XPRLTM - Draka Communications

XPRLTM - Draka Communications

XPRLTM - Draka Communications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

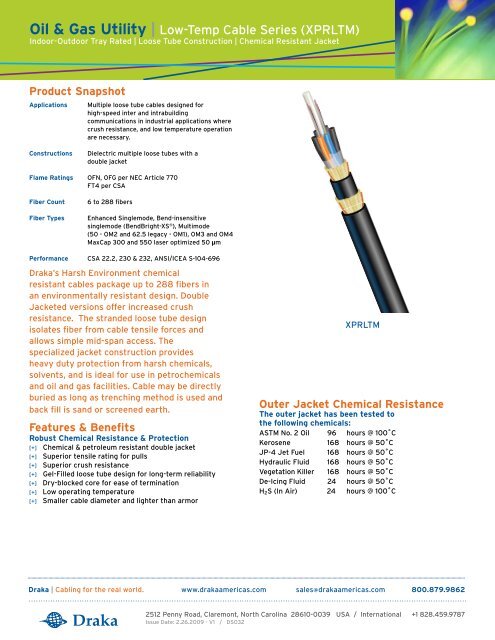

Oil & Gas Utility | Low-Temp Cable Series (<strong>XPRLTM</strong>)<br />

Indoor-Outdoor Tray Rated | Loose Tube Construction | Chemical Resistant Jacket<br />

Product Snapshot<br />

Applications Multiple loose tube cables designed for<br />

high-speed inter and intrabuilding<br />

communications in industrial applications where<br />

crush resistance, and low temperature operation<br />

are necessary.<br />

Constructions Dielectric multiple loose tubes with a<br />

double jacket<br />

Flame Ratings OFN, OFG per NEC Article 770<br />

FT4 per CSA<br />

Fiber Count 6 to 288 fibers<br />

Fiber Types Enhanced Singlemode, Bend-insensitive<br />

singlemode (BendBright-XS ® ), Multimode<br />

(50 - OM2 and 62.5 legacy - OM1), OM3 and OM4<br />

MaxCap 300 and 550 laser optimized 50 µm<br />

Performance CSA 22.2, 230 & 232, ANSI/ICEA S-104-696<br />

<strong>Draka</strong>’s Harsh Environment chemical<br />

resistant cables package up to 288 fibers in<br />

an environmentally resistant design. Double<br />

Jacketed versions offer increased crush<br />

resistance. The stranded loose tube design<br />

isolates fiber from cable tensile forces and<br />

allows simple mid-span access. The<br />

specialized jacket construction provides<br />

heavy duty protection from harsh chemicals,<br />

solvents, and is ideal for use in petrochemicals<br />

and oil and gas facilities. Cable may be directly<br />

buried as long as trenching method is used and<br />

back fill is sand or screened earth.<br />

Features & Benefits<br />

Robust Chemical Resistance & Protection<br />

[+] Chemical & petroleum resistant double jacket<br />

[+] Superior tensile rating for pulls<br />

[+] Superior crush resistance<br />

[+] Gel-Filled loose tube design for long-term reliability<br />

[+] Dry-blocked core for ease of termination<br />

[+] Low operating temperature<br />

[+] Smaller cable diameter and lighter than armor<br />

<strong>XPRLTM</strong><br />

Outer Jacket Chemical Resistance<br />

The outer jacket has been tested to<br />

the following chemicals:<br />

ASTM No. 2 Oil 96 hours @ 100˚C<br />

Kerosene 168 hours @ 50˚C<br />

JP-4 Jet Fuel 168 hours @ 50˚C<br />

Hydraulic Fluid 168 hours @ 50˚C<br />

Vegetation Killer 168 hours @ 50˚C<br />

De-Icing Fluid 24 hours @ 50˚C<br />

H2S (In Air) 24 hours @ 100˚C<br />

<strong>Draka</strong> | Cabling for the real world. www.drakaamericas.com sales@drakaamericas.com 800.879.9862<br />

2512 Penny Road, Claremont, North Carolina 28610-0039 USA / International +1 828.459.9787<br />

Issue Date: 2.26.2009 - V1 / DS032

Oil & Gas Utility | Low-Temp Cable Series (<strong>XPRLTM</strong>)<br />

Indoor-Outdoor Tray Rated | Loose Tube Construction | Chemical Resistant Jacket<br />

