Sustainable US Biofuels Expansion - Faap

Sustainable US Biofuels Expansion - Faap

Sustainable US Biofuels Expansion - Faap

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Este conteúdo é protegido por direitos autorais. Não é<br />

permitido modificar, reproduzir, expor, distribuir ou usar o<br />

conteúdo para quaisquer fins público ou comercial. O material<br />

está autorizado para consulta, desde que referenciado como<br />

produção da CONFERÊNCIA INTERNACIONAL DE<br />

BIOCOMB<strong>US</strong>TÍVEIS.<br />

CHUM, Helena. A indústria de biocombustíveis: expansão<br />

sustentável nos Estados Unidos. In: CONFERÊNCIA<br />

INTERNACIONAL DE BIOCOMB<strong>US</strong>TÍVEIS, 2010, São Paulo.<br />

Apresentações (Painel IV). São Paulo: Faculdade de<br />

Engenharia - FAAP, 2010.<br />

Outline<br />

1. <strong>Sustainable</strong> <strong>Biofuels</strong> – The thresholds<br />

– Challenges and Opportunities<br />

– Examples of EPA’s Results<br />

2. <strong>Biofuels</strong> Technologies and Systems Progress<br />

3. <strong>Biofuels</strong> part of agriculture and forestry systems,<br />

along with the recurrent and end of life products use<br />

– Food, Feed, Fiber, biomass, bioenergy, and ecosystems<br />

services and land use need integrated systems<br />

approaches<br />

3<br />

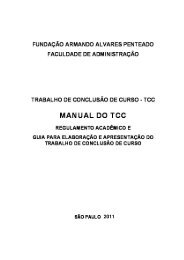

<strong>Sustainable</strong><br />

<strong>US</strong> <strong>Biofuels</strong> <strong>Expansion</strong><br />

Conferencia<br />

Internacional de<br />

Biocombustiveis<br />

Dr. Helena Chum<br />

NREL Fellow<br />

FAAP<br />

Sao Paulo, Brazil<br />

May 28, 2010<br />

NREL is a national laboratory of the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy operated by the Alliance for <strong>Sustainable</strong> Energy, LLC<br />

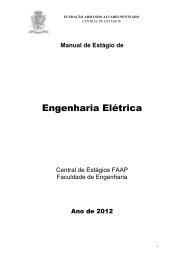

EISA Mandated Production Targets<br />

15 BGY [57 billion liters/yr] cap<br />

on conventional (starch) biofuel<br />

Renewable Fuel<br />

Standard (RFS)<br />

in the Energy 2022<br />

Independence<br />

and Security Act 2015<br />

(EISA) of 2007<br />

2012<br />

EPAct<br />

2005<br />

2012<br />

2010 EPA biofuels proportions:<br />

8.25% renewable fuel<br />

0.61% advanced biofuel<br />

1.10% biomass-based diesel<br />

0.004% cellulosic biofuel<br />

Advanced <strong>Biofuels</strong><br />

(include cellulosic biofuels other<br />

than starch-based ethanol)<br />

0 5 10 15 20 25 30 35 40<br />

Production Targets (Billions of Gallons)<br />

Ethanol & Biodiesel Conventional (Starch) Biofuel Biodiesel<br />

Cellulosic <strong>Biofuels</strong> Other Advanced <strong>Biofuels</strong><br />

EISA defines Cellulosic Biofuel as “renewable fuel derived from any cellulose, hemicellulose, or<br />

lignin that is derived from renewable biomass and that has lifecycle greenhouse gas<br />

emissions…that are at least 60 percent less than baseline lifecycle greenhouse gas emissions.”<br />

EISA defines Advanced Biofuel as “renewable fuel, other than ethanol derived from corn starch,<br />

that has lifecycle greenhouse gas emissions…that are at least 50 percent less than baseline<br />

lifecycle greenhouse gas emissions.”

