European Technical Approval ETA-09/0105 - ETA-Danmark

European Technical Approval ETA-09/0105 - ETA-Danmark

European Technical Approval ETA-09/0105 - ETA-Danmark

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

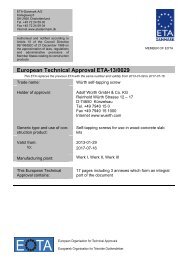

<strong>ETA</strong>-<strong>Danmark</strong> A/S<br />

Kollegievej 6<br />

DK-2920 Charlottenlund<br />

Tel. +45 72 24 59 00<br />

Fax +45 72 24 59 04<br />

Internet www.etadanmark.dk<br />

Authorised and notified according to<br />

Article 10 of the Council Directive<br />

89/106/EEC of 21 December 1988 on<br />

the approximation of laws, regulations<br />

and administrative provisions of<br />

Member States relating to construction<br />

products<br />

<strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

MEMBER OF EOTA<br />

This <strong>ETA</strong> replaces the previous <strong>ETA</strong> with the same number and validity from 20<strong>09</strong>-05-29 to 2014-05-29<br />

Trade name:<br />

Holder of approval:<br />

Generic type and use of construction<br />

product:<br />

Valid from:<br />

to:<br />

Manufacturing plant:<br />

This <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong> contains:<br />

Gutzeit concealed beam hangers 90, 120 160, 200<br />

and 240<br />

Gutzeit Verbindungssysteme GmbH & Co.<br />

Rudolf-Diesel-Strasse 1<br />

D-58730 Fröndenberg, Industriegebiet<br />

Tel. +49 2373 - 979261<br />

Fax +49 2373 - 979266<br />

Internet www.gutzeit-holzverbinder.de<br />

Three-dimensional nailing plate (concealed beam<br />

hangers)<br />

2010-05-04<br />

2014-05-29<br />

Gutzeit Verbindungssysteme GmbH & Co.<br />

Rudolf-Diesel-Strasse 1<br />

D-58730 Fröndeberg, Industriegebiet<br />

12 pages including 3 annexes which form an integral<br />

part of the document

I LEGAL BASIS AND GENERAL<br />

CONDITIONS<br />

Page 2 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

1 This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is issued by<br />

<strong>ETA</strong>-<strong>Danmark</strong> A/S in accordance with:<br />

- Council Directive 89/106/EEC of 21 December<br />

1988 on the approximation of laws, regulations<br />

and administrative provisions of Member States<br />

relating to construction products 1) , as amended by<br />

Council Directive 93/68/EEC of 22 July 1993 2) .<br />

- Bekendtgørelse 559 af 27-06-1994 (afløser<br />

bekendtgørelse 480 af 25-06-1991) om ikrafttræden<br />

af EF direktiv af 21. december 1988 om<br />

indbyrdes tilnærmelse af medlemsstaternes love<br />

og administrative bestemmelser om byggevarer.<br />

- Common Procedural Rules for Requesting,<br />

Preparing and the Granting of <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong>s set out in the Annex to Commission<br />

Decision 94/23/EC 3) .<br />

- EOTA Guideline <strong>ETA</strong>G 015 Three-dimensional<br />

nailing plates, September 2002 edition.<br />

2 <strong>ETA</strong>-<strong>Danmark</strong> A/S is authorized to check whether<br />

the provisions of this <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong> are met. Checking may take place in the<br />

manufacturing plant. Nevertheless, the responsibility<br />

for the conformity of the products to the<br />

<strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> and for their fitness<br />

for the intended use remains with the holder of<br />

the <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

3 This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is not to be<br />

transferred to manufacturers or agents of manufacturers<br />

other than those indicated on page 1, or<br />

manufacturing plants other than those indicated<br />

on page 1 of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

4 This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> may be<br />

withdrawn by <strong>ETA</strong>-<strong>Danmark</strong> A/S pursuant to<br />

Article 5(1) of Council Directive89/106/EEC.<br />

1) Official Journal of the <strong>European</strong> Communities N o L40, 11 Feb 1989, p 12.<br />

2) Official Journal of the <strong>European</strong> Communities N o L220, 30 Aug 1993, p 1.<br />

