2003 Caramel--Raw Materials and Formulations - staging.files.cms ...

2003 Caramel--Raw Materials and Formulations - staging.files.cms ...

2003 Caramel--Raw Materials and Formulations - staging.files.cms ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ers used are simplified to help you underst<strong>and</strong><br />

things easier. For your use, talk to<br />

your supplier <strong>and</strong> find out exactly what is<br />

in the raw material you are using.<br />

Ingredients<br />

Water — 170.0 g No, we’re not going to<br />

break down the water but just make a few<br />

comments. Its level before, after <strong>and</strong> at<br />

each stage of the process can have a lot of<br />

influence.With other ingredients, you may<br />

be off a percent or two <strong>and</strong> it will modify<br />

the product some if it does anything at all.<br />

If you are off a percent or two on water, the<br />

following could happen:<br />

• The caramel could grain when you don’t<br />

want it to or not grain when you do.<br />

• It could be too hard or too soft.<br />

• It could be less stable due to the water<br />

activity being too high, where you have<br />

problems with micro if sealed or its tendency<br />

to dry out if not; or too low, with<br />

problems of it picking up moisture <strong>and</strong><br />

requiring more expensive packaging.<br />

As an ingredient before cook, a starting<br />

point for how much water to add is about<br />

one-third the level of sugar, to help make<br />

sure all the sugar is dissolved. This of<br />

course will change due to the process you<br />

use. For after cook, it’s the final texture<br />

you want that determines how much water<br />

is left. For each of the processing stages,<br />

it’s how fast or slow you want to develop<br />

the color <strong>and</strong> flavor or the when <strong>and</strong> how<br />

it will or will not grain.<br />

Don’t forget about the water quality.<br />

You write specifications <strong>and</strong> have quality<br />

control checks for all of your ingredients,<br />

yet even with the importance of the water<br />

in your recipe, how many of you know<br />

what is in your water? The best example is<br />

if it’s too acidic you may need to use a<br />

buffer salt to prevent the milk proteins<br />

from denaturing or precipitating out,<br />

Sugar, granulated — 454.0 g Sugar we can<br />

break down.Although for this exercise you<br />

<strong>Caramel</strong> — <strong>Raw</strong> <strong>Materials</strong> <strong>and</strong> <strong>Formulations</strong><br />

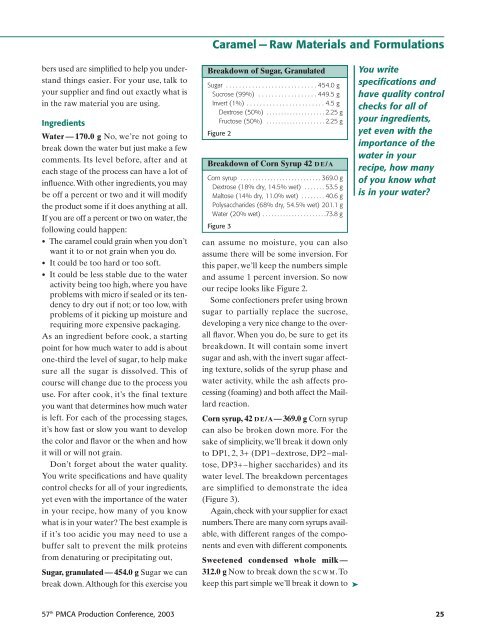

Breakdown of Sugar, Granulated<br />

Sugar . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454.0 g<br />

Sucrose (99%) . . . . . . . . . . . . . . . . . . 449.5 g<br />

Invert (1%) . . . . . . . . . . . . . . . . . . . . . . . . 4.5 g<br />

Dextrose (50%) . . . . . . . . . . . . . . . . . . . . 2.25 g<br />

Fructose (50%) . . . . . . . . . . . . . . . . . . . . 2.25 g<br />

Figure 2<br />

Breakdown of Corn Syrup 42 DE/A<br />

Corn syrup . . . . . . . . . . . . . . . . . . . . . . . . . . . 369.0 g<br />

Dextrose (18% dry, 14.5% wet) . . . . . . . 53.5 g<br />

Maltose (14% dry, 11.0% wet) . . . . . . . . 40.6 g<br />

Polysaccharides (68% dry, 54.5% wet) 201.1 g<br />

Water (20% wet) . . . . . . . . . . . . . . . . . . . . . .73.8 g<br />

Figure 3<br />

can assume no moisture, you can also<br />

assume there will be some inversion. For<br />

this paper, we’ll keep the numbers simple<br />

<strong>and</strong> assume 1 percent inversion. So now<br />

our recipe looks like Figure 2.<br />

Some confectioners prefer using brown<br />

sugar to partially replace the sucrose,<br />

developing a very nice change to the overall<br />

flavor. When you do, be sure to get its<br />

breakdown. It will contain some invert<br />

sugar <strong>and</strong> ash, with the invert sugar affecting<br />

texture, solids of the syrup phase <strong>and</strong><br />

water activity, while the ash affects processing<br />

(foaming) <strong>and</strong> both affect the Maillard<br />

reaction.<br />

Corn syrup, 42 DE/A— 369.0 g Corn syrup<br />

can also be broken down more. For the<br />

sake of simplicity, we’ll break it down only<br />

to DP1, 2, 3+ (DP1–dextrose, DP2–maltose,<br />

DP3+–higher saccharides) <strong>and</strong> its<br />

water level. The breakdown percentages<br />

are simplified to demonstrate the idea<br />

(Figure 3).<br />

Again, check with your supplier for exact<br />

numbers.There are many corn syrups available,<br />

with different ranges of the components<br />

<strong>and</strong> even with different components.<br />

Sweetened condensed whole milk—<br />

312.0 g Now to break down the scwm.To<br />

keep this part simple we’ll break it down to<br />

➤<br />

You write<br />

specifications <strong>and</strong><br />

have quality control<br />

checks for all of<br />

your ingredients,<br />

yet even with the<br />

importance of the<br />

water in your<br />

recipe, how many<br />

of you know what<br />

is in your water?<br />

57 th PMCA Production Conference, <strong>2003</strong> 25