />

mechanical faults, but not due to inclement weather.<br />

• The number of system breakdowns per year should be less than eight per<br />

cent (8%) of the number of systems installed.<br />

Should any faults arise, this warranty will provide <strong>for</strong> the necessary maintenance<br />

or component replacement in order <strong>for</strong> full functionality to be restored within ten<br />

(10) working days.<br />

If lightning protection is installed in accordance with Section 2.4.4, then lightning<br />

damage will be considered <strong>for</strong>ce majeure and will not be covered by the system<br />

warranty. Theft and vandalism will also be considered <strong>for</strong>ce majeure.<br />

In addition to the five-year system warranty, a ten year warranty on PV modules<br />

is required as referred to in Section 2.<strong>3.</strong>2.<br />

1.2.2 Maintenance<br />

Over the course of the five-year warranty period, a routine maintenance regime<br />

will be implemented according to the technical specifications provided in Section<br />

2.5.1. The routine maintenance will be undertaken at each and every solar PV<br />

system installed in accordance with this scope of work.<br />

As part of the routine maintenance, at least one complete battery replacement shall<br />

be scheduled during the course of the five year period at each solar PV system<br />

installed.<br />

In addition, a break-down repair service shall be available to users in accordance<br />

with Section 2.5.2.<br />

1.3 Sales and services to private customers<br />

The DOE 30/AMORE Contractor must offer a product range to private<br />

(household and business) customers that meets the functionality requirements set<br />

out in the technical specifications.<br />

Some customers may pay cash <strong>for</strong> their system, but the DOE 30/AMORE<br />

Contractor must offer financing arrangements so that a household can lease, hirepurchase,<br />

or use a loan to obtain access to a solar PV system. This arrangement<br />

can be in collaboration with a micro-finance institution.<br />

The DOE 30/AMORE contractor must offer after-sales services to private<br />

customers, including warranties and an optional maintenance agreement.<br />

The DOE 30/AMORE contractor must put in place a marketing plan that aims to<br />

install a minimum number of systems in the DOE 30/AMORE area to the private<br />

market, as set out in the Barangay Requirements below, within twelve months<br />

(12). This requirement will be reduced by one <strong>for</strong> every system installed by a<br />

competitor under the Rural Power Project and in the DOE 30 area during the same<br />

time period. The target of installing the required minimum number of systems is<br />

an obligation in the contract against which a per<strong>for</strong>mance guarantee is required.<br />

10

Table 3 Barangay Requirements<br />

For each DOE 30/WI-AMORE area, there is a minimum requirement on the<br />

commercial marketing, selling and installation of solar home systems (SHS) to<br />

20 households in each barangay.<br />

11

<strong>Annex</strong> 2: Technical specifications and<br />

standards<br />

2<br />

2.1 Load assessment and sizing<br />

A spreadsheet detailing the load assessment and sizing approach is available at<br />

Winrock International - AMORE <strong>for</strong> in<strong>for</strong>mation purposes.<br />

2.1.1 Minimum sizes<br />

The minimum array, battery, charge controller and inverter sizes are summarised<br />

below.<br />

Table 4 Minimum sizes<br />

System Array<br />

Wp<br />

System A<br />

-PV School<br />

Electrification<br />

System B<br />

-PV Streetlights<br />

Battery<br />

Ah @ C20 x V<br />

Charge<br />

controller A<br />

Inverter<br />

VA<br />

300 300 x 12V 12 A 300 VA<br />

100 100 x 12V 5 A N/A<br />

Details on requirements <strong>for</strong> balance of systems, lighting and appliances to be<br />

provided are provided under “2.3 Project requirements <strong>for</strong> public facilities” and<br />

“2.4 Project specific technical specifications <strong>for</strong> Public Systems”.<br />

2.2 Project requirements <strong>for</strong> private customers<br />

The Rural Power Project specifications <strong>for</strong> Solar Home Systems are set out in<br />

<strong>Annex</strong> D, see page 2.<br />

2.3 Project requirements <strong>for</strong> public facilities<br />

These general specifications provide the overall specifications <strong>for</strong> components<br />

and materials supplied within the bid.<br />

Details regarding the solar PV systems <strong>for</strong> public facilities are set out in Section<br />

2.4.<br />

2.<strong>3.</strong>1 Applicable standards<br />

In general, products which bear the Photovoltaic Global Approval Program (PV<br />

GAP) Mark or Seal or which are certified according to PVPS requirements are<br />

12

preferred <strong>for</strong> use. For more in<strong>for</strong>mation refer to http://www.pvgap.org/ and<br />

http://www.iea-pvps.org.<br />

Products which are not certified or compliant with PVGAP PVRS specifications<br />

but which have a currently valid certification <strong>for</strong> use in the following World<br />

Bank-assisted projects, are eligible <strong>for</strong> use:<br />

• Philippines Rural Power Project (list of qualified products are provided in<br />

Attachment A)<br />

• Sri Lanka Energy Services Delivery Project and the Sri Lanka Renewable<br />

Energy <strong>for</strong> Rural Economic Development Project (<strong>for</strong> list of certified<br />

products see: http://www.energyservices.lk or write to info@dfccbank.com)<br />

Test certificates from a testing and certification organization acceptable to the<br />

Republic of the Philippines must be provided to verify certification.<br />

Organizations accredited according to ISO 17025 2 or equivalent standards will be<br />

acceptable <strong>for</strong> issuing the component certifications. A maximum measurement<br />

error of 3 percent is permitted on all tests of compliance.<br />

Interested parties wishing to use such products must submit documentation<br />

attesting to the fact that their products have been certified <strong>for</strong> use in the above<br />

referenced projects.<br />

The applicable standards <strong>for</strong> individual system components are set out in<br />

Attachment 1: Solar Home Systems Component <strong>Specifications</strong> in <strong>Annex</strong> D:<br />

Philippines: Rural Power Project: General Requirements and <strong>Specifications</strong> <strong>for</strong><br />

Solar Photovoltaic Home Systems.<br />

2.<strong>3.</strong>2 PV modules<br />

Crystalline modules are required and the relevant PV GAP standard is PVRS 2<br />

