Exclusive U.S. Distributor - Apollo Design Technology

Exclusive U.S. Distributor - Apollo Design Technology

Exclusive U.S. Distributor - Apollo Design Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

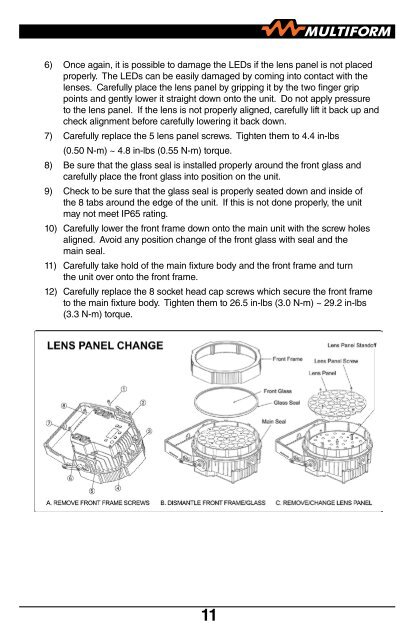

6) Once again, it is possible to damage the LEDs if the lens panel is not placed<br />

properly. The LEDs can be easily damaged by coming into contact with the<br />

lenses. Carefully place the lens panel by gripping it by the two finger grip<br />

points and gently lower it straight down onto the unit. Do not apply pressure<br />

to the lens panel. If the lens is not properly aligned, carefully lift it back up and<br />

check alignment before carefully lowering it back down.<br />

7) Carefully replace the 5 lens panel screws. Tighten them to 4.4 in-lbs<br />

(0.50 N-m) ~ 4.8 in-lbs (0.55 N-m) torque.<br />

8) Be sure that the glass seal is installed properly around the front glass and<br />

carefully place the front glass into position on the unit.<br />

9) Check to be sure that the glass seal is properly seated down and inside of<br />

the 8 tabs around the edge of the unit. If this is not done properly, the unit<br />

may not meet IP65 rating.<br />

10) Carefully lower the front frame down onto the main unit with the screw holes<br />

aligned. Avoid any position change of the front glass with seal and the<br />

main seal.<br />

11) Carefully take hold of the main fixture body and the front frame and turn<br />

the unit over onto the front frame.<br />

12) Carefully replace the 8 socket head cap screws which secure the front frame<br />

to the main fixture body. Tighten them to 26.5 in-lbs (3.0 N-m) ~ 29.2 in-lbs<br />

(3.3 N-m) torque.<br />

11