Moisture Separator Reheater - Balcke-Dürr Energietechnik Gmbh

Moisture Separator Reheater - Balcke-Dürr Energietechnik Gmbh

Moisture Separator Reheater - Balcke-Dürr Energietechnik Gmbh

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

22 000<br />

7<br />

3<br />

6<br />

Ø 3 200<br />

2<br />

Ø 4 500<br />

Drain pipe<br />

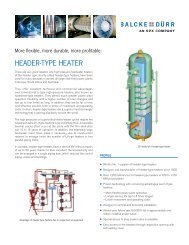

Figure 4. <strong>Moisture</strong> separator and reheater of the<br />

Unterweser Nuclear Power Plant.<br />

5<br />

1<br />

4<br />

1 Fine separator<br />

2 Coarse separator<br />

3 <strong>Reheater</strong><br />

4 Turbine steam inlet<br />

5 Turbine steam outlet<br />

6 Heating steam inlet<br />

7 Heating steam condensate outlet<br />

Condensate outlet nozzle<br />

7<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Agglomerator<br />

6<br />

<strong>Moisture</strong> <strong>Separator</strong> <strong>Reheater</strong>s<br />

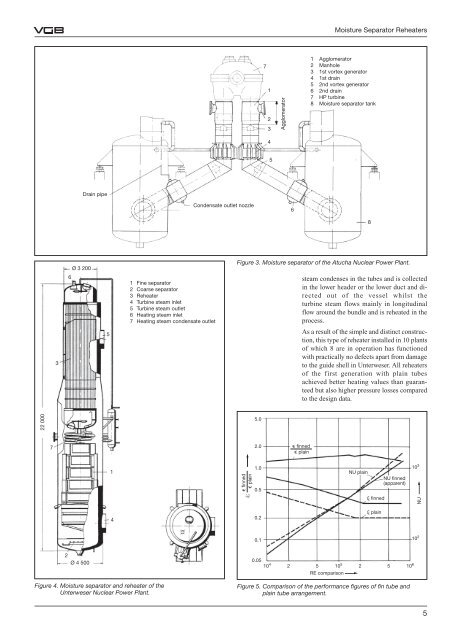

1 Agglomerator<br />

2 Manhole<br />

3 1st vortex generator<br />

4 1st drain<br />

5 2nd vortex generator<br />

6 2nd drain<br />

7 HP turbine<br />

8 <strong>Moisture</strong> separator tank<br />

Figure 3. <strong>Moisture</strong> separator of the Atucha Nuclear Power Plant.<br />

e finned<br />

e plain<br />

j;<br />

5.0<br />

2.0<br />

1.0<br />

0.5<br />

0.2<br />

0.1<br />

steam condenses in the tubes and is collected<br />

in the lower header or the lower duct and directed<br />

out of the vessel whilst the<br />

turbine steam flows mainly in longitudinal<br />

flow around the bundle and is reheated in the<br />

process.<br />

As a result of the simple and distinct construction,<br />

this type of reheater installed in 10 plants<br />

of which 8 are in operation has functioned<br />

with practically no defects apart from damage<br />

to the guide shell in Unterweser. All reheaters<br />

of the first generation with plain tubes<br />

achieved better heating values than guaranteed<br />

but also higher pressure losses compared<br />

to the design data.<br />

e finned<br />

e plain<br />

NU plain<br />

8<br />

j finned<br />

j plain<br />

NU finned<br />

(apparent)<br />

10<br />

RE comparison<br />

4 2 5 105 2 5 106 0.05<br />

Figure 5. Comparison of the performance figures of fin tube and<br />

plain tube arrangement.<br />

10 3<br />

NU<br />

10 2<br />

5