“Crystalline silicon terrestrial Photovoltaic (PV) modules”. The applicable<br />

international standard <strong>for</strong> PV modules is IEC 61215: 1993 Crystalline Silicon<br />

Terrestrial PV Modules – Design Qualification and Type Approval.<br />

PV modules that are not PV GAP certified shall comply with RPP Project<br />

component specifications.<br />

If bypass diodes are supplied, they shall be included in the PV module connection<br />

box so that they can be replaced without replacing the module.<br />

The PV modules must be warranted to retain at least 90 percent of its rated<br />

capacity measured at STC <strong>for</strong> at least ten years.<br />

In<strong>for</strong>mation on the per<strong>for</strong>mance of the chosen modules in respect of currentvoltage<br />

characteristics and daily energy output, in Ah and at STC, shall be<br />

submitted to verify that the output of the modules will meet the requirements of<br />

2 ISO/IEC 17025:2005 - General requirements <strong>for</strong> the competence of testing and calibration laboratories<br />

13

each of the systems given in Table 4. NOTE: The energy output shall be<br />

calculated <strong>for</strong> a day of 4 hours at STC.<br />

For public facilities, the watt-peak power <strong>for</strong> each module shall be at least 50 Wp<br />

to minimize the number of connections in the array and array junction box.<br />

2.<strong>3.</strong>3 Batteries<br />

Modified SLI, deep-cycle and tubular plate flooded lead acid batteries are<br />

acceptable.<br />

The applicable standards are:<br />

• IEC Standard 61427 © IEC:2001 Ed.2, Secondary Cells and Batteries <strong>for</strong><br />

Solar Photovoltaic Energy Systems – General Requirements and Methods of<br />

Test<br />

In addition, a relevant PV GAP standard is PVRS 5 “Lead-acid batteries <strong>for</strong> solar<br />

photovoltaic (PV) energy systems (modified automotive batteries)”.<br />

Batteries that are not PV GAP or IEC-certified shall comply with RPP Project<br />

component specifications.<br />

The minimum rated capacity at C20 shall be not less than the values specified in<br />

Table 4.<br />

2.<strong>3.</strong>4 Solar charge controllers<br />

A solid state photovoltaic charge controller is required <strong>for</strong> all systems.<br />

The relevant PV GAP Standard is PVRS 6 “Charge controllers <strong>for</strong> photovoltaic<br />

(PV) stand-alone systems with a nominal system voltage below 50 V”<br />

Charge Controllers that are not PV GAP certified shall comply with RPP Project<br />

component specifications.<br />

Charge controllers must be supplied with charge and discharge voltage set points,<br />

which match the battery requirements to ensure adequate protection and cycling<br />

regimes. In the case of systems that incorporate an inverter it is essential that the<br />

battery is protected against deep discharge by means of an AC load-shed<br />

protection device.<br />

2.<strong>3.</strong>5 Inverters<br />

The relevant PV GAP standard is “PVRS 8 “Inverters <strong>for</strong> photovoltaic (PV)<br />

stand-alone systems”.<br />

DC/AC Inverters that are not PV GAP certified shall comply with RPP Project<br />

component specifications.<br />

14

2.<strong>3.</strong>6 Interior luminaires<br />

The relevant PV GAP standard is PVRS 7 “Lighting systems with fluorescent<br />

lamps <strong>for</strong> photovoltaic (PV) stand-alone systems with a nominal voltage below 24<br />

V”.<br />

Luminaires that are not PV GAP certified shall comply with RPP Project<br />

component specifications.<br />

All lighting should be 12 V DC screw mounted E27 compact fluorescents of 11 W<br />

providing a minimum of 500 lumens. All lights are to be individually switched<br />

and mounted at 1400 mm above ground level.<br />

2.<strong>3.</strong>7 Exterior luminaires<br />

Exterior luminaires shall comply with RPP Project component specifications.<br />

The luminaires shall be 12 V DC screw mounted E27 compact fluorescents of<br />

11 W school exterior or 18 W PV streetlights providing a minimum of 500 and<br />

900 lumens respectively.<br />

In addition, the luminaires shall be suitable <strong>for</strong> surface mounting on an exterior<br />

wall. They shall have a minimum ingress protection of IP65. The luminaire<br />

housing shall allow <strong>for</strong> surface conduits to enter on all sides. All screws, bolts<br />

and metal parts shall be stainless steel or non-corrosive material. The electrical<br />

connections shall be by means of a suitable screw terminal block with a wire<br />

clamping contact.<br />

The exterior luminaire shall be mounted on the wall above the entrance door or on<br />

the corner of the building adjacent to the entrance door.<br />

2.<strong>3.</strong>8 Streetlight<br />

The streetlight shall consist of a pole, luminiaire and all associated solar<br />

components to provide outdoor lighting which is switched with a daylight sensing<br />

switch.<br />

The lamp shall be a 12 V DC screw mounted E27 compact fluorescent of 15 W<br />

providing a minimum of 900 lumens mounted in an appropriate streetlight<br />

housing. The housings <strong>for</strong> the lamp, charge controller and electrical components<br />

shall have a minimum ingress protection of IP65.<br />

The solar array, battery, charge controller with automatic night switch and<br />

associated PV system components shall meet the minimum sizes in Table 4.<br />

The solar array shall be mounted on an array mounting frame which attaches to<br />

the top of the pole and allows <strong>for</strong> the array to be oriented in any direction at a<br />

fixed angle of tilt of 15 o to the horizontal.<br />

The battery and charge controller with automatic night switch may be mounted at<br />

the top of the pole or on the ground in a corrosion protected, lockable, ventilated<br />

and tamper proof housing. The battery enclosure shall have an insulated lid or a<br />

double skin lid to minimise heat transfer to the battery.<br />

15

The pole shall be suitable <strong>for</strong> mounting of the luminaire at a height of 6 m above<br />

ground level. It shall be located in the ground in a suitably compacted or concrete<br />

foundation suitable of withstanding wind gusts of 200 km/hr. The luminaire<br />

bracket shall be of galvanised mild steel and suitable <strong>for</strong> pole mounting.<br />

