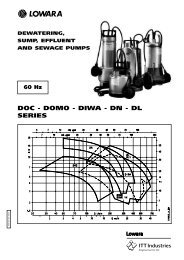

Submersible Electric Pump for Solids-laden Wastewater DL Series

Submersible Electric Pump for Solids-laden Wastewater DL Series

Submersible Electric Pump for Solids-laden Wastewater DL Series

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Submersible</strong><br />

<strong>Electric</strong> <strong>Pump</strong><br />

<strong>for</strong><br />

<strong>Solids</strong>-<strong>laden</strong><br />

<strong>Wastewater</strong><br />

<strong>DL</strong> <strong>Series</strong><br />

The <strong>DL</strong> series electric pumps come with single-channel<br />

or Vortex impeller (<strong>DL</strong>V), and are designed to handle<br />

solids-<strong>laden</strong> wastewater, with up to 20 m head and 100<br />

m 3 /h capacity.<br />

0.6 kW (0.8 HP) to 4 kW (5.5 HP) rated power.<br />

<strong>Solids</strong> handled up to 65 mm in diameter.<br />

● Versions:<br />

Single-phase 220-230 V 50 Hz,<br />

with built-in thermal protector and<br />

capacitor box with on/off switch.<br />

Three-phase 220-240 or 380-415<br />

V 50 Hz.<br />

Overload protection to be provided<br />

by the user (in the control panel).<br />

● 5-metre cable <strong>for</strong> 2-pole <strong>DL</strong>-<strong>DL</strong>V<br />

