EXTRUDED MARSHMALLOW NCA Candy School Pilot Plant Exercise

EXTRUDED MARSHMALLOW NCA Candy School Pilot Plant Exercise

EXTRUDED MARSHMALLOW NCA Candy School Pilot Plant Exercise

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

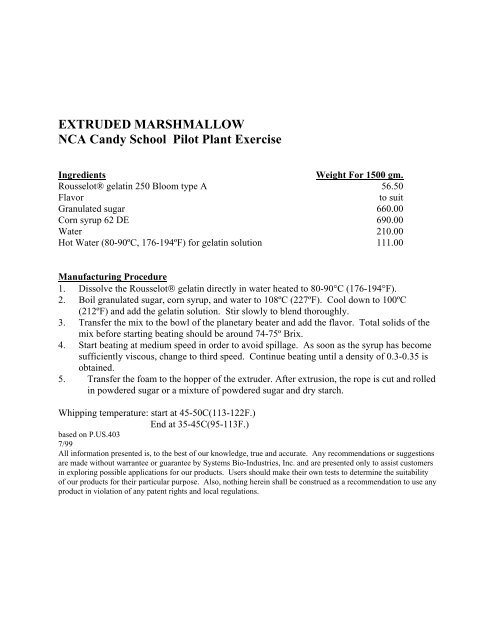

<strong>EXTRUDED</strong> <strong>MARSHMALLOW</strong><br />

<strong>NCA</strong> <strong>Candy</strong> <strong>School</strong> <strong>Pilot</strong> <strong>Plant</strong> <strong>Exercise</strong><br />

Ingredients Weight For 1500 gm.<br />

Rousselot® gelatin 250 Bloom type A 56.50<br />

Flavor to suit<br />

Granulated sugar 660.00<br />

Corn syrup 62 DE 690.00<br />

Water 210.00<br />

Hot Water (80-90ºC, 176-194ºF) for gelatin solution 111.00<br />

Manufacturing Procedure<br />

1. Dissolve the Rousselot® gelatin directly in water heated to 80-90°C (176-194°F).<br />

2. Boil granulated sugar, corn syrup, and water to 108ºC (227ºF). Cool down to 100ºC<br />

(212ºF) and add the gelatin solution. Stir slowly to blend thoroughly.<br />

3. Transfer the mix to the bowl of the planetary beater and add the flavor. Total solids of the<br />

mix before starting beating should be around 74-75º Brix.<br />

4. Start beating at medium speed in order to avoid spillage. As soon as the syrup has become<br />

sufficiently viscous, change to third speed. Continue beating until a density of 0.3-0.35 is<br />

obtained.<br />

5. Transfer the foam to the hopper of the extruder. After extrusion, the rope is cut and rolled<br />

in powdered sugar or a mixture of powdered sugar and dry starch.<br />

Whipping temperature: start at 45-50C(113-122F.)<br />

End at 35-45C(95-113F.)<br />

based on P.US.403<br />

7/99<br />

All information presented is, to the best of our knowledge, true and accurate. Any recommendations or suggestions<br />

are made without warrantee or guarantee by Systems Bio-Industries, Inc. and are presented only to assist customers<br />

in exploring possible applications for our products. Users should make their own tests to determine the suitability<br />

of our products for their particular purpose. Also, nothing herein shall be construed as a recommendation to use any<br />

product in violation of any patent rights and local regulations.

Aerated Marshmallows Lab Outline<br />

Objective: to develop a working knowledge of gelatin in a marshmallow<br />

application. This exercise will include making a benchtop extruded<br />

marshmallow formula(part 1) and also observing a pilot size extruded<br />

aeration(Mondomix) demonstration(part 2). Students will realize the texture<br />

behavior of gelatin in an aerated formula.<br />

Part 1 Benchtop Extruded Marshmallow <strong>Exercise</strong><br />

Materials: 250 bloom Type A (pigskin) 30 mesh gelatin<br />

62 D.E. corn syrup<br />

granulated sugar<br />

flavor and color<br />

water<br />

see attached formula<br />

Method: The gelatin will be dissolved and set aside. The sugar syrup should<br />

be cooked to temperature and cooled. The gelatin solution is added and<br />

blended thoroughly. The mixture is transferred to a Hobart mixer together<br />

with another group’s mixture. At this point flavor and color should be<br />

added(NO oil soluble flavors!!). The mixture should be whipped to the<br />

desired density. Plastic 7 oz. Cups and density chart will be provided.<br />

Marshmallow mixture is then transferred to 18” plastic pastry bags for<br />

extrusion into starch board “troughs”.

