downloading this information - GEA Farm Technologies

downloading this information - GEA Farm Technologies

downloading this information - GEA Farm Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AUTOMATION<br />

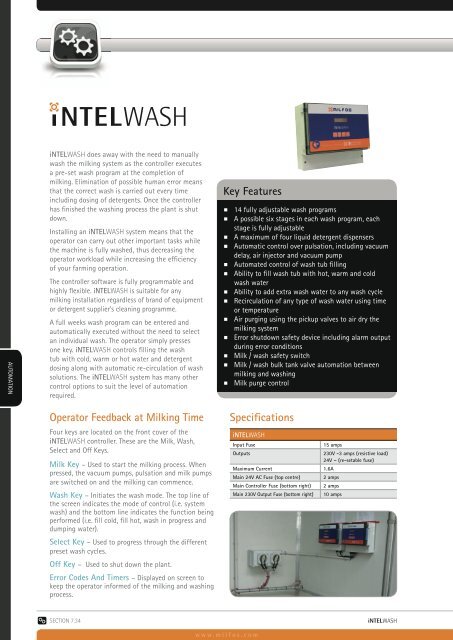

iNTELWASH does away with the need to manually<br />

wash the milking system as the controller executes<br />

a pre-set wash program at the completion of<br />

milking. Elimination of possible human error means<br />

that the correct wash is carried out every time<br />

including dosing of detergents. Once the controller<br />

has finished the washing process the plant is shut<br />

down.<br />

Installing an iNTELWASH system means that the<br />

operator can carry out other important tasks while<br />

the machine is fully washed, thus decreasing the<br />

operator workload while increasing the efficiency<br />

of your farming operation.<br />

The controller software is fully programmable and<br />

highly flexible. iNTELWASH is suitable for any<br />

milking installation regardless of brand of equipment<br />

or detergent supplier’s cleaning programme.<br />

A full weeks wash program can be entered and<br />

automatically executed without the need to select<br />

an individual wash. The operator simply presses<br />

one key. iNTELWASH controls filling the wash<br />

tub with cold, warm or hot water and detergent<br />

dosing along with automatic re-circulation of wash<br />

solutions. The iNTELWASH system has many other<br />

control options to suit the level of automation<br />

required.<br />

Key Features<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

◼<br />

14 fully adjustable wash programs<br />

A possible six stages in each wash program, each<br />

stage is fully adjustable<br />

A maximum of four liquid detergent dispensers<br />

Automatic control over pulsation, including vacuum<br />

delay, air injector and vacuum pump<br />

Automated control of wash tub filling<br />

Ability to fill wash tub with hot, warm and cold<br />

wash water<br />

Ability to add extra wash water to any wash cycle<br />

Recirculation of any type of wash water using time<br />

or temperature<br />

Air purging using the pickup valves to air dry the<br />

milking system<br />

Error shutdown safety device including alarm output<br />

during error conditions<br />

Milk / wash safety switch<br />

Milk / wash bulk tank valve automation between<br />

milking and washing<br />

Milk purge control<br />

Operator Feedback at Milking Time<br />

Four keys are located on the front cover of the<br />

iNTELWASH controller. These are the Milk, Wash,<br />

Select and Off Keys.<br />

Milk Key – Used to start the milking process. When<br />

pressed, the vacuum pumps, pulsation and milk pumps<br />

are switched on and the milking can commence.<br />

Wash Key – Initiates the wash mode. The top line of<br />

the screen indicates the mode of control (i.e. system<br />

wash) and the bottom line indicates the function being<br />

performed (i.e. fill cold, fill hot, wash in progress and<br />

dumping water).<br />

Select Key – Used to progress through the different<br />

preset wash cycles.<br />

Off Key – Used to shut down the plant.<br />

Error Codes And Timers – Displayed on screen to<br />

keep the operator informed of the milking and washing<br />

process.<br />

Specifications<br />

iNTELWASH<br />

Input Fuse<br />

15 amps<br />

Outputs<br />

230V -3 amps (resistive load)<br />

24V – (re-setable fuse)<br />

Maximum Current 1.6A<br />

Main 24V AC Fuse (top centre) 2 amps<br />

Main Controller Fuse (bottom right) 2 amps<br />