3) Official Journal of the <strong>European</strong> Communities N o L 17, 20 Jan 1994, p 34.<br />

5 Reproduction of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong><br />

including transmission by electronic means shall be<br />

in full. However, partial reproduction can be made<br />

with the written consent of <strong>ETA</strong>-<strong>Danmark</strong> A/S. In<br />

this case partial reproduction has to be designated as<br />

such. Texts and drawings of advertising brochures<br />

shall not contradict or misuse the <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong>.<br />

6 This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is issued by <strong>ETA</strong>-<br />

<strong>Danmark</strong> A/S in English.<br />

This version corresponds fully to the version circulated<br />

within EOTA. Translations into other languages<br />

have to be designated as such.

Page 3 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

I SPECIAL CONDITIONS OF THE<br />

EUROPEAN TECHNICAL APPROVAL<br />

1 Definition of product and intended use<br />

Definition of the product<br />

Gutzeit concealed beam hangers are one-piece, face-fixed<br />

concealed beam hangers to be used in timber to timber<br />

connections.<br />

The concealed beam hangers are made from pre-galvanized<br />

steel Grade DX51D + Z (min Z275) according to EN<br />

10327:2004 with a minimum Re of 295 MPa, a maximum<br />

tensile strength Rm of 360 MPa and a minimum ultimate<br />

strain A80 of 22 % with tolerances according to EN<br />

10143:1993. Dimensions, hole positions, steel type and<br />

typical installations are shown in Annex A.<br />

Intended use<br />

The concealed beam hangers are intended for use in making<br />

end-grain to side-grain connections in load bearing timber<br />

structures, as a connection between a wood based joist and a<br />

solid timber or wood based header, where requirements for<br />

mechanical resistance and stability and safety in use in the<br />

sense of the Essential Requirements 1 and 4 of Council<br />

Directive 89/106/EEC shall be fulfilled.<br />

The concealed beam hangers can be installed as<br />

connections between wood based members such as:<br />

• Structural solid timber classified to C14-C40<br />

according to EN 338 / EN 14081,<br />

• Glulam classified to GL24-GL36 according to<br />

EN 1194 / EN 14080,<br />

• LVL according to EN 14374,<br />

• Parallam PSL,<br />

• Intrallam LSL,<br />

• Duo- and Triobalken,<br />

• Layered wood plates,<br />

• Kreuzbalken,<br />

• I-beams with backer blocks on both sides of the web<br />

in the header and web stiffeners in the joist,<br />

• Plywood according to EN 636.<br />

However, the calculation methods are only allowed for a<br />

characteristic wood density of up to 460 kg/m 3 . Even<br />

though the wood based material may have a larger density,<br />

this must not be used in the formulas for the load-carrying<br />

capacities of the fasteners.<br />

Annex B states the formulas for the characteristic loadcarrying<br />

capacities of the connections with concealed beam<br />

hangers. The design of the connections shall be in<br />

accordance with Eurocode 5 or a similar national Timber<br />

Code.<br />

It is assumed that the forces acting on the concealed beam<br />

hanger connection are Fup or Fdown perpendicular to the<br />

header axis. The forces Fup and Fdown shall act in the<br />

symmetry plane of the concealed beam hanger. It is<br />

assumed that the forces are acting with an eccentricity e<br />

with regard to side grain surface of the header.<br />

It is assumed that the header beam is prevented from<br />

rotating. If the header beam only has installed a concealed<br />

beam hanger on one side the eccentricity moment<br />

M = F ⋅ (B / 2 + 40mm) shall be considered. The same<br />

v d H<br />

applies when the header has concealed beam hanger<br />

connections on both sides, but with vertical forces which<br />

differ more than 20%.<br />

The concealed beam hangers are intended for use for<br />

connections subject to static or quasi static loading.<br />

The zinc-coated hangers are for use in timber structures<br />

subject to the dry, internal conditions defined by the service<br />

classes 1 and 2 of EN 1995-1-1:2004, (Eurocode 5).<br />

Assumed working life<br />

The assumed intended working life of concealed beam<br />

hangers for the intended use is 50 years, provided that they<br />

are subject to appropriate use and maintenance.<br />

The information on the working life should not be regarded<br />

as a guarantee provided by the manufacturer or<br />

<strong>ETA</strong> <strong>Danmark</strong>. An “assumed intended working life” means<br />

that it is expected that, when this working life has elapsed,<br />

the real working life may be, in normal use conditions,<br />

considerably longer without major degradation affecting<br />

the essential requirements.

