Policy Statement on Flammability Testing of Interior Materials Final

Policy Statement on Flammability Testing of Interior Materials Final

Policy Statement on Flammability Testing of Interior Materials Final

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

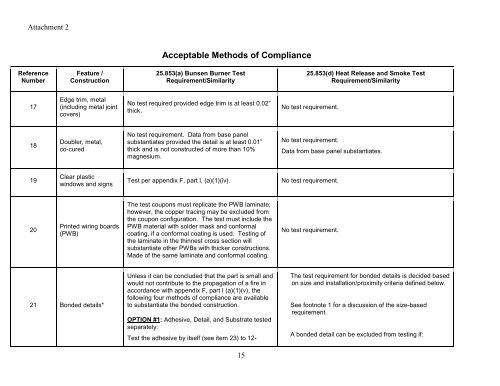

Attachment 2<br />

Reference<br />

Number<br />

17<br />

18<br />

19<br />

20<br />

Feature /<br />

C<strong>on</strong>structi<strong>on</strong><br />

Edge trim, metal<br />

(including metal joint<br />

covers)<br />

Doubler, metal,<br />

co-cured<br />

Clear plastic<br />

windows and signs<br />

Printed wiring boards<br />

(PWB)<br />

21 B<strong>on</strong>ded details*<br />

Acceptable Methods <strong>of</strong> Compliance<br />

25.853(a) Bunsen Burner Test<br />

Requirement/Similarity<br />

No test required provided edge trim is at least 0.02”<br />

thick.<br />

No test requirement. Data from base panel<br />

substantiates provided the detail is at least 0.01”<br />

thick and is not c<strong>on</strong>structed <strong>of</strong> more than 10%<br />

magnesium.<br />

15<br />

25.853(d) Heat Release and Smoke Test<br />

Requirement/Similarity<br />

No test requirement.<br />

No test requirement.<br />

Data from base panel substantiates.<br />

Test per appendix F, part l, (a)(1)(iv). No test requirement.<br />

The test coup<strong>on</strong>s must replicate the PWB laminate;<br />

however, the copper tracing may be excluded from<br />

the coup<strong>on</strong> c<strong>on</strong>figurati<strong>on</strong>. The test must include the<br />

PWB material with solder mask and c<strong>on</strong>formal<br />

coating, if a c<strong>on</strong>formal coating is used. <strong>Testing</strong> <strong>of</strong><br />

the laminate in the thinnest cross secti<strong>on</strong> will<br />

substantiate other PWBs with thicker c<strong>on</strong>structi<strong>on</strong>s.<br />

Made <strong>of</strong> the same laminate and c<strong>on</strong>formal coating.<br />

Unless it can be c<strong>on</strong>cluded that the part is small and<br />

would not c<strong>on</strong>tribute to the propagati<strong>on</strong> <strong>of</strong> a fire in<br />

accordance with appendix F, part I (a)(1)(v), the<br />

following four methods <strong>of</strong> compliance are available<br />

to substantiate the b<strong>on</strong>ded c<strong>on</strong>structi<strong>on</strong>.<br />

OPTION #1: Adhesive, Detail, and Substrate tested<br />

separately:<br />

Test the adhesive by itself (see item 23) to 12-<br />

No test requirement.<br />

The test requirement for b<strong>on</strong>ded details is decided based<br />

<strong>on</strong> size and installati<strong>on</strong>/proximity criteria defined below.<br />

See footnote 1 for a discussi<strong>on</strong> <strong>of</strong> the size-based<br />

requirement.<br />

A b<strong>on</strong>ded detail can be excluded from testing if: