MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

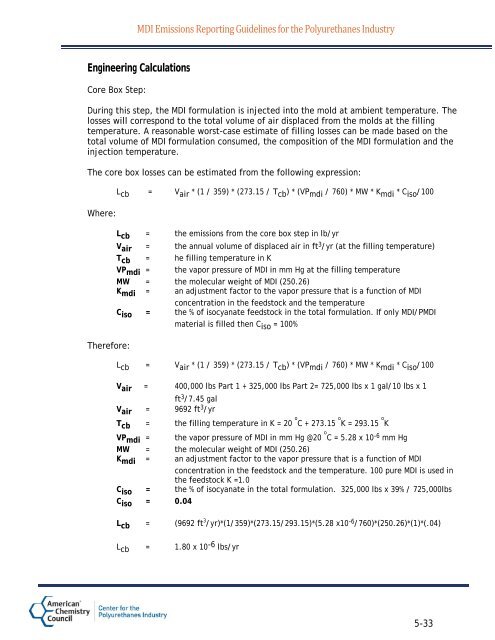

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

Engineering Calculations<br />

Core Box Step:<br />

During this step, <strong>the</strong> <strong>MDI</strong> <strong>for</strong>mulation is injected into <strong>the</strong> mold at ambient temperature. The<br />

losses will correspond to <strong>the</strong> total volume of air displaced from <strong>the</strong> molds at <strong>the</strong> filling<br />

temperature. A reasonable worst-case estimate of filling losses can be made based on <strong>the</strong><br />

total volume of <strong>MDI</strong> <strong>for</strong>mulation consumed, <strong>the</strong> composition of <strong>the</strong> <strong>MDI</strong> <strong>for</strong>mulation and <strong>the</strong><br />

injection temperature.<br />

The core box losses can be estimated from <strong>the</strong> following expression:<br />

Where:<br />

There<strong>for</strong>e:<br />

L cb = V air * (1 / 359) * (273.15 / T cb ) * (VP mdi / 760) * MW * K mdi * C iso /100<br />

Lcb = <strong>the</strong> emissions from <strong>the</strong> core box step in lb/yr<br />

Vair = <strong>the</strong> annual volume of displaced air in ft3 /yr (at <strong>the</strong> filling temperature)<br />

Tcb = he filling temperature in K<br />

VPmdi = <strong>the</strong> vapor pressure of <strong>MDI</strong> in mm Hg at <strong>the</strong> filling temperature<br />

MW = <strong>the</strong> molecular weight of <strong>MDI</strong> (250.26)<br />

Kmdi = an adjustment factor to <strong>the</strong> vapor pressure that is a function of <strong>MDI</strong><br />

Ciso =<br />

concentration in <strong>the</strong> feedstock and <strong>the</strong> temperature<br />

<strong>the</strong> % of isocyanate feedstock in <strong>the</strong> total <strong>for</strong>mulation. If only <strong>MDI</strong>/P<strong>MDI</strong><br />

material is filled <strong>the</strong>n Ciso = 100%<br />

L cb = V air * (1 / 359) * (273.15 / T cb ) * (VP mdi / 760) * MW * K mdi * C iso /100<br />

Vair = 400,000 lbs Part 1 + 325,000 lbs Part 2= 725,000 lbs x 1 gal/10 lbs x 1<br />

ft3 /7.45 gal<br />

Vair = 9692 ft3 /yr<br />

Tcb = <strong>the</strong> filling temperature in K = 20 o<br />

C + 273.15 o<br />

K = 293.15 o<br />

K<br />

VPmdi = <strong>the</strong> vapor pressure of <strong>MDI</strong> in mm Hg @20 o<br />

C = 5.28 x 10 –6 mm Hg<br />

MW = <strong>the</strong> molecular weight of <strong>MDI</strong> (250.26)<br />

Kmdi = an adjustment factor to <strong>the</strong> vapor pressure that is a function of <strong>MDI</strong><br />

concentration in <strong>the</strong> feedstock and <strong>the</strong> temperature. 100 pure <strong>MDI</strong> is used in<br />

<strong>the</strong> feedstock K =1.0<br />

Ciso = <strong>the</strong> % of isocyanate in <strong>the</strong> total <strong>for</strong>mulation. 325,000 lbs x 39% / 725,000lbs<br />

Ciso = 0.04<br />

L cb = (9692 ft 3 /yr)*(1/359)*(273.15/293.15)*(5.28 x10 -6 /760)*(250.26)*(1)*(.04)<br />

L cb = 1.80 x 10 -6 lbs/yr<br />

5-33