Multiple Simultaneous Advances in Technologies for<br />

Feedstocks --- Conversion --- End Use<br />

Goal: Drive towards an<br />

economic integrated<br />

multistep process<br />

DuPont Danisco<br />

Cellulose Ethanol<br />

<strong>US</strong>DA Data: 5-fold increase since 1940<br />

Can industry reach these yields?<br />

80 new hybrids in 2010

Exploring Routes to Convert Biomass<br />

Feedstock<br />

Production<br />

& Logistics<br />

• Energy<br />

crops<br />

• Forest<br />

Residue<br />

• Agricultural<br />

wastes<br />

• Algae<br />

Integrated Biorefineries<br />

Biochemical Conversion<br />

Pretreatment &<br />

Conditioning<br />

Distillation<br />

Enzymatic<br />

Hydrolysis<br />

Sugars Fermentation<br />

Enzyme<br />

By-Products<br />

Production<br />

Wastes/Residue<br />

Thermochemical Conversion<br />

Upgrading<br />

Fast Liquid Zeolite Cracking<br />

Pyrolysis Bio-oil Hydrogenolysis<br />

Gasification Syngas<br />

Lipid (Oil)<br />

Extraction<br />

Algal<br />

Oil<br />

Fischer Tropsch<br />

Alcohol Synthesis<br />

Transesterification<br />

Upgrading<br />

R E F I N I N G<br />

Research on multiple conversion pathways aims to improve the<br />

efficiency and economics of biofuels production.<br />

DDGS (corn)<br />

Lignin<br />

(for power)<br />

Ethanol<br />

Butanol<br />

Olefins<br />

Gasoline<br />

Diesel<br />

Others<br />

Program Areas & Key Challenges<br />

Feedstock<br />

Systems<br />

– Diverse regional<br />

biomass<br />

resources<br />

– Yield & price<br />

– Water & fertilizer<br />

– Land use<br />

– Metrics &<br />

standards<br />

Sustainability<br />

Research & Development Demonstration & Deployment<br />

Conversion Technologies<br />

Biochemical<br />

– Cost & Efficiency<br />

• Pretreatments<br />

• Enzymes/yields<br />

– Fermentation<br />

Thermochemical<br />

– Cost & Efficiency<br />

– Gasification Process<br />

– Fuel Stabilization<br />

• GHG emissions<br />

• Water quality<br />

• Land use<br />

• Socioeconomics<br />

Integrated<br />

Biorefineries<br />

– Integrating<br />

process<br />

technologies<br />

– Financing<br />

– Technical<br />

expertise<br />

– Profit potential<br />

Product Development<br />

− Fuel purity & cost<br />

− By-products/markets<br />

− Infrastructure compatibility<br />

Major DOE <strong>Biofuels</strong> Project Locations<br />

Pacific Ethanol<br />

(Boardman, OR)<br />

Nov ozymes<br />

(Dav is, CA)<br />

Genencor<br />

(Palo Alto, CA)<br />

Ceres, Inc<br />

(Thousand Oaks, CA)<br />

Verenium Corp (2)<br />

(San Diego, CA)<br />

BlueFire Ethanol<br />

(Mecca, CA)<br />

Eight Small-Scale Biorefinery Projects<br />

Four Commercial-Scale Biorefinery Projects<br />

Four Improved Enzyme Projects<br />

Emery Energy<br />

(Salt Lake City, UT)<br />

Five Projects for Fermentation Organisms<br />

Five Thermochemical Syngas Projects<br />

DOE Joint Solicitation Biomass Projects<br />

Five Thermochemical Bio-Oil Projects<br />

Six University Conversion Projects<br />

Montana State University<br />

(Bozeman, MT)<br />

Lignol<br />

(Grand Junction, CO)<br />

Abengoa<br />

(Hugoton, KS )<br />

Cargill Inc<br />

(Minneapolis, MN)<br />

Flambeau Riv er<br />

(Park Falls, WI)<br />

NewPage<br />

(Wisconsin Rapids, WI)<br />

Poet<br />

(Emmetsburg, IA)<br />

Office of Science Bioenergy<br />

Centers<br />

DOE Great Lakes, Madison, WI<br />

DOE Joint Bioenergy Institute, Berkeley,<br />

CA<br />

DOE Bioenergy Science Center, Oak<br />

Ridge, TN<br />

Univ ersity of Minnesota<br />

(Minneapolis, MN)<br />

Iowa State (3) Univ ersity<br />

(Ames, IA)<br />

UOP, LLC<br />

(De s Plaines, IL)<br />

Infrastructure<br />

– Transport<br />

– Storage<br />

– Codes &<br />

Standards<br />

(Blend wall)<br />

– Demand/<br />

markets<br />

– Compatibility<br />

• Predictive Modeling<br />

• International<br />

Purdue Univ ersity (2)<br />

