MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

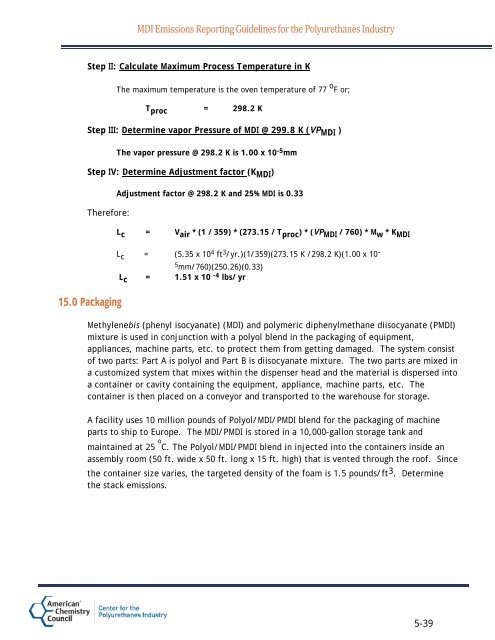

Step II: Calculate Maximum Process Temperature in K<br />

The maximum temperature is <strong>the</strong> oven temperature of 77 o F or;<br />

T proc = 298.2 K<br />

Step III: Determine vapor Pressure of <strong>MDI</strong> @ 299.8 K (VP <strong>MDI</strong> )<br />

The vapor pressure @ 298.2 K is 1.00 x 10 –5 mm<br />

Step IV: Determine Adjustment factor (K <strong>MDI</strong> )<br />

There<strong>for</strong>e:<br />

15.0 Packaging<br />

Adjustment factor @ 298.2 K and 25% <strong>MDI</strong> is 0.33<br />

L c = V air * (1 / 359) * (273.15 / T proc ) * (VP <strong>MDI</strong> / 760) * M w * K <strong>MDI</strong><br />

Lc = (5.35 x 104 ft3 /yr.)(1/359)(273.15 K /298.2 K)(1.00 x 10 –<br />

5mm/760)(250.26)(0.33) Lc = 1.51 x 10 -4 lbs/ yr<br />

Methylenebis (phenyl isocyanate) (<strong>MDI</strong>) and polymeric diphenylmethane diisocyanate (P<strong>MDI</strong>)<br />

mixture is used in conjunction with a polyol blend in <strong>the</strong> packaging of equipment,<br />

appliances, machine parts, etc. to protect <strong>the</strong>m from getting damaged. The system consist<br />

of two parts: Part A is polyol and Part B is diisocyanate mixture. The two parts are mixed in<br />

a customized system that mixes within <strong>the</strong> dispenser head and <strong>the</strong> material is dispersed into<br />

a container or cavity containing <strong>the</strong> equipment, appliance, machine parts, etc. The<br />

container is <strong>the</strong>n placed on a conveyor and transported to <strong>the</strong> warehouse <strong>for</strong> storage.<br />

A facility uses 10 million pounds of Polyol/<strong>MDI</strong>/P<strong>MDI</strong> blend <strong>for</strong> <strong>the</strong> packaging of machine<br />

parts to ship to Europe. The <strong>MDI</strong>/P<strong>MDI</strong> is stored in a 10,000-gallon storage tank and<br />

maintained at 25 o<br />

C. The Polyol/<strong>MDI</strong>/P<strong>MDI</strong> blend in injected into <strong>the</strong> containers inside an<br />

assembly room (50 ft. wide x 50 ft. long x 15 ft. high) that is vented through <strong>the</strong> roof. Since<br />

<strong>the</strong> container size varies, <strong>the</strong> targeted density of <strong>the</strong> foam is 1.5 pounds/ft3 . Determine<br />

<strong>the</strong> stack emissions.<br />

5-39