Collaboration - Apriso

Collaboration - Apriso

Collaboration - Apriso

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

16<br />

Collaborative Environments in<br />

Manufacturing Operations<br />

<strong>Apriso</strong> (www.apriso.com)<br />

<strong>Apriso</strong> offers FlexNet software to provide global control of manufacturing and supply processes. FlexNet<br />

uses an approach that is event-driven, real-time, and process-aware. By integrating into an existing<br />

software infrastructure, <strong>Apriso</strong> can effectively extend the reach of an existing enterprise resource planning<br />

(ERP) system to an extended production and supply network.<br />

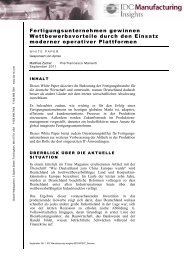

The FlexNet “enterprise execution” software builds on an integrated business process modelling capability<br />

focused on supply chain execution. FlexNet Process Builder manages relationships between operations,<br />

steps, work centres, machines, materials, tooling, documentation, operator skills and operator capacity to<br />

define procedures and workflows. Production users, quality controllers, maintenance operators and<br />

logistics users work according to this framework to synchronise execution and reporting of their work.<br />

Critical events are signalled as FlexNet alerts which can trigger e-mail and SMS messages, and can be<br />

handled by FlexNet applications. Appropriate information is stored for traceability, and used to drive<br />

suitable ERP transactions.<br />

Many production processes require several people, each with different rights and skills, to collaborate to<br />

execute coordinated actions. <strong>Apriso</strong> use FlexNet’s process modelling to create a collaborative<br />

environment, which not only maintains a shared model of operations executed by people with different<br />

roles, but also automatically triggers selected tasks or processes when defined conditions occur. This<br />

approach blends automation with collaboration between people to support, for example:<br />

• Quality control, where automated sampling may lead to review by an operator with certified skills, and<br />

approval by a superviser to initiate a machine adjustment;<br />

• Automated signalling from a production line for material replenishment from a warehouse;<br />

• Search for and identification of a particular resource or component;<br />

• Prioritisation of selected activities, for example, final assembly, to match shippng plans;<br />

Creation and maintenance of documentation required to satisfy relevant regulations.<br />

•<br />

FlexNet is fully Web-based using the Microsoft .NET Framework. FlexNet Alerts are communicated to<br />

e-mail and other recipients using Microsoft Exchange Server. FlexNet uses the Microsoft SQL Server 2000<br />

database, and integrates with ERP systems using Microsoft BizTalk Server. Documents and generated<br />

reports can be stored and shared using Microsoft Office SharePoint Portal Server.<br />

The FlexNet “enterprise execution” software<br />

Distribution of tasks<br />

and information<br />

between employees<br />

and managers<br />

With company<br />

business rules<br />

and logic<br />

LEADING EDGE COLL ABORATIVE ENVIRONMENTS IN DISCRETE MANUFACTURING INDUSTRIES<br />

Warehouse location Data<br />

and Components<br />

Material Identification Data<br />

and Components<br />

Quality Data and<br />

Components<br />

Production Data and<br />

Components<br />

Packaging Data and<br />

Components<br />

Time/Labour Data<br />

and Components