pdf - Eurofer

pdf - Eurofer

pdf - Eurofer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

11. Co-Product Methodology<br />

CO and CO2 are produced (and some CH4) during the combustion of coal and coke in the<br />

blast furnace which are used for energy purposes (producing hot metal, slag and gases).<br />

Allocation of these emissions to air is therefore to both the hot metal and the slag, based on<br />

the energy function (fEHM and fES(BF)).<br />

Energy sources e.g. natural gas, coal, coke: these are used in the operation of the process<br />

and therefore associated with both the hot metal and the slag and thus allocated in this<br />

manner, based on the energy function (fEHM and fES(BF)). The allocation for blast furnace<br />

gas by energy later determines the burden of process gas combustion as well as the credit<br />

due to the avoided production of electricity, which are allocated between the slag and the hot<br />

metal.<br />

Fluorspar – is added to control the slag efficiency and is therefore allocated totally to the<br />

slag.<br />

Hydrogen sulphide, H2S, is allocated to both the hot metal and the slag by the energy<br />

function (fEHM and fES(BF)) as, although the emissions of the H2S mainly occur during<br />

quenching of the slag at the slag pouring tap, this has no more link (metallurgically) to the<br />

slag than to the hot metal.<br />

Iron ore, sinter, pellets, sinter fines and direct reduced iron – allocations between the<br />

slag and hot metal of these flows are calculated based on the proportion of gangue and iron<br />

that is present in the material. Gangue content is defined as the non-iron content of the<br />

material and is determined by calculating the iron/ferrous content in the material – the<br />

proportion of the material that is iron is therefore allocated to the hot metal. The gangue<br />

content in the iron ore is calculated based on the iron content using the formula: [gangue = 1<br />

– (1.43 * iron content)], where the 1.43 relates to the proportion of iron ore (which is a mix of<br />

haematite, Fe2O3, and gangue) that is iron. Where no site specific data is available, default<br />

values are used instead. The gangue forms the slag product and therefore the proportion of<br />

gangue content is allocated to the slag.<br />

The benefits of having gangue present in the sinter product is that it produces a material that<br />

can be inserted into the blast furnace due to its hardness and using such products produces a<br />

good quality slag that can beneficially be used by industries such as the cement industry.<br />

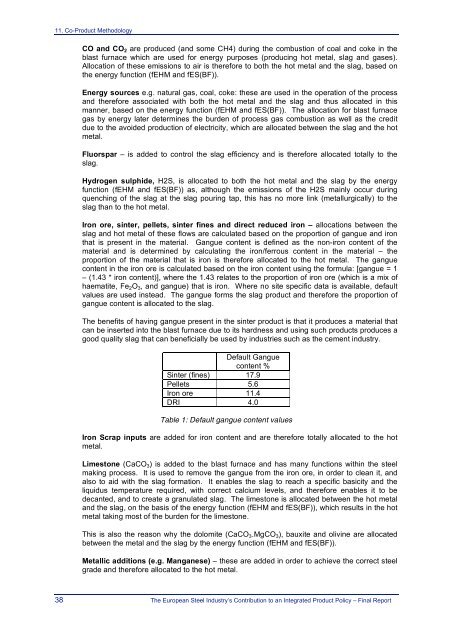

Default Gangue<br />

content %<br />

Sinter (fines) 17.9<br />

Pellets 5.6<br />

Iron ore 11.4<br />

DRI 4.0<br />

Table 1: Default gangue content values<br />

Iron Scrap inputs are added for iron content and are therefore totally allocated to the hot<br />

metal.<br />

Limestone (CaCO3) is added to the blast furnace and has many functions within the steel<br />

making process. It is used to remove the gangue from the iron ore, in order to clean it, and<br />

also to aid with the slag formation. It enables the slag to reach a specific basicity and the<br />

liquidus temperature required, with correct calcium levels, and therefore enables it to be<br />

decanted, and to create a granulated slag. The limestone is allocated between the hot metal<br />

and the slag, on the basis of the energy function (fEHM and fES(BF)), which results in the hot<br />

metal taking most of the burden for the limestone.<br />

This is also the reason why the dolomite (CaCO3.MgCO3), bauxite and olivine are allocated<br />

between the metal and the slag by the energy function (fEHM and fES(BF)).<br />

Metallic additions (e.g. Manganese) – these are added in order to achieve the correct steel<br />

grade and therefore allocated to the hot metal.<br />

38 The European Steel Industry’s Contribution to an Integrated Product Policy – Final Report