Page 4 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

2 Characteristics of product and assessment<br />

<strong>ETA</strong>G<br />

paragraph<br />

6.1.1<br />

6.1.2<br />

6.1.3<br />

6.2.1<br />

6.3.1<br />

6.7.1<br />

6.7.2<br />

6.7.3<br />

Characteristic<br />

2.1 Mechanical resistance and stability*)<br />

Characteristic load-carrying capacity<br />

Stiffness<br />

Ductility in cyclic testing<br />

2.2 Safety in case of fire<br />

Reaction to fire<br />

2.3 Hygiene, health and the environment<br />

Influence on air quality<br />

2.4 Safety in use<br />

2.5 Protection against noise<br />

2.6 Energy economy and heat retention<br />

2.7 Related aspects of serviceability<br />

Durability<br />

Serviceability<br />

Identification<br />

Assessment of characteristic<br />

See Annex B<br />

No performance determined<br />

No performance determined<br />

The concealed beam hangers are made from<br />

steel classified as Euroclass A1 in accordance<br />

with EN 1350-1 and EC decision 96/603/EC,<br />

amended by EC Decision 2000/605/EC<br />

No dangerous materials **)<br />

Not relevant<br />

Not relevant<br />

Not relevant<br />

The concealed beam hangers have been assessed<br />

as having satisfactory durability and<br />

serviceability when used in timber structures<br />

using the timber species described in Eurocode 5<br />

and subject to the conditions defined by service<br />

class 1 and 2<br />

See Annex A<br />

*) See page 5 of this <strong>ETA</strong><br />

**) In accordance with http://europa.eu.int-/comm/enterprise/construction/internal/dangsub/dangmain.htm In addition to the specific clauses relating to dangerous<br />

substances contained in this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>, there may be other requirements applicable to the products falling within its scope (e.g. transposed <strong>European</strong><br />

legislation and national laws, regulations and administrative provisions). In order to meet the provisions of the EU Construction Products Directive, these requirements need<br />

also to be complied with, when and where they apply.