and 8-metre cable <strong>for</strong> 4-pole <strong>DL</strong>-<br />

<strong>DL</strong>V.<br />

● 60 Hz versions are available on<br />

request.<br />

● Pre-assembled float available on<br />

request <strong>for</strong> single-phase versions<br />

(<strong>DL</strong>…CG, <strong>DL</strong>V…CG).<br />

TABLE OF MATERIALS<br />

APPLICATIONS<br />

● <strong>Pump</strong>ing of sewage with<br />

suspended solids and filaments.<br />

● Emptying of sumps, septic tanks<br />

and wastewater discharge tanks.<br />

● Draining of flooded excavations<br />

and marshy ground.<br />

SPECIFICATIONS<br />

● Maximum immersion depth: 5 m.<br />

● Maximum temperature of<br />

pumped liquid:<br />

50°C with fully submerged<br />

pump.<br />

25°C with partially submerged<br />

pump.<br />

● Passes solids up to:<br />

45 mm (<strong>DL</strong> 80, 90, 105,<br />

Minivortex, Vortex).<br />

50 mm (<strong>DL</strong> 109, 125, 160,<br />

<strong>DL</strong>V 100, 115).<br />

60 mm (<strong>DL</strong> 180, 200).<br />

65 mm (<strong>DL</strong>V 120, 140, 160).<br />

● Squirrel cage motor in a dielectric<br />

non-toxic oil bath, which ensures<br />

the lubrication of the ball bearings<br />

and more efficient cooling.<br />

● Class F insulation.<br />

● 2-pole (0.6 to 1.5 kW) and 4-pole<br />

(1.8 to 4 kW) motors.<br />

● Mechanical seal protected by<br />

sand labyrinth.<br />

2-POLE ELECTRIC PUMPS:<br />

<strong>DL</strong>80,90,105,109,125; MINIVORTEX<br />

and VORTEX,<strong>DL</strong>V 100, 115<br />

PART<br />

MATERIAL<br />

<strong>Pump</strong> body<br />

200 UNI ISO 185 CAST IRON*<br />

Impeller<br />

STAINLESS STEEL<br />

(AISI 304 - DIN 1.4301)<br />

200 UNI ISO 185 CAST IRON* FOR<br />

MINIVORTEX AND VORTEX<br />

Suction flange,<br />

Supporting feet,<br />

STAINLEES STEEL<br />

Shaft (extension), (AISI 304 - DIN 1.4301)<br />

Motor casing<br />

O-ring<br />

Mechanical seal<br />

Delivery elbow<br />

(<strong>DL</strong> 109,125 e <strong>DL</strong>V 100, 115)<br />

PART<br />

<strong>Pump</strong> body<br />

Motor-pump support<br />

Shaft<br />

NITRILE RUBBER<br />

CARBON/CERAMIC/<br />

NITRILE RUBBER<br />

200 UNI ISO 185 CAST IRON*<br />

4- POLE ELECTRIC PUMPS:<br />

<strong>DL</strong> 160,180, 200 and <strong>DL</strong>V 120, 140, 150<br />

MATERIAL<br />

200 UNI ISO 185 CAST IRON*<br />

STAINLEESS STEEL<br />

(AISI 420 - DIN 1.4021)<br />

Motor casing,<br />

Motor cover,<br />

STAILEESS STEEL<br />

Handle tie rod with bracket, (AISI 304 - DIN 1.4301)<br />

Base<br />

Mechanical seal<br />

O-Ring<br />

WIDIA/WIDIA/FPM<br />

NITRILIC RUBBER<br />

* Cast iron with polybutadiene coating through<br />

electrophoresis at 180°C.<br />

25

<strong>DL</strong> SERIES (SINGLE-CHANNEL IMPELLER)<br />

OPERATING CHARACTERISTICS AT 2850 rpm 50 Hz<br />

<strong>DL</strong><br />

PUMP TYPE<br />

SINGLE-PHASE THREE-PHASE<br />

220-240 V 220-240/<br />

50 Hz 380-415 V<br />

50 Hz<br />

ABSORBED CAPACITOR ABSORBED<br />

Q = DELIVERY<br />

kW HP POWER POWER<br />

IN AMP. l/min 100 200 300 400 500 600 700<br />

SINGLE-<br />

PHASE<br />

THREE-PHASE<br />

220- 380-<br />

MONO- TRI-<br />

FASE FASE µF V<br />

m 3 /h 6 12 18 24 30 36 42<br />

220- 240 V 415 V<br />

240 V<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

<strong>DL</strong>M 80 <strong>DL</strong> 80 0,6 0,8 0,8 0,7 20 450 3,8 2,8 1,6<br />

<strong>DL</strong>M 90 <strong>DL</strong> 90 0,6 0,8 0,9 0,85 20 450 4,2 3 1,75<br />

– <strong>DL</strong> 105 1,1 1,5 – 1,5 – – – 5 2,9<br />

<strong>DL</strong>M 109 <strong>DL</strong> 109 1,1 1,5 1,75 1,75 30 450 8 5,7 3,3<br />

– <strong>DL</strong> 125 1,5 2 – 2,2 – – – 6,6 3,8<br />

5,8 4,5 3,3 – – – –<br />

7,2 5,7 4,5 3,3 – – –<br />

12,5 10,5 8,8 7,4 5,5 – –<br />

14,5 12,5 10,5 8,5 6,5 5 –<br />

18,5 16 14 12 10 8 5,5<br />

These per<strong>for</strong>mances are valid <strong>for</strong> liquids with density p = 1.0 kg/dm 3 and kinematic viscosity γ = 1 mm 3 /sec.<br />

26

<strong>DL</strong>V SERIES (VORTEX IMPELLER)<br />

OPERATING CHARACTERISTICS AT 2850 rpm 50 Hz<br />

PUMP TYPE<br />

SINGLE-PHASE THREE-PHASE<br />

220-240 V 220-240/<br />

50 Hz 380-415 V<br />

50 Hz<br />

ABSORBED CAPACITOR ABSORBE<br />

Q = DELIVERY<br />

kW HP POWER CURRENT<br />

IN AMP. l/min 100 200 300 400 500 580<br />

SINGLE- THREE- SINGLE- THREE-PHASE<br />

PHASE PHASE µF V PHASE 220- 380-<br />

m 3 /h 6 12 18 24 30 34,8<br />

220-<br />

240 V<br />

240 V<br />

50 Hz<br />

415 V<br />

50 Hz H = TOTAL HEAD METRES COLUMN OF WATER<br />

MINI VORTEX M MINI VORTEX 0,6 0,8 1 1 20 450 4,7 3,2 1,85<br />

– VORTEX 1,1 1,5 – 1,7 – – – 5,5 3,2<br />

<strong>DL</strong>VM 100 <strong>DL</strong>V 100 1,1 1,5 1,7 1,7 30 450 7,8 5,6 3,2<br />

