Volume 15 - Philips Lighting

Volume 15 - Philips Lighting

Volume 15 - Philips Lighting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

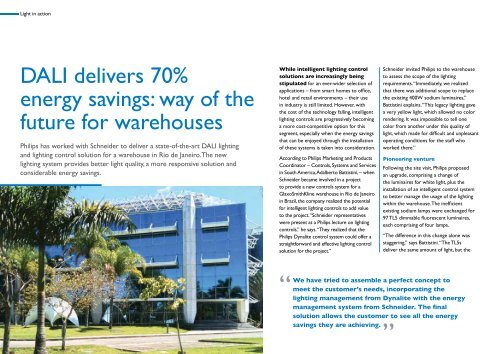

Light in action<br />

DALI delivers 70%<br />

energy savings: way of the<br />

future for warehouses<br />

<strong>Philips</strong> has worked with Schneider to deliver a state-of-the-art DALI lighting<br />

and lighting control solution for a warehouse in Rio de Janeiro. The new<br />

lighting system provides better light quality, a more responsive solution and<br />

considerable energy savings.<br />

38 | Lightnews Vol <strong>15</strong><br />

While intelligent lighting control<br />

solutions are increasingly being<br />

stipulated for an ever-wider selection of<br />

applications – from smart homes to office,<br />

hotel and retail environments – their use<br />

in industry is still limited. However, with<br />

the cost of the technology falling, intelligent<br />

lighting controls are progressively becoming<br />

a more cost-competitive option for this<br />

segment, especially when the energy savings<br />

that can be enjoyed through the installation<br />

of these systems is taken into consideration.<br />

According to <strong>Philips</strong> Marketing and Products<br />

Coordinator – Controls, Systems and Services<br />

in South America, Adalberto Battistini, – when<br />

Schneider became involved in a project<br />

to provide a new controls system for a<br />

GlaxoSmithKline warehouse in Rio de Janeiro<br />

in Brazil, the company realized the potential<br />

for intelligent lighting controls to add value<br />

to the project. “Schneider representatives<br />

were present at a <strong>Philips</strong> lecture on lighting<br />

controls,” he says. “They realized that the<br />

<strong>Philips</strong> Dynalite control system could offer a<br />

straightforward and effective lighting control<br />

solution for the project.”<br />

Schneider invited <strong>Philips</strong> to the warehouse<br />

to assess the scope of the lighting<br />

requirements. “Immediately, we realized<br />

that there was additional scope to replace<br />

the existing 400W sodium luminaires,”<br />

Battistini explains. “This legacy lighting gave<br />

a very yellow light, which allowed no color<br />

rendering. It was impossible to tell one<br />

color from another under this quality of<br />

light, which made for difficult and unpleasant<br />

operating conditions for the staff who<br />

worked there.”<br />

Pioneering venture<br />

Following the site visit, <strong>Philips</strong> proposed<br />

an upgrade, comprising a change of<br />

the luminaires for white light, plus the<br />

installation of an intelligent control system<br />

to better manage the usage of the lighting<br />

within the warehouse. The inefficient<br />

existing sodium lamps were exchanged for<br />

97 TL5 dimmable fluorescent luminaires,<br />

each comprising of four lamps.<br />

“The difference in this change alone was<br />

staggering,” says Battistini. “The TL5s<br />

deliver the same amount of light, but the<br />

We have tried to assemble a perfect concept to<br />

meet the customer’s needs, incorporating the<br />

lighting management from Dynalite with the energy<br />

management system from Schneider. The final<br />

solution allows the customer to see all the energy<br />

savings they are achieving.<br />

“<br />

”