Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

- Subject to modifications -<br />

6<br />

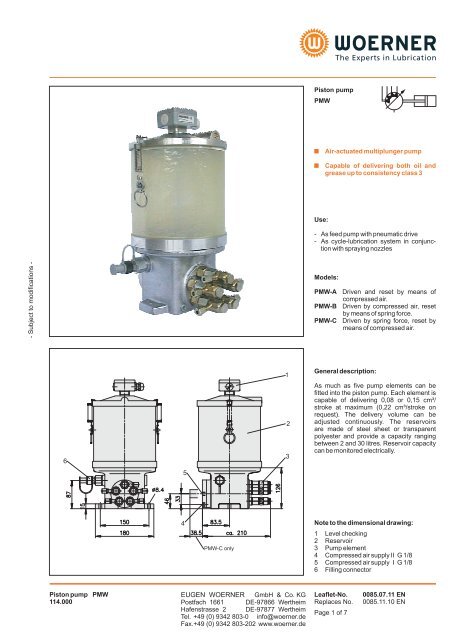

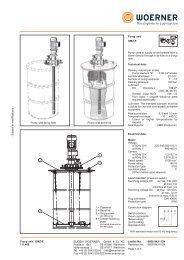

<strong>Piston</strong> <strong>pump</strong> <strong>PMW</strong><br />

114.000<br />

4<br />

5<br />

<strong>PMW</strong>-C only<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

