Plate Heat Exchangers for Marine Applications - Gulf Sondex

Plate Heat Exchangers for Marine Applications - Gulf Sondex

Plate Heat Exchangers for Marine Applications - Gulf Sondex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

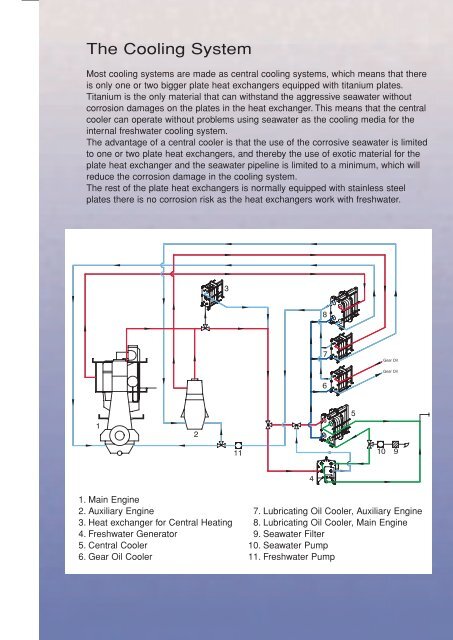

The Cooling System<br />

Most cooling systems are made as central cooling systems, which means that there<br />

is only one or two bigger plate heat exchangers equipped with titanium plates.<br />

Titanium is the only material that can withstand the aggressive seawater without<br />

corrosion damages on the plates in the heat exchanger. This means that the central<br />

cooler can operate without problems using seawater as the cooling media <strong>for</strong> the<br />

internal freshwater cooling system.<br />

The advantage of a central cooler is that the use of the corrosive seawater is limited<br />

to one or two plate heat exchangers, and thereby the use of exotic material <strong>for</strong> the<br />

plate heat exchanger and the seawater pipeline is limited to a minimum, which will<br />

reduce the corrosion damage in the cooling system.<br />

The rest of the plate heat exchangers is normally equipped with stainless steel<br />

plates there is no corrosion risk as the heat exchangers work with freshwater.<br />

1. Main Engine<br />

2. Auxiliary Engine<br />

3. <strong>Heat</strong> exchanger <strong>for</strong> Central <strong>Heat</strong>ing<br />

4. Freshwater Generator<br />

5. Central Cooler<br />

6. Gear Oil Cooler<br />

7. Lubricating Oil Cooler, Auxiliary Engine<br />

8. Lubricating Oil Cooler, Main Engine<br />

9. Seawater Filter<br />

10. Seawater Pump<br />

11. Freshwater Pump