download

download

download

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Table 1 shows the test conditions. The test confirmed<br />

the fluctuation (degradation) of insulation resistance<br />

due to different surface treatments of the PCB.<br />

Tests were prepared using the following 3 types of<br />

surface treatments for specimens.<br />

➀ Clean only<br />

➁ Coating with non-cleaning flux after cleaning<br />

➂ Solder treatment after cleaning and coating with noncleaning<br />

flux<br />

Temperature<br />

and humidity<br />

+60°C<br />

90%RH<br />

500 hours<br />

Applied<br />

voltage<br />

25 V DC<br />

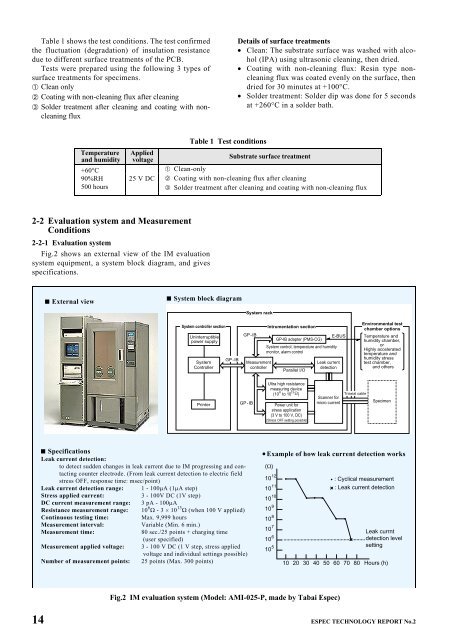

2-2 Evaluation system and Measurement<br />

Conditions<br />

2-2-1 Evaluation system<br />

Fig.2 shows an external view of the IM evaluation<br />

system equipment, a system block diagram, and gives<br />

specifications.<br />

External view<br />

Table 1 Test conditions<br />

Details of surface treatments<br />

· Clean: The substrate surface was washed with alcohol<br />

(IPA) using ultrasonic cleaning, then dried.<br />

· Coating with non-cleaning flux: Resin type noncleaning<br />

flux was coated evenly on the surface, then<br />

dried for 30 minutes at +100°C.<br />

· Solder treatment: Solder dip was done for 5 seconds<br />

at +260°C in a solder bath.<br />

Substrate surface treatment<br />

➀ Clean-only<br />

➁ Coating with non-cleaning flux after cleaning<br />

➂ Solder treatment after cleaning and coating with non-cleaning flux<br />

System block diagram<br />

System controller section<br />

Uninterruptible<br />

power supply<br />

System<br />

Controller<br />

Printer<br />

GP-IB<br />

Specifications<br />

Leak current detection:<br />

to detect sudden changes in leak current due to IM progressing and contacting<br />

counter electrode. (From leak current detection to electric field<br />

stress OFF, response time: msec/point)<br />

Leak current detection range: 1 - 100mA (1mA step)<br />

Stress applied current: 3 - 100V DC (1V step)<br />

DC current measurement range: 3 pA - 100mA<br />

Resistance measurement range: 10 6 W - 3 ´ 10 13 W (when 100 V applied)<br />

Continuous testing time: Max. 9,999 hours<br />

Measurement interval: Variable (Min. 6 min.)<br />

Measurement time: 80 sec./25 points + charging time<br />

(user specified)<br />

Measurement applied voltage: 3 - 100 V DC (1 V step, stress applied<br />

voltage and individual settings possible)<br />

Number of measurement points: 25 points (Max. 300 points)<br />

System rack<br />

GP-IB<br />

Measurement<br />

controller<br />

GP-IB<br />

Intrumentation section<br />

E-BUS<br />

GP-IB adapter (PMS-CG)<br />

System control, temperature and humidity<br />

monitor, alarm control<br />

Parallel I/O<br />

Ultra high resistance<br />

measuring device<br />

6 13<br />

(10 to 10 )<br />

Power unit for<br />

stress application<br />

(3 V to 100 V, DC)<br />

(Stress OFF setting possible)<br />

Leak current<br />

detection<br />

Scanner for<br />

micro current<br />

Fig.2 IM evaluation system (Model: AMI-025-P, made by Tabai Espec)<br />

10 12<br />

10 11<br />

10 10<br />

10 9<br />

10 8<br />

10 7<br />

10 6<br />

10 5<br />

Triaxial cable<br />

Environmental test<br />

chamber options<br />

Temperature and<br />

humidity chamber,<br />

or<br />

Highly accelerated<br />

temperature and<br />

humidity stress<br />

test chamber,<br />

and others<br />

Specimen<br />

· Example of how leak current detection works<br />

: Cyclical measurement<br />

: Leak current detection<br />

Leak currnt<br />

detection level<br />

setting<br />

10 20 30 40 50 60 70 80 Hours (h)<br />

14 ESPEC TECHNOLOGY REPORT No.2