Results:<br />

Process Explanation<br />

Too soupy Marshmallow syrup too hot at<br />

beginning of whipping step<br />

Too stiff Marshmallow syrup too cool-<br />

reached setting point before fully<br />

aerated<br />

Texture<br />

Firm, dense Not enough whipping/aeration<br />

Chewy, tough Gelatin bloom too low, not enough<br />

aeration<br />

Appearance<br />

Uneven (internal cross-section) Inconsistent whipping- causes air<br />

pocket size to vary<br />

Collapsed Too warm when extruded (above set<br />

point)<br />

Density is too low (structure is too<br />

weak to hold it in place)<br />

Conclusions:<br />

• Gelatin gives unique and characteristic elastic texture to marshmallows<br />

• Gelatin provides gelation of the structure and aeration foam ability: 2<br />

functions in 1 stabilizer<br />

• Thermoreversability is a beautiful thing (roasting gooey marshmallows<br />

over a campfire, making Rice Krispie bars)!!<br />

• Density can be greatly varied to provide different textures- traditional<br />

extruded, deposited, enrobed, grained

Objectives:<br />

Nougat and Cream - Lab <strong>Exercise</strong> 1<br />

Nougat and Fruit Chew Lab Outline<br />

Resident Course<br />

- To understand basic factors of candy making through making four types of fruit chews.<br />

- Most important factors for making candy are “how to control moisture content” and “how<br />

to control sugar crystal”. We can understand clearly the importance of those factors and<br />

how to manage those factors.<br />

- Aeration is another important factor for final product quality of nougat/fruit chew. All<br />

members are requested to prepare two types of fruit chew with same formula, aerated and<br />

un-aerated.<br />

- Separately, traditional nougat with nuts and fruits are prepared as a demonstration.<br />

Ingredients:<br />

42 Sugar, corn syrup(DE 42), hydrogenated fat (m.p. 35°C), lecithin, icing sugar, citric<br />

Acid (hydrouse), gelatin (A type, 150 bloom), egg albumen, honey, dried cranberry and<br />

almond.<br />

Equipment and materials:<br />

- Electric skillet, cooling slab, Hobart mixer, taffy hook and wax paper.<br />

Methods :<br />

- Cook sugar, corn syrup and water to appropriate temperature (depends on formula). Cool<br />

to 110°C and mix fat/lecithin and presoaked gelatin.<br />

- Pour into Hobart mixer and after reaching 60°C, mix fondant or icing sugar, acid, flavor<br />

and color.<br />

- Cool to 50°C on a cooling slab, and after that, pull on pulling hook.<br />

- Cut and wrap with wax paper.<br />

Nougat and Cream -Lab <strong>Exercise</strong> - 1

Results:<br />

Nougat and Cream - Lab <strong>Exercise</strong> 2<br />

- Density should be measured just after cutting.<br />

- After two day, members are asked to evaluate 4 types of fruit chew. Appearance (cold<br />

flow/shrinkage), chewing character (initial chew, stickiness and final chew character) are<br />

important parameters for final products.<br />

Formula:<br />

A B C D<br />

Sugar 960g 1,300g 1,265g 1,600g<br />

Corn syrup DE42 2,000 2,090 1,620 1,708<br />

Water 250 350 350 400<br />

Fat 300 300 300 300<br />

Lecithin 5 5 5 5<br />

Fondant 540 0 540 0<br />

Icing sugar 0 72 0 72<br />

Citric acid 30 30 30 30<br />

Gelatin 150bloom, A 36 36 36 36<br />

Water 54 54 54 54<br />

Total solid 3035g 3044g 3036g 3038g<br />

Moisture content 7.0% 7.0% 7.0% 7.0%<br />

Graining factor* 45% 45% 55% 55%<br />

Cooking temperature 132°C 123°C 132°C 123°C<br />

• Graining factor =( total accelerators solid/ total sugars solid) x 100<br />

Demonstration of Montelimar Nougat (E)<br />

- to demonstrate traditional Montelimar nougat by using Hobart mixer<br />

Nougat and Cream -Lab <strong>Exercise</strong> - 2

Nougat and Cream - Lab <strong>Exercise</strong> 3<br />

- Formula/ingredients<br />

Ingredients Specification Gram of ingredients<br />

Frappe<br />

Egg albumen Powder 30 g<br />

Soy protein Mira foam 120V 30<br />

Water 180<br />

Corn syrup 42 DE, 80% solid 620<br />

Syrup<br />

Corn syrup 42 DE 2,660<br />

Sugar 2,475<br />

Water 670<br />

Salt 25<br />

Other Ingredients<br />

Vegetable fat m.p. 35°C 135<br />

Nuts Crushed almond 400<br />

Dried fruit Cranberry 200<br />

Procedure:<br />

- mix egg albumen and soy protein with warm water to hydrate<br />

- warm corn syrup for frappe to 60°C<br />

- weigh 3600 of pre-cooked syrup (132°C) and allow to cool to 115°C.<br />

- mix frappe ingredient in Hobart mixer with wire whisk<br />

- after having light and stiff foam, change wire whisk to flat(leaf) and add cooled syrup<br />

slowly (should take a couple of minutes)<br />

- after frappe and syrup are mixed, reduce to lowest speed and add melted fat, nut and fruit.<br />