Winning bidder must provide adequate drawings of streetlight, showing details of<br />

wiring, installation, civil works, and system grounding <strong>for</strong> Winrock International<br />

– AMORE’s approval prior to implementation/installation.<br />

2.<strong>3.</strong>9 LCD and DVD<br />

The LCD shall be a colour unit operating on 220 V AC with a minimum screen<br />

size of 22’ or 56 cm, and a maximum power consumption of 40 W.<br />

The DVD player should be suitable <strong>for</strong> playing Zone 3 DVDs and have a<br />

maximum power consumption of 15 W. It shall be a front loading unit. The<br />

unit(s) shall be supplied with a power cord and appropriate connector.<br />

All units should passed/bear the Philippine Standards or other international<br />

standards.<br />

2.<strong>3.</strong>10 Public Address system<br />

The public address system shall be portable and provide a minimum of a<br />

microphone, amplifier and speaker system with minimum 10 W RMS audio<br />

output. It shall have at least one 1/4 in. input jack <strong>for</strong> the microphone and one<br />

RCA jack <strong>for</strong> CD/cassette and controls <strong>for</strong> volume, treble and bass.<br />

It shall be suitable <strong>for</strong> external power supply from 240 V AC or DC (12 -15 V) or<br />

internal battery powered using rechargeable D-cells. The maximum power<br />

consumption shall be 50 W. The unit shall be supplied with a power cord and<br />

appropriate connector.<br />

All units should passed/bear the Philippine Standards or other international<br />

standards.<br />

2.<strong>3.</strong>11 Portable lanterns<br />

Portable lanterns shall be integrated rechargeable units comprising a lamp, battery<br />

storage and associated control gear. The lantern shall be suitable <strong>for</strong> charging<br />

from an external 12 V DC supply through an appropriate jack.<br />

The lantern shall provide 360o coverage with a minimum of 400 lumens <strong>for</strong> a<br />

minimum of 4 hours/day. The lamp shall be a 9 W compact fluorescent or<br />

equivalent.<br />

The lantern shall provide indications of the status of the battery <strong>for</strong> charging and<br />

low battery conditions. It shall be protected <strong>for</strong> reverse polarity.<br />

The lantern shall be supplied with a charging cable. The solar lantern should be<br />

connected so as to ensure adequate charging (e.g. if the solar lantern battery is 12<br />

V, it should be connected to the battery side of the charge controller).<br />

16

2.4 Project specific technical specifications <strong>for</strong> Public<br />

Systems<br />

2.4.1 SYSTEM A - PV School Electrification<br />

Site description<br />

Primary/Secondary School have a floor area ranging from 20 to 50m 2 , and a<br />

typical ceiling height of 2.7m. They usually have a single room with temporary<br />

partitions or a two-roomed structure.<br />

System description<br />

The system is a small DC-bus system providing 12 V DC electricity <strong>for</strong> lighting<br />

and 220 - 240 V AC electricity at 60 Hz <strong>for</strong> energy efficient appliances such as<br />

karaoke or PA systems, LCD/DVD and Cellphone charging facility. The system<br />

is wired <strong>for</strong> 12 V DC luminaires, with four (4) indoor 11 W CFL luminaires and<br />

one (1) external 11 W CFL luminaire mounted at the main entrance or outside the<br />

building with switches and two (2) portable solar lanterns.<br />

A small inverter is included to power small AC appliances, including a public<br />

address system, LCD/DVD, DVD-LCD Inter-phase device, and power strip .<br />

Technical specifications<br />

The system consists of:<br />

• A solar array of 300 Wp panels minimum;<br />

• A minimum storage capacity of 225 Ah @ C20 12 V solar batteries;<br />

• A minimum 21 A charging current @ 12 V – the charge set points are to be<br />

determined by (or applicable to) the proposed battery;<br />

• Circuit breaker 30 A on DC side;<br />

• Circuit breaker 15 A on AC side;<br />

• A minimum of 300 VA pure sine wave inverter <strong>for</strong> AC loads;<br />

• 4 x 11 W DC interior CFL luminaires <strong>for</strong> interior mounting;<br />

• 1 x 11 W DC exterior CFL luminaire <strong>for</strong> external mounting;<br />

• 1 x 50 W maximum <strong>for</strong> Karaoke/PA;<br />

• 1 x 40 W maximum LCD;<br />

• 1 x 15 W maximum DVD Player;<br />

• 1 x 7 W maximum LCD-DVD Inter-phase device;<br />

• Power strip <strong>for</strong> AC loads;<br />

17

• Balance of system materials including: array mounting structure, battery<br />

box with warning stickers, circuit breaker, wiring, light switches, O&M<br />

manual.<br />

Note: It is intention of the specifications to call <strong>for</strong> finish work, tested, and ready<br />

<strong>for</strong> operation. Wherever the words, “provide” are used, it shall mean provide and<br />

install complete and ready <strong>for</strong> use. Any apparatus, material or work not indicated<br />

in the specifications or any incidental accessories necessary to make the work<br />

complete and perfect in all aspect and ready <strong>for</strong> operation even if not particularly<br />

specified (e.g. battery grease, staple wires, clamps, etc.) in the scope of work shall<br />

be furnished, delivered, and installed without additional expense to WI-AMORE .<br />

2.4.2 SYSTEM B - PV Streetlighting System<br />

Site description<br />

The public lighting systems are required <strong>for</strong> area lighting <strong>for</strong> streets, paths, piers<br />

and play areas. In general, the systems are located on free-standing pole mounted<br />

structures.<br />

System description<br />

The public lighting systems are small dedicated stand-alone 12 V DC solar PV<br />

systems with pole mounted module(s) and 15 W luminaire with ground mounted<br />

battery box and charge controller.<br />

Technical specifications<br />

The specific sizing and specification <strong>for</strong> application in the DOE 30 project<br />

requires, <strong>for</strong> each of the public lights to be installed:<br />

• A solar array of 100 Wp panel minimum;<br />

• A minimum storage capacity of 100 Ah @ C20 12 V solar batteries;<br />

• A minimum 5A charge controller with night switch @ 12 V – the charge set<br />

points are to be determined by (or applicable to) the proposed battery;<br />

• Automotive type fuse of 2 A and 10A;<br />

• 1 x 15 W energy efficient CFL in a streetlighting luminaire mounted on a<br />

cantilevered arm in a IP65 fitting<br />

• Balance of system materials including: six meter streetlight pole and array<br />

mounting structure, battery box with warning sticker, battery fuse, wiring,<br />