1<br />

2<br />

3<br />

<strong>Piston</strong> <strong>pump</strong><br />

<strong>PMW</strong><br />

<br />

<br />

Use:<br />

-<br />

-<br />

As feed <strong>pump</strong> with pneumatic drive<br />

As cycle-lubrication system in conjunction<br />

with spraying nozzles<br />

Models:<br />

<strong>PMW</strong>-A<br />

<strong>PMW</strong>-B<br />

<strong>PMW</strong>-C<br />

General description:<br />

Note to the dimensional drawing:<br />

Level checking<br />

Reservoir<br />

Pump element<br />

Compressed air supply<br />

Compressed air supply<br />

Filling connector<br />

Leaflet-No. 0085.07.11 <strong>EN</strong><br />

Replaces No. 0085.11.10 <strong>EN</strong><br />

Page 1 of 7<br />

Driven and reset by means of<br />

compressed air.<br />

Driven by compressed air, reset<br />

by means of spring force.<br />

Driven by spring force, reset by<br />

means of compressed air.<br />

As much as five <strong>pump</strong> elements can be<br />

fitted into the piston <strong>pump</strong>. Each element is<br />

capable of delivering 0,08 or 0,15 cm³/<br />

stroke at maximum (0,22 cm³/stroke on<br />

request) . The delivery volume can be<br />

adjusted continuously. The reservoirs<br />

are made of steel sheet or transparent<br />

polyester and provide a capacity ranging<br />

between 2 and 30 litres. Reservoir capacity<br />

can be monitored electrically.<br />

1<br />

2<br />

3<br />

Air-actuated multiplunger <strong>pump</strong><br />

Capable of delivering both oil and<br />

grease up to consistency class 3<br />

4 II G 1/8<br />

5<br />

6<br />

I G 1/8

<strong>PMW</strong>-A<br />

Pressure stroke:<br />

By pressurisation of compressed air line I<br />

and pressure relief of compressed air line<br />

II, pneumatic piston 1 and driver 2 are<br />

pushed to the left. Concurrently, the <strong>pump</strong><br />

element 3 hooked into drive 2 makes a<br />

pressure stroke and delivers the lubricant<br />

from the proportioning section to the<br />

outlet.<br />

<strong>PMW</strong>-B<br />

Pressure stroke:<br />

By pressurisation of compressed air line I,<br />

pneumatic piston 1 and driver 2 are<br />

pushed to the left. Concurrently, the <strong>pump</strong><br />

element 3 hooked into drive 2 makes a<br />

pressure stroke and delivers the lubricant<br />

from the proportioning section to the<br />

outlet.<br />

<strong>PMW</strong>-C<br />

Intake stroke:<br />

By pressurisation of compressed air line<br />

II, pneumatic piston 1 and driver 2 are<br />

pushed to the right. Concurrently, the<br />

<strong>pump</strong> element 3 hooked into drive 2<br />

makes an intake stroke and draws<br />

lubricant into the proportioning section.<br />

4<br />

3<br />

2 1<br />

Intake stroke:<br />

After pressurisation of compressed air line<br />

II and pressure relief of compressed air<br />

line I,<br />

the pneumatic piston is shifted back<br />

into its home position. Concurrently, the<br />

<strong>pump</strong> element 3 hooked into drive 2<br />

makes an intake stroke and draws<br />

lubricant into the proportioning section.<br />

3<br />

Intake stroke:<br />

After pressure relief in compressed air line<br />

I, pressure spring 4 shifts the pneumatic<br />

piston back into its home position again.<br />

Concurrently, the <strong>pump</strong> element 3 hooked<br />

into drive 2 makes an intake stroke and<br />

draws lubricant into the proportioning<br />

section.<br />

3<br />

2 1<br />

2 1<br />

Pressure stroke:<br />

After pressure relief of compressed air line<br />

II, pressure spring 4 shifts the pneumatic<br />

piston back into its home position again.<br />

Concurrently, the <strong>pump</strong> element 3 hooked<br />

into drive 2 makes a pressure stroke and<br />

delivers lubricant from the proportioning<br />

section to the outlet.<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

I<br />

II<br />

I<br />

II<br />

4<br />

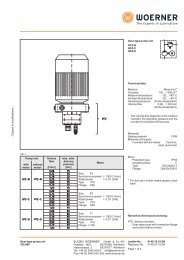

Common technical data:<br />

Delivery medium:<br />

Oil and grease<br />

up to consistency class 3;<br />

from consistency class 1 on,<br />

a reservoir with follow-up<br />

piston is required<br />

Lubricant: The intended lubricant must be<br />

suitable for use with centralized lubrication<br />

equipment.<br />

Weight ( without reservoir):<br />

2,7 kg<br />

( for further weights, see<br />

description)<br />

"r eservoir"<br />

Material<br />

Reservoir:<br />

Polyester, fibreglass<br />

reinforced, transparent<br />

