DISHWASHING EQUIPMENT - fagor

DISHWASHING EQUIPMENT - fagor

DISHWASHING EQUIPMENT - fagor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

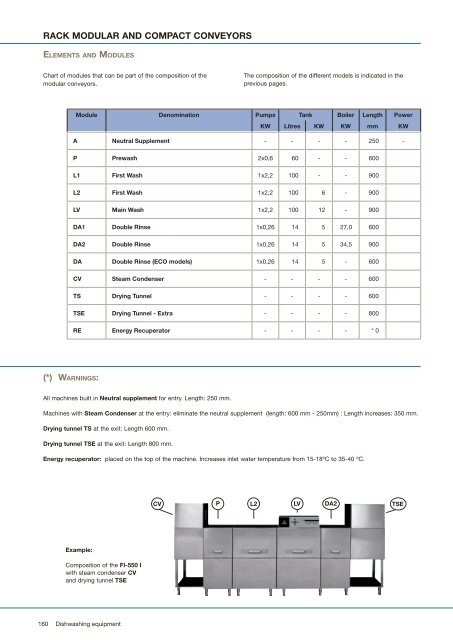

RaCK mOduLaR and COmpaCt COnVeYORs<br />

EL E M E N T S A N D MO D U L E S<br />

Chart of modules that can be part of the composition of the<br />

modular conveyors.<br />

(*) WA R N I N G S:<br />

module denomination pumps tank Boiler Length power<br />

Kw Litres Kw Kw mm Kw<br />

a neutral supplement - - - - 250 -<br />

p prewash 2x0,6 60 - - 600<br />

L1 First wash 1x2,2 100 - - 900<br />

L2 First wash 1x2,2 100 6 - 900<br />

LV main wash 1x2,2 100 12 - 900<br />

da1 double Rinse 1x0,26 14 5 27,0 600<br />

da2 double Rinse 1x0,26 14 5 34,5 900<br />

da double Rinse (eCO models) 1x0,26 14 5 - 600<br />

CV steam Condenser - - - - 600<br />

ts drying tunnel - - - - 600<br />

tse drying tunnel - extra - - - - 800<br />

Re energy Recuperator - - - - * 0<br />

All machines built in neutral supplement for entry. Length: 250 mm.<br />

Machines with steam Condenser at the entry: eliminate the neutral supplement (length: 600 mm - 250mm) : Length increases: 350 mm.<br />

drying tunnel ts at the exit: Length 600 mm.<br />

drying tunnel tse at the exit: Length 800 mm.<br />

energy recuperator: placed on the top of the machine. Increases inlet water temperature from 15-18ºC to 35-40 ºC.<br />

example:<br />

Composition of the Fi-550 i<br />

with steam condenser CV<br />

and drying tunnel tse<br />

160 Dishwashing equipment<br />

The composition of the different models is indicated in the<br />

previous pages.<br />

CV p L2 LV da2 tse