Safety principles and partial factors<br />

2.1 Mechanical resistance and stability<br />

Page 5 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

See annex B for characteristic load-carrying capacities of<br />

the concealed beam hangers.<br />

The characteristic capacities of the concealed beam hangers<br />

are determined by calculation assisted by testing as<br />

described in the EOTA Guideline 015 clause 5.1.2. They<br />

should be used for designs in accordance with Eurocode 5<br />

or a similar national Timber Code.<br />

The design models allow the use of fasteners described in<br />

the table on page 10 in Annex A:<br />

Threaded nails (ringed shank nails) in accordance to<br />

EN 14592<br />

In the formulas in Annex B the capacities for threaded<br />

nails calculated from the formulas of Eurocode 5 are<br />

used assuming a thick steel plate when calculating the<br />

lateral nail load-carrying-capacity.<br />

The load bearing capacities of the brackets has been<br />

determined based on the use of connector nails 4,0 x 40<br />

mm in accordance with the German national approval for<br />

the nails.<br />

The characteristic withdrawal capacity of the nails has to be<br />

determined by calculation in accordance with EN 1995-1-<br />

1: 2004, paragraph 8.3.2 (head pull-through is not<br />

relevant):<br />

Fax,Rk = fax,k × d × tpen<br />

Where:<br />

fax,k Characteristic value of the withdrawal parameter in<br />

N/mm 2<br />

d Nail diameter in mm<br />

Penetration depth of the profiles in mm<br />

tpen<br />

Based on tests by Versuchsanstalt für Stahl, Holz und<br />

Steine, University of Kalrsruhe, the characteristic value of<br />

the withdrawal resistance for the threaded nails used can be<br />

calculated as:<br />

fax,k = 50 × 10 -6 × σk 2<br />

Where:<br />

σk<br />

Characteristic density of the timber in kg/m 3<br />

The shape of the nail directly under the head shall be in the<br />

form of a truncated cone with a diameter under the nail<br />

head which exceeds the hole diameter.<br />

No performance has been determined in relation to ductility<br />

of a joint under cyclic testing. The contribution to the<br />

performance of structures in seismic zones, therefore, has<br />

not been assessed.<br />

No performance has been determined in relation to the<br />

joint’s stiffness properties - to be used for the analysis of<br />

the serviceability limit state.<br />

2.7 Related aspects of serviceability<br />

2.7.1 Corrosion protection in service class 1 and 2.<br />

In accordance with <strong>ETA</strong>G 015 the zinc- coated concealed<br />

beam hangers have a zinc coating weight of min Z275. The<br />

steel employed is DX51D with min Z275 according to EN<br />

10327:2004.

3 Attestation of Conformity and<br />

CE marking<br />

3.1 Attestation of Conformity system<br />

Page 6 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

The system of attestation of conformity is 2+<br />

described in Council Directive 89/106/EEC<br />

(Construction Products Directive) Annex III.<br />

a) Tasks for the manufacturer:<br />

(1) Factory production control,<br />

(2) Initial type testing of the product,<br />

b) Tasks for the notified body:<br />

3.2 Responsibilities<br />

(1) Initial inspection of the factory and the<br />

factory production control,<br />

(2) Continuous surveillance<br />

3.2.1 Tasks of the manufacturer<br />

3.2.1.1 Factory production control<br />

The manufacturer has a factory production control<br />

system in the plant and exercises permanent internal<br />

control of production. All the elements, requirements<br />

and provisions adopted by the manufacturer are<br />

documented in a systematic manner in the form of<br />

written policies and procedures. This production<br />

control system ensures that the product is in<br />

conformity with the <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

The manufacturer shall only use raw materials<br />

supplied with the relevant inspection documents as<br />

laid down in the control plan 4 . The incoming raw<br />

materials shall be subject to controls and tests by the<br />

manufacturer before acceptance. Check of materials,<br />

such as sheet metal, shall include control of the<br />

inspection documents presented by suppliers<br />

(comparison with nominal values) by verifying<br />

dimension and determining material properties, e.g.<br />

chemical composition, mechanical properties and<br />

zinc coating thickness.<br />

The manufactured components are checked visually<br />

and for dimensions.<br />

The control plan, which is part of the technical<br />

documentation of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>,<br />

4 The control plan has been deposited at <strong>ETA</strong>-<strong>Danmark</strong> and is<br />

only made available to the approved bodies involved in the<br />

conformity attestation procedure.<br />

includes details of the extent, nature and frequency of<br />

testing and controls to be performed within the<br />

factory production control and has been agreed<br />

between the approval holder and <strong>ETA</strong> <strong>Danmark</strong>.<br />

The results of factory production control are recorded<br />

and evaluated. The records include at least the<br />

following information:<br />

- Designation of the product, basic material and<br />

components;<br />

- Type of control or testing;<br />

- Date of manufacture of the product and date of<br />

testing of the product or basic material and<br />

components;<br />

- Result of control and testing and, if appropriate,<br />

comparison with requirements;<br />

- Signature of person responsible for factory<br />

production control.<br />

The records shall be presented to <strong>ETA</strong> <strong>Danmark</strong> on<br />

request.<br />

3.2.1.1 Initial type testing of the product<br />

For initial type-testing the results of the tests<br />

performed as part of the assessment for the <strong>European</strong><br />

<strong>Technical</strong> <strong>Approval</strong> shall be used unless there are<br />

changes in the production line or plant. In such cases<br />

the necessary initial type testing has to be agreed<br />

between <strong>ETA</strong> <strong>Danmark</strong> and the notified body.<br />

