effect of contiguity on shear elastic modulus of fibre reinforced ...

effect of contiguity on shear elastic modulus of fibre reinforced ...

effect of contiguity on shear elastic modulus of fibre reinforced ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

18 Raluca Hohan, Liliana Bejan and Nicolae Ţăranu<br />

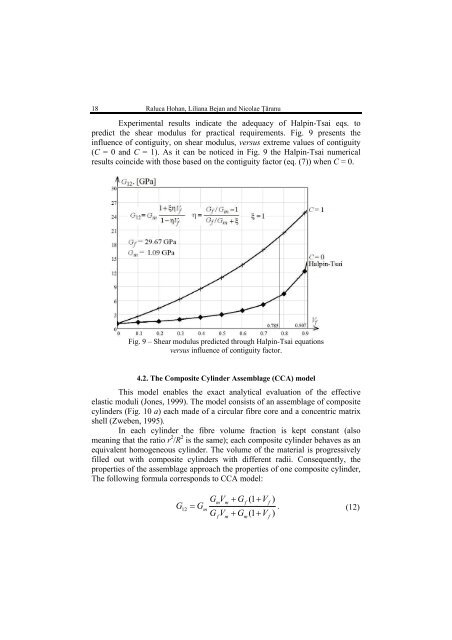

Experimental results indicate the adequacy <str<strong>on</strong>g>of</str<strong>on</strong>g> Halpin-Tsai eqs. to<br />

predict the <strong>shear</strong> <strong>modulus</strong> for practical requirements. Fig. 9 presents the<br />

influence <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>c<strong>on</strong>tiguity</str<strong>on</strong>g>, <strong>on</strong> <strong>shear</strong> <strong>modulus</strong>, versus extreme values <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>c<strong>on</strong>tiguity</str<strong>on</strong>g><br />

(C = 0 and C = 1). As it can be noticed in Fig. 9 the Halpin-Tsai numerical<br />

results coincide with those based <strong>on</strong> the <str<strong>on</strong>g>c<strong>on</strong>tiguity</str<strong>on</strong>g> factor (eq. (7)) when C = 0.<br />

Fig. 9 – Shear <strong>modulus</strong> predicted through Halpin-Tsai equati<strong>on</strong>s<br />

versus influence <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>c<strong>on</strong>tiguity</str<strong>on</strong>g> factor.<br />

4.2. The Composite Cylinder Assemblage (CCA) model<br />

This model enables the exact analytical evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the <str<strong>on</strong>g>effect</str<strong>on</strong>g>ive<br />

<strong>elastic</strong> moduli (J<strong>on</strong>es, 1999). The model c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> an assemblage <str<strong>on</strong>g>of</str<strong>on</strong>g> composite<br />

cylinders (Fig. 10 a) each made <str<strong>on</strong>g>of</str<strong>on</strong>g> a circular <strong>fibre</strong> core and a c<strong>on</strong>centric matrix<br />

shell (Zweben, 1995).<br />

In each cylinder the <strong>fibre</strong> volume fracti<strong>on</strong> is kept c<strong>on</strong>stant (also<br />

meaning that the ratio r 2 /R 2 is the same); each composite cylinder behaves as an<br />

equivalent homogeneous cylinder. The volume <str<strong>on</strong>g>of</str<strong>on</strong>g> the material is progressively<br />

filled out with composite cylinders with different radii. C<strong>on</strong>sequently, the<br />

properties <str<strong>on</strong>g>of</str<strong>on</strong>g> the assemblage approach the properties <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>on</strong>e composite cylinder,<br />

The following formula corresp<strong>on</strong>ds to CCA model:<br />

GV + G (1 + V)<br />

.<br />

(1 )<br />

m m f f<br />

G12 = Gm GV f m + Gm + Vf<br />

(12)