NCA Resident Course Soft Panning, Class Exercise Syrup ...

NCA Resident Course Soft Panning, Class Exercise Syrup ...

NCA Resident Course Soft Panning, Class Exercise Syrup ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

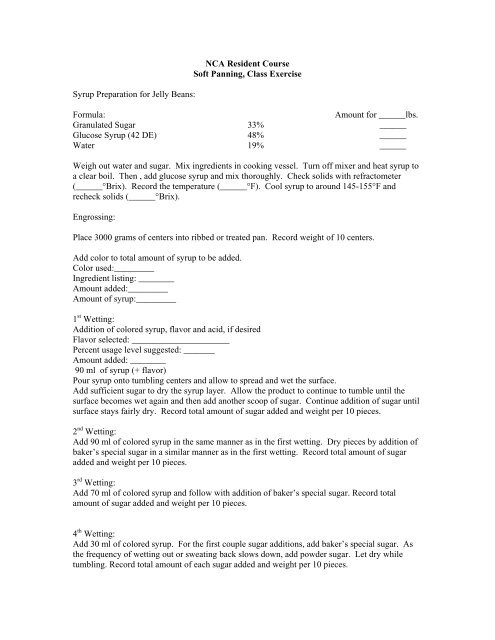

<strong>Syrup</strong> Preparation for Jelly Beans:<br />

<strong>NCA</strong> <strong>Resident</strong> <strong>Course</strong><br />

<strong>Soft</strong> <strong>Panning</strong>, <strong>Class</strong> <strong>Exercise</strong><br />

Formula: Amount for ______lbs.<br />

Granulated Sugar 33% ______<br />

Glucose <strong>Syrup</strong> (42 DE) 48% ______<br />

Water 19% ______<br />

Weigh out water and sugar. Mix ingredients in cooking vessel. Turn off mixer and heat syrup to<br />

a clear boil. Then , add glucose syrup and mix thoroughly. Check solids with refractometer<br />

(______°Brix). Record the temperature (______°F). Cool syrup to around 145-155°F and<br />

recheck solids (______°Brix).<br />

Engrossing:<br />

Place 3000 grams of centers into ribbed or treated pan. Record weight of 10 centers.<br />

Add color to total amount of syrup to be added.<br />

Color used:_________<br />

Ingredient listing: ________<br />

Amount added:_________<br />

Amount of syrup:_________<br />

1 st Wetting:<br />

Addition of colored syrup, flavor and acid, if desired<br />

Flavor selected: ______________________<br />

Percent usage level suggested: _______<br />

Amount added: ________<br />

90 ml of syrup (+ flavor)<br />

Pour syrup onto tumbling centers and allow to spread and wet the surface.<br />

Add sufficient sugar to dry the syrup layer. Allow the product to continue to tumble until the<br />

surface becomes wet again and then add another scoop of sugar. Continue addition of sugar until<br />

surface stays fairly dry. Record total amount of sugar added and weight per 10 pieces.<br />

2 nd Wetting:<br />

Add 90 ml of colored syrup in the same manner as in the first wetting. Dry pieces by addition of<br />

baker’s special sugar in a similar manner as in the first wetting. Record total amount of sugar<br />

added and weight per 10 pieces.<br />

3 rd Wetting:<br />

Add 70 ml of colored syrup and follow with addition of baker’s special sugar. Record total<br />

amount of sugar added and weight per 10 pieces.<br />

4 th Wetting:<br />

Add 30 ml of colored syrup. For the first couple sugar additions, add baker’s special sugar. As<br />

the frequency of wetting out or sweating back slows down, add powder sugar. Let dry while<br />

tumbling. Record total amount of each sugar added and weight per 10 pieces.

Finishing/Smoothing <strong>Syrup</strong>:<br />

<strong>NCA</strong> <strong>Resident</strong> <strong>Course</strong><br />

<strong>Soft</strong> <strong>Panning</strong>, <strong>Class</strong> <strong>Exercise</strong><br />

Finishing and Polishing<br />

Sugar 65%<br />

Water 35%<br />

Heat to boiling and then turn off. Cool before using.<br />

Add small amount of color to syrup before adding to engrossed product. Add 1 ladle at a time<br />

until pieces are covered but not over wet. Allow to dry and then repeat. Stop before product<br />

becomes dusty (slightly damp).