O&M manual<br />

2.4.3 Example bill of quantities<br />

Presented below is an example bill of quantities (BOQ). The quantities below<br />

are not intended to be restrictive but should serve as an example <strong>for</strong> bidders<br />

to prepare their own BOQ as part of their submissions.<br />

18

Item Description PV School<br />

Electrification<br />

System<br />

PV modules<br />

55 Wp module<br />

75 Wp module<br />

PV array mounting<br />

structure<br />

PV<br />

Streetlight<br />

100 Wp module 3 1<br />

Pole and base 1 1<br />

galvanised mild steel: 1 – 2 modules 1<br />

galvanised mild steel: 3 – 4 modules 1<br />

Array interconnects 1 1<br />

Array junction box IP65 1 1<br />

Batteries<br />

100 Ah @ 12 V modified SLI<br />

150 Ah @ 2 V tubular plate, flooded<br />

300 Ah @ 2 V tubular plate, flooded<br />

3 1<br />

Battery interconnects 2 1<br />

Battery box Small 1<br />

Large 1<br />

Circuit breaker 30 A 1<br />

15 A<br />

10 A<br />

5 A<br />

1<br />

Battery fuseholder automotive type 2<br />

Charge controller 5 A with automatic night switch<br />

10 A with automatic night switch<br />

15 A<br />

1<br />

25 A 1<br />

Inverter<br />

100 VA<br />

300 VA 1<br />

Meters of 2.5 mm 2 Meters of 4 mm<br />

40 10<br />

2<br />

Meters of 6 mm 2 Meters of 10 mm<br />

42<br />

2<br />

Wiring<br />

Meters of 16 mm 2<br />

Indoor lights<br />

11 Watt / 500 lumen 12 V DC CFL 4<br />

Exterior lights 11 Watt / 500 lumen 12 V DC CFL 1<br />

Streetlight 15 Watt / 900 lumen CFL on 6m pole 1<br />

Public address system 50 W integrated PA system 1<br />

Equipment enclosure Battery box<br />

1<br />

1<br />

Electronic system<br />

1<br />

Warning signs <strong>for</strong> battery box<br />

User manual <strong>for</strong> customers 1 1<br />

O&M manual <strong>for</strong> customers and technicians 1 1<br />

Spares assorted 1 1<br />

19

2.4.4 Code of practice <strong>for</strong> installation<br />

In general, installations should comply with the PV Gap standard PVRS 10 ”Code<br />

of Practice <strong>for</strong> Installation of Photovoltaic systems”.<br />

The Ac elements of installations shall comply with the Electrical Code<br />

(Philippines Republic Act No. 7920). In addition, the installations shall comply<br />

with the latest edition of the Philippine Electrical Code – in particular Article<br />

6.90: Solar photovoltaic systems <strong>for</strong> stand-alone PV systems.<br />

System grounding<br />

Systems A & B, require grounding. These systems will be provided with a) an<br />

equipment ground and b) a system ground. For the equipment ground, the PV<br />

array structure, the chassis and any conductive surfaces of the inverter and AC<br />

distribution system shall be connected to a copper-plated ground rod – 16 mm<br />

minimum diameter x 2 m long – with an insulated 16 mm 2 conductor or an uninsulated<br />

25 mm 2 flat copper conductor. For the system ground, the negative DC<br />

bus at the negative battery terminal shall be connected to the copper-plated ground<br />

rod with an insulated 16 mm 2 conductor by means of the shortest route practical.<br />

In addition, the neutral AC conductor shall be grounded.<br />

The bidder must submit to DOE/WI-AMORE <strong>for</strong> approval the system grounding<br />

wiring diagram with appropriate wiring sizes with calculation of voltage drop.<br />

Lightning protection<br />

Lightning protection is optional. If lightning protection is not installed, then the<br />

system warranty referred to in Section 1.2.1 will cover lightning damage. If<br />

lightning protection is installed, then the system warranty will not cover lightning<br />

damage.<br />

If lightning protection is installed, then the following (Level A – common<br />

lightning risk) is required as a minimum:<br />

• Interconnection between the masses and proper connection to the earth;<br />

• Protection by varistors In>= 2 to 5kA (or Imax >= 6 to 15kA) on external<br />

connections (DC and AC circuits);<br />

• Specific protection on other external lines.<br />

20

Scheme 3 : Electrical configuration (<strong>for</strong> regulator on negative conductor)<br />

when location exposed to lightning risk<br />

PV array mounting<br />

The following installation requirements are set out:<br />

• If more than one module is used, identical models shall be used and they<br />

shall be connected in parallel.<br />

• The modules must be framed in such a way as to allow secure connection to<br />

the module mounting structure.<br />

• The array mounting structure will hold the photovoltaic module(s). The<br />

module(s) must be mounted on a support structure made of corrosion<br />

resistant material that assures stable and secure attachment.<br />

• The PV array and support structure must be designed to withstand loads<br />

from wind gusts of 200 km/hour and shall be supplied with fixings <strong>for</strong><br />

ground mounting.<br />

• The structure must be mounted such that the modules are at a fixed angle of<br />

15 degrees to the horizontal facing due south.<br />

• Array orientation must be adjustable in the field.<br />

• The structure will incorporate corrosion resistant hardware <strong>for</strong> all external<br />

connections. These include the modules to structure, structure to pole and<br />

pole to building attachments.<br />

• There should be no shading from nearby trees or buildings between 9:00 to<br />

