technology and engineeringTEACHER - Unionville High School ...

technology and engineeringTEACHER - Unionville High School ...

technology and engineeringTEACHER - Unionville High School ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

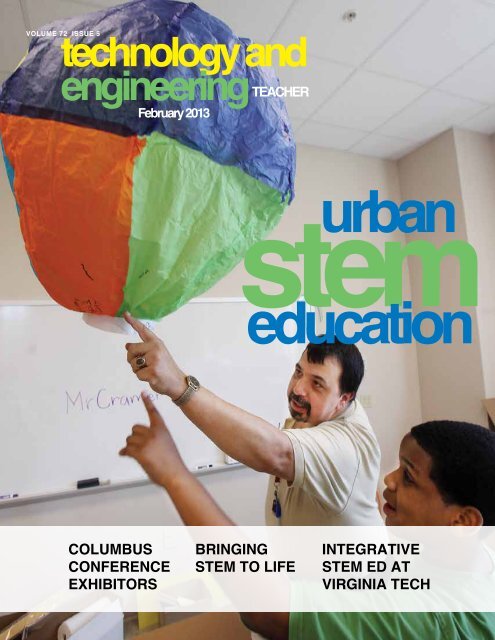

VOLUME 72 ISSUE 5<br />

<strong>technology</strong> <strong>and</strong><br />

engineering TEACHER<br />

February 2013<br />

COLUMBUS<br />

CONFERENCE<br />

EXHIBITORS<br />

stem<br />

BRINGING<br />

STEM TO LIFE<br />

urban<br />

education<br />

INTEGRATIVE<br />

STEM ED AT<br />

VIRGINIA TECH

BRINGING STEM TO LIFE<br />

BRINGING<br />

Our high school students have been warned repeatedly that they must prepare<br />

<br />

stemTO LIFE<br />

BY MIKE BERKEIHISER AND DORI RAY<br />

Have you been looking for quality STEM activities for your <strong>technology</strong> <strong>and</strong> engineering<br />

program? Would you like to expose a wider variety of students to your curriculum? Do<br />

you strive to involve your Technology <strong>and</strong> Engineering Education Department in inter-<br />

disciplinary activities with other academic subject areas?<br />

The interdisciplinary approach that STEM projects inspire in<br />

both teachers <strong>and</strong> students “brings to light a larger picture that<br />

<br />

been shown to increase undergraduate persistence in STEM”<br />

(diverseeducation.com).<br />

Our high school students have been warned<br />

repeatedly that they must prepare themselves<br />

<br />

exist. These warnings have resulted in an<br />

increased emphasis on cooperative problem<br />

solving, innovative solution writing, <strong>and</strong> technological<br />

skill acquisition across the curricula of<br />

secondary schools. By pairing mathematics <strong>and</strong><br />

<strong>technology</strong> classes together in unique ways,<br />

<br />

jobs may dem<strong>and</strong> (Figure 1).<br />

At <strong>Unionville</strong> <strong>High</strong> <strong>School</strong> in Kennett Square,<br />

PA, calculus teacher Dori Ray requires her<br />

advanced placement calculus students to build<br />

three-dimensional solids of known cross-section<br />

out of layers of h<strong>and</strong>-cut foam. The process<br />

is very similar to the process <strong>technology</strong> <strong>and</strong><br />

engineering teachers have used for years to make 3-D models<br />

from sheet goods using laser cutters, vinyl sign cutters, CNC<br />

routers, <strong>and</strong> manual processes. Each slice of a thin material is<br />

<br />

the result is a functional 3-D model (Figure 2).<br />

Figure 1: Engineering CAD <strong>and</strong> AP Calculus students draw a parabola using AutoCAD.<br />

February 2013 <strong>technology</strong> <strong>and</strong> engineering teacher 21

BRINGING STEM TO LIFE<br />

Figure 2: <br />

This year, Ms. Ray’s students completed their models by h<strong>and</strong><br />

using graphing calculators, spreadsheets, scissors, <strong>and</strong> glue.<br />

They converted coordinate units to centimeters, determined<br />

<br />

functions, <strong>and</strong> painstakingly cut each shape to build their mod-<br />

<br />

<strong>technology</strong> <strong>and</strong> engineering teacher at UHS. The two teachers<br />

then created a new <strong>and</strong> exciting stage of the project in which the<br />

calculus students could communicate their sophisticated scaling,<br />

slicing, <strong>and</strong> cutting needs to Mr. Berkeihiser’s engineering CAD<br />

drafting students who would exp<strong>and</strong> the task to one involving<br />

AutoCAD <strong>and</strong> a laser cutter (Figure 3). Calculus students <strong>and</strong><br />

Figure 3: <br />

22 <strong>technology</strong> <strong>and</strong> engineering teacher February 2013<br />

engineering CAD students were paired into teams so they could<br />

better use each student’s unique background <strong>and</strong> skills. A few<br />

of Mr. Berkeihiser’s current <strong>and</strong> past engineering CAD students<br />

were also in Ms. Ray’s calculus class <strong>and</strong> proved tremendously<br />

valuable in translating the task between calculus terminology<br />

<strong>and</strong> CAD terminology <strong>and</strong> back to calculus terms when it came<br />

time to evaluate the volumes of the resulting models.<br />

<br />

interrupted by a few absences which, fortuitously, provided Ms.<br />

Ray with an additional learning opportunity. Because some<br />

calculus students were absent, there were extra engineering<br />

CAD students without partners, <strong>and</strong> Ms. Ray, knowing that a<br />