or steel sheet, galvanized<br />

Pump body: Aluminium<br />

Pump element: Steel<br />

Temperatur range: -20 ... +80 °C<br />

In case of low temperatures, the<br />

grease`s penetration shall be observed.<br />

When NLGI-class 3 grease is used,<br />

functional safety may already be<br />

restricted below room temperature.<br />

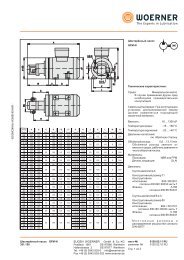

<strong>PMW</strong>-Aand <strong>PMW</strong>-B technical data:<br />

Delivery volume<br />

Pump element 6: 0,08 cm³/stroke<br />

Pump element 8: 0,15 cm³/stroke<br />

Special <strong>pump</strong> element: 0,22 cm³ /stroke<br />

(on request)<br />

Number of strokes at max.: 75 min<br />

Number of <strong>pump</strong> elements:<br />

1 ... 5<br />

Delivery pressure<br />

with 5 <strong>pump</strong> elements 6<br />

and maximum driving pressure:125<br />

bar<br />

with 5 <strong>pump</strong> elements 8<br />

and maximum driving pressure:<br />

70 bar<br />

Driving pressure (air):<br />

4 ... 10 bar<br />

<strong>PMW</strong>-C technical data:<br />

Delivery volume<br />

Pump element 6: 0,08 cm³/stroke<br />

Pump element 8: 0,15 cm³/stroke<br />

Special <strong>pump</strong> element: 0,22 cm³ /stroke<br />

(on request)<br />

Number of <strong>pump</strong> elements:<br />

1<br />

(more details available on request)<br />

Delivery pressure<br />

with <strong>pump</strong> elements 6: 60 bar<br />

with <strong>pump</strong> elements 8: 35 bar<br />

Air pressure:<br />

3 ... 10 bar<br />

Leaflet-No. 0085 <strong>EN</strong><br />

Page 2 of 7<br />

-1<br />

- Subject to modifications -

- Subject to modifications -<br />

7<br />

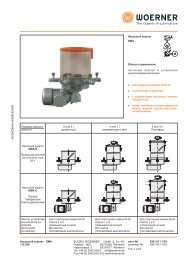

Pump elements mode of operation:<br />

Delivery piston 1 and control piston 2<br />

perform the intake stroke.<br />

Concurrently,<br />

the driver actuates delivery piston 1,<br />

and<br />

the spring actuates control piston 2.<br />

The<br />

control pistons locks pressure hole 3 and<br />

stops, depending on the delivery volume<br />

preset, at a certain position. The delivery<br />

piston keeps on moving, whilst a vacuum is<br />

being built up in the proportioning section.<br />

When delivery piston has opened intake<br />

hole 4,<br />

lubricant is drawn from the reservoir.<br />

During pressure stroke, delivery piston 1<br />

moves to the left. As a result, intake hole 4<br />

will be locked. At the same time, the<br />

lubricant being present in between the<br />

delivery and control pistons, is displaced<br />

Intake stroke Pressure stroke<br />

R<br />

3<br />

4<br />

Delivery volume<br />

until it releases pressure hole 3 and the<br />

delivery pistons delivers the lubricant to the<br />

outlet.<br />

The delivery volume can be adjusted<br />

continuously between 25 and 100% of the<br />

nominal delivery volume. After having<br />

removed lock screw 7,<br />

the stroke is to be<br />

changed by means of the enclosed spanner<br />

through adjustment nipple 6.<br />

When turning<br />

the nippe to the right, delivery volume will<br />

decrease. At the adjustment nipple, there is<br />

a hexagon against which a spring loaded<br />

piston is pressing radially. Thus, any<br />

independent change of the delivery volume<br />

will be prevented. At the same time, the<br />

latching serves as a measure for setting the<br />

Mounting the <strong>pump</strong> elements:<br />

Notes to operation:<br />

When another <strong>pump</strong> element is to be fitted<br />

into the piston <strong>pump</strong> or an existing <strong>pump</strong><br />

element is to be replaced, the sketch shown<br />

on the left should be followed. Insert the<br />

<strong>pump</strong> element with the delivery piston being<br />

pulled out approximately to half of its length<br />

diagonally upward into the location hole in<br />

the casing. Filling with grease the hole of<br />

the <strong>pump</strong> element that serves to receive the<br />

delivery piston facilitates insertion and<br />

commissioning. Do not place the <strong>pump</strong><br />

element into horizontal position and screw<br />

in unless the delivery piston's head is fitting<br />

closely to the pressure ring and gearing into<br />

the latter's groove.<br />

When demounting the <strong>pump</strong> element, be<br />

careful to pull it out of the casing cautiously<br />

so that the delivery piston will remain within<br />

the <strong>pump</strong> element.<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