Main 230V Output Fuse (bottom right) 10 amps<br />

SECTION 7.34<br />

iNTELWASH

System Features<br />

Remote Enable – Allows the iNTELWASH to be remotely<br />

started and changed into different operating modes.<br />

Safety Switch Enable – A safety switch may be installed<br />

on the bulk milk tank to ensure that the fill valve is<br />

configured correctly before milking or washing commences.<br />

Detergent Dispense Time – The time in seconds for<br />

operating the detergent dispensing pumps.<br />

Extra Detergent Time – The extra time in seconds that<br />

the detergent pumps will operate for once the tub has filled.<br />

Air Purge Cycle Time – The pick-up valves are pulsed<br />

during washing, forcing air into the Jetter Line, Jetters and<br />

Clusters so the equipment will be flushed correctly for the<br />

next wash stage.<br />

Milk Purging System – Set to purge at the end of milking<br />

and at the end of each wash cycle.<br />

Vacuum Delay – Delay time in seconds to assist with<br />

getting the plant to vacuum before switching on the<br />

pulsation and other devices that consume vacuum.<br />

Vacuum Operation – The vacuum pump can be switched<br />

off when filling the tub to save on power.<br />

Recirculation Delay Time – The time delay in seconds to<br />

dump the initial cold water that comes back from the plant<br />

before recirculating the hot water.<br />

Recirculation Time – The time in seconds that the<br />

recirculation valve will be open to recirculate the wash<br />

water back to the washtub.<br />

Temperature Before Recirculation – The<br />

temperature taken by the sensor before the<br />

recirculation valve is operated and the wash water<br />

is recirculated.<br />

Temperature Before Dumping – The temperature<br />

taken by the sensor before the recirculation valve is<br />

opened allowing wash water to waste.<br />

Warm Fill – Allows the tub to be filled with warm<br />

water.<br />

Maximum Wash Tub Fill Time – The maximum<br />

time in seconds that the system will wait for a<br />

high level switch signal before shutting down and<br />

reporting an error.<br />

Preset Wash Time – This is the total time for<br />

the wash stage.<br />

Detergent Type – The type of detergent that<br />

will be added to the wash water during filling.<br />

The system can dose up to 4 different detergents<br />

or be programmed not to dose any detergent at all.<br />

Water Type – The water type being either hot,<br />

cold or warm.<br />

Extra Water Fill – Allows extra water to be<br />

added to any wash cycle.<br />

Hold And Wait – Allows a pause to be<br />

programmed in any wash stage so that filter<br />

sleeves may be changed or other duties carried out.<br />

iNTELWASH<br />

AUTOMATION<br />

A<br />

Q<br />

R<br />

B<br />

U<br />

2<br />

C<br />

D<br />

S<br />

T<br />

V<br />

1<br />

E<br />

4<br />

W<br />

F<br />

G<br />

H<br />

L<br />

K<br />

M<br />

K<br />

L<br />

M<br />

N<br />

O<br />

5<br />

3<br />

Ref Description<br />

1 Pick up valve suction<br />

2 Jetter delivery line<br />

3 Milk pump delivery<br />

I<br />

4 Wash return line<br />

J<br />

P<br />

5 Wash drain line<br />

A Vacuum pump control 230V I Remote start push button Q Vacuum supply<br />

B Pulsator control 230V J Safety switch R Valve box control 24V<br />

C Air injector control 230V K Detergent pump 230V S Cold fill valve control 24V<br />

D Alarm 24V L Detergent pump suction T Hot valve signal<br />

E Hold & wait push button M Detergent pump delivery U Pick up valve control<br />

F Milk mode indicator 24V N Cold level tub switch V Recirculation valve control<br />