(West Lafaye tte, IN)<br />

Alltech<br />

Env irofine<br />

(Washington<br />

County, KY)<br />

Southern Research<br />

Institute<br />

(Birmingham, AL)<br />

Mascoma<br />

(Kinross, MI)<br />

Gas Technology Institute<br />

(Des Plaines, IL)<br />

Verenium <strong>Biofuels</strong> Corp.<br />

(Jennings, LA)<br />

Georgia Tech<br />

(Atlanta, GA)<br />

Range Fuels<br />

(Soperton, GA)<br />

Mascoma<br />

(Lebanon, NH)<br />

Univ ersity of Georgia<br />

(Athens, GA)<br />

Univ ersity of Maine<br />

(Orono, ME)<br />

Regional<br />

Partnerships<br />

South Dakota State Univ., Brookings, SD<br />

Cornell University, Ithaca, NY<br />

Univ. of Tennessee, Knoxville, TN<br />

Oklahoma State Univ., Stillwater, OK<br />

Oregon State Univ., Corvallis, OR<br />

RSE Pulp &<br />

Chemical, LLC<br />

(Old Town, ME)<br />

Cornell Univ ersity Univ ersity of Mass<br />

(Ithaca, NY)<br />

(Amherst, MA)<br />

GE Global Research<br />

(Niskayuna, NY)<br />

Stevens Institute of<br />

Technology<br />

(Hoboken NJ)<br />

Univ eristy of<br />

Toledo<br />

(Toldeo, OH)<br />

Virginia Tech<br />

(Blacksburg, VA)<br />

DSM Innovation Center<br />

(Parsippany, NJ)<br />

Dupont<br />

(Wilmington, DE )<br />

Research Triangle Institute (2)<br />

(Research Triangle Park, NC)<br />

Modified 10/1/2008

Key Recent Accomplishments and Deliverables<br />

EPACT Section 932 “Commercial-Scale” Biorefineries<br />

DOE investments in cellulosic biofuels will accelerate commercialization<br />

and help create a biofuels market based on non-food feedstocks.<br />

Performers<br />

Poet<br />

Emmetsburg, IA<br />

Range Fuels<br />

Soperton, GA<br />

Abengoa<br />

Hugoton, KS<br />

Bluefire<br />

Fulton, MS<br />

Feedstock<br />

Type<br />

Corn Cob<br />

Corn Fiber<br />

Woody<br />

Waste<br />

Agricultural<br />

Residue<br />

Conversion<br />

Technology<br />

Fuel Type Status<br />

Biochemical Ethanol Engineering and construction in<br />

progress. Cobs feedstock<br />

infrastructure set up<br />

Gasification + Mixed<br />

Alcohol synthesis<br />

Mixed<br />

alcohols<br />

Engineering and construction in<br />

progress.<br />

Biochemical Ethanol NEPA EIS process initiated. Corn<br />

stover infrastructure set up<br />

Sorted MSW Biochemical-<br />

Concentrated Acid<br />

Hydrolysis<br />

Ethanol Lease and NEPA issues being<br />

resolved.<br />

Key Recent Accomplishments and Deliverables<br />

Demonstration-Scale Biorefineries: FY08 Award One, Under Negotiation<br />

Alltech-Envirofine<br />

Washington County, KY<br />

Lignol Innovations<br />

Grand Junction, CO<br />

Mascoma<br />

Upper Peninsula, MI<br />

NewPage<br />

Wisconsin Rapids, WI<br />

Pacific Ethanol<br />

Boardman, OR<br />

RSA<br />

Old Town, ME<br />

Performers Feedstock Type<br />

Verenium <strong>Biofuels</strong> Corp.<br />

Jennings, LA<br />

Flambeau River <strong>Biofuels</strong> LLC<br />

Park Falls, WI<br />

Corn Cobs, Corn<br />

Fiber<br />

Conversion<br />

Technology<br />

Biochemical-Solid<br />

State Fermentation<br />

Woody Biomass Biochemical-<br />

Organisolve<br />

Ethanol<br />

Ethanol<br />

Woody Biomass Biochemical Ethanol<br />

Woody Biomass<br />

- Mill Residue<br />

Wheat Straw,<br />

Stover, Poplar<br />

Residuals<br />

Woody Biomass<br />

- Mill residues<br />

Energy Cane and<br />

Bagasse<br />

Forest residues<br />

and wood waste<br />

Thermochemical-<br />

Fischer-Tropsch<br />

Biochemical-Biogasol Ethanol<br />

Biochemical-Pentose<br />

Extraction<br />

Biochemical Process Ethanol<br />

Thermochem to<br />

Fischer-Tropsch<br />

Fuel Type<br />

Fischer-Tropsch liquids<br />

To be determined<br />

Fischer-Tropsch liquids<br />

Pilot Plant, Scotland, South Dakota<br />

Key Stakeholder Relationships<br />

Regional Biomass Energy Feedstock Partnership Bioenergy Crop Trials<br />

In 2008, the Biomass Program, Sun Grant Initiative universities, and <strong>US</strong>DA selected, and<br />