6<br />

delivery volume. Six latches equal one<br />

rotation of the adjustment nipple and a<br />

reduction of the nominal delivery volume by<br />

33%. 14 latches (minimum) equal a delivery<br />

volume reduction down to 25% of the<br />

nominal delivery volume. When leaving the<br />

factory, the <strong>pump</strong> elements are preset to<br />

maximum delivery volume, i.e. they are set<br />

to full stroke.<br />

The element having a piston diameter of<br />

8 mm = 0,15 cm³/stroke is marked with a<br />

red ring "R" .<br />

<strong>Piston</strong> <strong>pump</strong>s should be operated with<br />

clean oil or grease from original packing<br />

d<strong>ru</strong>ms only. If, upon commissioning, filling is<br />

not done through the filling nipple, then the<br />

<strong>pump</strong>, at initial filling, should be filled with<br />

gear lubricant oil up to the reservoir's lower<br />

edge. This way, proper deaeration is<br />

ensured. The lubricant lines must be clean<br />

and have no obstuctions. They shall not be<br />

connected to the lubrication points, unless<br />

the lubricant comes out free of bubbles. All<br />

connections of the delivery line shall be<br />

checked for leakages.<br />

Leaflet-No. 0085 <strong>EN</strong><br />

Page 3 of 7<br />

2<br />

1

Steel sheet Transparent polyester<br />

2l<br />

4l<br />

7l<br />

25l<br />

5l<br />

10l<br />

30l<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Reservoir:<br />

Deliverable are reservoirs with capacities<br />

ranging between 2 l and 30 l. Every <strong>pump</strong><br />

type any of the reservoirs shown can be<br />

allocated to. When selecting the reservoir,<br />

level monitoring and lubricant need to be<br />

taken into account as well.<br />

Reservoir data:<br />

Capacity Material Weight<br />

2 l<br />

1,0 kg<br />

4 l stainless 1,4 kg<br />

7 l steel 2,0 kg<br />

25 l<br />

4,6 kg<br />

5 l Polyester, 1,5 kg<br />

10 l fibre glass 1,8 kg<br />

30 l reinforced 4,0 kg<br />

Reservoirs and options<br />

for level monitoring:<br />

Capacity Level monitoring<br />

2 l<br />

4 l<br />

7 l<br />

25 l<br />

5 l<br />

10 l<br />

30 l<br />

When a follow-up piston is used, the<br />

utilisable reservoir volumes are reduced as<br />

follows:<br />

In case of 5 and 10 litres<br />

reservoir capacities by approx. 2,5 l<br />

In case of 30 litres<br />

reservoir capacity by approx.<br />

6,0 l<br />

For more information see "level checking"<br />

description.<br />

Model without reservoir:<br />

( with cover plate)<br />

Leaflet-No. 0085 <strong>EN</strong><br />

Page 4 of 7<br />

for oil: float switch<br />

minimum level<br />

for oil: float switch<br />

min. and max. level<br />

for oil: float switch<br />

min. and max. level<br />

for grease: follow-up piston<br />

min. and max. level<br />

- Subject to modifications -

- Subject to modifications -<br />

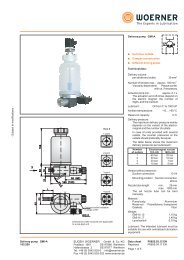

Level checking via<br />

level switch " S"<br />

Level switch weight<br />

0,15 ... 0,18 kg<br />

Filling connector:<br />

Pipe 12<br />

Filling connector "V"<br />

DN6<br />

Filling connector "B"<br />

Float at top<br />

( reservoir full)<br />

Float at bottom<br />

( reservoir empty)<br />

Level checking via<br />

level switch<br />

with follow-up piston " K"<br />

Follow-up piston weight<br />

for reservoirs: 5 and 10 l = 0,8 kg<br />

for reservoirs: 30 l = 2,7 kg<br />

Auxiliaries:<br />

Follow-up piston<br />

at top<br />

( reservoir full)<br />

Follow-up piston<br />

at bottom<br />

( reservoir empty)<br />

Coupling for filling connector "V"<br />