– <strong>DL</strong>V 115 1,5 2 – 2,2 – – – 6,6 3,8<br />

6,2 4,2 1,7 – – –<br />

8,1 7,3 6,2 4,8 3,2 –<br />

9 8 6,5 5 2 –<br />

12 10,5 9,5 8 6 3<br />

<strong>DL</strong><br />

These per<strong>for</strong>mances are valid <strong>for</strong> liquids with density p = 1.0 kg/dm 3 and kinematic viscosity γ = 1 mm 2 /sec.<br />

27

<strong>DL</strong> SERIES (SINGLE-CHANNEL IMPELLER)<br />

OPERATING CHARACTERISTICS AT 1450 rpm 50 Hz<br />

<strong>DL</strong><br />

PUMP TYPE<br />

SINGLE-PHASE THREE-PHASE<br />

220-240 V 220-240/<br />

50 Hz 380-415 V<br />

50 Hz<br />

ABSORBED CAPACITOR ABSORBED<br />

Q = DELIVERY<br />

kW HP POWER CURRENT<br />

IN AMP. l/min 500 750 1000 1250 1500 1750 2000<br />

SINGLE-<br />

PHASE<br />

THREE-PHASE<br />

220- 380-<br />

SINGLE- THREE<br />

PHASE PHASE µF V<br />

m 3 /h 30 45 60 75 90 105 120<br />

220- 240 V 415 V<br />

240 V<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

– <strong>DL</strong> 160 1,85 2,5 – 2,1 – – – 6 3,5<br />

– <strong>DL</strong> 180 2,75 3,75 – 3,2 – – – 10 5,8<br />

– <strong>DL</strong> 200 4 5,5 – 4,7 – – – 15 8,7<br />

7,3 6,2 5,3 4 – – –<br />

9,2 8 7 6,2 5,3 4,2 –<br />

12 10,7 9,6 8,6 7,6 6,6 5,3<br />

These per<strong>for</strong>mances are valid <strong>for</strong> liquids with density p = 1.0 kg/dm 3 and kinematic viscosity γ = 1 mm 2 /sec.<br />

28

<strong>DL</strong>V SERIES (VORTEX IMPELLER)<br />

OPERATING CHARACTERISTICS AT 1450 rpm 50 Hz<br />

PUMP TYPE<br />

SINGLE-PHASE THREE-PHASE<br />

220-240 V 220-240/<br />

50 Hz 380-415 V<br />

50 Hz<br />

ABSORBED CAPACITOR ABSORBED<br />

Q = DELIVERY<br />

kW HP POWER CURRENT<br />

IN AMP. l/min 250 500 750 1000 1250 1350<br />

SINGLE-<br />

PHASE<br />

THREE-PHASE<br />

220- 380-<br />

SINGLE- THREE-<br />

PHASE PHASE µF V<br />

m 3 /h 15 30 45 60 75 84<br />

220- 240 V 415 V<br />

240 V<br />

H = TOTAL HEAD METRES COLUMN OF WATER<br />

– <strong>DL</strong>V 120 1,85 2,5 – 2,3 – – – 7,8 4,5<br />

– <strong>DL</strong>V 140 2,75 3,75 – 3,4 – – – 11,2 6,5<br />

– <strong>DL</strong>V 150 4 5,5 – 4,9 – – – 16,5 9,5<br />

6,7 6 5 3,8 – –<br />

8,6 8,1 7,4 6,4 5,3 4,7<br />

11,5 10,2 8,7 7,2 5,7 5<br />

<strong>DL</strong><br />

These per<strong>for</strong>mances are valid <strong>for</strong> liquids with density p = 1.0 kg/dm 3 and kinematic viscosity γ = 1 mm 2 /sec.<br />

