Technical Data Sheet - Octopart

Technical Data Sheet - Octopart

Technical Data Sheet - Octopart

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

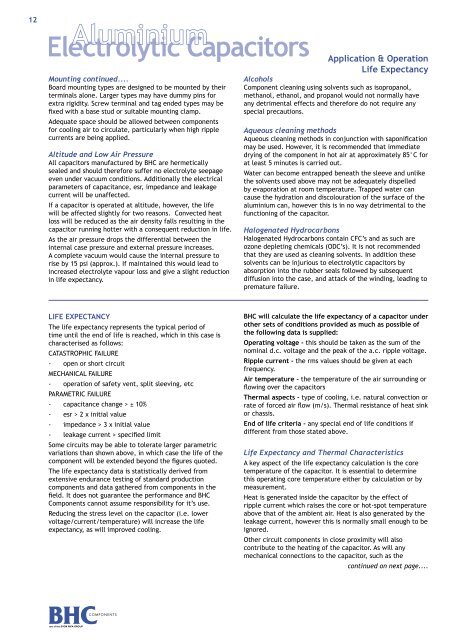

12<br />

Mounting continued....<br />

Board mounting types are designed to be mounted by their<br />

terminals alone. Larger types may have dummy pins for<br />

extra rigidity. Screw terminal and tag ended types may be<br />

fixed with a base stud or suitable mounting clamp.<br />

Adequate space should be allowed between components<br />

for cooling air to circulate, particularly when high ripple<br />

currents are being applied.<br />

Altitude and Low Air Pressure<br />

All capacitors manufactured by BHC are hermetically<br />

sealed and should therefore suffer no electrolyte seepage<br />

even under vacuum conditions. Additionally the electrical<br />

parameters of capacitance, esr, impedance and leakage<br />

current will be unaffected.<br />

If a capacitor is operated at altitude, however, the life<br />

will be affected slightly for two reasons. Convected heat<br />

loss will be reduced as the air density falls resulting in the<br />

capacitor running hotter with a consequent reduction in life.<br />

As the air pressure drops the differential between the<br />

internal case pressure and external pressure increases.<br />

A complete vacuum would cause the internal pressure to<br />

rise by 15 psi (approx.). If maintained this would lead to<br />

increased electrolyte vapour loss and give a slight reduction<br />

in life expectancy.<br />

LIFE EXPECTANCY<br />

The life expectancy represents the typical period of<br />

time until the end of life is reached, which in this case is<br />

characterised as follows:<br />

CATASTROPHIC FAILURE<br />

- open or short circuit<br />

MECHANICAL FAILURE<br />

- operation of safety vent, split sleeving, etc<br />

PARAMETRIC FAILURE<br />

- capacitance change > ± 10%<br />

- esr > 2 x initial value<br />

- impedance > 3 x initial value<br />

- leakage current > specified limit<br />

Some circuits may be able to tolerate larger parametric<br />

variations than shown above, in which case the life of the<br />

component will be extended beyond the figures quoted.<br />

The life expectancy data is statistically derived from<br />

extensive endurance testing of standard production<br />

components and data gathered from components in the<br />

field. It does not guarantee the performance and BHC<br />

Components cannot assume responsibility for it’s use.<br />

Reducing the stress level on the capacitor (i.e. lower<br />

voltage/current/temperature) will increase the life<br />

expectancy, as will improved cooling.<br />

Application & Operation<br />

Life Expectancy<br />

Alcohols<br />

Component cleaning using solvents such as isopropanol,<br />

methanol, ethanol, and propanol would not normally have<br />

any detrimental effects and therefore do not require any<br />

special precautions.<br />

Aqueous cleaning methods<br />

Aqueous cleaning methods in conjunction with saponification<br />

may be used. However, it is recommended that immediate<br />

drying of the component in hot air at approximately 85°C for<br />

at least 5 minutes is carried out.<br />

Water can become entrapped beneath the sleeve and unlike<br />

the solvents used above may not be adequately dispelled<br />

by evaporation at room temperature. Trapped water can<br />

cause the hydration and discolouration of the surface of the<br />

aluminium can, however this is in no way detrimental to the<br />

functioning of the capacitor.<br />

Halogenated Hydrocarbons<br />

Halogenated Hydrocarbons contain CFC’s and as such are<br />

ozone depleting chemicals (ODC’s). It is not recommended<br />

that they are used as cleaning solvents. In addition these<br />

solvents can be injurious to electrolytic capacitors by<br />

absorption into the rubber seals followed by subsequent<br />

diffusion into the case, and attack of the winding, leading to<br />

premature failure.<br />

BHC will calculate the life expectancy of a capacitor under<br />

other sets of conditions provided as much as possible of<br />

the following data is supplied:<br />

Operating voltage - this should be taken as the sum of the<br />

nominal d.c. voltage and the peak of the a.c. ripple voltage.<br />

Ripple current - the rms values should be given at each<br />

frequency.<br />

Air temperature - the temperature of the air surrounding or<br />

flowing over the capacitors<br />

Thermal aspects - type of cooling, i.e. natural convection or<br />

rate of forced air flow (m/s). Thermal resistance of heat sink<br />

or chassis.<br />

End of life criteria - any special end of life conditions if<br />

different from those stated above.<br />

Life Expectancy and Thermal Characteristics<br />

A key aspect of the life expectancy calculation is the core<br />

temperature of the capacitor. It is essential to determine<br />

this operating core temperature either by calculation or by<br />

measurement.<br />

Heat is generated inside the capacitor by the effect of<br />

ripple current which raises the core or hot-spot temperature<br />

above that of the ambient air. Heat is also generated by the<br />

leakage current, however this is normally small enough to be<br />

ignored.<br />

Other circuit components in close proximity will also<br />

contribute to the heating of the capacitor. As will any<br />

mechanical connections to the capacitor, such as the<br />

continued on next page....