ETA 060158 IMPERBEL Double layer UK renew Final - ETA-Danmark

ETA 060158 IMPERBEL Double layer UK renew Final - ETA-Danmark

ETA 060158 IMPERBEL Double layer UK renew Final - ETA-Danmark

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

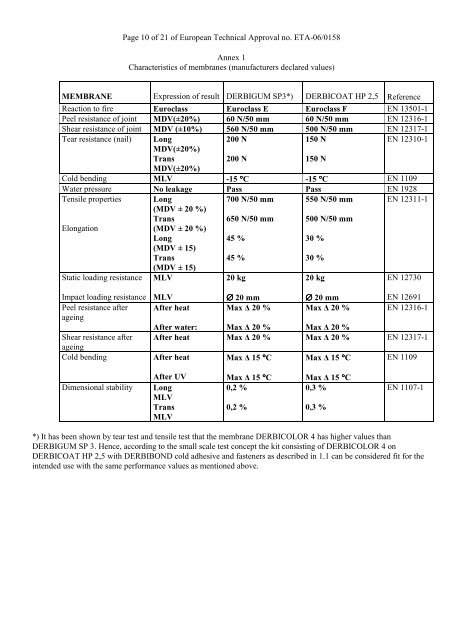

Page 10 of 21 of European Technical Approval no. <strong>ETA</strong>-06/0158<br />

Annex 1<br />

Characteristics of membranes (manufacturers declared values)<br />

MEMBRANE Expression of result DERBIGUM SP3*) DERBICOAT HP 2,5 Reference<br />

Reaction to fire Euroclass Euroclass E Euroclass F EN 13501-1<br />

Peel resistance of joint MDV(±20%) 60 N/50 mm 60 N/50 mm EN 12316-1<br />

Shear resistance of joint MDV (±10%) 560 N/50 mm 500 N/50 mm EN 12317-1<br />

Tear resistance (nail) Long<br />

MDV(±20%)<br />

200 N<br />

150 N<br />

EN 12310-1<br />

Trans<br />

MDV(±20%)<br />

200 N<br />

150 N<br />

Cold bending MLV -15 °C -15 °C EN 1109<br />

Water pressure No leakage Pass Pass EN 1928<br />

Tensile properties Long<br />

(MDV ± 20 %)<br />

700 N/50 mm 550 N/50 mm EN 12311-1<br />

Trans<br />

650 N/50 mm 500 N/50 mm<br />

Elongation<br />

(MDV ± 20 %)<br />

Long<br />

(MDV ± 15)<br />

45 %<br />

30 %<br />

Trans<br />

(MDV ± 15)<br />

45 %<br />

30 %<br />

Static loading resistance MLV<br />

20 kg<br />

20 kg<br />

EN 12730<br />

Impact loading resistance MLV<br />

Peel resistance after After heat<br />

ageing<br />

After water:<br />

Shear resistance after After heat<br />

ageing<br />

Cold bending After heat<br />

After UV<br />

Dimensional stability Long<br />

MLV<br />

Trans<br />

MLV<br />

∅ 20 mm<br />

Max ∆ 20 %<br />

∅ 20 mm<br />

Max ∆ 20 %<br />

EN 12691<br />

EN 12316-1<br />

Max ∆ 20 % Max ∆ 20 %<br />

Max ∆ 20 % Max ∆ 20 % EN 12317-1<br />

Max ∆ 15 °C<br />

Max ∆ 15 °C<br />

0,2 %<br />

0,2 %<br />

Max ∆ 15 °C<br />

Max ∆ 15 °C<br />

0,3 %<br />

0,3 %<br />

EN 1109<br />

EN 1107-1<br />

*) It has been shown by tear test and tensile test that the membrane DERBICOLOR 4 has higher values than<br />

DERBIGUM SP 3. Hence, according to the small scale test concept the kit consisting of DERBICOLOR 4 on<br />

DERBICOAT HP 2,5 with DERBIBOND cold adhesive and fasteners as described in 1.1 can be considered fit for the<br />

intended use with the same performance values as mentioned above.