in some cases established the first round of replicated field trials of corn stover<br />

removal and dedicated herbaceous energy crops.<br />

This map shows<br />

the selected<br />

locations and<br />

types of crops.

DOE<br />

Office of<br />

Science<br />

Advanced<br />

Feedstock &<br />

Conversion<br />

Technologies

Grand Challenge: Next-Generation Bioenergy Crops Center Strategies<br />

• GLBRC – Engineer “model” plants and potential energy crops to produce new forms of lignin and more<br />

starches and oils, which are more easily processed into fuels.<br />

• JBEI – Enhance lignin degradation in “model” plants by changing cross-links among lignin subunits;<br />

improve deconstruction and subsequent fermentation by altering linkages between lignin and other cellwall<br />

components; translate genetic developments to switchgrass.<br />

• BESC – Decrease or eliminate harsh chemical pretreatments by engineering plant cell walls in poplar<br />

and switchgrass to be less recalcitrant; simultaneously increase total biomass produced per acre.<br />

Grand Challenge: Discovery and Design of Enzymes and Microbes with Novel<br />

Biomass-Degrading Capabilities Center Strategies<br />

• GLBRC – Identify combinations of enzymes and pretreatment needed to digest specific biomass types;<br />

express biomass-degrading enzymes in the stems and leaves of corn and other plants.<br />

• JBEI – Develop new ionic liquid pretreatments that can completely solubilize and fractionate biomass<br />

components; improve performance and stability of enzymes obtained from the rainforest floor and<br />

other environments; engineer, through directed evolution, highly efficient cellulase enzymes.<br />

• BESC – Screen natural thermal springs to identify enzymes and microbes that effectively break down<br />

and convert biomass at high temperatures; understand and engineer cellulosomes (multifunctional<br />

enzyme complexes for degrading cellulose).<br />

Grand Challenge: Development of Transformational Microbe-Mediated Strategies<br />

for Biofuel Production Center Strategies<br />

• GLBRC – Start with an ethanol-producing microbe and add lignocellulose-degrading capabilities to<br />

substantially reduce costs.<br />

• JBEI – Connect diverse biological parts and pathways to create entirely new organisms that produce<br />

fuels other than ethanol; engineer organisms to produce and withstand high concentrations of biofuels;<br />

derive useful chemical products from lignin degradation.<br />

• BESC – Start with a lignocellulose-degrading microbe and add ethanol-producing capabilities to<br />

substantially reduce costs; develop a knowledgebase and pathway analysis tools to aid this manipulation.<br />

Chum, 12/2009 Chum, 12/2009

Chum, 12/2009<br />

NSF. 2008. Breaking the Chemical and Engineering Barriers to Lignocellulosic <strong>Biofuels</strong>: Next Generation Hydrocarbon<br />

Biorefineries. Ed. George W. Huber, University of Massachusetts Amherst. National Science Foundation. Chemical,<br />

Bioengineering, Environmental, and Transport Systems Division. Washington D.C. 180 p.<br />

http://www.ecs.umass.edu/biofuels/Images/Roadmap2-08.pdf<br />

Chum, 12/2009

Chum, 12/2009<br />

Chum, 12/2009<br />

Summary<br />

• Promises<br />

– Increased Understanding from Advances in Science and<br />

Engineering Leading the Possibility of Designed Systems<br />

– Recognized the Need for Integration of Technologies along the<br />

Supply Chain, Systems and Uses – Buying Down Risk<br />

• Challenges<br />

– Technology Development and Learning Curves - timing<br />

– Uncertainties and Risks – Financial, Regulatory, Security…<br />

– Complexity of systems, families of technologies, multiplicity of<br />

choices with no clear winner<br />

• Innovation and Leadership<br />

– Required for the Development of Integrated <strong>Sustainable</strong> Biomass<br />

