2004 Soft Panning - staging.files.cms.plus.com

2004 Soft Panning - staging.files.cms.plus.com

2004 Soft Panning - staging.files.cms.plus.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

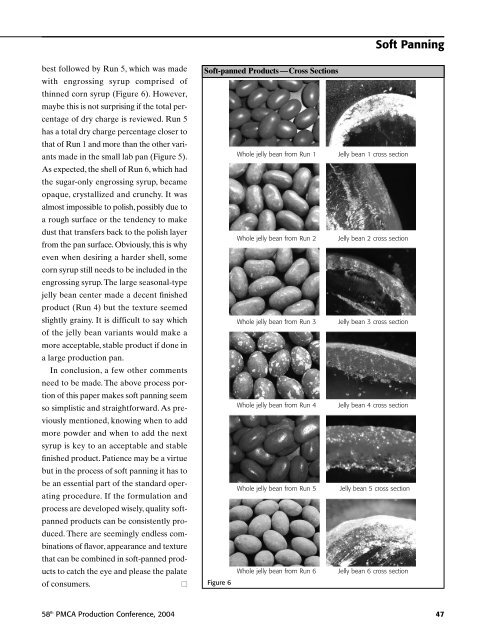

est followed by Run 5, which was made<br />

with engrossing syrup <strong>com</strong>prised of<br />

thinned corn syrup (Figure 6). However,<br />

maybe this is not surprising if the total percentage<br />

of dry charge is reviewed. Run 5<br />

has a total dry charge percentage closer to<br />

that of Run 1 and more than the other variants<br />

made in the small lab pan (Figure 5).<br />

As expected, the shell of Run 6, which had<br />

the sugar-only engrossing syrup, became<br />

opaque, crystallized and crunchy. It was<br />

almost impossible to polish, possibly due to<br />

a rough surface or the tendency to make<br />

dust that transfers back to the polish layer<br />

from the pan surface. Obviously, this is why<br />

even when desiring a harder shell, some<br />

corn syrup still needs to be included in the<br />

engrossing syrup. The large seasonal-type<br />

jelly bean center made a decent finished<br />

product (Run 4) but the texture seemed<br />

slightly grainy. It is difficult to say which<br />

of the jelly bean variants would make a<br />

more acceptable, stable product if done in<br />

a large production pan.<br />

In conclusion, a few other <strong>com</strong>ments<br />

need to be made. The above process portion<br />

of this paper makes soft panning seem<br />

so simplistic and straightforward. As previously<br />

mentioned, knowing when to add<br />

more powder and when to add the next<br />

syrup is key to an acceptable and stable<br />

finished product. Patience may be a virtue<br />

but in the process of soft panning it has to<br />

be an essential part of the standard operating<br />

procedure. If the formulation and<br />

process are developed wisely, quality softpanned<br />

products can be consistently produced.<br />

There are seemingly endless <strong>com</strong>binations<br />

of flavor, appearance and texture<br />

that can be <strong>com</strong>bined in soft-panned products<br />

to catch the eye and please the palate<br />

of consumers. ■<br />

<strong>Soft</strong>-panned Products —Cross Sections<br />

Figure 6<br />

Whole jelly bean from Run 1<br />

Whole jelly bean from Run 2<br />

Whole jelly bean from Run 3<br />

Jelly bean 2 cross section<br />

Jelly bean 3 cross section<br />

Whole jelly bean from Run 4 Jelly bean 4 cross section<br />

Whole jelly bean from Run 5 Jelly bean 5 cross section<br />

Whole jelly bean from Run 6<br />

Jelly bean 1 cross section<br />

Jelly bean 6 cross section<br />

<strong>Soft</strong> <strong>Panning</strong><br />

58 th PMCA Production Conference, <strong>2004</strong> 47