New York/ New Jersey Harbor: Alternative Methods for Ex ... - CLU-IN

New York/ New Jersey Harbor: Alternative Methods for Ex ... - CLU-IN

New York/ New Jersey Harbor: Alternative Methods for Ex ... - CLU-IN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Metcalf & Eddy<br />

The Process<br />

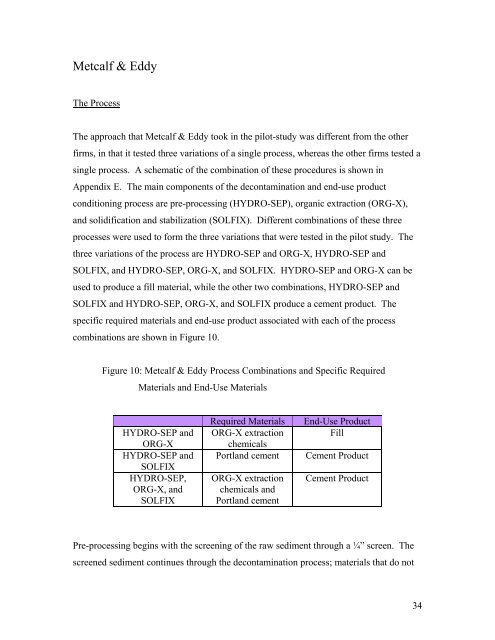

The approach that Metcalf & Eddy took in the pilot-study was different from the other<br />

firms, in that it tested three variations of a single process, whereas the other firms tested a<br />

single process. A schematic of the combination of these procedures is shown in<br />

Appendix E. The main components of the decontamination and end-use product<br />

conditioning process are pre-processing (HYDRO-SEP), organic extraction (ORG-X),<br />

and solidification and stabilization (SOLFIX). Different combinations of these three<br />

processes were used to <strong>for</strong>m the three variations that were tested in the pilot study. The<br />

three variations of the process are HYDRO-SEP and ORG-X, HYDRO-SEP and<br />

SOLFIX, and HYDRO-SEP, ORG-X, and SOLFIX. HYDRO-SEP and ORG-X can be<br />

used to produce a fill material, while the other two combinations, HYDRO-SEP and<br />

SOLFIX and HYDRO-SEP, ORG-X, and SOLFIX produce a cement product. The<br />

specific required materials and end-use product associated with each of the process<br />

combinations are shown in Figure 10.<br />

Figure 10: Metcalf & Eddy Process Combinations and Specific Required<br />

Materials and End-Use Materials<br />

HYDRO-SEP and<br />

ORG-X<br />

HYDRO-SEP and<br />

SOLFIX<br />

HYDRO-SEP,<br />

ORG-X, and<br />

SOLFIX<br />

Required Materials End-Use Product<br />

ORG-X extraction<br />

chemicals<br />

Fill<br />

Portland cement Cement Product<br />

ORG-X extraction<br />

chemicals and<br />

Portland cement<br />

Cement Product<br />

Pre-processing begins with the screening of the raw sediment through a ³“ screen. The<br />

screened sediment continues through the decontamination process; materials that do not<br />

34