Purchase-no.: 110.135-65<br />

(state purchase-no., please)<br />

The coupling serves to establish<br />

a connection between the filling<br />

connector "V" and the hose.<br />

DN6<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Level checking:<br />

Electrical data:<br />

Switching power at max.: 40 W / 60 VA<br />

Switching voltage at max.: 230 VUC<br />

Switching current at max.: 0,5A<br />

For inductive and capacitive loads<br />

protective switchings (diode, RC<br />

module, varistor) have to be provided<br />

for.<br />

System of protection: IP65<br />

Connection type: Terminal screws<br />

Cable gland: PG11<br />

Cable cross section: 0,5 ... 1,5 mm²<br />

Connecting diagram:<br />

black<br />

orange<br />

blue<br />

black<br />

orange<br />

blue<br />

black<br />

orange<br />

blue<br />

Level switches with follow-up pistons can<br />

only be fitted into reservoirs made of polyester.<br />

Spare parts:<br />

Leaflet-No. 0085 <strong>EN</strong><br />

Page 5 of 7<br />

grey<br />

red<br />

brown<br />

grey<br />

red<br />

brown<br />

grey<br />

red<br />

brown<br />

Reservoir<br />

full<br />

Reservoir<br />

empty<br />

Filling connector "V": 110.125-65<br />

Filling connector "B": 110.550-65<br />

Adjusting key for<br />

<strong>pump</strong> element: 110.004-65<br />

Sealing set: 114.140-64<br />

(without pneum. driving piston)<br />

Pneumatic driving piston: 114.004-65

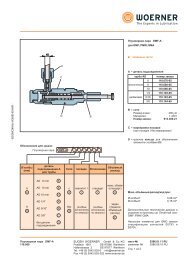

Purchase-designation:<br />

Purchase-example:<br />

<strong>PMW</strong>-A <strong>pump</strong>; with 10 l polyester reservoir;<br />

3 elements 6 with pipe connection ø6<br />

and<br />

1 element 6 with pipe connection ø8; filling<br />

Purchase-example:<br />

<strong>PMW</strong>-C <strong>pump</strong>; with 10 l polyester-made<br />

reservoir; delivery pressure A 1 element 8<br />

with pipe connection ø8; filling connector V,<br />

1)<br />

2)<br />

3)<br />

<strong>Piston</strong> <strong>pump</strong><br />

<strong>Piston</strong> <strong>pump</strong><br />

Reservoir capacity [l]<br />

stainless<br />

Polyester steel<br />

5<br />

10<br />

30<br />

without 0<br />

reservoir<br />

2V<br />

4V<br />

7V<br />

25V<br />

intern<br />

Purchase-designation:<br />

Reservoir capacity [l]<br />

stainless<br />

Polyester steel<br />

5<br />

10<br />

30<br />

without 0<br />

reservoir<br />

<strong>Piston</strong> <strong>pump</strong><br />

2V<br />

4V<br />

7V<br />

25V<br />

intern<br />

<strong>PMW</strong>-A . B<br />

<strong>PMW</strong>-B . B<br />

3)<br />

Element 6<br />

with pipe connection<br />

ø6 ø8 ø10<br />

3)<br />

Element 8<br />

with pipe connection<br />

ø6 ø8 ø10<br />

0 ... 5 0 ... 5 0 ... 5 0 ... 5 0 ... 5 0 ... 5<br />

<br />

<strong>PMW</strong>-C . B<br />

Delivery<br />

pressure<br />

altogether, 5 elements are possible!<br />

Element 3)<br />

ø6 ø8<br />

on<br />

request<br />

Filling<br />

connector<br />

without<br />

conector V, 1 lock screw, level checking by<br />

means of level switch and follow-up piston.<br />

Pipe<br />

connection<br />

Filling<br />

connector<br />

0 ... 1 0 ... 1<br />

A 8 with B<br />

<br />

altogether<br />

1 element possible<br />

at maximum!<br />

Lock<br />

1)<br />

screw<br />

number<br />

4 lock screws, level checking by means of<br />

level switch and follow-up piston.<br />

All element-free connectors have to be locked with lock screw!<br />

Level checking devices "K" and "F" are possible in case of polyester-made reservoirs only!<br />

Pump element with larger delivery volume on request: 0,22 cm³/stroke Order-no. 110.990-65<br />

