Ama -Drainer-Box - Filter

Ama -Drainer-Box - Filter

Ama -Drainer-Box - Filter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

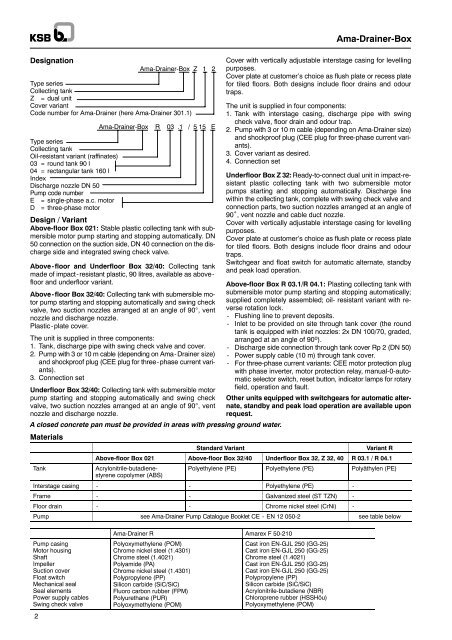

Designation<br />

2<br />

<strong>Ama</strong>-<strong>Drainer</strong>-<strong>Box</strong> Z 1 2<br />

Type series<br />

Collecting tank<br />

Z = dual unit<br />

Cover variant<br />

Code number for <strong>Ama</strong>-<strong>Drainer</strong> (here <strong>Ama</strong>-<strong>Drainer</strong> 301.1)<br />

<strong>Ama</strong>-<strong>Drainer</strong>-<strong>Box</strong> R 03 .1 / 5 15 E<br />

Type series<br />

Collecting tank<br />

Oil-resistant variant (raffinates)<br />

03 = round tank 90 l<br />

04 = rectangular tank 160 l<br />

Index<br />

Discharge nozzle DN 50<br />

Pump code number<br />

E = single-phase a.c. motor<br />

D = three-phase motor<br />

Design / Variant<br />

Above-floor <strong>Box</strong> 021: Stable plastic collecting tank with submersible<br />

motor pump starting and stopping automatically. DN<br />

50 connection on the suction side, DN 40 connection on the discharge<br />

side and integrated swing check valve.<br />

Above-floor and Underfloor <strong>Box</strong> 32/40: Collecting tank<br />

made of impact-resistant plastic, 90 litres, available as abovefloor<br />

and underfloor variant.<br />

Above-floor <strong>Box</strong> 32/40: Collecting tank with submersible motor<br />

pump starting and stopping automatically and swing check<br />

valve, two suction nozzles arranged at an angle of 90°, vent<br />

nozzle and discharge nozzle.<br />

Plastic-plate cover.<br />

The unit is supplied in three components:<br />

1. Tank, discharge pipe with swing check valve and cover.<br />

2. Pump with 3 or 10 m cable (depending on <strong>Ama</strong>-<strong>Drainer</strong> size)<br />

and shockproof plug (CEE plug for three-phase current variants).<br />

3. Connection set<br />

Underfloor <strong>Box</strong> 32/40: Collecting tank with submersible motor<br />

pump starting and stopping automatically and swing check<br />

valve, two suction nozzles arranged at an angle of 90°, vent<br />

nozzle and discharge nozzle.<br />

A closed concrete pan must be provided in areas with pressing ground water.<br />