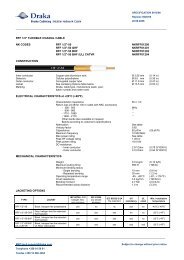

Fiber Count # of Buffer Tubes<br />

Outer/Inner Layer<br />

Diameter<br />

inches (mm)<br />

Cable Weight<br />

lb/1000ft (kg/km)<br />

Bend Radius | Load<br />

inches (cm)<br />

6-72 6 0.602 (15.3) 152 (227) 12 (31) 6 (15)<br />

84 7 0.636 (16.2) 170 (253) 13 (32) 6 (16)<br />

96 8 0.672 (17.1) 189 (282) 13 (34) 7 (17)<br />

108 9 0.706 (18.0) 209 (312) 14 (36) 7 (18)<br />

120 10 0.741 (18.9) 230 (343) 15 (38) 7 (19)<br />

132 11 0.776 (19.7) 252 (376) 16 (39) 8 (20)<br />

14 12 0.826 (21.0) 286 (426) 17 (42) 8 (21)<br />

146-216 12/6 0.806 (20.5) 272 (406) 16 (41) 8 (21)<br />

218-264 14/8 0.898 (22.8) 338 (504) 18 (46) 9 (23)<br />

266-288 15/9 0.932 (23.7) 364 (543) 19 (47) 9 (24)<br />

Mechanical Specifications<br />

Installation<br />

[+] Maximum Installation load 1000 lbs (4450 N)<br />

[+] Maximum Operation load 333 lbs (1335 N)<br />

[+] Crush Resistance:<br />

4500 newton load - tested per CSA C22.2 No. 230-M 1988<br />

[+] Impact load: 11.8 N*M<br />

[+] Cold Imact load: 5.88 N*M at -30˚C<br />

Ordering Guide<br />

For Ordering or More Information Contact Us at sales@drakaamericas.com or 800.879.9862.<br />

Temperature Range<br />

[+] Shipping and Storage -40˚C to 70˚C<br />

[+] Installation -30˚C to 70˚C<br />

[+] Operation -50˚C to 70˚C<br />

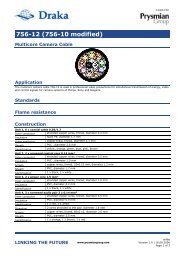

Example: ezPREP ® Loose Tube | Harsh Environment, Dielectric (Single Jacket), 48 multimode 62.5/125 Fibers (printed in feet)<br />

PRINT PRODUCT FAMILY FIBERS/UNIT FIBER TYPE FIBER COUNT FIBER GRADE<br />

F <strong>XPRLTM</strong> 12 6S 048 m2 example onlY<br />

1 2 3 4 5 6<br />

PRINT<br />

F Feet<br />

PRODUCT FAMILY<br />

Indoor-Outdoor & Specialty Cables<br />

M Meters ezPREP ® 1 2 3 FIBERS/UNIT<br />

12 12 fibers/unit<br />

5<br />

Loose Tube | Indoor-Outdoor<br />

<strong>XPRLTM</strong> Non-Armored Chemical Resistant Loose Tube,<br />

Double Jacket<br />

FIBER COUNT<br />

### 001 to 288 Fibers<br />

Bend Radius | No Load<br />

inches (cm)<br />

4 FIBER TYPE<br />

MULTIMODE<br />

6 FIBER GRADE WAVELENGTHS ATTENUATION BANDWIDTH 1 GbE DISTANCE<br />

(nm) (dB/km) (MHz.km) (m at 850/1300nm)<br />

10 GbE DISTANCE<br />

(m at 850nm)<br />

5S Legacy, 50 µm (OM2) M1 850 / 1300 3.5 / 1.5 500 / 500 550 / 550 82<br />

6S Legacy, 62.5 µm (OM1) M2 850 / 1300 3.5 / 1.0 200 / 500 300 / 550 33<br />

5H HiCap (1 GbE), 50 µm (OM2+) M1 850 / 1300 3.5 / 1.5 600 / 1200 750 / 2000 110<br />

6H HiCap (1 GbE), 62.5µm (OM1+) M2 850 / 1300 3.5 / 1.0 200 / 600 500 / 1000 65<br />

53 MaxCap ® (10 GbE), 50 µm, 300m (OM3) M1 850 / 1300 3.5 / 1.5 1500 / 500 1000 / 550 300<br />

55 MaxCap ® pt (10 GbE), 50 µm, 550m (OM3+) M1 850 / 1300 3.5 / 1.5 3500 / 500 1100 / 550 550<br />

SINGLEMODE<br />

ES ESMF | Loose Tube E1 1310 / 1383 / 1550 0.4 / 0.4 / 0.3<br />

BB BendBright ® | Loose Tube E1 1310 / 1383 / 1550 0.4 / 0.4 / 0.3<br />

BX BendBright-XS ® | Loose Tube E1 1310 / 1383 / 1550 0.4 / 0.4 / 0.3<br />

Other cable constructions and fiber performance grades available on request.<br />

PRINT PRODUCT FAMILY FIBERS/UNIT FIBER TYPE FIBER COUNT FIBER GRADE<br />

1 2 3 4 5 6<br />

<strong>Draka</strong> | Cabling for the real world. www.drakaamericas.com sales@drakaamericas.com 800.879.9862<br />

2512 Penny Road, Claremont, North Carolina 28610-0039 USA / International +1 828.459.9787<br />

The <strong>Draka</strong> policy of continuous improvement may result in changes to specifications without prior notice.<br />

Issue Date: 2.26.2009 - V1 / DS032