3.2.2. Tasks of notified bodies<br />

3.2.2.1 Initial inspection of the factory and the factory<br />

production control<br />

The approved body should ascertain that, in<br />

accordance with the control plan, the factory, in<br />

particular the staff and equipment, and the factory<br />

production control, are suitable to ensure a<br />

continuous and orderly manufacturing of the angle<br />

brackets with the specifications given in part 2.<br />

3.2.2.2 Continuous surveillance<br />

The approved body shall visit the factory at least<br />

twice a year for routine inspections. It shall be<br />

verified that the system of factory production control<br />

and the specified manufacturing processes are<br />

maintained, taking account of the control plan.<br />

The results of product certification and continuous<br />

surveillance shall be made available on demand by<br />

the certification body to <strong>ETA</strong> <strong>Danmark</strong>. Where the<br />

provisions of the <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> and<br />

the control plan are no longer fulfilled, the certificate

Page 7 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

of conformity shall be withdrawn by the approved<br />

body.<br />

3.3 CE marking<br />

The CE marking shall be affixed on each packaging<br />

of angle brackets. The initials "CE" shall be followed<br />

by the identification number of the notified body and<br />

shall be accompanied by the following information:<br />

- Name or identifying mark of the<br />

manufacturer<br />

- The last two digits of the year in which the<br />

marking was affixed<br />

- Number of the <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong><br />

- Name and size of product<br />

- Number of the <strong>ETA</strong> Guideline<br />

(<strong>ETA</strong>G no. 015)<br />

- Number of the EC Certificate of<br />

Conformity

Page 8 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

4 Assumptions under which the fitness of the<br />

product for the intended use was favourably<br />

assessed<br />

4.1 Manufacturing<br />

Gutzeit concealed beam hangers are manufactured in<br />

accordance with the provisions of this <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong> using the manufacturing processes as identified<br />

in the inspection of the plant by the notified inspection<br />

body and laid down in the technical documentation.<br />

4.2 Installation<br />

Concealed beam hanger connections<br />

A concealed beam hanger connection is deemed fit for its<br />

intended use provided:<br />

Header – support conditions<br />

• The header beam shall be restrained against rotation<br />

and be free from wane under the concealed beam<br />

hanger.<br />

If the header carries joists only on one side the<br />

eccentricity moment from the joists Mec = Rjoist<br />

(bheader/2+40mm) shall be considered at the strength<br />

verification of the header.<br />

Rjoist Reaction force from the joists<br />

Width of header<br />

bheader<br />

• For a header with joists from both sides but with<br />

different reaction forces a similar consideration<br />

applies.<br />

Wood to wood connections<br />

• Concealed beam hangers are fastened to wood-based<br />

members by nails.<br />

• There shall be nails in all holes or a partial nailing<br />

pattern as prescribed in Annex A-C may be used.<br />

• The characteristic capacity of the concealed beam<br />

hanger connection is calculated according to the<br />

manufacturer’s technical documentation, dated 2008-<br />

12-15.<br />

• The concealed beam hanger connection is designed<br />

in accordance with Eurocode 5 or an appropriate<br />

national code.<br />

• The gap between the end of the joist and the surface,<br />

where contact stresses can occur during loading shall<br />

be limited. This means that for concealed beam<br />

hangers the gap between the surface of the nail heads<br />

in the flaps and the end of the joist shall be<br />

maximum 8 mm.<br />

• The cross section of the header shall have a plane<br />

surface against the whole concealed beam hanger.<br />

• The depth of the joist shall be so large that the top<br />

(bottom) of the joist is at least a4,t above (below) the<br />

upper (lower) dowel in the joist.<br />

• Nails to be used shall have a diameter, which fits the<br />

holes of the concealed beam hangers.<br />

4.3 Maintenance and repair<br />

Maintenance is not required during the assumed intended<br />

working life. Should repair prove necessary, it is normal to<br />

replace the concealed beam hanger.<br />

Thomas Bruun<br />

Manager, <strong>ETA</strong>-<strong>Danmark</strong>

Page 9 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

Annex A<br />

Product details and definitions<br />

Concealed beam hanger<br />

Face mount hanger with flanges. 3.0 mm thick pre-galvanized steel DX51D + Z (min Z275) according<br />

to EN 10327:2004 with a minimum Re of 295 MPa, a maximum tensile strength Rm of 360 MPa and a<br />

minimum ultimate strain A80 of 22 % with tolerances according to EN 10143:1993.<br />