<strong>Ama</strong>-<strong>Drainer</strong>-<strong>Box</strong><br />

Cover with vertically adjustable interstage casing for levelling<br />

purposes.<br />

Cover plate at customer’s choice as flush plate or recess plate<br />

for tiled floors. Both designs include floor drains and odour<br />

traps.<br />

The unit is supplied in four components:<br />

1. Tank with interstage casing, discharge pipe with swing<br />

check valve, floor drain and odour trap.<br />

2. Pump with 3 or 10 m cable (depending on <strong>Ama</strong>-<strong>Drainer</strong> size)<br />

and shockproof plug (CEE plug for three-phase current variants).<br />

3. Cover variant as desired.<br />

4. Connection set<br />

Underfloor <strong>Box</strong> Z 32: Ready-to-connect dual unit in impact-resistant<br />

plastic collecting tank with two submersible motor<br />

pumps starting and stopping automatically. Discharge line<br />

within the collecting tank, complete with swing check valve and<br />

connection parts, two suction nozzles arranged at an angle of<br />

90°, vent nozzle and cable duct nozzle.<br />

Cover with vertically adjustable interstage casing for levelling<br />

purposes.<br />

Cover plate at customer’s choice as flush plate or recess plate<br />

for tiled floors. Both designs include floor drains and odour<br />

traps.<br />

Switchgear and float switch for automatic alternate, standby<br />

and peak load operation.<br />

Above-floor <strong>Box</strong> R 03.1/R 04.1: Plasting collecting tank with<br />

submersible motor pump starting and stopping automatically;<br />

supplied completely assembled; oil- resistant variant with reverse<br />

rotation lock.<br />

- Flushing line to prevent deposits.<br />

- Inlet to be provided on site through tank cover (the round<br />

tank is equipped with inlet nozzles: 2x DN 100/70, graded,<br />

arranged at an angle of 90o ).<br />

- Discharge side connection through tank cover Rp 2 (DN 50)<br />

- Power supply cable (10 m) through tank cover.<br />

- For three-phase current variants: CEE motor protection plug<br />

with phase inverter, motor protection relay, manual-0-automatic<br />

selector switch, reset button, indicator lamps for rotary<br />

field, operation and fault.<br />

Other units equipped with switchgears for automatic alternate,<br />

standby and peak load operation are available upon<br />

request.<br />

Materials<br />

Standard Variant Variant R<br />

Above-floor <strong>Box</strong> 021 Above-floor <strong>Box</strong> 32/40 Underfloor <strong>Box</strong> 32, Z 32, 40 R 03.1 / R 04.1<br />

Tank Acrylonitrile-butadienestyrene<br />

copolymer (ABS)<br />

Polyethylene (PE) Polyethylene (PE) Polyäthylen (PE)<br />

Interstage casing - - Polyethylene (PE) -<br />

Frame - - Galvanized steel (ST TZN) -<br />

Floor drain - - Chrome nickel steel (CrNi) -<br />

Pump see <strong>Ama</strong>-<strong>Drainer</strong> Pump Catalogue Booklet CE - EN 12 050-2 see table below<br />

Pump casing<br />

Motor housing<br />

Shaft<br />

Impeller<br />

Suction cover<br />

Float switch<br />

Mechanical seal<br />

Seal elements<br />

Power supply cables<br />

Swing check valve<br />

<strong>Ama</strong>-<strong>Drainer</strong> R <strong>Ama</strong>rex F 50-210<br />

Polyoxymethylene (POM)<br />

Cast iron EN-GJL 250 (GG-25)<br />

Chrome nickel steel (1.4301)<br />

Cast iron EN-GJL 250 (GG-25)<br />

Chrome steel (1.4021)<br />

Chrome steel (1.4021)<br />

Polyamide (PA)<br />

Cast iron EN-GJL 250 (GG-25)<br />

Chrome nickel steel (1.4301)<br />

Cast iron EN-GJL 250 (GG-25)<br />

Polypropylene (PP)<br />

Polypropylene (PP)<br />

Silicon carbide (SiC/SiC)<br />

Silicon carbide (SiC/SiC)<br />

Fluoro carbon rubber (FPM)<br />

Acrylonitrile-butadiene (NBR)<br />

Polyurethane (PUR)<br />

Chloroprene rubber (HSSHöu)<br />

Polyoxymethylene (POM)<br />

Polyoxymethylene (POM)<br />

Zubehör siehe Seite 117.