6<br />

10<br />

without<br />

with<br />

0<br />

V<br />

4<br />

with<br />

with<br />

Oil<br />

0<br />

B<br />

V<br />

Grease<br />

Grease<br />

Oil<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

<strong>PMW</strong>-A <strong>Piston</strong> <strong>pump</strong><br />

Drive and reset by means of<br />

compressed air.<br />

<strong>PMW</strong>-B <strong>Piston</strong> <strong>pump</strong><br />

Drive by compressed air, reset<br />

by means of spring force.<br />

Lock<br />

1)<br />

screw<br />

number<br />

0 4<br />

...<br />

Purchase-designation:<br />

<strong>PMW</strong>-A.B / 10 / 3 / 1 / 0 / 0 / 0 / 0 / V / 1 / K<br />

Purchase-designation:<br />

<strong>PMW</strong>-C.B / 10 /A/ 0 / 1 / 8 / V / 4 / K<br />

Leaflet-No. 0085 <strong>EN</strong><br />

Page 6 of 7<br />

Oil<br />

Grease<br />

Grease<br />

Oil<br />

Level checking 2)<br />

0 without level switch<br />

F<br />

K<br />

S<br />

with follow-up piston,<br />

without level switch<br />

with level switch<br />

and follow-up piston<br />

with level switch,<br />

without follow-up<br />

piston<br />

<strong>PMW</strong>-C <strong>Piston</strong> <strong>pump</strong><br />

Drive by means of spring force,<br />

reset by means of compressed air<br />

Level checking 2)<br />

0 without level switch<br />

F<br />

K<br />

S<br />

with follow-up piston,<br />

without level switch<br />

with level switch<br />

and follow-up piston<br />

with level switch,<br />

without follow-up<br />

piston<br />

- Subject to modifications -

- Subject to modifications -<br />

Important information on this publication<br />

Reproduction, also in extracts, only permitted with the approval of the firm of EUG<strong>EN</strong><br />

WOERNER GmbH & Co. KG.<br />

All the information in this publication has been examined for correctness with great care.<br />

Nevertheless, WOERNER cannot assume any liability for losses or damage resulting<br />

directly or indirectly from the application of the information contained in this publication.<br />

All products from WOERNER may only be used as intended and corresponding to the<br />

information in this publication.<br />

For products supplied with operating inst<strong>ru</strong>ctions, the additional directives and information<br />

contained in them are to be complied with.<br />

Materials deviating from those mentioned in this publication and the technical documents<br />

which further apply may only be poured into and processed in the appliances and systems<br />

manufactured and supplied by WOERNER by following agreement with and written<br />

approval by WOERNER.<br />

The safety and danger information stated in the safety data sheets of the substances used<br />

must be taken into account at all costs.<br />

Transportation of gases, liquefied gases, gases under pressure, vapours and liquids, the<br />

vapour pressure of which is more than 0,5 bar above normal atmospheric pressure<br />

(1013 mbar) at the maximum admissible temperature, of easy inflammable or explosive<br />

media as well as transportation of foodstuffs is forbidden.<br />

Information on EU Directive 2002/95/EC (RoHS)<br />

With Directive 2002/95/EC of January 27, 2003, for the limitation of the use of certain<br />

hazardous substances in electrical and electronic devices (RoHS) material bans come into<br />

effect from July 2006 for electrical and electronic devices newly placed on the market for<br />

lead, cadmium, hexavalent chromium, mercury and brominated flame retardants.<br />

In its controls and switching devices, WOERNER only uses materials which fulfil the criteria<br />

of EU Directive 2002/95/EC.<br />

To the extent that hexavalent chromium has been used as corrosion protection in the parts<br />

which we produce ourselves, it has already been replaced by other environmentally<br />

tolerable protective measures.<br />

The mechanical devices supplied by WOERNER are not affected by EU Directive<br />

2002/95/EC as they are appliances added or installed on "large-scale stationary industrial<br />

tools" (cf. EU Directive 2002/96/EC,Annex IA).<br />

But as WOERNER is conscious of its responsibility towards the environment, we shall also<br />

use materials fulfilling the requirements of the Directive for devices not covered by EU<br />

Directive 2002/95/EC as soon as they are generally available and their use is technically<br />

possible.<br />

Technical documents also valid for this product:<br />

B0085 Operating inst<strong>ru</strong>ctions <strong>PMW</strong><br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Leaflet-No. 0085 <strong>EN</strong><br />

Page 7 of 7