Drawing: beam hanger 90 (left), beam hanger 160 (right)<br />

Beam<br />

hanger<br />

N° of nail<br />

holes<br />

N° d<br />

N° of Bolt<br />

holes<br />

N° d<br />

90 8 5 4 8,5<br />

120 10 5 3 13<br />

160 14 5 4 13<br />

200 18 5 5 13<br />

240 22 5 6 13

Page 10 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

Fastener types and sizes<br />

NAIL diameter Length Nail type<br />

4.0 40 Ringed shank nails according to EN 14592<br />

In the formulas in Annex B the capacities for threaded nails calculated from the formulas of Eurocode 5 are used<br />

assuming a thick steel plate when calculating the lateral nail load-carrying-capacity. The load bearing capacities of<br />

the concealed beam hangers has been determined based on the use of connector nails 4,0 x L mm in accordance<br />

with the German national approval for the nails. The characteristic withdrawal capacity of the nails has to be<br />

determined by calculation in accordance with EN 1995-1-1: 2004, paragraph 8.3.2 (head pull-through is not<br />

relevant):<br />

Fax,Rk = f1,k × d × tpen<br />

Where:<br />

f1,k Characteristic value of the withdrawal parameter in N/mm 2<br />

d Nail diameter in mm<br />

Penetration depth of the profiled shank in mm<br />

tpen<br />

Based on tests by Versuchsanstalt für Stahl, Holz und Steine, University of Karlsruhe, the characteristic value of the<br />

withdrawal resistance for the threaded nails used can be calculated as:<br />

f1,k = 50 × 10 -6 × ρk 2<br />

Where:<br />

ρk Characteristic density of the timber in kg/m 3<br />

The shape of the nail directly under the head shall be in the form of a truncated cone with a diameter under the nail<br />

head which exceeds the hole diameter.<br />

DOWELS<br />

diameter<br />

8.0<br />

12.0<br />

Correspondence hole diameter in steel<br />

plate<br />

Max. 0.5 mm. larger than the dowel<br />

diameter<br />

Max. 1 mm. larger than the dowel<br />

diameter<br />

Dowels type<br />

dowels according to EN 14592<br />

dowels according to EN 14592

Page 11 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

Annex B<br />

Characteristic values of load-carrying-capacities<br />

The downward and the upward directed forces are assumed to act in the middle of the joist.<br />

Only a full nailing pattern is specified, where there are nails in all the holes of the header connection. Also dowels are<br />

placed in all the dowel holes in the joist.<br />

B.1 Concealed beam hangers fastened with nails and dowels<br />

nJ,ef<br />

nH<br />

⎧n<br />

J,ef ⋅ Fv,J,Rd<br />

⎪<br />

⎪<br />

1<br />

F Z,Rd = min ⎨<br />

⎪ ⎛ 1 ⎞ ⎛ 1 ⎞<br />

⎪ ⎜ +<br />

⎜<br />

⎟ ⎜ ⎟<br />

n H ⋅ F ⎟ ⎜<br />

v,H,Rd k H ⋅ F ⎟<br />

⎩ ⎝ ⎠ ⎝ ax,H,Rd ⎠<br />

2 2<br />

effective number of dowels in the joist, see Table B.1<br />

total number of nails in the side of the header<br />

(B.1)<br />

Fv,J,Rd Characteristic lateral load-carrying capacity of a dowel with two shear planes in the joist<br />

Fv,J,Rd Characteristic lateral load-carrying capacity of a nail in single shear in the header assuming a thick steel plate<br />

Fax,H,Rd Characteristic axial load-carrying capacity of a nail in the header<br />

kH<br />

form factor, see Table B.1<br />

Table B.1: Gutzeit concealed beam hangers: Form factors kH and effective number of dowels nJ,ef<br />

Beam hanger nJ nH<br />

kH nJ,ef<br />

Loading DOWN<br />

kH nJ,ef<br />

Loading UP<br />

90 4 8 5,00 0,85 6,67 1,12<br />

120 3 10 23,3 1,03 11,7 0,66<br />

160 4 14 45,1 1,66 22,6 1,26<br />

200 5 18 74,0 2,40 37,0 2,00<br />

240 6 22 110 3,22 55,0 2,84

Page 12 of 12 of <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> no. <strong>ETA</strong>-<strong>09</strong>/<strong>0105</strong><br />

Annex C<br />

Installation of concealed beam hangers