29

<strong>DL</strong><br />

DIMENSIONS AND WEIGHTS <strong>DL</strong>(V) WITH 2 POLES<br />

PUMP<br />

TYPE<br />

WEIGHT<br />

kg<br />

<strong>DL</strong> 80 - <strong>DL</strong>M 80 19,5<br />

<strong>DL</strong> 90 - <strong>DL</strong>M 90 20,5<br />

<strong>DL</strong> 105 21<br />

MINIVORTEX (M) 19<br />

VORTEX 19<br />

30

DIMENSIONS AND WEIGHTS <strong>DL</strong>(V) WITH 2 POLES<br />

PUMP<br />

TYPE<br />

WEIGHT<br />

kg<br />

<strong>DL</strong> 109 - <strong>DL</strong>M 109 27<br />

<strong>DL</strong> 125 27<br />

<strong>DL</strong>V 100 - <strong>DL</strong>M 100 27<br />

<strong>DL</strong>M 115 27<br />

<strong>DL</strong><br />

31

<strong>DL</strong><br />

DIMENSIONS AND WEIGHTS <strong>DL</strong>(V) WITH 4 POLES<br />

PUMP TYPE DIMENSIONS IN mm DNM WEIGHT<br />

A B C D E F G H kg<br />

<strong>DL</strong> 160 735 432 314 177 Ø200 Ø160 Ø18 275 Ø80 78<br />

<strong>DL</strong> 180 835 470 391 182 Ø200 Ø160 Ø18 275 Ø80 103<br />

<strong>DL</strong> 200 885 470 391 182 Ø200 Ø160 Ø18 275 Ø80 111<br />

<strong>DL</strong>V 120 760 409 268 183 Ø200 Ø160 Ø18 275 Ø80 76<br />

<strong>DL</strong>V 140 820 409 268 183 Ø200 Ø160 Ø18 275 Ø80 77<br />

<strong>DL</strong>V 150 865 345 380 160 Ø200 Ø160 Ø18 180 Ø80 116<br />

32

LIFTING AND LOWERING DEVICE<br />

Used <strong>for</strong> pump inspection and maintenance without<br />

going down the well.<br />

It consists of a support foot with built-in delivery elbow,<br />

a sliding adaptor and a bracket <strong>for</strong> fastening the<br />

guide tubes (tubes not included).<br />

Two models are available:<br />

• DS 3 <strong>for</strong> <strong>DL</strong> 160-180-200 and <strong>DL</strong>V 120, 140, 150<br />

pumps.<br />

• DS 2 <strong>for</strong> <strong>DL</strong> 109-125, <strong>DL</strong>V 100-115 and <strong>DL</strong> 80-90-<br />