solid model of a known cross section produces different looking<br />

solids depending on the axes of the slices’ orientations, wondered<br />

if the extra students could be added to the existing groups<br />

to complete a second model with slices featuring these alternate<br />

orientations. No sooner had the question been posed than the<br />

engineering CAD students jumped at the chance to undertake<br />

<br />

horizontally <strong>and</strong> vertically sliced models, are many times more<br />

valuable as teaching tools in AP Calculus because they provide<br />

powerful visual aids in explaining an abstract mathematical<br />

concept.<br />

<br />

to use as the base region for the solid. Calculus students were<br />

advised to pay close attention<br />

at this step to accommodate<br />

the 3mm thickness of the<br />

masonite they would be using<br />

to build their models since their<br />

<br />

40-50 slices. Students were<br />

then allowed to pick the shape<br />

of the cross-sectional slice<br />

of their solid. Their choices<br />

included an equilateral triangle,<br />

a semicircle, an isosceles right<br />

triangle, <strong>and</strong> a rectangle. They<br />

then named the formula that is<br />

used to calculate the area of<br />

that shape.<br />

At this point, calculus students<br />

communicated the size <strong>and</strong><br />

shape of the ellipse that they

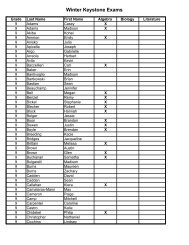

28.0000 39.191847.497454.2586<br />

60.0000 64.9923 69.3974 73.3212 76.8375 80.0000 82.8493 85.4166 87.7268 89.7998 91.6515 93.2952 94.7418 96.0000 96.5386 97.9796 98.7117 98.9945 99.6550 99.9200 100.0000<br />

Figure 4: Sample student drawing. Figure 5: Laser cut triangle pieces ready for assembly.<br />

the CAD students for their stage of the project. Since AutoCAD<br />

<br />

were forced to carefully use their language arts skills to assure<br />

that they were communicating clearly with each other.<br />

Once base areas were conveyed, the calculus students sat back<br />

<strong>and</strong> watched in amazement as the engineering students generated<br />

the ellipse on the screen, deftly sliced it into 40 pieces, <strong>and</strong><br />

began measuring key dimensions of those slices with the simple<br />

click of a button. After these measurements were labeled on the<br />

AutoCAD diagram, the engineering students quickly generated<br />

another drawing that held all<br />

of the individual slices that<br />

would make up the threedimensional<br />

solids (Figure 4).<br />

After having completed all of<br />

these tasks by h<strong>and</strong> during<br />

<br />

AP calculus students raved<br />

about the capabilities of the<br />

computers as well as their<br />

engineering partners who<br />

did the work so quickly. One<br />

student said, “Using the design<br />

students’ experience with the<br />

equipment <strong>and</strong> software, we<br />

were able to quickly <strong>and</strong> easily<br />

assemble an accurately sliced<br />

model.” It was wonderful to see<br />

engineering students tutoring<br />

calculus students so that they<br />

too could try using the technol-<br />

<br />

sent to the laser-cutter so that all pieces would be cut out (Figure<br />

5) <strong>and</strong> ready for assembly at our next meeting. Engineering<br />

students even developed another component in their diagrams<br />

of the individual slices that included a tiny groove in each slice<br />

that would allow students to line pieces up easily once they were<br />

ready to assemble <strong>and</strong> glue their models (Figure 6).<br />

The activities described above allowed the AP calculus students<br />

to be exposed to engineering applications of a classic calculus<br />

problem. Engineering CAD students were able to get a glimpse<br />

Figure 6: Students assembling a model using their groove in the bottom of the shape for alignment.<br />

February 2013 <strong>technology</strong> <strong>and</strong> engineering teacher 23

BRINGING STEM TO LIFE<br />

of the mathematics at work behind the scenes of their software<br />

environment. Perhaps most importantly, both the students <strong>and</strong><br />

the teachers were able to communicate <strong>and</strong> problem-solve in an<br />

<br />

These models will be useful instructional aids in our Academic<br />

<strong>and</strong> AP level calculus classrooms when students investigate the<br />

volumes of solids of known cross-sections. More importantly,<br />

however, we are keeping the STEM ideals alive for our learners.<br />

<br />

design students greatly changed my experience of building the<br />

model by allowing us to utilize <strong>technology</strong> to create a more sophisticated,<br />

intricate product. I now have a clearer underst<strong>and</strong>ing<br />

of the relationship between engineering <strong>and</strong> calculus after<br />

working with the design students.”<br />

<br />

ties<br />

that are spurring unprecedented cuts for education. After<br />

completing this unique project, Ms. Ray <strong>and</strong> Mr. Berkeihiser <strong>and</strong><br />

their students can continue to complement each others’ curricular<br />

knowledge <strong>and</strong> experiences in ways that provide cuttingedge,<br />

cross-curricular academic experiences without adding<br />

<br />

24 <strong>technology</strong> <strong>and</strong> engineering teacher February 2013<br />

REFERENCE<br />

Figure 7:<br />

AP Calculus student<br />

works with an Engineering<br />

CAD student.<br />

Cox, Matthews, <strong>and</strong> Associates, Inc. (2012). President Obama’s<br />

2012 commitment to STEM. Diverse: Issues In <strong>High</strong>er<br />

Education. Retrieved from http://diverseeducation.com/blogpost/333/president-obama-s-2012-commitment-to-stem.<br />

html<br />

Mike Berkeihiser is a <strong>technology</strong> <strong>and</strong> engineering<br />

teacher at <strong>Unionville</strong>-Chadds Ford<br />

<strong>School</strong> District in Kennett Square, PA. He can<br />

be reached via email at mberkeihiser@ucfsd.<br />

org.<br />

Dori Ray is a calculus teacher at <strong>Unionville</strong>-<br />

Chadds Ford <strong>School</strong> District in Kennett<br />

Square, PA.