15:00.<br />

• The modules may be ground-mounted or mounted on the roof or wall of the<br />

building.<br />

21

− In the case of ground mounting, a metal, concrete or treated wood pole<br />

must be used with the modules attached at the top of the pole. The<br />

modules must be at least four meters off the ground. The pole must be<br />

anchored in concrete or tightly packed soil at least one meter deep in the<br />

ground. The pole and mounting structure must be sufficiently rigid to<br />

prevent twisting in the wind or if large birds alight on the array.<br />

Appropriate holes shall be provided in the pole to allow fixing of the<br />

panel support frame (array) to the pole.<br />

− In the case of roof or wall mounting, a suitable location on the roof or<br />

wall of a dwelling shall be identified in agreement with the user. A<br />

purpose-built panel support frame shall be used. The frame shall not trap<br />

rain water or detritus against the roof or wall. Fixtures used to secure the<br />

frame to the wall or roof shall not allow rain water to penetrate the wall<br />

or roof. The panel support frame shall be made of galvanized steel.<br />

− The bolts used to assemble the structure shall be either galvanized or<br />

stainless steel. Each panel shall be individually mounted on the support<br />

frame with at least four tamper-proof fasteners. The fasteners shall be<br />

protected against corrosion. In all cases, the PV array shall be able to tilt<br />

at the required angle to the horizontal. The mechanism shall have a<br />

fastener to make it possible to set the tilt angle securely.<br />

Equipment Enclosure<br />

The battery must be housed in a vented compartment. All parts of the<br />

compartment subject to battery acid contact must be acid resistant. This<br />

compartment must be built strong enough to accommodate the weight of the<br />

battery. This compartment must adequately support and vent wet, lead-acid<br />

batteries. Access to the battery compartment by children must be prevented.<br />

The remainder of the system components (electronics, switches etc.) must be<br />

housed in a separate compartment or enclosures which prevent the system<br />

components being affected by battery acid spills or fumes. The compartment or<br />

enclosure design must allow the internal electronic equipment to operate within<br />

acceptable operating temperature limits.<br />

The enclosure must be constructed of a durable material so as to last 10 years<br />

without maintenance. A sample equipment enclosure must be submitted by the<br />

bidder to DOE/WI-AMORE <strong>for</strong> its approval prior to implementation/installation.<br />

All enclosure would need to have appropriate warning stickers.<br />

22

Wiring and switchgear<br />

Stranded and flexible insulated copper wiring must be used. All wiring must be<br />

sized to keep line voltage losses to less than 5% in each sub-circuit and to allow<br />

the circuit to operate within the ampacity rating of the wire.<br />

For systems permanently installed on a structure, all exposed wiring (with the<br />

possible exception of the module interconnects) must be in conduits or be firmly<br />

fastened to the building structure. Wiring through roofing, walls and other<br />

structures must be protected through the use of bushings. Wiring through roofing<br />

must <strong>for</strong>m a water-proof seal. Where the wiring is through flammable material<br />

(e.g. thatched roofs), they must be in a metal conduit. Adequate fasteners,<br />

conduits, bushings and other installation hardware must be supplied.<br />

Field-installed wiring must be joined using terminal strips or screw connectors.<br />

Soldering or crimping in the field must be avoided if at all possible. Wire nuts are<br />

not allowed. The rated current carrying capacity of the joint must not be less than<br />

the circuit current rating. All connections must be made in junction boxes.<br />

Fittings <strong>for</strong> lights, switches, and socket outlets may be used as junction boxes<br />

where practical.<br />

All wiring shall be colour coded and/or labelled.<br />

Switches should be provided <strong>for</strong> computer and printer plug points so that these<br />

devices can be isolated when not in use.<br />

The bidder must submit to DOE/WI-AMORE <strong>for</strong> approval the system grounding<br />

wiring diagram with appropriate wiring sizes with calculation of voltage drop.<br />

2.4.5 Spares<br />

Sets of spares are required to maintain immediate spares stocks <strong>for</strong> the number<br />

and type of systems in each service / DOE 30/AMORE contractor area. These<br />

spare shall be stored at the service centre in the service area / DOE 30/AMORE<br />

contractor area.<br />

Each service / DOE 30/AMORE contractor area requires:<br />

23

Item Description Number of spares<br />

PV modules For each size module installed * 1<br />

Batteries For each size battery installed * 3<br />

Battery interconnects n/a 2<br />

Circuit Breaker 30 A 2<br />

Charge controller<br />

25 A 1<br />

5A with automatic night switch 2<br />

Inverter 300 VA 1<br />

Wiring<br />

Meters of 2.5 mm 2 20<br />

Meters of 4 mm 2 20<br />

Meters of 6 mm 2 20<br />

Meters of 10 mm 2 20<br />

Meters of 16 mm 2 20<br />

Indoor lights 11 Watt 12 V DC CFL 2<br />

Exterior lights 11 Watt 12 V DC CFL 2<br />

Streetlight 18 W luminaire 1<br />

Distilled water 1 x 25 litre containers (if flooded lead acid batteries are used) 1<br />

* For example, if 75 Wp modules are used in all systems, keep 1 x 75 Wp module in spare. If both 75<br />

Wp and 110 Wp modules are used, keep 1 x 75 Wp module and 1 x 110 wp module in spare.<br />

** For example, if only 105 Ah batteries are used, keep 2 x 105 Ah batteries in spare.<br />

2.4.6 Training code<br />

Installation should include user-training of the systems and provision of userdocumentation.<br />

Training requirements are directed at the users and the<br />

administrators in the LGU’s. These include the following specific components:<br />

• Basic use of solar PV systems – operating principles, basic operating modes<br />

and practices, safety issues, energy and power limitations of solar PV<br />

systems<br />

• The uses and limitations of the system installed;<br />

• Basic fault diagnosis and key indicators of system or component failure<br />

• User-maintenance responsibilities, administration of maintenance visits and<br />

completion of user-sections of maintenance log sheets<br />

• Safety procedures and precautions;<br />

• Contact in<strong>for</strong>mation <strong>for</strong> queries and break-down maintenance service.<br />

2.4.7 Documentation to be provided<br />

A Users’ manual and an O&M manual must be provided with each system as set<br />

out below.<br />

24

Users’ manual<br />

The supplier must provide a User’s Manual intended <strong>for</strong> the customers and will be<br />

included with each of the packaged systems. The manual must be in local<br />

language understandable by the users. The User’s Manual documentation should<br />

be simple and easy to understand. Use of sketches or graphics should be used to<br />

make the manual easier to use. The documentation is to include the following:<br />

