effect of contiguity on shear elastic modulus of fibre reinforced ...

effect of contiguity on shear elastic modulus of fibre reinforced ...

effect of contiguity on shear elastic modulus of fibre reinforced ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10 Raluca Hohan, Liliana Bejan and Nicolae Ţăranu<br />

1. Introducti<strong>on</strong><br />

Fibre <strong>reinforced</strong> polymer (FRP) composites c<strong>on</strong>sist <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>fibre</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> high<br />

hardness, strength and <strong>modulus</strong> embedded in a s<str<strong>on</strong>g>of</str<strong>on</strong>g>ter and weaker matrix, with<br />

distinct interfaces between them. Both c<strong>on</strong>stituents retain their physical and<br />

chemical identities, but their combinati<strong>on</strong> leads to properties that cannot be<br />

achieved with either <str<strong>on</strong>g>of</str<strong>on</strong>g> comp<strong>on</strong>ents working individually (Mallick, 2008).<br />

In the case <str<strong>on</strong>g>of</str<strong>on</strong>g> FRP composites the reinforcing <strong>fibre</strong>s c<strong>on</strong>stitute the<br />

backb<strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> the material and they determine most <str<strong>on</strong>g>of</str<strong>on</strong>g> its strength and stiffness in<br />

the directi<strong>on</strong> parallel to <strong>fibre</strong>s. The polymeric matrix binds together the <strong>fibre</strong>s<br />

and protects their surfaces from damage. It disperses the <strong>fibre</strong>s, separates them<br />

and also transfers stresses to them.<br />

Most composite structures made <str<strong>on</strong>g>of</str<strong>on</strong>g> fibrous composites c<strong>on</strong>sist <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

several distinct unidirecti<strong>on</strong>al laminas.<br />

A unidirecti<strong>on</strong>al composite c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> parallel <strong>fibre</strong>s embedded in a<br />

matrix and a lamina is a flat or curved arrangement <str<strong>on</strong>g>of</str<strong>on</strong>g> unidirecti<strong>on</strong>al or woven<br />

<strong>fibre</strong>s in a support matrix.<br />

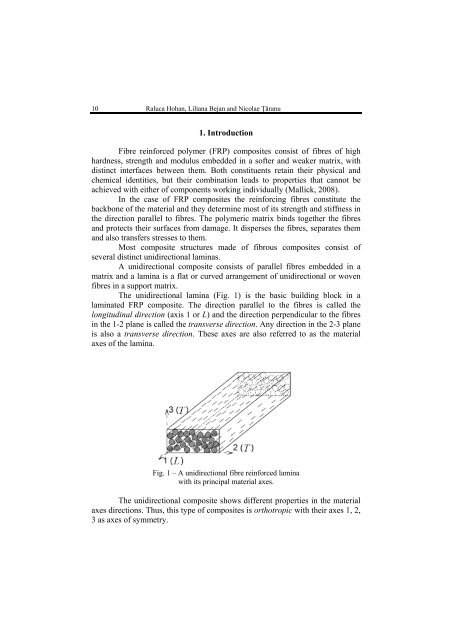

The unidirecti<strong>on</strong>al lamina (Fig. 1) is the basic building block in a<br />

laminated FRP composite. The directi<strong>on</strong> parallel to the <strong>fibre</strong>s is called the<br />

l<strong>on</strong>gitudinal directi<strong>on</strong> (axis 1 or L) and the directi<strong>on</strong> perpendicular to the <strong>fibre</strong>s<br />

in the 1-2 plane is called the transverse directi<strong>on</strong>. Any directi<strong>on</strong> in the 2-3 plane<br />

is also a transverse directi<strong>on</strong>. These axes are also referred to as the material<br />

axes <str<strong>on</strong>g>of</str<strong>on</strong>g> the lamina.<br />

Fig. 1 – A unidirecti<strong>on</strong>al <strong>fibre</strong> <strong>reinforced</strong> lamina<br />

with its principal material axes.<br />

The unidirecti<strong>on</strong>al composite shows different properties in the material<br />

axes directi<strong>on</strong>s. Thus, this type <str<strong>on</strong>g>of</str<strong>on</strong>g> composites is orthotropic with their axes 1, 2,<br />

3 as axes <str<strong>on</strong>g>of</str<strong>on</strong>g> symmetry.