MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

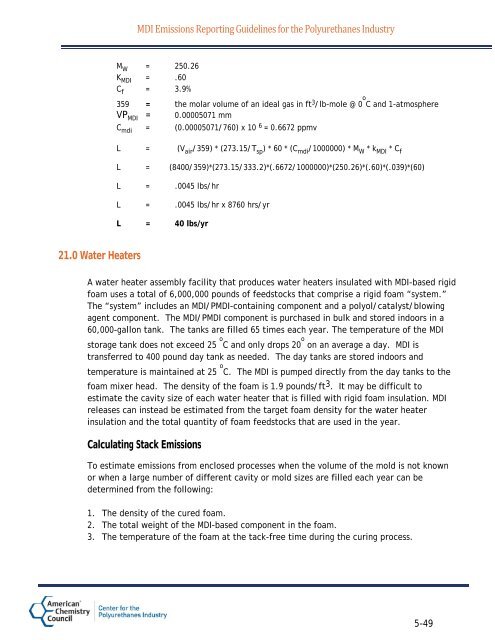

21.0 Water Heaters<br />

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

M W = 250.26<br />

K <strong>MDI</strong> = .60<br />

C f = 3.9%<br />

359 = <strong>the</strong> molar volume of an ideal gas in ft 3 /lb-mole @ 0 o<br />

C and 1-atmosphere<br />

VP <strong>MDI</strong> = 0.00005071 mm<br />

C mdi = (0.00005071/760) x 10 6 = 0.6672 ppmv<br />

L = (V air /359) * (273.15/T sp ) * 60 * (C mdi /1000000) * M W * k <strong>MDI</strong> * C f<br />

L = (8400/359)*(273.15/333.2)*(.6672/1000000)*(250.26)*(.60)*(.039)*(60)<br />

L = .0045 lbs/hr<br />

L = .0045 lbs/hr x 8760 hrs/yr<br />

L = 40 lbs/yr<br />

A water heater assembly facility that produces water heaters insulated with <strong>MDI</strong>-based rigid<br />

foam uses a total of 6,000,000 pounds of feedstocks that comprise a rigid foam “system.”<br />

The “system” includes an <strong>MDI</strong>/P<strong>MDI</strong>-containing component and a polyol/catalyst/blowing<br />

agent component. The <strong>MDI</strong>/P<strong>MDI</strong> component is purchased in bulk and stored indoors in a<br />

60,000-gallon tank. The tanks are filled 65 times each year. The temperature of <strong>the</strong> <strong>MDI</strong><br />

storage tank does not exceed 25 o<br />

C and only drops 20 o<br />

on an average a day. <strong>MDI</strong> is<br />

transferred to 400 pound day tank as needed. The day tanks are stored indoors and<br />

temperature is maintained at 25 o<br />

C. The <strong>MDI</strong> is pumped directly from <strong>the</strong> day tanks to <strong>the</strong><br />

foam mixer head. The density of <strong>the</strong> foam is 1.9 pounds/ft3 . It may be difficult to<br />

estimate <strong>the</strong> cavity size of each water heater that is filled with rigid foam insulation. <strong>MDI</strong><br />

releases can instead be estimated from <strong>the</strong> target foam density <strong>for</strong> <strong>the</strong> water heater<br />

insulation and <strong>the</strong> total quantity of foam feedstocks that are used in <strong>the</strong> year.<br />

Calculating Stack <strong>Emissions</strong><br />

To estimate emissions from enclosed processes when <strong>the</strong> volume of <strong>the</strong> mold is not known<br />

or when a large number of different cavity or mold sizes are filled each year can be<br />

determined from <strong>the</strong> following:<br />

1. The density of <strong>the</strong> cured foam.<br />

2. The total weight of <strong>the</strong> <strong>MDI</strong>-based component in <strong>the</strong> foam.<br />

3. The temperature of <strong>the</strong> foam at <strong>the</strong> tack-free time during <strong>the</strong> curing process.<br />

5-49