• How the system works: battery charging by the array, functions, battery low<br />

voltage protection, and battery overcharge protection. The relationship<br />

between energy available on a daily basis and sunlight conditions should be<br />

clearly and simply explained.<br />

• A description of all user interactive hardware including disconnect switches<br />

and status indicators.<br />

• Procedures <strong>for</strong> proper system operation, including a list of load limitations<br />

and any problem loads. These procedures should include suggested<br />

operation, including load conservation, during periods of inclement weather,<br />

and/or a low voltage disconnect event. The procedures <strong>for</strong> checking that the<br />

photovoltaic array is not shaded and how to prevent shading must be<br />

explained. For portable SHS, instructions must be given on how to orient<br />

the PV module to maximize energy generation. For systems without charge<br />

controllers, procedures <strong>for</strong> preventing overcharging must be given.<br />

• Any user maintenance items.<br />

• Emergency shut down procedures and recommendations <strong>for</strong> extended<br />

periods of system non-use.<br />

• A user trouble shooting guide.<br />

• A block diagram showing the main components.<br />

• Contact in<strong>for</strong>mation <strong>for</strong> maintenance and access to spare parts.<br />

O&M manual<br />

The supplier must provide an Operations and Maintenance Manual to be used by<br />

the service technicians. The manual must be in a language understandable by the<br />

technician. The manual will include the specific details on installation, operation<br />

and maintenance<br />

• A detailed technical description of the system.<br />

• A complete copy of the Users Manual.<br />

• A complete list of all system components, with associated manufacturers<br />

literature, specifications, and warranties.<br />

• A recommended annual maintenance schedule, with complete maintenance<br />

instructions.<br />

• A detailed trouble shooting guide referencing all the system components.<br />

This shall include repairs and diagnostic procedures that can be done by the<br />

supplier or a qualified third party. Repairs and procedures not to be<br />

attempted by non-electricians and/or electricians unfamiliar with<br />

photovoltaic systems shall also be identified.<br />

25

• A functional block diagram, electrical single-line drawing showing the<br />

placement of all hardware and ratings of all component and physical layout<br />

diagram.<br />

• A set of blank logsheets (see section 2.5.3).<br />

2.5 Technical specifications: Maintenance<br />

2.5.1 Routine maintenance<br />

The maintenance of the solar PV systems is an integral part of the overall contract<br />

to ensure the full benefits of the systems. The maintenance obligation includes a<br />

warranty obligation to replace all faulty or broken system components (excluding<br />

AC appliances) and including an obligation to replace batteries at least once<br />

during the five year period.<br />

Each system should be visited at least six times during the five year period<br />

according the following schedule:<br />

Table 4 Routine maintenance schedule<br />

Visit no. 1 2 – 3 4 – 6<br />

Maintenance<br />

Interval<br />

3 months 6 months 12 months<br />

Scheduled date Year 1: Q2 Year 1: Q4<br />

Year 2: Q2<br />

Year 3: Q1<br />

Year 4: Q1<br />

Year 5: Q1<br />

Bidders shall make full provision <strong>for</strong> the costs of materials, labor and transport to<br />

cover maintenance <strong>for</strong> five years after the date of successful commissioning and<br />

handover of the systems.<br />

At each routine maintenance visit, the following actions should be undertaken:<br />

• Confirm maintenance visit with responsible staff member approximately ten<br />

days in advance.<br />

• Meet the responsible staff member on site.<br />

• Check status of the system with him / her and obtain feed-back on<br />

per<strong>for</strong>mance since the last maintenance visit.<br />

• Per<strong>for</strong>m visual inspection – starting with appliances and working back<br />

towards the array. Check <strong>for</strong> corrosion, rust and physical damage to<br />

installation.<br />

• Per<strong>for</strong>m measurements of system status and per<strong>for</strong>mance – do not<br />

disconnect any wires or components, i.e. these measurements must be ‘noninvasive’<br />

to avoid creating new problems.<br />

• Diagnoses of any problems identified, check all array wiring and all battery<br />

connections, repair of any loose connections, corroded parts, or electrical<br />

cabling problems;<br />

• Ensure that array is not shaded and that panel surfaces are clean.<br />

• <strong>To</strong>p up battery electrolyte with distilled water.<br />

26

• Check status of all isolating switches and set correctly.<br />

• Check status of all time switches and set correctly.<br />

• Check level of spares in stock and make replacements as required.<br />

• Replacement of any faulty or damaged equipment, including light fittings<br />

but excluding other appliances. Solar batteries should be replaced when<br />

these have reached less than 80% of the original C20 capacity – plan <strong>for</strong> a<br />

minimum of one complete battery replacement per system within the five<br />

year period of this contract;<br />

• Record status and measurements on the maintenance log sheets<br />

• Obtain signature of the staff member on log sheets<br />

• Place one copy of the completed log sheet in the O&M manual stored at site<br />

• Retain one copy of the log sheet <strong>for</strong> storage at solar PV company office<br />

• Retain one copy <strong>for</strong> submission with the annual report to the contract<br />

administrator<br />

• In the event of a breakdown, the maintenance tasks will be focused on the<br />

specific problem as identified by a fault diagnosis procedure. The<br />

maintenance contractor must again complete a maintenance log sheet and<br />

store a copy both at the site and at the company office.<br />

2.5.2 Breakdown repair maintenance service<br />

Over the course of the five-year warranty period, a breakdown repair service,<br />

defined below, will be available to deal with system breakdowns. Users at each of<br />

the solar PV systems installed in accordance with this scope of work will have<br />

access to this breakdown repair service.<br />

The break-down repair service will provide customers with telephonic and<br />

physical access (at the DOE 30 Contractor’s offices) to the DOE 30 Contractor <strong>for</strong><br />

recording of complaints and notification of a system failure during working hours.<br />

A response to a recorded enquiry or complaint should be provided within three (3)<br />

working days and the system should be restored to full functional capability<br />

within five (5) working days.<br />

Each user complaint and notification of system failure shall be recorded by the<br />