Wetting<br />

number<br />

Ingredient<br />

usage<br />

1 Fine granular<br />

sugar<br />

or<br />

Baker’s<br />

special sugar<br />

2 Fine granular<br />

sugar<br />

or<br />

Baker’s<br />

special sugar<br />

3 Fine granular<br />

sugar<br />

4<br />

or<br />

Other notes:<br />

Baker’s<br />

special sugar<br />

Baker’s<br />

special sugar<br />

Powdered<br />

sugar<br />

<strong>NCA</strong> <strong>Soft</strong> <strong>Panning</strong> Lab <strong>Exercise</strong> Run Sheet<br />

Starting<br />

weight<br />

Ending<br />

weight<br />

weight<br />

per 10<br />

pieces<br />

Comments

CHOCOLATE PANNING EXERCISE<br />

<strong>NCA</strong> <strong>Resident</strong> <strong>Course</strong><br />

Instructor: Michelle Frame<br />

Objective: The application of a fat based coating (chocolate, compound or<br />

pastel) to a suitable prepared center in a revolving pan and finish with glaze<br />

and polish.<br />

Procedure:<br />

1. Dress rotating laboratory pan with a small amount of coating so product does not<br />

slide in the pan. Add small amount of dry ice to set coating.<br />

2. Weigh out material to be coated and place in the pan. Record weight. Determine<br />

count per pound of material to be coated.<br />

3. Turn on pan and add 1oz of gumming solution if required across the product in the<br />

pan. Allow gumming solution to uniformly coat all the pieces. Apply warm air to dry<br />

gumming solution.<br />

4. Repeat with a second application. Use cocoa mix to help dry and prepare surface for<br />

coating adhesion.<br />

5. Add 3 to 5 pellets of dry ice to revolving product in the pan and allow product to cool<br />

for 5 minutes.<br />

6. Obtain coating material assigned at a temperature of 100-115 F.<br />

7. Using small ladle, add coating material slowly to the material in the revolving pan to<br />

uniformly coat the centers without forming doubles. Break up doubles if formed.<br />

8. Continue adding coating, checking the count per pound regularly until the weight has<br />

doubled.<br />

9. If product becomes bumpy, remove dry ice and allow pan to warm to smooth out<br />

coating. Once smooth, add dry ice to set coating on the center.<br />

10. Remove from pan using cup and place in tray for polishing<br />

11. Clean up and dry pan.<br />

Results:<br />

Center Material<br />

Coating Material<br />

Weight Ct/lb<br />

1<br />

Chocolate <strong>Panning</strong><br />

<strong>NCA</strong> <strong>Resident</strong> <strong>Course</strong> in Confectionery Technology

NUT GUMMING PROCEDURE<br />

Objective: The application of a continuous film to nut centers to control oil<br />

migration prior to applying a coating (chocolate, compound or pastel).<br />

Center:<br />

Gumming Solution:<br />

Procedure:<br />

1. Place nuts in pan and turn on the pan.<br />

2. Add a small amount of previously prepared gumming solution across the<br />

nuts in the revolving pan to uniformly wet the nuts. Excess gumming<br />

solution will cause nuts to stick nuts together.<br />

3. Apply warm dry air to remove moisture and dry film on to nuts.<br />

4. Repeat Steps 2 & 3 two more times.<br />

5. Add small amount of Cocoa-Powdered Sugar Mix to complete drying<br />

and form surface for coating to adhere.<br />

GUMMING SOLUTIONS<br />

Procedure:<br />

1. Weigh out equal amounts of warm tap water and gum arabic.<br />

2. Place warm water in container<br />

3. Add gum arabic slowly with brisk mixing to incorporate gum arabic into<br />

solution. A wire wisk is good for mixing.<br />

4. Pour 50% solution into container and place in warm area overnight to<br />

allow air incorporated during mixing to rise to the top.<br />

5. Remove top layer of foam from container.<br />

6. Use only clear slightly yellow solution at room temperature for coating<br />

center material.<br />

7. Gumming solution can only be used for a day or two since microbial<br />

growth will occur.<br />

COCOA POWDERED SUGAR MIX<br />

Procedure:<br />

1. Weigh out 1 part natural cocoa powder to 9 parts powdered sugar<br />

2. Mix cocoa powder and sugar in container until uniform in color<br />

3. Store cover in container until used.<br />

2<br />

Chocolate <strong>Panning</strong><br />

<strong>NCA</strong> <strong>Resident</strong> <strong>Course</strong> in Confectionery Technology