Groove Welds Unit 16 - Goodheart-Willcox

Groove Welds Unit 16 - Goodheart-Willcox

Groove Welds Unit 16 - Goodheart-Willcox

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

This sample chapter is for review purposes only. Copyright © The <strong>Goodheart</strong>-<strong>Willcox</strong> Co., Inc. All rights reserved.<br />

1<br />

TO<br />

3<br />

<strong>16</strong> <strong>16</strong><br />

ANGLE X<br />

45° MIN<br />

20° MIN<br />

12° MIN<br />

X<br />

R 1 4 MIN<br />

3<br />

<strong>16</strong> MAX.<br />

POSITION<br />

ALL<br />

F, V, O<br />

F<br />

DETAIL E<br />

(EXCEPT FROM DWG B2345,<br />

"GROOVE WELD STANDARDS")<br />

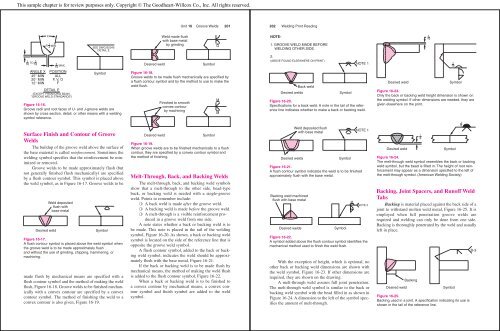

Figure <strong>16</strong>-<strong>16</strong>.<br />

<strong>Groove</strong> radii and root faces of U- and J-groove welds are<br />

shown by cross section, detail, or other means with a welding<br />

symbol reference.<br />

Surface Finish and Contour of <strong>Groove</strong><br />

<strong>Welds</strong><br />

The buildup of the groove weld above the surface of<br />

the base material is called reinforcement. Sometimes the<br />

welding symbol specifies that the reinforcement be minimized<br />

or removed.<br />

<strong>Groove</strong> welds to be made approximately flush (but<br />

not generally finished flush mechanically) are specified<br />

by a flush contour symbol. This symbol is placed above<br />

the weld symbol, as in Figure <strong>16</strong>-17. <strong>Groove</strong> welds to be<br />

Weld deposited<br />

flush with<br />

base metal<br />

SEE DWG B2345<br />

DETAIL E<br />

Symbol<br />

Desired weld Symbol<br />

Figure <strong>16</strong>-17.<br />

A flush contour symbol is placed above the weld symbol when<br />

the groove weld is to be made approximately flush<br />

and without the use of grinding, chipping, hammering, or<br />

machining.<br />

made flush by mechanical means are specified with a<br />

flush contour symbol and the method of making the weld<br />

flush, Figure <strong>16</strong>-18. <strong>Groove</strong> welds to be finished mechanically<br />

with a convex contour are specified by a convex<br />

contour symbol. The method of finishing the weld to a<br />

convex contour is also given, Figure <strong>16</strong>-19.<br />

Weld made flush<br />

with base metal<br />

by grinding<br />

Desired weld Symbol<br />

Figure <strong>16</strong>-18.<br />

<strong>Groove</strong> welds to be made flush mechanically are specified by<br />

a flush contour symbol and by the method to use to make the<br />

weld flush.<br />

Finished to smooth<br />

convex contour<br />

by machining<br />

<strong>Unit</strong> <strong>16</strong> <strong>Groove</strong> <strong>Welds</strong> 201<br />

Desired weld Symbol<br />

Figure <strong>16</strong>-19.<br />

When groove welds are to be finished mechanically to a flush<br />

contour, they are specified by a convex contour symbol and<br />

the method of finishing.<br />

Melt-Through, Back, and Backing <strong>Welds</strong><br />

The melt-through, back, and backing weld symbols<br />

show that a melt-through to the other side, bead-type<br />

back, or backing weld is needed with a single-groove<br />

weld. Points to remember include:<br />

❍ A back weld is made after the groove weld.<br />

❍ A backing weld is made before the groove weld.<br />

❍ A melt-through is a visible reinforcement produced<br />

in a groove weld from one side.<br />

A note states whether a back or backing weld is to<br />

be made. This note is placed in the tail of the welding<br />

symbol, Figure <strong>16</strong>-20. As shown, a back or backing weld<br />

symbol is located on the side of the reference line that is<br />

opposite the groove weld symbol.<br />

A flush contour symbol, added to the back or backing<br />

weld symbol, indicates the weld should be approximately<br />

flush with the base metal, Figure <strong>16</strong>-21.<br />

If the back or backing weld is to be made flush by<br />

mechanical means, the method of making the weld flush<br />

is added to the flush contour symbol, Figure <strong>16</strong>-22.<br />

When a back or backing weld is to be finished to<br />

a convex contour by mechanical means, a convex contour<br />

symbol and finish symbol are added to the weld<br />

symbol.<br />

G<br />

M<br />

M<br />

202 Welding Print Reading<br />

NOTE-<br />

1. GROOVE WELD MADE BEFORE<br />

WELDING OTHER SIDE.<br />

2.<br />

(ABOVE FOUND ELSEWHERE ON PRINT)<br />

Back weld<br />

Desired welds<br />

Backing weld machined<br />

flush with base metal<br />

Weld deposited flush<br />

with base metal<br />

Symbol<br />

Desired welds Symbol<br />

Desired welds Symbol<br />

Figure <strong>16</strong>-22.<br />

A symbol added above the flush contour symbol identifies the<br />

mechanical method used to finish the weld flush.<br />

With the exception of height, which is optional, no<br />

other back or backing weld dimensions are shown with<br />

the weld symbol, Figure <strong>16</strong>-23. If other dimensions are<br />

required, they are shown on the drawing.<br />

A melt-through weld assures full joint penetration.<br />

The melt-through weld symbol is similar to the back or<br />

backing weld symbol with the bead filled in as shown in<br />

Figure <strong>16</strong>-24. A dimension to the left of the symbol specifies<br />

the amount of melt-through.<br />

M<br />

NOTE 1<br />

Figure <strong>16</strong>-20.<br />

Specifications for a back weld. A note in the tail of the reference<br />

line indicates whether to make a back or backing weld.<br />

NOTE 1<br />

Figure <strong>16</strong>-21.<br />

A flush contour symbol indicates the weld is to be finished<br />

approximately flush with the base metal.<br />

NOTE 2<br />

1<br />

<strong>16</strong><br />

1<br />

<strong>16</strong><br />

Desired weld Symbol<br />

Figure <strong>16</strong>-23.<br />

Only the back or backing weld height dimension is shown on<br />

the welding symbol. If other dimensions are needed, they are<br />

given elsewhere on the print.<br />

1<br />

8<br />

Desired weld Symbol<br />

Figure <strong>16</strong>-24.<br />

The melt-through weld symbol resembles the back or backing<br />

weld symbol, but the bead is filled in. The height of root reinforcement<br />

may appear as a dimension specified to the left of<br />

the melt-through symbol. (American Welding Society)<br />

Backing, Joint Spacers, and Runoff Weld<br />

Tabs<br />

Backing is material placed against the back side of a<br />

joint to withstand molten weld metal, Figure <strong>16</strong>-25. It is<br />

employed when full penetration groove welds are<br />

required and welding can only be done from one side.<br />

Backing is thoroughly penetrated by the weld and usually<br />

left in place.<br />

Backing<br />

Desired weld Symbol<br />

Figure <strong>16</strong>-25.<br />

Backing used in a joint. A specification indicating its use is<br />

shown in the tail of the reference line.<br />

1<br />

8<br />

B-3