DOE 30 Contractor, and the actions taken and action time should be recorded<br />

using the log sheet provided in Section 2.5.<strong>3.</strong><br />

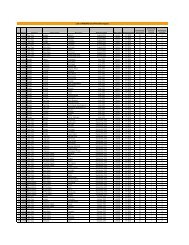

2.5.3 Maintenance log sheets<br />

A pair of templates <strong>for</strong> maintenance log sheets is presented below <strong>for</strong> routine<br />

maintenance and breakdown maintenance.<br />

Three copies of these log sheets must be completed <strong>for</strong> each system at the time of<br />

each routine maintenance or breakdown visit. One copy should be inserted in the<br />

O&M manual on site, one should be retained <strong>for</strong> submission in the annual report<br />

to the contract administrator; and the third should be kept by the solar PV<br />

company.<br />

27

Table 5: Routine maintenance logsheet<br />

Site details<br />

Site name:<br />

Date:<br />

Weather conditions:<br />

Type of system:<br />

Visual inspection<br />

Is the user manual available? (Y/N)<br />

Is the operation and maintenance manual available? (Y / N)<br />

Are there any complaints / comments from the staff at the site? (Y / N)<br />

If so, write these down<br />

Are there any indications of damage or abuse? (Y / N)<br />

If so, write down the details<br />

What is the condition of the array – dusty<br />

or clean; any shading between 09:00 –<br />

17:00 from vegetation or other causes?<br />

What is the status indication on the<br />

charge controller?<br />

Are all the appliances operating? (Y / N)<br />

If not, write down the details<br />

Starting time:<br />

Finishing time:<br />

28

Routine measurements<br />

Array and battery<br />

Array generation current A Electrolyte<br />

levels<br />

Battery voltage under charge V Specific gravity Cell<br />

No<br />

Battery voltage under C20<br />

discharge<br />

SG Cell<br />

No<br />

V 1 4<br />

C20 discharge current A 2 5<br />

Charge controller<br />

Status?<br />

Appliances<br />

Lights working<br />

Lights not<br />

working<br />

Inverter<br />

Status?<br />

AC appliances<br />

working<br />

AC appliances<br />

not working<br />

Maintenance tasks (tick each box as complete)<br />

Clean PV array and check <strong>for</strong> damage<br />

Trim vegetation so PV array not shaded<br />

<strong>To</strong>p up battery electrolyte with distilled water<br />

Check <strong>for</strong> corrosion, rust and physical damage to installation<br />

Check all array wiring connections<br />

Check all battery connections<br />

Check status of all isolating switches and set correctly<br />

Check status of all time switches and set correctly<br />

Check all light fittings and replace if necessary<br />

3 6<br />

Register of equipment replaced: Note each item & serial number of equipment replaced during this visit<br />

Existing equipment removed:<br />

Replacement equipment provided:<br />

SG<br />

29

Signatures<br />

Responsible staff member Maintenance technician<br />

Signature:<br />

Name:<br />

Signature:<br />

Name:<br />

Date Date<br />

30

Table 6: Breakdown maintenance log sheet<br />

Site details<br />

Site name:<br />

Date:<br />

Weather conditions:<br />

Type of system:<br />

Description of problem(s)<br />

What problems are reported by the customers / users ?<br />

Description of repair(s)<br />

Describe all the repairs which have been made<br />

Starting time:<br />

Finishing time:<br />

Register of equipment replaced: Note each item & serial number of equipment replaced during this visit<br />

Existing equipment removed:<br />

Replacement equipment provided:<br />

31

Maintenance tasks (tick each box as complete)<br />

Clean PV array and check <strong>for</strong> damage<br />

Trim vegetation so PV array not shaded<br />

<strong>To</strong>p up battery electrolyte with distilled water<br />

Check <strong>for</strong> corrosion, rust and physical damage to installation<br />

Check all array wiring connections<br />

Check all battery connections<br />

Check status of all isolating switches and set correctly<br />

Check status of all time switches and set correctly<br />

Check all light fittings and replace if necessary<br />

Signatures<br />

Responsible staff member Maintenance technician<br />

Signature:<br />

Name:<br />

Signature:<br />

Name:<br />

Date Date<br />

32

2.6 Product range <strong>for</strong> the private market<br />

2.6.1 Solar home systems<br />

Solar home systems <strong>for</strong> the residential or commercial market should include systems<br />

larger than 20 Wp. And comply with RPP Project requirements <strong>for</strong> SHS, see page 36.<br />

Solar home system should include the option of a 12V DC-plug point (cigarette lighter<br />

style) <strong>for</strong> connecting a mobile phone charger.<br />

2.6.2 Business systems<br />

According to interviews/surveys with residents in the barangay there may be demand <strong>for</strong><br />

a range of products by businesses or entrepreneurs in the area. The product range <strong>for</strong><br />

businesses could include systems that offer the following functionality:<br />

Application Description<br />

Mobile phone handset<br />

charging<br />

Facility based at small store to recharge mobile handsets.<br />

Solar lantern recharging As above, with up to five lanterns charged per 75 Wp<br />

panel. May also sell lanterns with support from DOE 30<br />

contractor.<br />

Community video &<br />

karaoke<br />

Solar PV systems sized to power<br />

• Coin operated karaoke machine and/or<br />

• Video/DVD machine with TV/projector.<br />

Cassava & coconut grater For grating of cassava and coconut<br />

Pay phone services Use of mobile or satellite phone, powered by the solar PV<br />

system, as a public pay phone based at a shop or other<br />

business.<br />

The winning bidder is encouraged to offer these products, although there is not<br />

contractual obligation to supply these.<br />

2.7 Experience, organisational and competence requirements<br />

The DOE 30/AMORE contractor must propose an organisational solution that provides<br />

<strong>for</strong>:<br />

• Ready access by customers to after-sales support, maintenance and spare parts at a<br />

local service centre;<br />

• A supply system that can deliver spare parts and equipment at short notice;<br />