Systems

37<br />

Update on EPA RFS2<br />

Type of Model Example Explanation<br />

General equilibrium models represent the<br />

whole economy and the main interactions<br />

between economic sectors of a single<br />

region or multiple regions.<br />

Partial equilibrium models give a detailed<br />

description of a specific economic sector.<br />

Optimization models aim to allocate<br />

resources by maximizing or minimizing an<br />

objective function, generally an economic<br />

objective function of profit or utility.<br />

Agent-based models focus on the<br />

simulation of actors’ decisions<br />

System Dynamics models simulate timedependent<br />

phenomena such as land-use<br />

change and account for feedbacks in the<br />

system<br />

GTAP Global Trade Analysis Project model, a multi-region, multi-sector, computable<br />

general equilibrium model that estimates changes in world agricultural<br />

production. Maintained through Purdue University, GTAP projects international<br />

land use change based on the economics of land conversion. Website:<br />

https://www.gtap.agecon.purdue.edu/default.asp<br />

FAPRI Integrated Food and Agricultural Policy and Research Institute with the<br />

international models, as maintained by the Center for Agricultural and Rural<br />

Development (FAPRI-CARD) at Iowa State University. Website:<br />

http://www.fapri.iastate.edu/<br />

FASOM Forestry and Agriculture Optimization Model (FASOM) of Texas A&M University<br />

with a much more detailed economic description of the agriculture and<br />

forestry sector. Website: http://agecon2.tamu.edu/people/faculty/mccarlbruce/FASOM.html<br />

Carnegie- Linking global and local dynamics and modeling indirect land use change from<br />

Stanford <strong>Biofuels</strong> biofuel demand (e.g., simulate sugarcane expansion dynamics in the Brazilian<br />

project<br />

agricultural frontier) .Work presented at Roundtable on <strong>Sustainable</strong> <strong>Biofuels</strong>,<br />

Sao Paulo, November, 2008.<br />

http://cgse.epfl.ch/webdav/site/cgse/shared/<strong>Biofuels</strong>/Regional<br />

%20Outreaches%20&%20Meetings/LUC%20Workshop%20Sao%20Paulo/<br />

Presentations%20day%202/Fernandez.pdf<br />

STELLA-based<br />

SheehanBoyce<br />

The Systems Thinking Experimental Learning Laboratory with<br />

Animation (STELLA) simulate the biofuel production chain in the<br />

U.S. accounting for land in the feedstock-production phase and the<br />

greenhouse-gas emissions from indirect land-use changes.<br />

http://www.bio.org/letters/CARB_LCFS_Sheehan_200904.pdf<br />

Lifecycle Assessment (LCA) GREET Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation<br />

Model, developed by Argonne National Laboratory. Website:<br />

http://www.transportation.anl.gov/modeling_simulation/GREET/

EPA, 2010, Renewable Fuel Standard Program (RFS2)<br />

Regulatory Impact Analysis, EPA-420-R-10-006,<br />

February 2010,<br />

http://www.epa.gov/otaq/renewablefuels/420r10006.pdf<br />

CARB, 2010. January 10, 2010, FINAL REGULATION ORDER,<br />

Subchapter 10. Climate Change, Article 4. Regulations to<br />

Achieve Greenhouse Gas Emission Reductions, Subarticle 7.<br />

Low Carbon Fuel Standard,<br />

http://www.arb.ca.gov/regact/2009/lcfs09/lcfs09.htm<br />

For information on current DOE Biomass<br />

Program Activities see:<br />

http://www.obpreview2009.govtools.us/review/<br />

Support from the DOE Office of the Biomass Program is<br />

greatly acknowledged<br />

Helena.Chum@nrel.gov.<br />

Visit us online at www.nrel.gov .<br />

National Renewable<br />

Energy Laboratory<br />

Operated Innovation for the U.S. for Department Our Energy of Energy Office of Energy Efficiency and Renewable Energy by Midwest Research Institute • Battelle<br />

Future