LA grinding wheels in Abral corunduml - Mole Abrasivi Ermoli

LA grinding wheels in Abral corunduml - Mole Abrasivi Ermoli

LA grinding wheels in Abral corunduml - Mole Abrasivi Ermoli

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MOLE ABRASIVI ERMOLI S.R.L.<br />

Sede ed uffici: Via Cairoli, 4 - 21046 - Malnate (VA)<br />

Tel. 0332-425114 - Fax 0332-426742 - <strong>in</strong>fo@ermoli.it - www.ermoli.it<br />

Stabilimento: Via Cairoli, 14 - 21046 Malnate (VA)<br />

Tel 0332-426088<br />

Codice Fiscale e Partita IVA IT 00210280129 - Registro Imprese VA 2386 - R.E.A. Varese 5558<br />

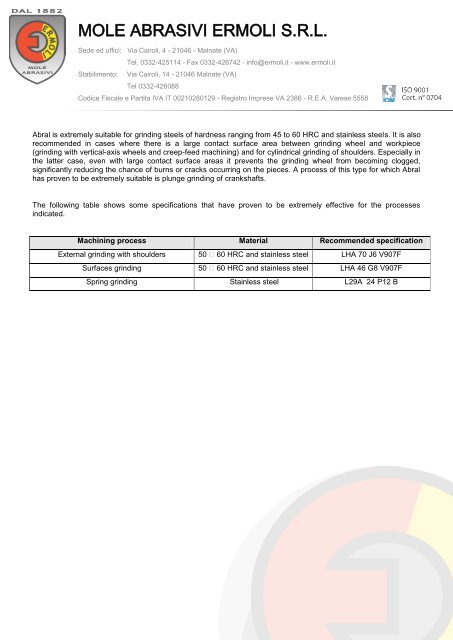

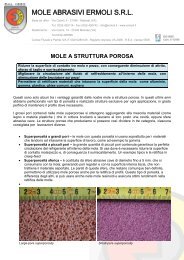

<strong>Abral</strong> is extremely suitable for <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> steels of hardness rang<strong>in</strong>g from 45 to 60 HRC and sta<strong>in</strong>less steels. It is also<br />

recommended <strong>in</strong> cases where there is a large contact surface area between <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> wheel and workpiece<br />

(<strong>gr<strong>in</strong>d<strong>in</strong>g</strong> with vertical-axis <strong>wheels</strong> and creep-feed mach<strong>in</strong><strong>in</strong>g) and for cyl<strong>in</strong>drical <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> of shoulders. Especially <strong>in</strong><br />

the latter case, even with large contact surface areas it prevents the <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> wheel from becom<strong>in</strong>g clogged,<br />

significantly reduc<strong>in</strong>g the chance of burns or cracks occurr<strong>in</strong>g on the pieces. A process of this type for which <strong>Abral</strong><br />

has proven to be extremely suitable is plunge <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> of crankshafts.<br />

The follow<strong>in</strong>g table shows some specifications that have proven to be extremely effective for the processes<br />

<strong>in</strong>dicated.<br />

Mach<strong>in</strong><strong>in</strong>g process Material Recommended specification<br />

External <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> with shoulders 50 60 HRC and sta<strong>in</strong>less steel LHA 70 J6 V907F<br />

Surfaces <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> 50 60 HRC and sta<strong>in</strong>less steel LHA 46 G8 V907F<br />

Spr<strong>in</strong>g <strong>gr<strong>in</strong>d<strong>in</strong>g</strong> Sta<strong>in</strong>less steel L29A 24 P12 B