- pour onto oiled cooling slab and allow to cool<br />

- cut and wrap in wax paper<br />

1. Calculation<br />

- Calculate Graining Factor of the following formula.<br />

a) sugar (moisture content 0%) 500g,, corn syrup (moisture content 20%) 500g, water 200g<br />

Nougat and Cream -Lab <strong>Exercise</strong> - 3

Nougat and Cream - Lab <strong>Exercise</strong> 4<br />

b) sugar (moisture content 0%) 1,000g, corn syrup ( moisture content 20%) 1,000g and<br />

fondant (moisture content 12%, sugar content 72% and corn syrup solid 16%) 150g<br />

2. Product evaluation<br />

Appearance Initial chew Chew character Stickiness Other observation<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F*<br />

G**<br />

* A fruit chew product sold in USA<br />

** Salt water taffy sold in USA<br />

Nougat and Cream -Lab <strong>Exercise</strong> - 4

Nougat Lab<br />

Objective: To prepare nougat and compare the effects of different graining factors, as well as<br />

the effects of formulation changes.<br />

Formulations<br />

Frappe<br />

Batch A Batch B Batch C Batch D Batch E Batch F<br />

Egg Albumen 15 g 15 g 15 g 15 g 13.5 g 15 g<br />

Soy Protein (Mira<br />

Foam 120V)<br />

15 g 15 g 15 g 15 g 13.5 g 15 g<br />

Water 90 g 90 g 90 g 110 g 99 g 110 g<br />

Corn Syrup 310 g 310 g 310 g - - -<br />

Confectioner's<br />

Sugar<br />

- - - 106 g 95 g 106 g<br />

Total Frappe 430 g 430 g 430 g 246 g 221 g 246 g<br />

Syrup<br />

Corn Syrup 42DE 1330 g 1330 g 1330 g 1133 g 1133 g 1133 g<br />

Sugar 1238 g 1238 g 1238 g 1416 g 1416 g 1416 g<br />

Water 334 g 334 g 334 g 334 g 334 g 334 g<br />

Salt 13 g 13 g 13 g 16 g 16 g 16 g<br />

Syrup Cook Temp 268 F 273 F 268 F 258 F 258 F 258 F<br />

Powdered Sugar - - - 100 g 100 g 100 g<br />

Vegetable Fat 68 g 68 g 68 g 125 g 125 g 125 g<br />

Nuts 68 g 68 g 68 g 68 g 68 g 68 g<br />

Chocolate - - 50 g - - 50 g<br />

Vanilla 5 g 5 g 5 g 5 g 5 g 5 g<br />

Procedure:<br />

1 Mix egg albumin and soy protein with warm water to hydrate<br />

2 Warm corn syrup for frappè to 140 o F<br />

3 Weigh syrup ingredients into electric skillet and cook to desired cook temp<br />

4 Allow syrup to cool to 240 o F<br />

5 Mix frappè ingredients in mixing bowl<br />

6 Whip (use wire whisk) for 6 minutes on setting #3 until stiff, while syrup is cooling<br />

7 Melt fat (130 – 140 o F) in microwave while frappè is whipping<br />

8 After frappè has been whipped, weigh correct amount into Hobart mixing bowl<br />

9 Add 1800g of cooled syrup slowly on medium speed and using leaf mixer (should take<br />

a couple of minutes)<br />

10 After syrup and frappè are mixed, reduce to lowest speed and add remaining ingredients<br />

11 Mix at low speed until batch comes together (fat is well mixed in)<br />

12 Pour onto oiled cold table and allow to cool<br />

13 Cut into pieces and wrap in waxed paper

Nougat Lab Evaluation<br />

Evaluation Batch A Batch B Batch C Batch D Batch E Batch F<br />

Texture<br />

Graining Factor

Demonstration of Salt Water Taffy<br />

Objective: To demonstrate Salt Water Taffy using a puller to aerate.<br />

Formulation:<br />

Corn Syrup, 42DE 15 lbs.<br />

Granulated Sugar 6 lbs.<br />

Water 3 lbs.<br />

Vegetable Fat 1 lbs.<br />

Thin Boiling Starch 0.5 lbs.<br />

Mono & diglycerides 0.05 lbs.<br />

Salt 0.05 lbs.<br />

Lecithin<br />

Color / Flavoring<br />

0.01 lbs.<br />

Procedures:<br />

Mix corn syrup, sugar and water.<br />

Add starch, mono & diglycerides, salt, vegetable fat and lecithin.<br />

Cook to 250 o F.<br />

Pour onto cooling slab and allow to cool to 100 – 110 o F.<br />

Use puller to aerate and give texture.<br />

Add flavor of choice while pulling.<br />

Form into quarter inch ropes on cold table and cut into segments.<br />

Wrap each piece in wax paper.<br />

Page 1