G Purge valve 24V O Hot level tub switch W Temperature sensor control<br />

H Bulk tank actuator 24V P Low level sensor<br />

iNTELWASH<br />

SECTION 7.35

Milfos<br />

Jetter<br />

The iCIP range of jetters are easy to use and deliver a set flow<br />

rate of wash solution to the cluster ensuring maximum hygiene.<br />

iCIP is a new generation of jetter, moulded in the latest durable<br />

engineering plastics. The family of products are designed<br />

for herringbone and rotary in both low line and midline<br />

installations.<br />

The jetter includes an innovative “one piece” non return valve<br />

and easy flow adjustment device. This makes installation and<br />

service easy while allowing the clusters to be loaded into the<br />

jetters without losing vacuum.<br />

With the iCIP Rubber Cup Jetter the teat cup liner fits securely<br />

into the rubber cup, cleaning the head of the liner thoroughly.<br />

The rubber cup protects and extends liner life and does not<br />

distort the liner mouthpiece.<br />

The iCIP Clip-In model inverts the cluster for washing and is self<br />

supporting. Designed especially for low line mounting under the<br />

pit edge the jetter is easily loaded for washing and stored away<br />

after use.<br />

Both models have options of pipeline mount or nipple feed to<br />

suit the installation.<br />

Key Features<br />

◼ Delivers a set flow rate of wash water<br />

to the cluster for maximum hygiene<br />

◼ Non-return valve and one piece<br />

adjustment device<br />

◼ Rubber Cup and Clip-In models<br />

available<br />

◼ Options of pipeline mount or nipple<br />

feed<br />

Specifications<br />

Body<br />

Screws<br />

Non-Return Valve<br />

Flow Adjustment<br />

Dimensions<br />

Glass filled polypropylene<br />

Stainless Steel<br />

Yes<br />

2-5 litres per minute<br />

210mmL x 210mmW x 90mmH<br />

MILKING<br />

COMPONENTS<br />

SECTION 9.22<br />

iCIP

iCIP Rubber Cup –<br />

Rotary Mount<br />

iCIP Clip-In –<br />

Rotary Mount<br />

iCIP Rubber Cup –<br />

Herringbone Mount<br />

iCIP Clip-In –<br />

Herringbone Mount<br />

◼<br />

◼<br />

◼<br />

◼<br />

Mounts using 4 x<br />

M6 screws into brass<br />

tapex in body back<br />

plate<br />

Various mounting<br />

plate options<br />

Fed using 12.7mm<br />

ID hose<br />

Stainless steel cover<br />

option<br />

◼<br />

◼<br />

◼<br />

◼<br />

Mounts using 4 x<br />

M6 screws into brass<br />

tapex in body back<br />

plate<br />

Jetter folds out in<br />

cabinet system or<br />

under platform edge<br />

Fed using 12.7mm<br />

ID hose<br />

Self supporting,<br />

no cluster bracket<br />

required<br />

◼<br />

◼<br />

◼<br />

◼<br />

Mounts using 2 x<br />

heavy duty saddles<br />

with M8 screws into<br />

brass tapex in body<br />

back plate<br />

Pipeline mounted<br />

Can be set-up on<br />

swing arm or winch<br />

system for ease of use<br />

and loading clusters<br />

Stainless steel fly<br />

cover option<br />

◼<br />

◼<br />

◼<br />

Mounts using 2 x<br />

heavy duty saddles<br />

with M8 screws into<br />

brass tapex in body<br />

back plate<br />

Pipeline mounted<br />

Recessed under<br />

pit edge, the jetter<br />

swings out for cluster<br />

attachment and back<br />

under out of the way<br />

for milking<br />

1<br />

10<br />

1<br />

10<br />

11<br />

2<br />

11<br />

2<br />

12<br />

3<br />

12<br />

3<br />

3<br />

4<br />

3<br />

4<br />

4<br />

5<br />

4<br />

5<br />

5<br />

5<br />

6<br />

7<br />

8/9<br />

6<br />

7<br />

8/9<br />

13<br />

7<br />

14<br />

15<br />

13<br />

7<br />

14<br />

15<br />

MILKING<br />

COMPONENTS<br />

Ref Description Code<br />

1 iCIP rubber cup retainer JMF9020<br />

2 Milfos 44 iCIP jetter cup JMF9010<br />

3 iCIP flow adjuster / NRV complete components JMF9120<br />

4 iCIP front cover JMF9070<br />

5 iCIP body seal JMF9100<br />

6 iCIP back plate rotary JMF9090<br />

7 iCIP body screw JMF9110<br />

8 iCIP elbow JMF9095<br />

Ref Description Code<br />

9 iCIP elbow o’ring JMF9096<br />

10 iCIP clip in cup retainer JMF9030<br />

11 iCIP clip in cup seal JMF9050<br />

12 iCIP clip in cup holder JMF9040<br />

13 iCIP back plate 50mm JMF9080<br />

14 iCIP saddle 50mm JMF9060<br />

15 iCIP saddle screw QSP0630<br />

iCIP<br />

SECTION 9.23

NEW<br />

The iNTELJET system consists of an electronic timer, collection vessel and<br />

air injector valve. The assembly is connected to the end of the 4” milkline.<br />

During washing, water is drawn into the collection vessel from the jetter<br />

line. Periodically the injector valve is opened which propels the washing<br />

solution from the collector down the milkline to the milk receiver. As the<br />

solution is propelled down the milkline, a slug is formed which scrubs the<br />

milkline for maximum plant hygiene. The slug creates added turbulence<br />

in the receiver ensuring a thorough clean. The iNTELJET is Interactive<br />

capable. The unit is automatically initiated in Wash Mode if installed with<br />

other Interactive units such as the iNTELPUMP, iNTELFLOW or iNTELWASH.<br />

Key Features<br />

◼ Suits 4” Milklines<br />

◼ Cleans line with washing slug<br />

◼ Interactive capable<br />

◼ 150mm diameter collection<br />

vessel<br />

◼ Fully automatic operation<br />

3 Way Diverter Valve<br />

The 3 Way Diverter Valve is a simple but effective<br />

control device for liquids. The configuration consists<br />

of two butterfly valves controlled by a double<br />

acting pneumatic ram.<br />

The diverter valve can be used for any installation<br />

where liquids need to be controlled. This may be for<br />

recirculation of wash water, diverting calf milk, or<br />

controlling the filling of multiple bulk milk tanks.<br />

Key Features<br />

◼ Positive control of liquids<br />

◼ Multiple uses<br />

◼ Controlled by double acting ram<br />

◼ Robust and can handle pressures of milk delivery lines<br />

◼ Safe handling of high temperature and corrosive fluids<br />

MILKING<br />

COMPONENTS<br />

Valve Diverting Open<br />

Valve Diverter Closed<br />

iNTELJET | 3 Way Diverter Valve<br />

SECTION 9.25