• A marketing arrangement that actively markets solar PV systems to the private<br />

sector in the DOE 30/AMORE area;<br />

• Either self-provision of financing/leasing services to private customers, or a link<br />

with a micro-finance institution in order to offer user finance.<br />

33

The DOE 30/AMORE Contractor (with micro-finance partner as necessary) must<br />

incorporate the following competencies in the team that serves the DOE 30/AMORE<br />

area:<br />

• Managerial and marketing competencies;<br />

• Technical competencies with experience in solar PV technology;<br />

• Micro-finance competencies, with experience in rural areas.<br />

34

<strong>Annex</strong> 3: General requirements and<br />

specifications <strong>for</strong> solar photovoltaic home<br />

systems<br />

<strong>3.</strong>1 Solar Home System Hardware Description<br />

<strong>3.</strong>1.2 The Solar Photovoltaic Home System (SHS) is intended to provide the user with a<br />

convenient means of supplying power <strong>for</strong> small electrical loads such as lights,<br />

radio/cassette players or TV. A typical SHS operates at a rated voltage of 12 Vdc<br />

and provides power <strong>for</strong> direct current fluorescent luminaires, radio/cassette players,<br />

small black and white TV or similar low-power appliances <strong>for</strong> about three to five<br />

hours a day. Additionally, other types of luminaires, 12 Vdc or lower voltage socket<br />

outlets or a DC/AC inverter may be supplied as options. Each SHS consists of one or<br />

more photovoltaic (PV) modules with an output of 20 Wp or more charging a 12<br />

Vdc rechargeable battery along with luminaires, related electronic and electrical<br />

components and mounting hardware. Examples of SHS PV module sizes and typical<br />

service levels provided with five peak sunlight hours per day are shown below:<br />

SHS Useful energy<br />

Operation of fluorescent lights and TV in hours per day<br />

7W light 7W light 7W light 7W light 12W TV<br />

25 Wp 75 Wh/day 3 2 X X 3<br />

36 Wp 110 Wh/day 3 3 2 X 4<br />

40 Wp 120 Wh/day 4 3 3 X 4<br />

50 Wp 150 Wh/day 5 3 3 X 6<br />

75 (70) Wp 225 Wh/day 8 3 3 3 8<br />

Note: These are representative levels of service assuming 10% module derating, 20% wiring,<br />

misalignment and other losses, and 20% battery round-trip Wh losses. Actual operating hours<br />

per day will vary depending on the number and wattage of the lights and other appliances<br />

switched on at any given time and peak hours of sunlight available on any given day.<br />

<strong>3.</strong>1.2 The SHS is packaged and pre-wired to provide convenient installation at a remote<br />

customer home site by a qualified technician. The system is constructed such that a<br />

user can per<strong>for</strong>m routine maintenance such as adding battery water and replacing<br />

light bulbs and fuses, and a technician can easily per<strong>for</strong>m system diagnostics or<br />

replace components.<br />

35

<strong>3.</strong>2 Certification Requirements<br />

<strong>3.</strong>2.1 Products to be financed under the World Bank-assisted Rural Power Project must<br />

have a type-test certificate from an accredited testing and certification organization<br />

acceptable to the Republic of the Philippines and the IBRD stating that the Solar<br />

Home System meets or exceeds the specifications given in <strong>Annex</strong> 1. Organizations<br />

accredited according to ISO 25 or equivalent standards will be acceptable <strong>for</strong> issuing<br />

the component certifications.<br />

<strong>3.</strong>2.2 SHS components or systems that bear the Photovoltaic Global Approval Program<br />

(PV GAP) Mark or Seal will be acceptable <strong>for</strong> use in the SHS Project. 3<br />

<strong>3.</strong>2.3 SHS battery charge controllers, DC fluorescent lamps, and DC-AC inverters that<br />

have been tested at an accredited testing institute and have a currently valid<br />

certification <strong>for</strong> use in the following World Bank-assisted projects, are eligible <strong>for</strong><br />

use in the Philippines Rural Power Project:<br />

• Philippines Rural Power Project (list of qualified products are provided in<br />

Attachment A)<br />

• Sri Lanka Energy Services Delivery Project and the Sri Lanka Renewable<br />

Energy <strong>for</strong> Rural Economic Development Project (<strong>for</strong> list of certified products<br />

see: http://www.energyservices.lk or write to info@dfccbank.com)<br />

Interested parties wishing to use such products must submit documentation attesting<br />

to the fact that their products have been certified <strong>for</strong> use in the above referenced<br />

projects.<br />

<strong>3.</strong>2.4 A maximum measurement error of 3 percent is permitted on all tests of compliance.<br />

<strong>3.</strong>2.5 The supplier provides the most appropriate system integration, components,<br />

assembly and packaging that meet all the component specifications in Attachment 1<br />

- Solar Home System Component <strong>Specifications</strong> and the best practices<br />

recommendations in Section <strong>3.</strong><br />

<strong>3.</strong>3 Recommended Best Practices<br />

This section provides a minimum set of requirements that shall be followed in the<br />

design, specification and installation of the qualified SHS. They <strong>for</strong>m a set of “Best<br />

Practices” which when followed will ensure adequate levels of safety, per<strong>for</strong>mance,<br />

reliability and system lifetime. Suppliers are required to adhere to these Best<br />

Practices in order to participate in the Project.<br />

3 PV GAP is a Geneva, Switzerland-based, not-<strong>for</strong>-profit international organization, dedicated to the sustained growth<br />

of global photovoltaics (PV) markets to meet energy needs worldwide in an environmentally sound manner. For<br />

more in<strong>for</strong>mation see http://www.pvgap.org/.<br />

36

<strong>3.</strong><strong>3.</strong>1 PV Module Installation<br />

a) If more than one module is used, identical models shall be used and they shall<br />

be connected in parallel.<br />

b) For SHS installed permanently on a structure (in contrast with portable units):<br />

The modules must be framed in such a way as to allow secure connection to<br />

the module mounting structure.<br />

i. The array mounting structure will hold the photovoltaic module(s). The<br />

module(s) must be mounted on a support structure made of corrosion<br />

resistant material that assures stable and secure attachment.<br />

ii. The PV array and support structure must be able to withstand wind<br />

gusts up to 100 km/hour without damage.<br />

iii. The structure must be mounted at a fixed angle and oriented to<br />

maximize the useful energy supplied to the user during the design<br />

month (i.e., the month with the worst average daily insolation) Array<br />

orientation must be adjustable in the field.<br />