105 MINIVORTEX, VORTEX pumps with flange.<br />

OVERALL DIMENSIONS WHITH DS3 DEVICE<br />

PUMP TYPE<br />

DIMENSIONS (mm)<br />

A B C D E F G<br />

<strong>DL</strong> 160 667 525 337 314 540 85 368<br />

<strong>DL</strong> 180 705 563 337 391 636 80 368<br />

<strong>DL</strong> 200 705 563 337 391 686 80 368<br />

<strong>DL</strong>V 120 645 503 337 268 558 78 368<br />

<strong>DL</strong>V 140 645 503 337 268 618 78 368<br />

<strong>DL</strong>V 150 580 436 242 380 690 106 273<br />

DS 2<br />

3/4” BSP<br />

DS 3<br />

1” BSP<br />

<strong>DL</strong><br />

33

<strong>DL</strong><br />

PUMP SECTIONS AND LIST OF MAIN COMPONENTS<br />

<strong>DL</strong>-<strong>DL</strong>M 80-90-105 - MINI VORTEX - VORTEX<br />

REF. N.<br />

DESCRIPTION<br />

1 <strong>Pump</strong> body<br />

* 2 Impeller<br />

3 Suction flange<br />

4 Supporting foot<br />

5 Impeller lock washer<br />

* 6 O-Ring<br />

* 7 Mechanical seal<br />

* 8 Lower bearing<br />

9 Shaft and rotor<br />

10 Motor casing and wound<br />

stator<br />

* 11 Upper bearing<br />

12 Plug end washer<br />

13 Supply cable gland<br />

14 Suplly cable<br />

15 Control box base<br />

16 Control box cover<br />

17 Capacitor<br />

18 Cord with plug<br />

19 Switch with cup<br />

20 Float<br />

21 Float cable gland<br />

22 Insert and plug <strong>for</strong><br />

coupling<br />

23 Cable fastener with base<br />

24 Mechanical seal spacer<br />

25 Mechanical seal shoulder<br />

washer<br />

26 Labyrint cap<br />

27 Labyrint insert<br />

28 Cable gland (<strong>for</strong> pump<br />

cable)<br />

29 Cable gland (<strong>for</strong> plug<br />

cable)<br />

* Recommended spare parts<br />

Reference number indicate spare parts as<br />

per relevant catalogue<br />

Reference numbers indicate spare parts as per relevant catalogue<br />

34

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

<strong>DL</strong> 109-125 / <strong>DL</strong>V 100-115<br />

REF. N.<br />

DESCRIPTION<br />

1 <strong>Pump</strong> body<br />

* 2 Impeller<br />

3 Suction flange<br />

4 Supporting foot<br />

5 Impeller lock washer<br />

* 6 O-Ring<br />

* 7 Mechanical seal<br />

* 8 Lower bearing<br />

9 Shaft an rotor<br />

10 Motor casing and wound<br />

stator<br />

* 11 Upper bearing<br />

12 Plug and washer<br />

13 Supply cable gland<br />

14 Supply cable<br />

15 Control box base<br />

16 Control box cover<br />

17 Capacitor<br />

18 Cord with plug<br />

19 Switch with cap<br />

20 Float<br />

21 Float cable gland<br />

22 Insert and plug <strong>for</strong><br />

coupling<br />

23 Cable fastener with base<br />

* 24 Wear ring<br />

25 Gasket <strong>for</strong> delivery union<br />

26 Delivery union<br />

27 Cable gland (<strong>for</strong> pump<br />

cable)<br />

28 Cable gland (<strong>for</strong> plug<br />

cable)<br />

* Recommended spare parts<br />

Reference numbers indicate spare parts<br />

as per relevant catalogue<br />

<strong>DL</strong><br />

Reference numbers indicate spare parts as per relevant catalogue<br />

35

<strong>DL</strong><br />

PUMP SECTION AND LIST OF MAIN COMPONENTS<br />

<strong>DL</strong> 160-180-200 /<br />

<strong>DL</strong>V 120-140-150<br />

REF. N.<br />

DESCRIPTION<br />

1 <strong>Pump</strong> body<br />

* 2 Impeller<br />

3 Motor/pump support<br />

4 Wound stator<br />

5 Shaft and rotor<br />

6 Motor casing<br />

7 Bracket with liquid level<br />

plate<br />

8 Motor lid<br />

9 Tie rod and bracket<br />

10 Base support<br />

11 Tab<br />

12 Seal protector<br />

* 13 <strong>Pump</strong> body/support gasket<br />

* 14 Mechanical seal<br />

* 17 Lower bearing<br />

18 Bearing locking plate<br />

19 Terminal board<br />

21 Supply cable gland<br />

26 Cable<br />

28 Fill plug and washer<br />

29 Cable gland <strong>for</strong> upper<br />

support<br />

* 30 O-Ring<br />

* 31 Upper bearing<br />

* 32 O-ring<br />

33 Impeller lock washer<br />

34 Impeller spacer<br />

* Recomended spare parts<br />

Reference numbers indicate spare parts<br />

as per relevant catalogue<br />

Reference numbers indicate spare parts as per relevant catalogue<br />

36