Policy Statement on Flammability Testing of Interior Materials Final

Policy Statement on Flammability Testing of Interior Materials Final

Policy Statement on Flammability Testing of Interior Materials Final

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

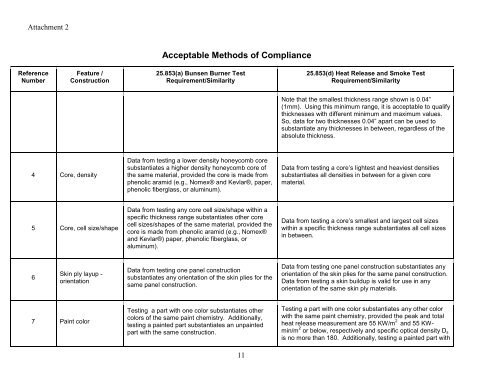

Attachment 2<br />

Reference<br />

Number<br />

Feature /<br />

C<strong>on</strong>structi<strong>on</strong><br />

4 Core, density<br />

5 Core, cell size/shape<br />

6<br />

Skin ply layup -<br />

orientati<strong>on</strong><br />

7 Paint color<br />

Acceptable Methods <strong>of</strong> Compliance<br />

25.853(a) Bunsen Burner Test<br />

Requirement/Similarity<br />

Data from testing a lower density h<strong>on</strong>eycomb core<br />

substantiates a higher density h<strong>on</strong>eycomb core <strong>of</strong><br />

the same material, provided the core is made from<br />

phenolic aramid (e.g., Nomex® and Kevlar®, paper,<br />

phenolic fiberglass, or aluminum).<br />

Data from testing any core cell size/shape within a<br />

specific thickness range substantiates other core<br />

cell sizes/shapes <strong>of</strong> the same material, provided the<br />

core is made from phenolic aramid (e.g., Nomex®<br />

and Kevlar®) paper, phenolic fiberglass, or<br />

aluminum).<br />

Data from testing <strong>on</strong>e panel c<strong>on</strong>structi<strong>on</strong><br />

substantiates any orientati<strong>on</strong> <strong>of</strong> the skin plies for the<br />

same panel c<strong>on</strong>structi<strong>on</strong>.<br />

<strong>Testing</strong> a part with <strong>on</strong>e color substantiates other<br />

colors <strong>of</strong> the same paint chemistry. Additi<strong>on</strong>ally,<br />

testing a painted part substantiates an unpainted<br />

part with the same c<strong>on</strong>structi<strong>on</strong>.<br />

11<br />

25.853(d) Heat Release and Smoke Test<br />

Requirement/Similarity<br />

Note that the smallest thickness range shown is 0.04”<br />

(1mm). Using this minimum range, it is acceptable to qualify<br />

thicknesses with different minimum and maximum values.<br />

So, data for two thicknesses 0.04” apart can be used to<br />

substantiate any thicknesses in between, regardless <strong>of</strong> the<br />

absolute thickness.<br />

Data from testing a core’s lightest and heaviest densities<br />

substantiates all densities in between for a given core<br />

material.<br />

Data from testing a core’s smallest and largest cell sizes<br />

within a specific thickness range substantiates all cell sizes<br />

in between.<br />

Data from testing <strong>on</strong>e panel c<strong>on</strong>structi<strong>on</strong> substantiates any<br />

orientati<strong>on</strong> <strong>of</strong> the skin plies for the same panel c<strong>on</strong>structi<strong>on</strong>.<br />

Data from testing a skin buildup is valid for use in any<br />

orientati<strong>on</strong> <strong>of</strong> the same skin ply materials.<br />

<strong>Testing</strong> a part with <strong>on</strong>e color substantiates any other color<br />

with the same paint chemistry, provided the peak and total<br />

heat release measurement are 55 KW/m 2 and 55 KWmin/m<br />

2 or below, respectively and specific optical density Ds<br />

is no more than 180. Additi<strong>on</strong>ally, testing a painted part with