MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

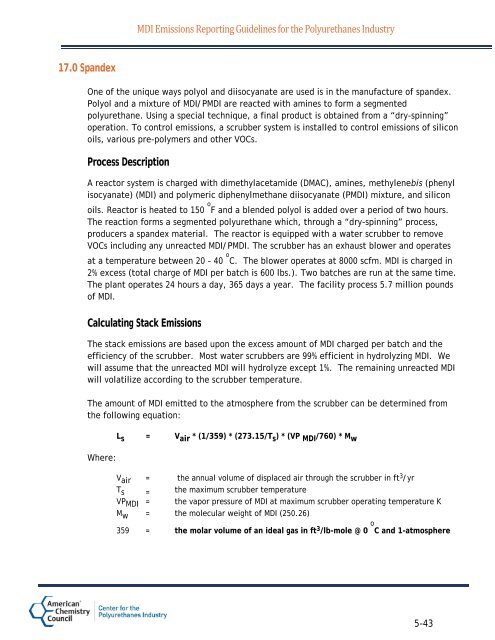

17.0 Spandex<br />

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

One of <strong>the</strong> unique ways polyol and diisocyanate are used is in <strong>the</strong> manufacture of spandex.<br />

Polyol and a mixture of <strong>MDI</strong>/P<strong>MDI</strong> are reacted with amines to <strong>for</strong>m a segmented<br />

polyurethane. Using a special technique, a final product is obtained from a “dry-spinning”<br />

operation. To control emissions, a scrubber system is installed to control emissions of silicon<br />

oils, various pre-polymers and o<strong>the</strong>r VOCs.<br />

Process Description<br />

A reactor system is charged with dimethylacetamide (DMAC), amines, methylenebis (phenyl<br />

isocyanate) (<strong>MDI</strong>) and polymeric diphenylmethane diisocyanate (P<strong>MDI</strong>) mixture, and silicon<br />

oils. Reactor is heated to 150 o<br />

F and a blended polyol is added over a period of two hours.<br />

The reaction <strong>for</strong>ms a segmented polyurethane which, through a “dry-spinning” process,<br />

producers a spandex material. The reactor is equipped with a water scrubber to remove<br />

VOCs including any unreacted <strong>MDI</strong>/P<strong>MDI</strong>. The scrubber has an exhaust blower and operates<br />

at a temperature between 20 – 40 o<br />

C. The blower operates at 8000 scfm. <strong>MDI</strong> is charged in<br />

2% excess (total charge of <strong>MDI</strong> per batch is 600 lbs.). Two batches are run at <strong>the</strong> same time.<br />

The plant operates 24 hours a day, 365 days a year. The facility process 5.7 million pounds<br />

of <strong>MDI</strong>.<br />

Calculating Stack <strong>Emissions</strong><br />

The stack emissions are based upon <strong>the</strong> excess amount of <strong>MDI</strong> charged per batch and <strong>the</strong><br />

efficiency of <strong>the</strong> scrubber. Most water scrubbers are 99% efficient in hydrolyzing <strong>MDI</strong>. We<br />

will assume that <strong>the</strong> unreacted <strong>MDI</strong> will hydrolyze except 1%. The remaining unreacted <strong>MDI</strong><br />

will volatilize according to <strong>the</strong> scrubber temperature.<br />

The amount of <strong>MDI</strong> emitted to <strong>the</strong> atmosphere from <strong>the</strong> scrubber can be determined from<br />

<strong>the</strong> following equation:<br />

Where:<br />

L s = V air * (1/359) * (273.15/T s ) * (VP <strong>MDI</strong> /760) * M w<br />

Vair = <strong>the</strong> annual volume of displaced air through <strong>the</strong> scrubber in ft3 /yr<br />

Ts = <strong>the</strong> maximum scrubber temperature<br />

VP<strong>MDI</strong> = <strong>the</strong> vapor pressure of <strong>MDI</strong> at maximum scrubber operating temperature K<br />

Mw = <strong>the</strong> molecular weight of <strong>MDI</strong> (250.26)<br />

359 = <strong>the</strong> molar volume of an ideal gas in ft3 /lb-mole @ 0 o<br />

C and 1-atmosphere<br />

5-43